High-purity m-phthaloyl chloride/paraphthaloyl chloride continuous reaction system and reaction method thereof

A technology of terephthaloyl chloride and reaction system, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylate, etc., can solve the problem that the reaction tail gas cannot be discharged in time, restrict the production rate of the reaction process, and the floor space of the equipment Large and other problems, to achieve the effect of saving energy consumption, small footprint and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

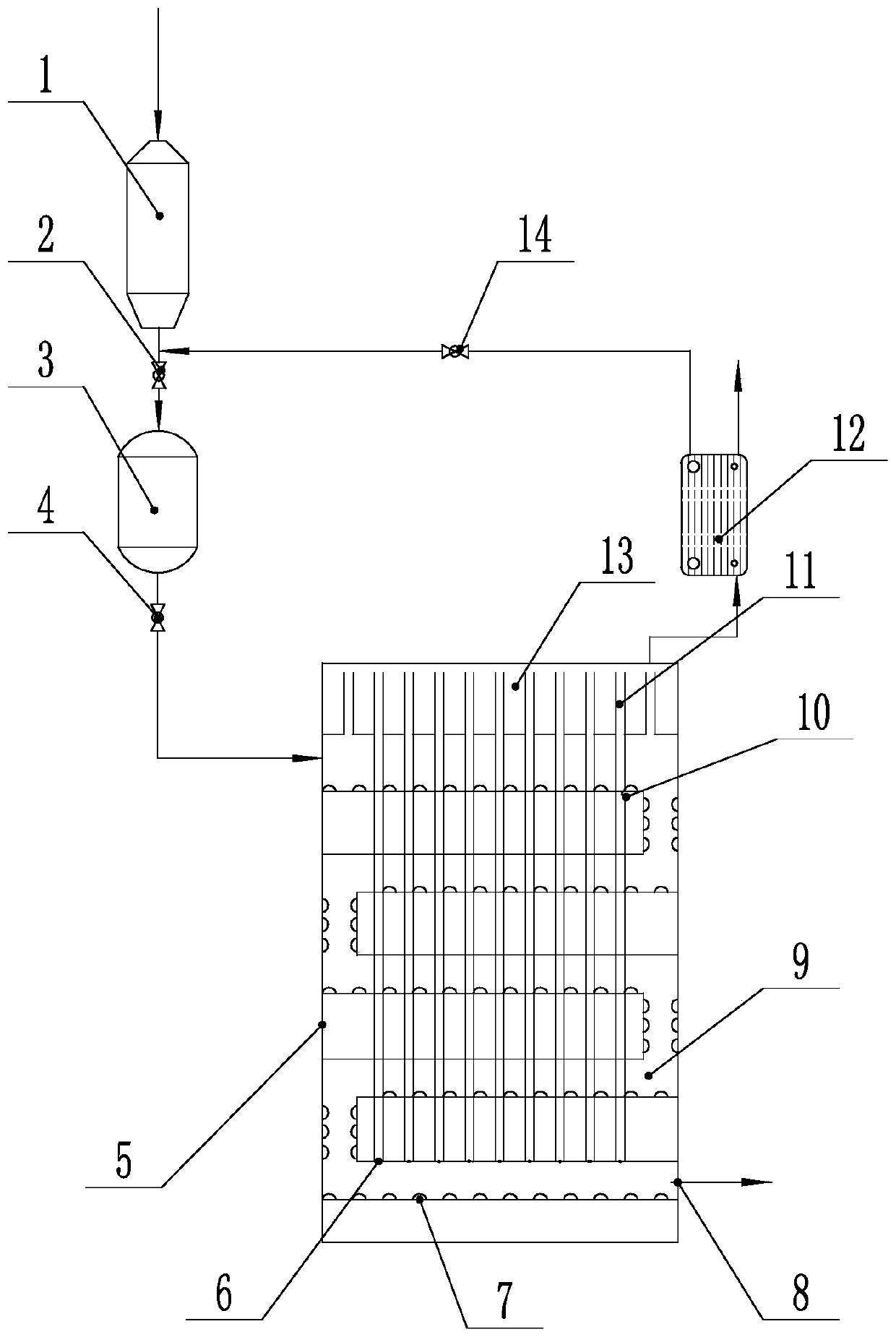

[0023] Such as figure 1 As shown, the continuous reaction system of high-purity meta / terephthaloyl dichloride of the present invention comprises a granulator 1, a mixing tank 3 and a reactor 5 connected in series in sequence, and the exhaust port of the reactor 5 is externally connected to a condenser 12. The discharge end of the condenser 12 is communicated with the feed port of the mixing tank 3, and an S-shaped passage 9 is arranged inside the reaction kettle 5, and a plurality of exhaust pipes 11 run through the S-shaped passage 9, and the exhaust pipes 11 The air pipe 11 is fixedly connected with the S-shaped channel 9, and the top of the reaction kettle 5 is provided with an exhaust chamber 13. The top of the exhaust pipe 11 is located in the exhaust chamber 13 and communicates with the exhaust chamber 13. A plurality of capillary holes 10 are arranged on the upper part of the exhaust pipe 11 inside the 9.

[0024] Wherein, a protrusion 7 is set on the side wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com