Patents

Literature

53results about How to "Achieving Continuous Response" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation and application of supermolecule polymer framework material

InactiveCN107936262AAchieving Continuous ResponseRealize highly sensitive detectionFluorescence/phosphorescencePolymer scienceCyclohexanol

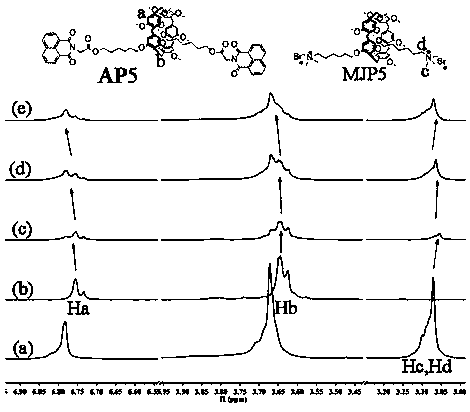

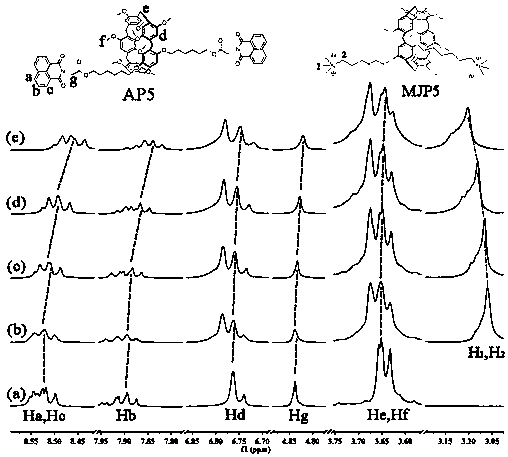

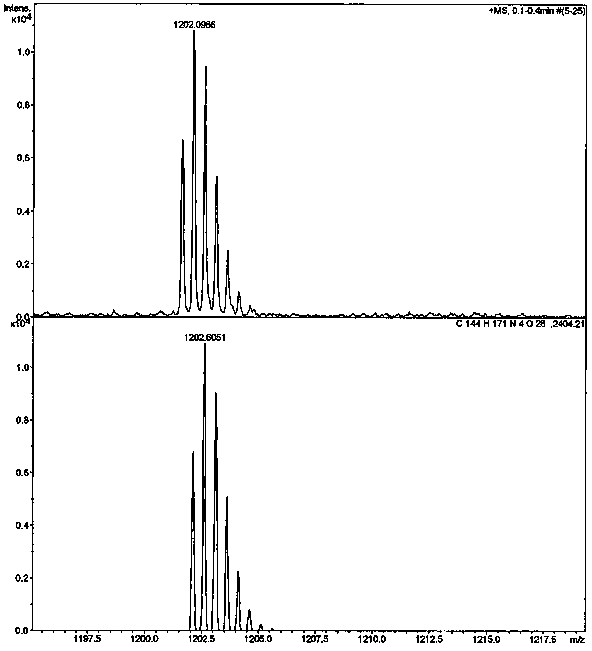

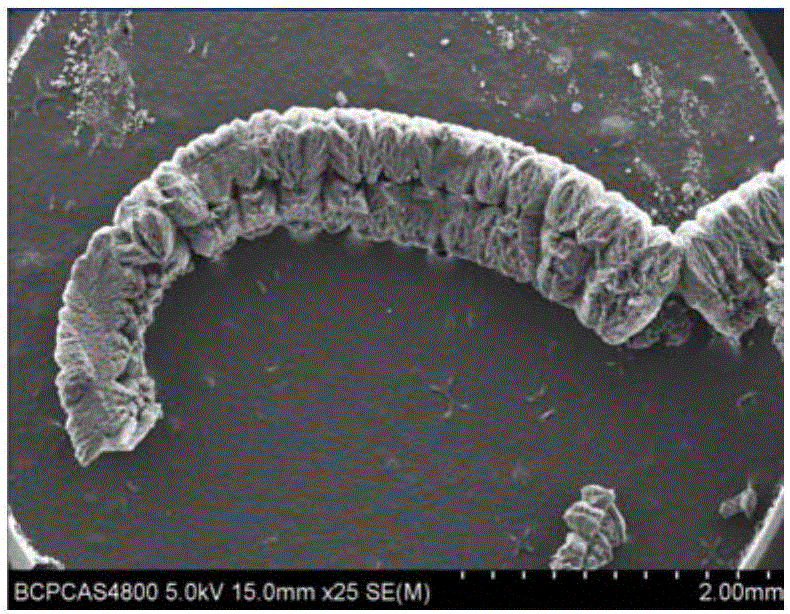

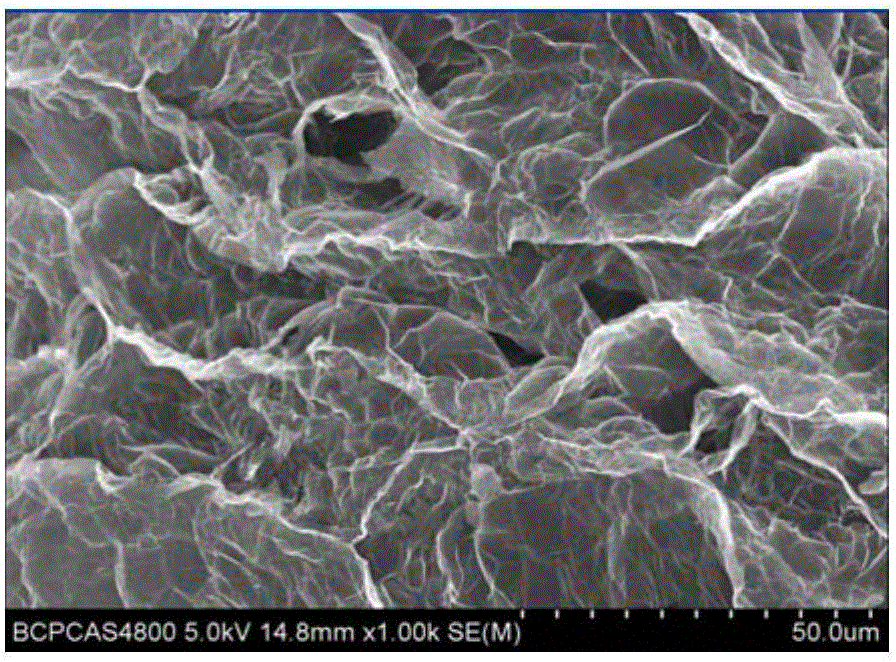

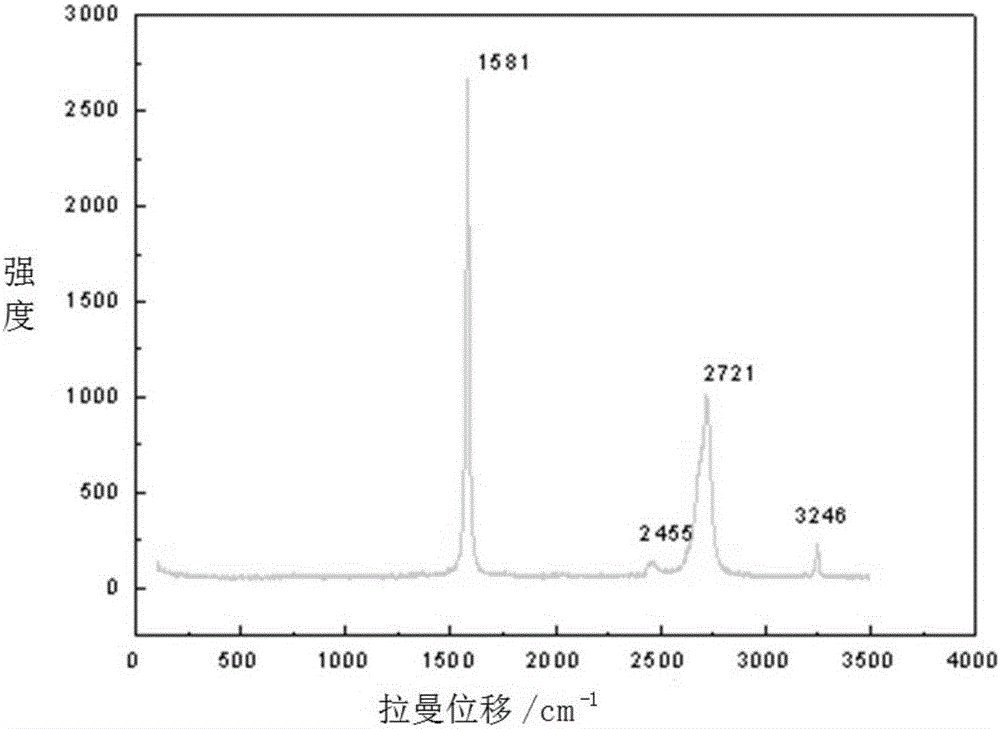

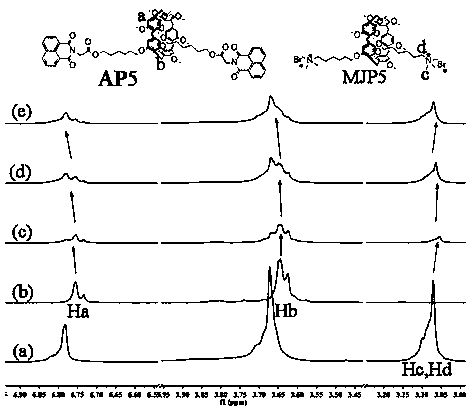

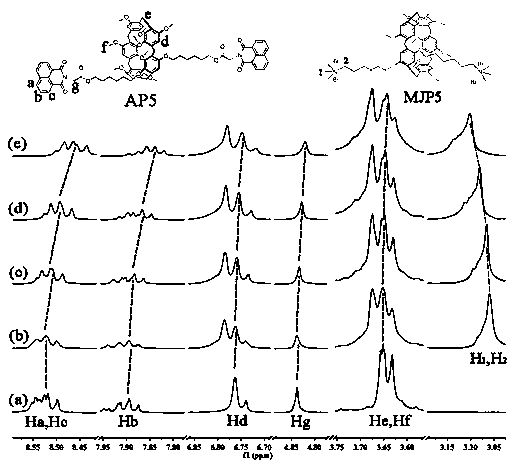

The invention designs and synthetizes a supermolecule polymer framework material. The supermolecule polymer framework material is formed through self assembly in cyclohexanol by using naphthalimide functionalized pillar [5] arene as a subject and bilateral quaternization pillar [5] arene as an object, wherein the mole ratio of the subject to the object is 1:1. Through competitive coordination mechanism, the supermolecule polymer framework material (SOF-AP5-MJP5) and a metal supermolecule polymer framework material (M-SOF-AP5-MJP5) can respectively realize continuous response and high-sensitivity detection to Fe<3+> and H2PO4<->; the recognition performance has important application values in the field of ion recognition.

Owner:NORTHWEST NORMAL UNIVERSITY

Preparation method of 1, 3-butylene glycol

ActiveCN109422624AControl PH valueTemperature controlOrganic compound preparationHydroxy compound preparationFixed bed1,3-Butanediol

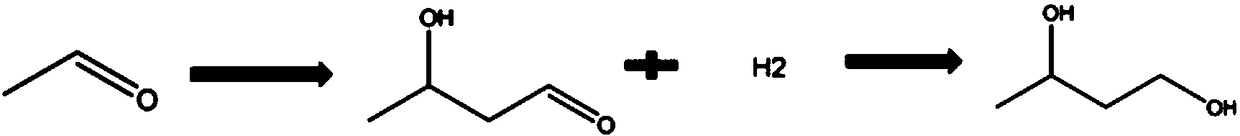

The invention provides a preparation method of 1, 3-butylene glycol. The preparation method comprises following steps: A, acetaldehyde is introduced into a fixed bed reactor, under the effect of a supported type solid basic catalyst, aldol condensation reaction is carried out so as to obtain 3-hydroxybutyraldehyde; and B, 3-hydroxybutyraldehyde is subjected to continuous hydrogenation reaction inthe fixed bed reactor so as to obtain 1, 3-butylene glycol. According to the preparation method, the fixed bed reactor is adopted, at the same time, the supported type solid basic catalyst is adoptedto replace a conventional liquid alkali (such as sodium hydroxide) catalysts, and in the step of hydrogenation reduction, a supported nickel hydrogenation catalyst is adopted. The preparation method is capable of solving problems in the prior art product quality is poor, product yield is low, technology process is complex, and a large amount of waste water and waste residue is generated; aldol condensation quenching step is avoided; side reactions are reduced; relatively high reaction conversion rate and yield are achieved; no neutralizing or desalting process is needed in reaction process; and great improvement of traditional 1, 3-butylene glycol preparation technology is realized.

Owner:DONGYING HI TECH SPRING CHEM IND

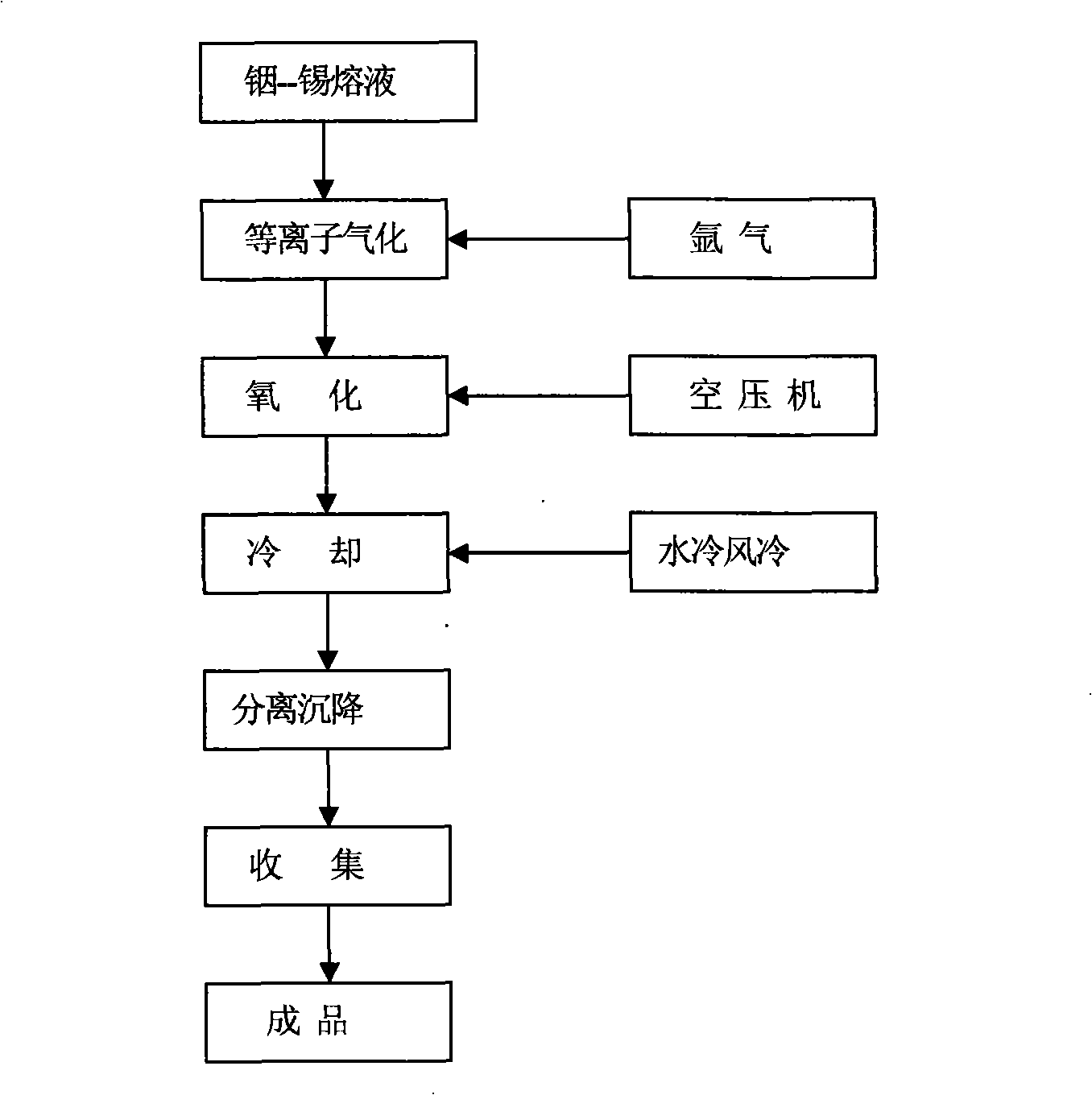

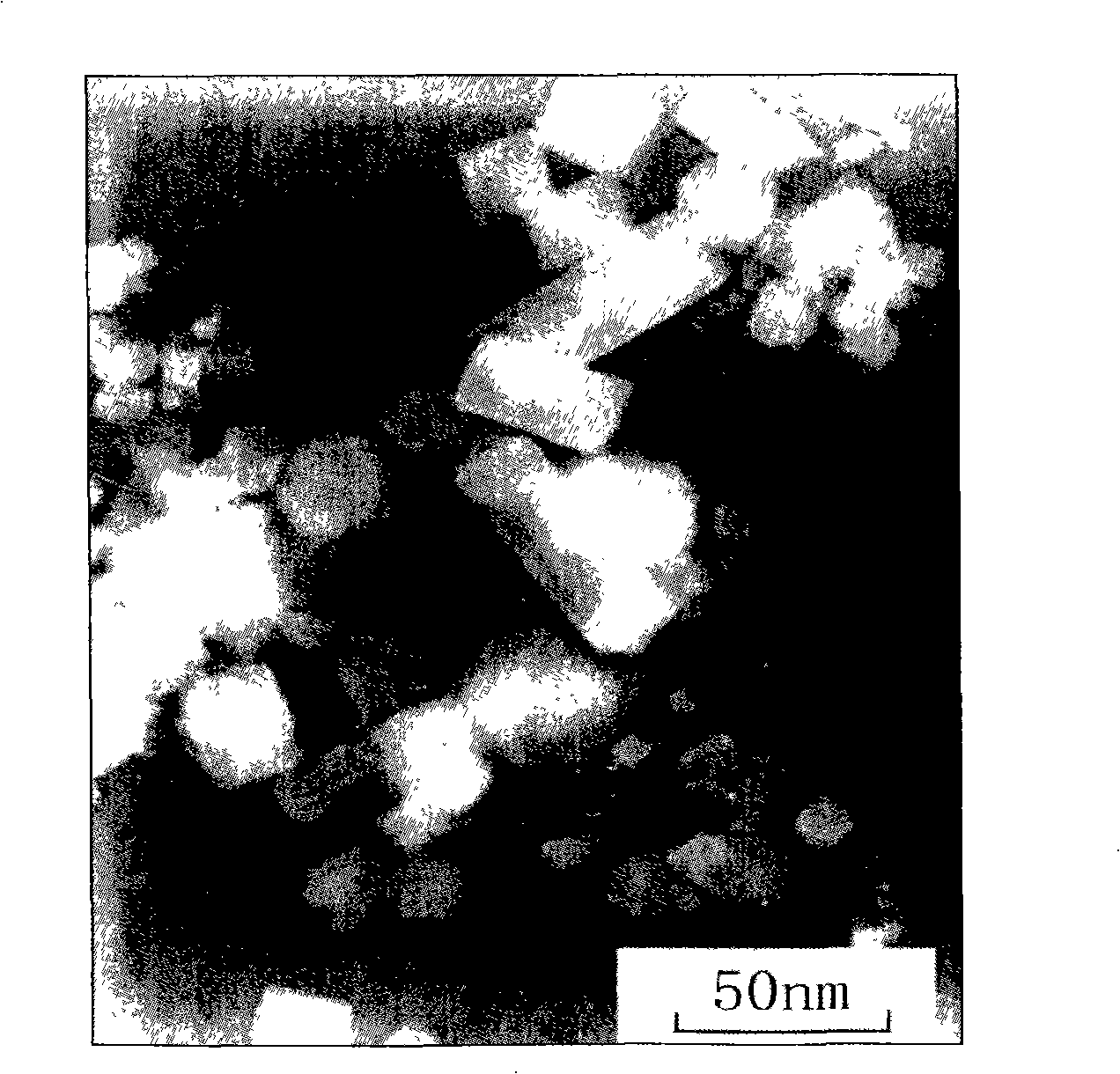

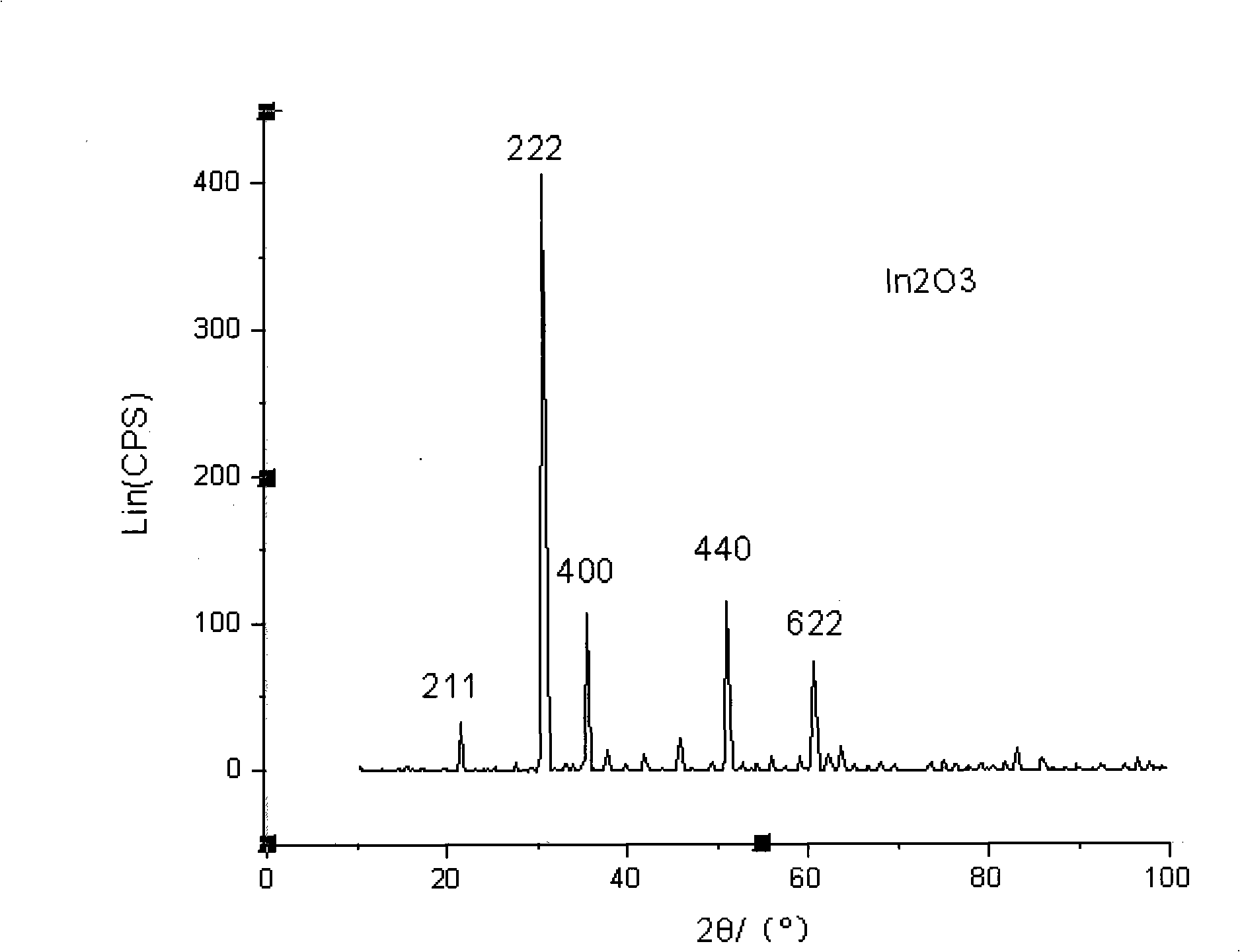

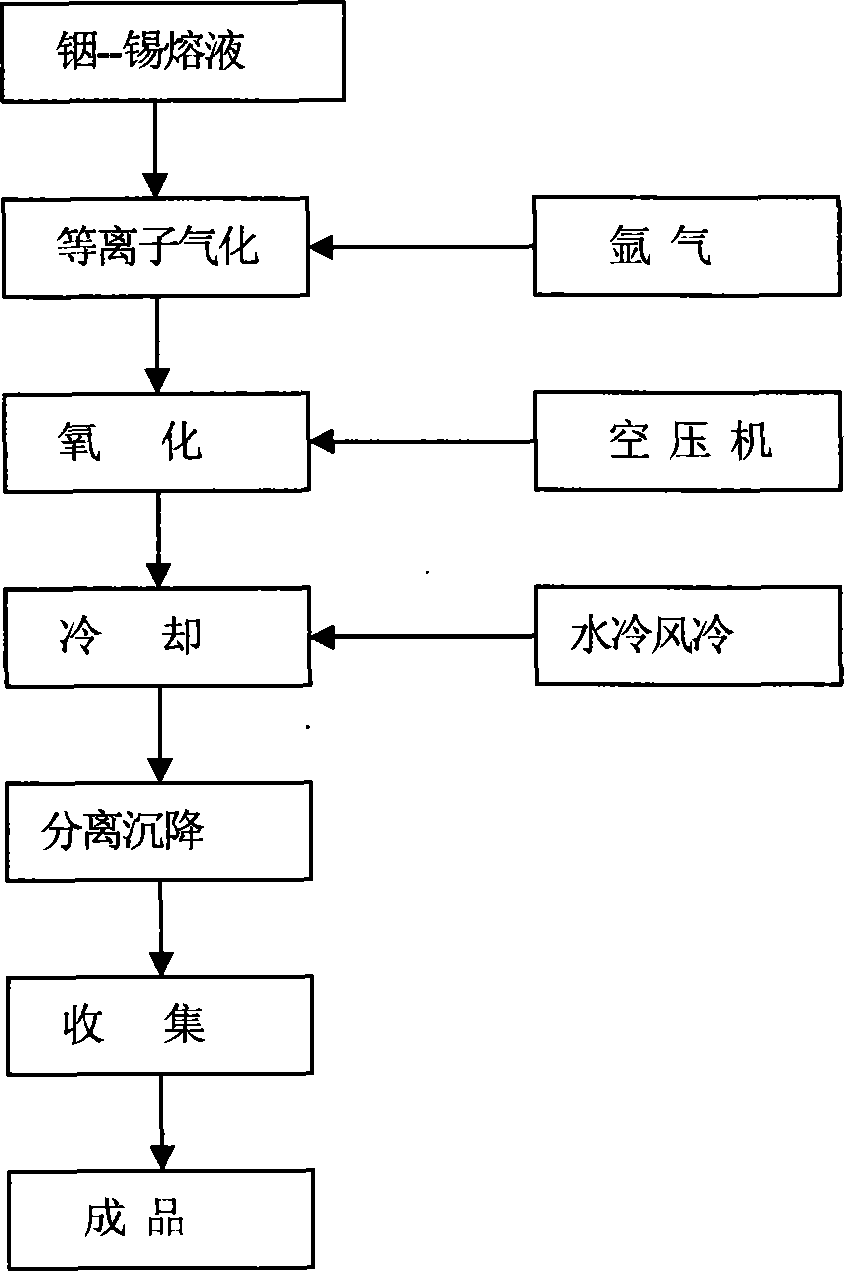

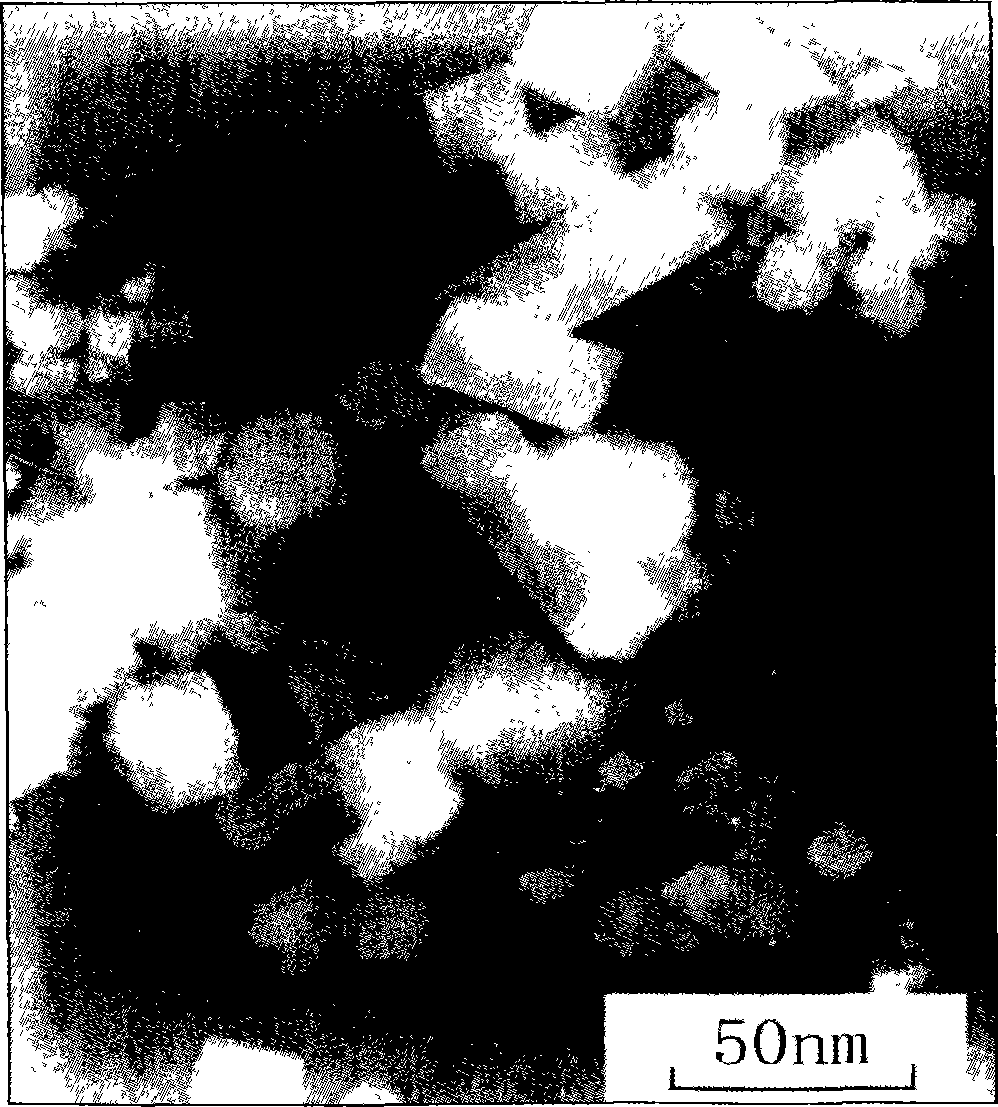

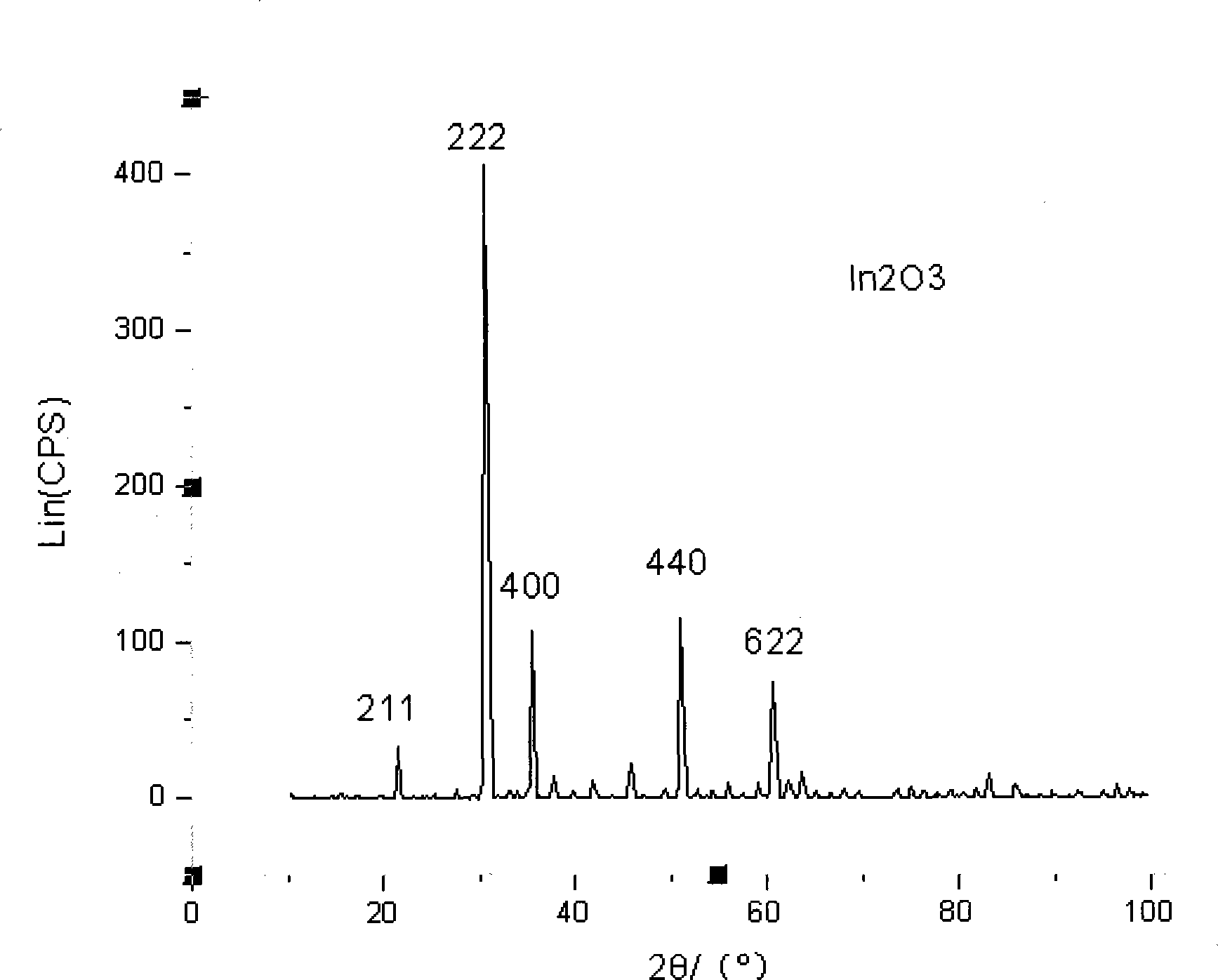

Method for producing nano-ITO powder with plasma electrical arc one-step method

InactiveCN101269834AGood dispersionGrowth inhibitionGallium/indium/thallium compoundsTin oxidesNano sizeGas phase

The invention relates to a method using a plasma arc one step method to prepare nano-size ITO powder. The method is characterized in that In-Sn alloy is continuously sent into a pot of a plasma reaction chamber by a feeding fixed point and fixed amount method, and the plasma reaction chamber uses Ar as a plasma gas, wherein, the working voltage ranges from 30 to 60 V, and the working current ranges from 100 to 400 A; alloyed material is used as a positive pole in the plasma reaction chamber, and a high igniter inflames between the positive pole and the negative pole of a nozzle to form an electric arc; inert gas around ionization forms stable plasma; raw materials are heated and melted by high temperature plasma to evaporate to form metal vapor which reacts with oxygen, and a great temperature grade is formed under the function of flowing water cooling of an inter layer of a reactor, thereby resulting in a high supersaturated zone in the metal vapor; through self nucleation, condensation and growth in a gas phase, nano-size to particle is formed. The nano-size ITO powder made by the method has the advantages of regular grain shape and high powder purity, and the method can realize continuous feeding, continuous reaction, and continuous milling. The efficiency is high, and compared with other methods, the method is easier to realize mass production.

Owner:KUNMING UNIV OF SCI & TECH

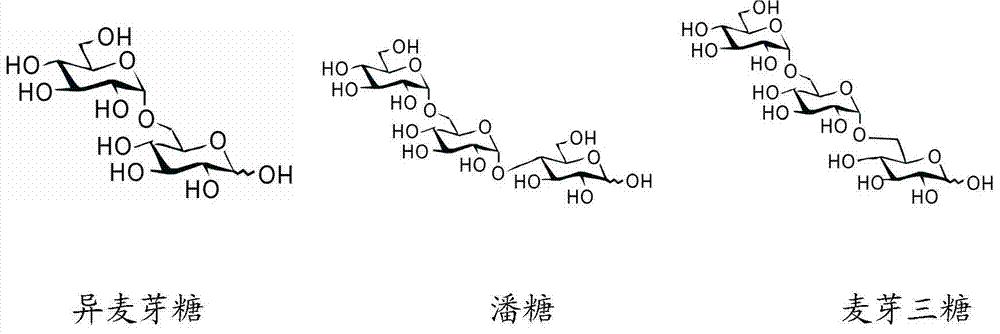

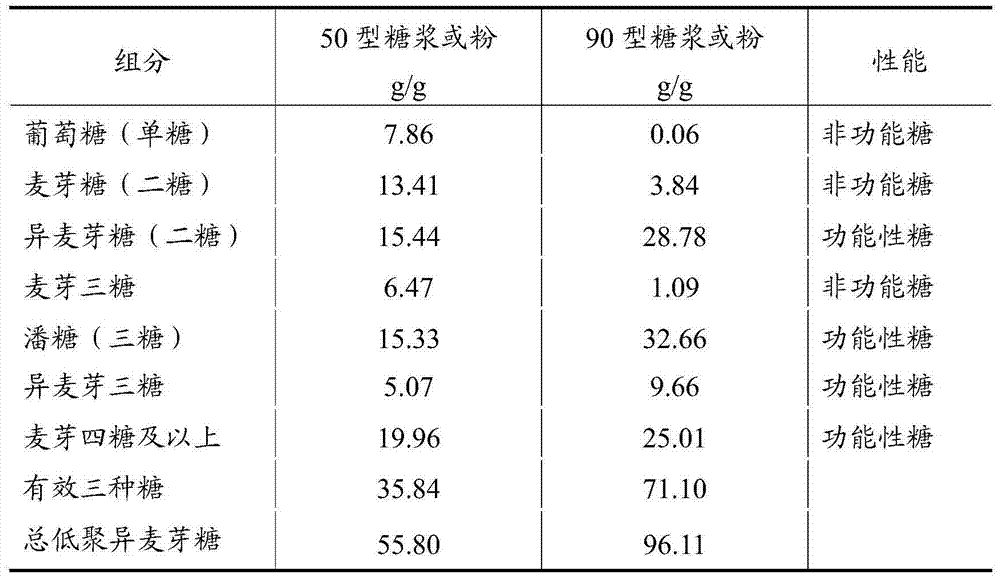

Method of using alpha-glucosidase for preparing isomaltooligosaccharide

ActiveCN103497983AHigh yieldImprove stabilityOn/in organic carrierFermentationAlgluceraseIsomaltooligosaccharide

The invention relates to a method of using alpha-glucosidase for preparing isomaltooligosaccharide. The method includes alpha-glucosidase immobilization, continuous reaction and isomaltooligosaccharide preparation. The alpha-glucosidase is immobilized through alginate, carrageenan and chitosan to implement continuous reaction, converting rate of raw material is 75%, and production cost is reduced by 1 / 3. By the aid of the method, isomaltooligosaccharide 50 or total isomaltooligosaccharide content of the isomaltooligosaccharide 50 is 55%, and the total content of isomalt, panose and isomaltotriose is 35%; isomaltooligosaccharide 90 or total isomaltooligosaccharide content of the isomaltooligosaccharide 90 is 95%, and the the total content of isomalt, panose and isomaltotriose is 70%.

Owner:WUXI JIANTE PHARM CO LTD

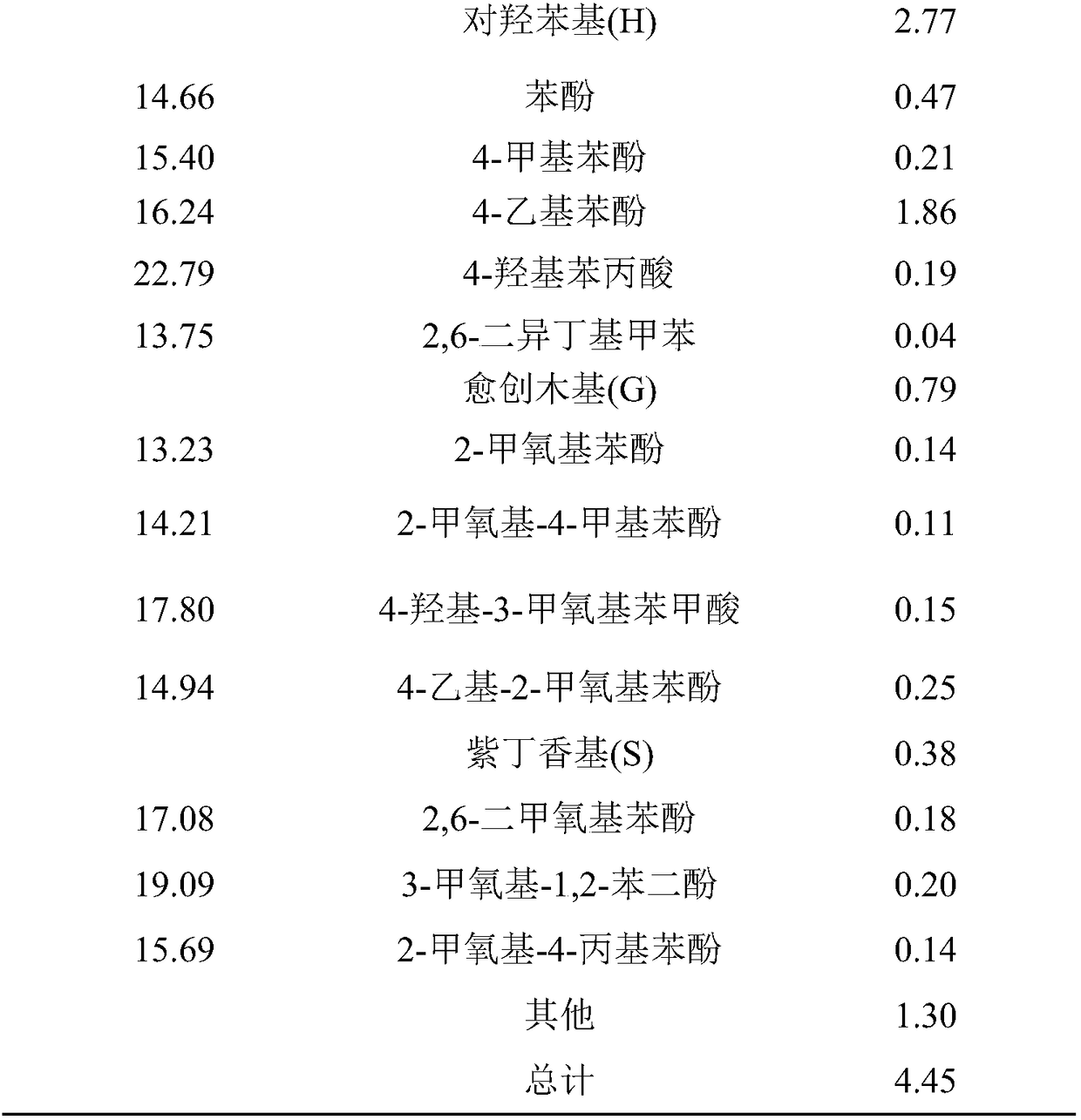

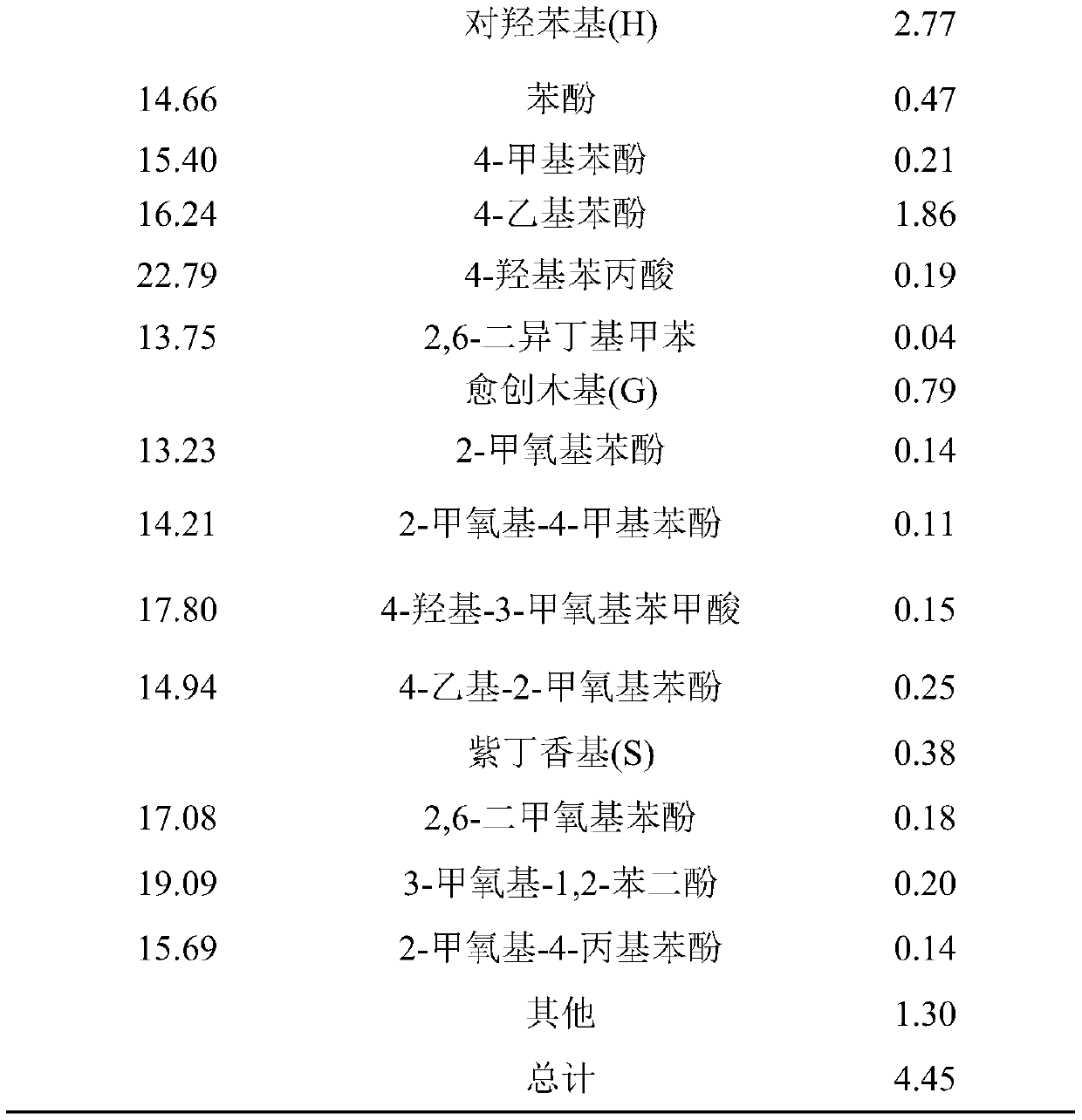

Method for catalyzing selective hydrogenolysis of lignin by zirconium phosphate loaded nickel-based material

ActiveCN108558608AHigh selectivityLow priceOrganic compound preparationCatalyst activation/preparationReaction temperatureFuel oil

The invention discloses a method for catalyzing selective hydrogenolysis of lignin by a zirconium phosphate loaded nickel-based material. The method is used for preparing a monophenol chemical productthrough the hydrogenolysis. The method comprises the following steps: taking a renewable biomass as a raw material; adding a nickel-based catalyst into an alcohol solution reaction medium; regulatinga phosphorus-zirconium ratio of a carrier in the catalyst and reaction temperature; carrying out selective catalytic hydrogenolysis on the raw material under the conditions that the H2 pressure is 1to 4MPa and the reaction time is 1 to 5h, so as to obtain the monophenol chemical product with high additional value. The phosphorus-zirconium ratio of the carrier in the nickel-based catalyst is 1 to(1 to 3) and the loading amount of Ni is 5 weight percent to 25 weight percent. The conversion rate of the lignin is 85.1 percent and the yield of monophenol is 13.0 percent; the selectivity of 4-ethylphenol is higher than 38.3 percent. The method disclosed by the invention has a simple technology and moderate reaction conditions, and can be used for intermittent and continuous production. The obtained small-molecular product can be used as the chemical product with the high additional value and also can be used as a biomass fuel oil precursor.

Owner:SOUTH CHINA UNIV OF TECH

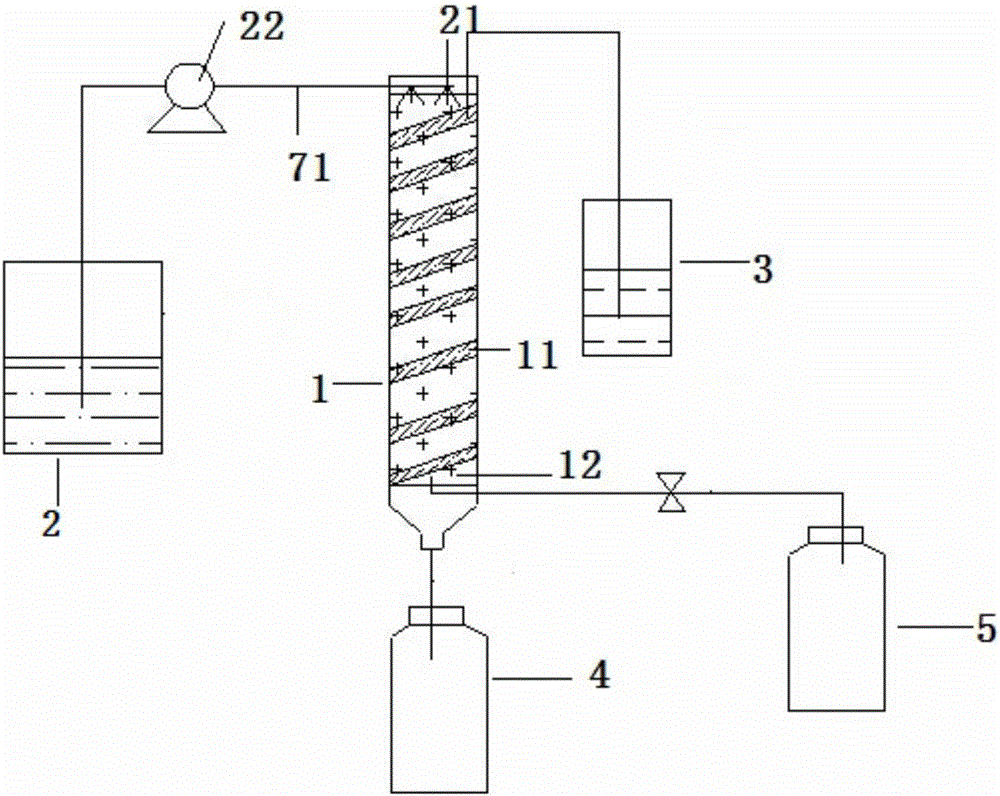

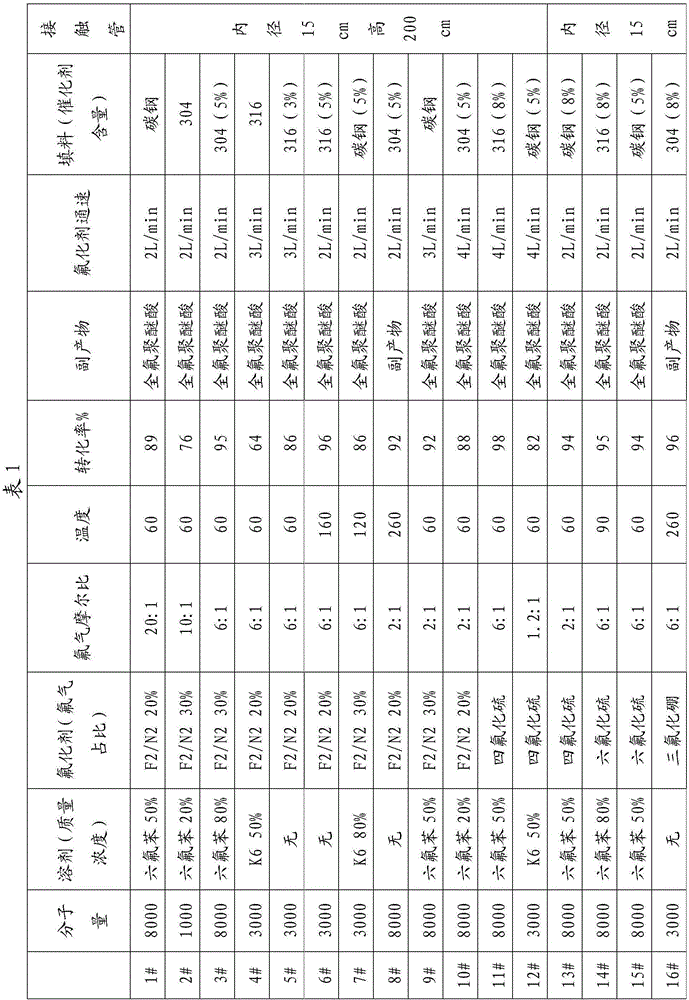

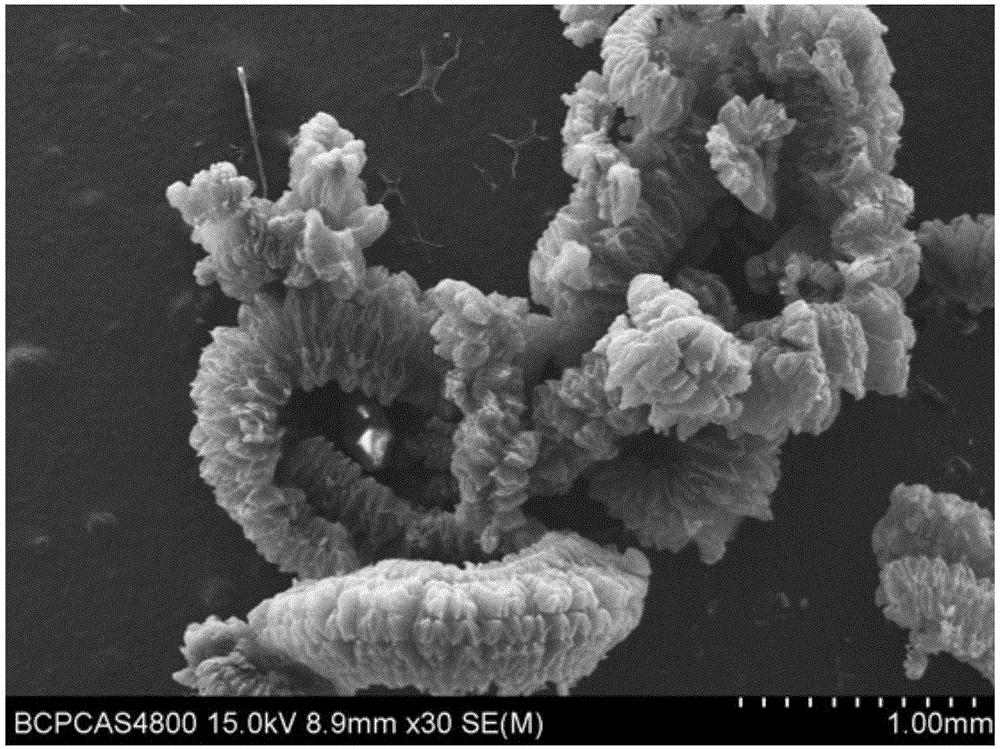

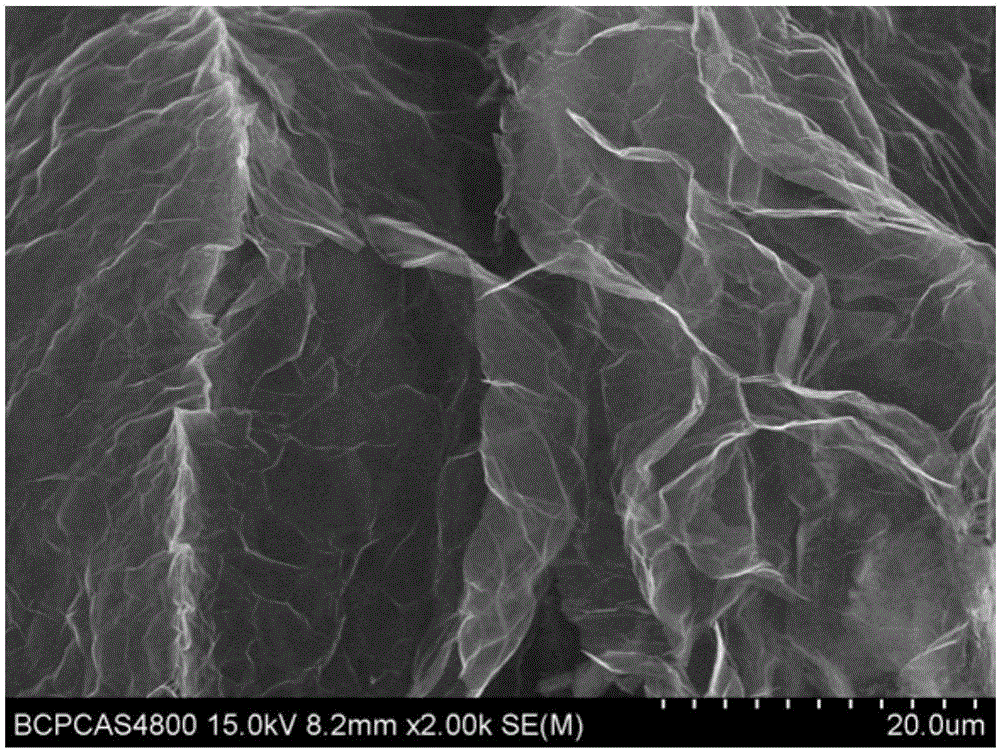

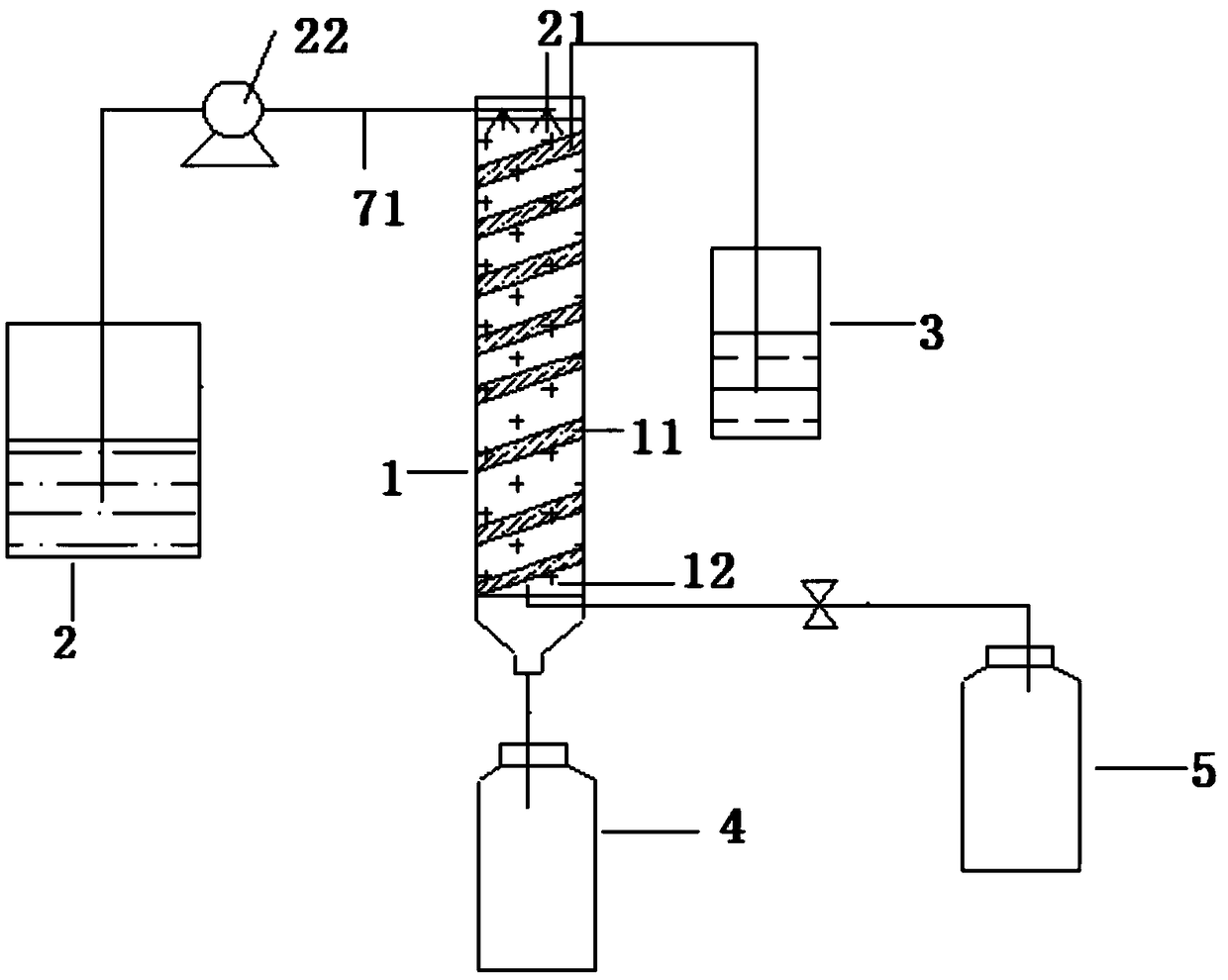

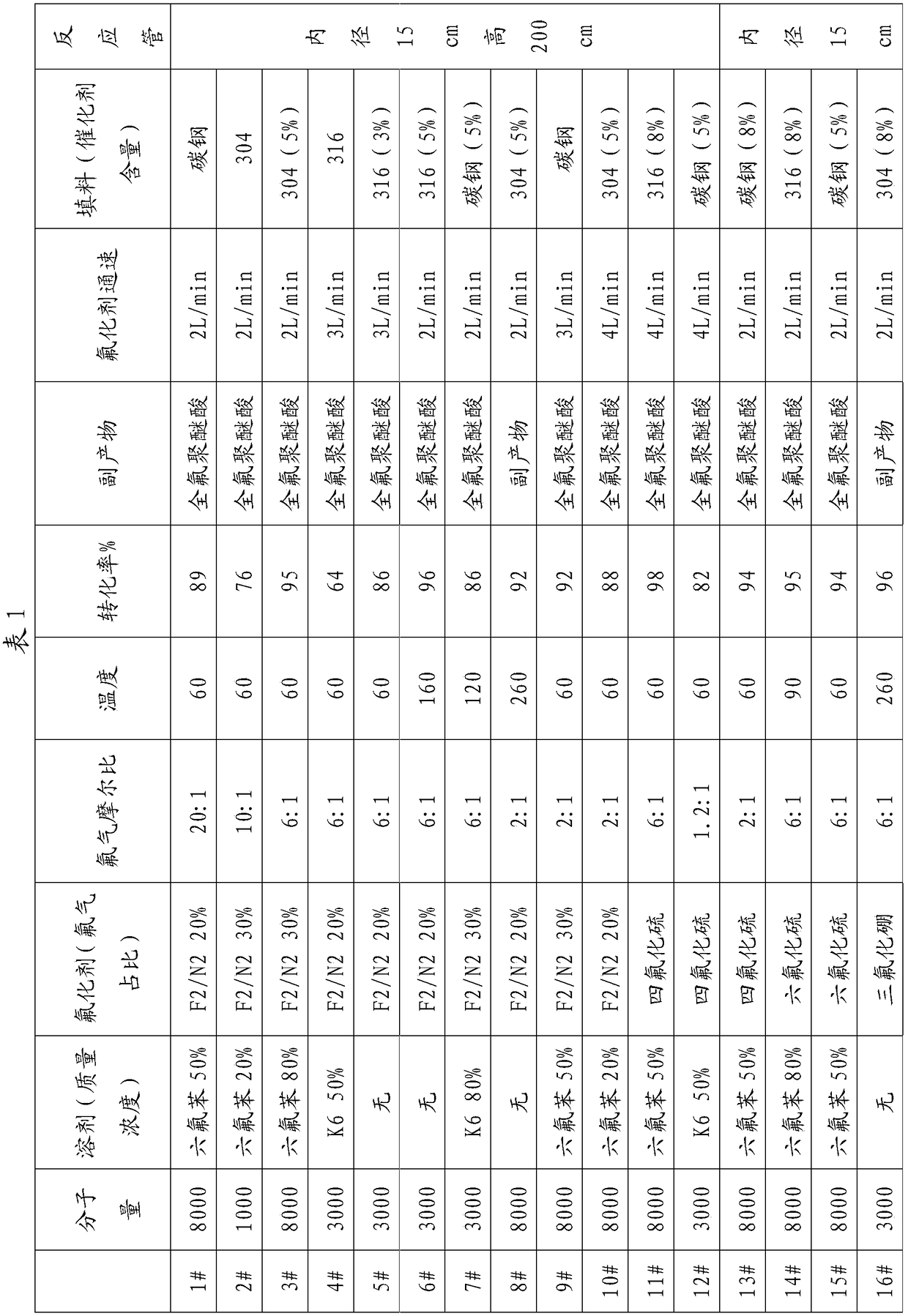

Application of gas-liquid contact reaction device to fluorination of perfluoropolyether acid

ActiveCN106311097AAchieve utilizationFull fluorination reactionChemical/physical/physico-chemical stationary reactorsLiquid-gas reaction processesChemical synthesisPerfluoropolyether

The invention belongs to the field of fluorine chemical synthesis and particularly relates to application of a gas-liquid contact reaction device to fluorination of perfluoropolyether acid. The gas-liquid contact reaction device comprises a gas inlet cylinder for containing fluorinating agent gas, a reaction tube filled with filler, a liquid cylinder, a product collecting cylinder and a tail gas treatment device, wherein a liquid outlet connected with the product collecting cylinder and a gas inlet connected with the gas inlet cylinder are formed in the bottom of the reaction tube, a spray head is arranged at the top end of the reaction tube and is connected with the liquid cylinder through a liquid pump, a gas outlet connected with the tail gas treatment device is formed in the top of the reaction tube, and heating strips are arranged on the outer wall of the reaction tube. The gas-liquid contact reaction device is capable of fluorinating the perfluoropolyether acid by fluorine gas effectively.

Owner:TIANJIN CHANGLU CHEM NEW MATERIAL CO LTD +1

Preparation method of expanded graphite

ActiveCN106744924AThoroughly oxidizedHigh intercalation efficiencyCarbon compoundsSodium chloratePhosphoric acid

The invention relates to the field of new materials. A preparation method of expanded graphite comprises the steps of preparing a first mixed solution which comprises potassium permanganate, perchloric acid and phosphoric acid; adding the first mixed solution to crystalline flake graphite and carrying out stirring reaction at 20-45 DEG C for 15-35min to obtain a first mixed system; preparing a second mixed solution which comprises sodium chlorate, perchloric acid and nitric acid; adding the second mixed solution to the first mixed system and carrying out stirring reaction at 20-45 DEG C for 5-15min to obtain a second mixed system; filtering the second mixed system, taking a solid, and washing the solid until washing liquid is neutral to obtain a head product; and burning the expanded graphite in an environment of 850-1,000 DEG C until the volume does not change any more to obtain the expanded graphite. According to the preparation method of the expanded graphite, graphite oxidation is more thorough and higher in intercalating efficiency; the expansion rate of the prepared expanded graphite can reach 500-700ml / g; and the step is simple, the continuous reaction can be achieved, the production cycle is short and the method is suitable for industrial production.

Owner:北京鼎臣石墨科技有限公司

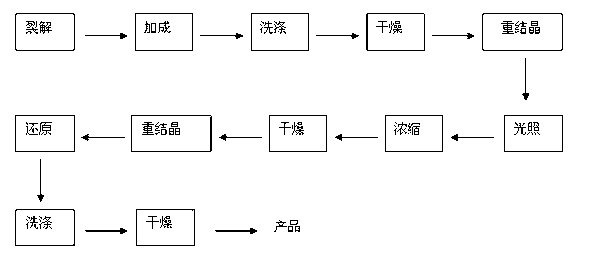

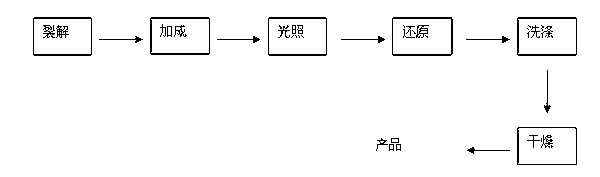

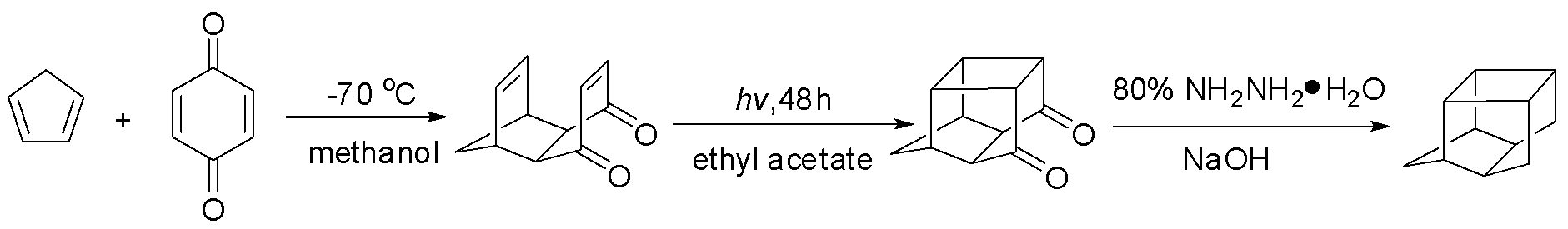

Synthetic method of pentacycloundecane

ActiveCN103204760AImprove efficiencyShort cycleHydrocarbonsHydrocarbon preparationRamjetSynthesis methods

The invention provides a synthetic method of pentacycloundecane (PCUD). The method uses cyclopentadiene and benzoquinone as initial raw materials, and a high boiling solvent; and the pentacycloundecane is synthesized through the following three reactions: Diels-Alder addition, ultraviolet cyclization and carbonyl reduction. According to the invention, the Diels-Alder addition, the ultraviolet cyclization and the carbonyl reduction can be continuously carried out without post-treatment, and unnecessary processes in the reactions is simplified, thereby achieving purposes of improving efficiency and reducing cost. The method has advantages of short period, low cost and easily expanded technology; and the synthesized target compound PCUD can be used as a high-energy additive for fuel of solid turbine stamping engines or liquid rocket fuel.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

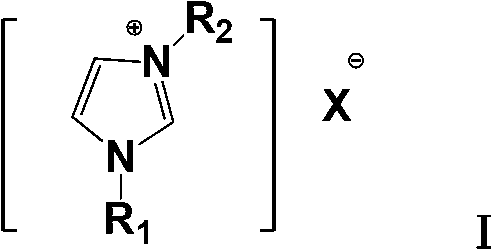

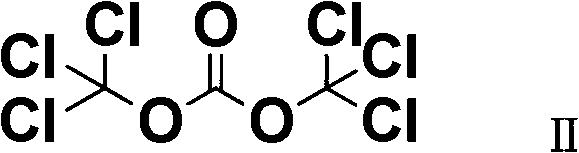

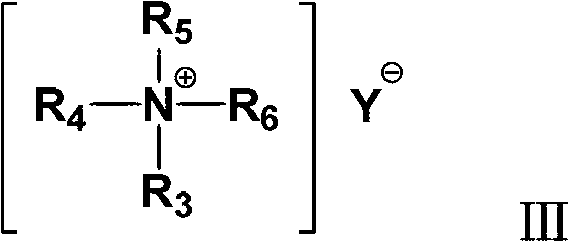

Improved method for preparing 4-phenyl-cyanophenyl

ActiveCN103012203AOvercome the conditionsOvercoming pollutionPreparation by carboxylic acid amide dehydrationBulk chemical productionPhenyl groupPhosgene

The invention relates to a method for preparing 4-phenyl-cyanophenyl. The method mainly comprises the steps of: carrying out Friedel-Crafts acylation on biphenyl which is a starting material to obtain 1-chloroacetyl-4-phenyl-benzene; carrying out ammonolysis reaction on the 1-chloroacetyl-4-phenyl-benzene to obtain 4-phenyl-benzamide; and carrying out dehydration reaction on the 4-phenyl-benzamide in the presence of a dehydrating agent to obtain the target product. The method is characterized in that (1) a catalyst used in the Friedel-Crafts acylation reaction is imidazole ionic liquid; and (2) the dehydrating agent used in the dehydration reaction is a mixture of triphosgene and ammonium salt, the molar ratio of the triphosgene to the ammonium salt is 1:(0.05-0.1), and the ammonium salt is organic ammonium salt or / and inorganic ammonium salt. The method for preparing the 4-phenyl-cyanophenyl with better commercial value is provided by the invention.

Owner:LILY GRP CO LTD +1

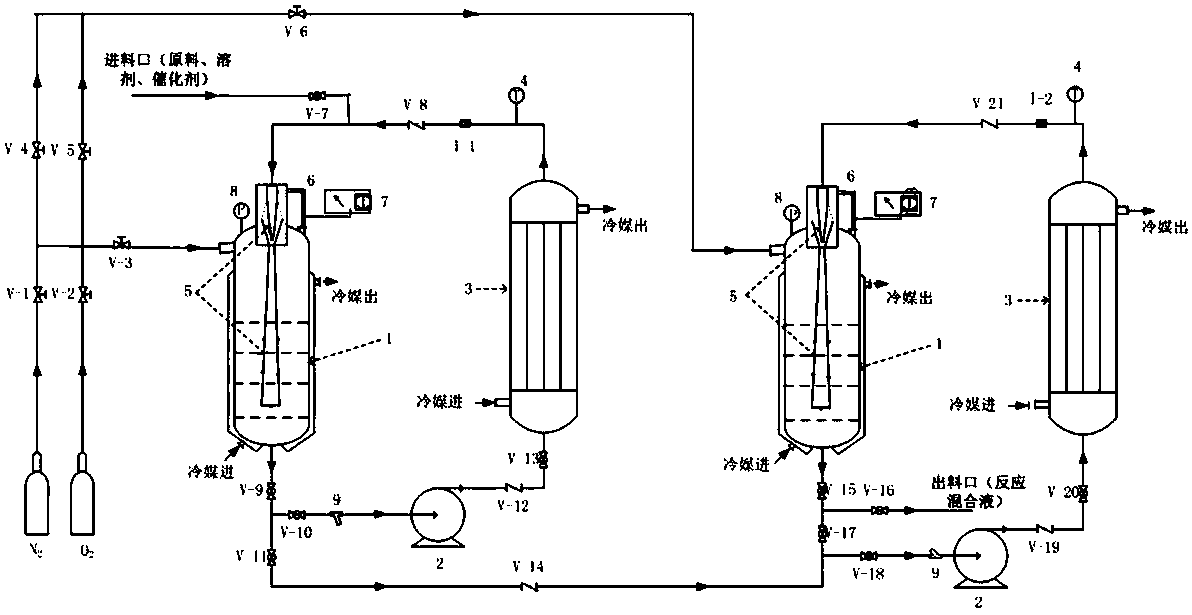

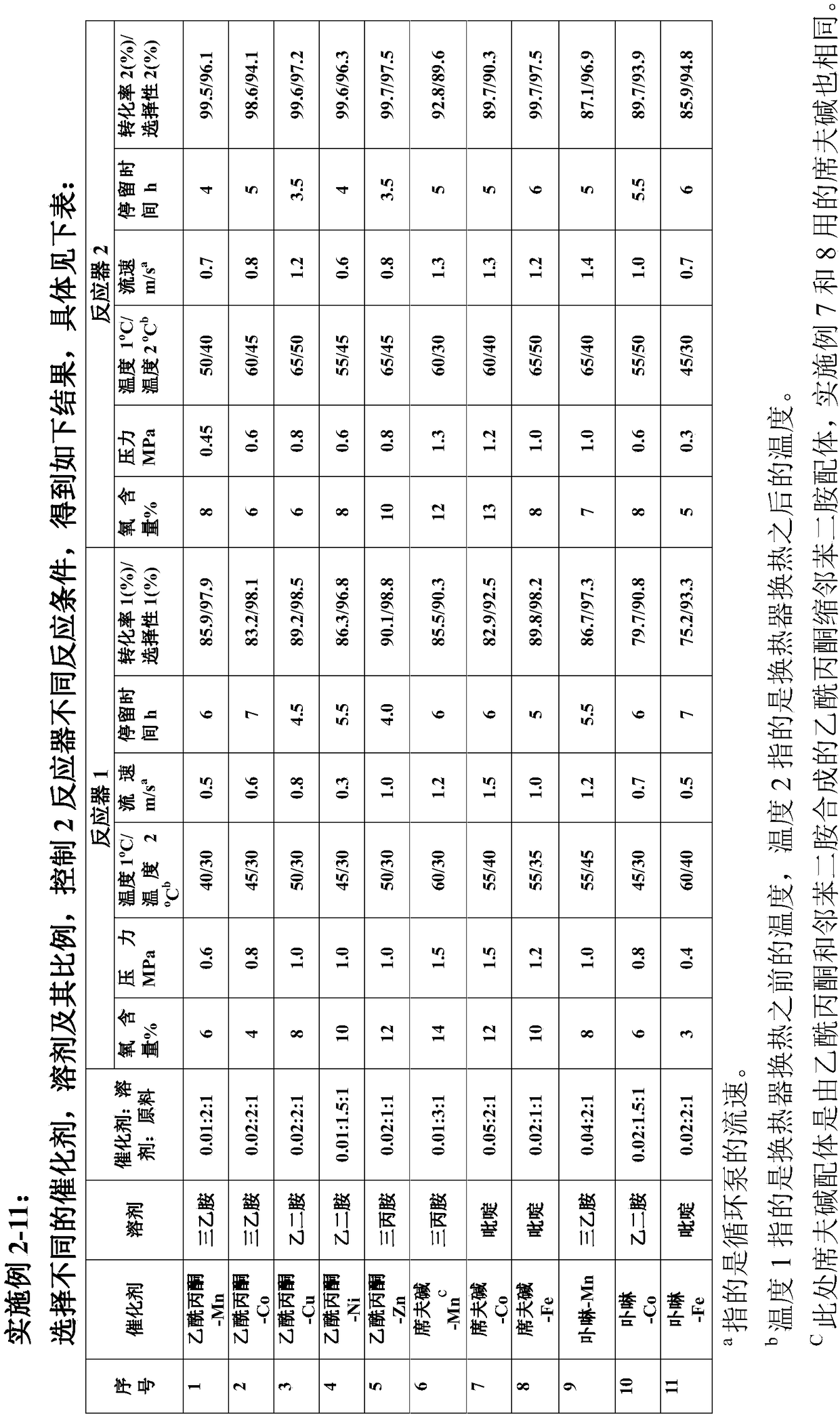

Method for continuously and efficiently preparing 2, 6, 6-trimethyl-2-cyclohexene-1, 4-diketone by oxidation

ActiveCN109438199AShort reaction timeImprove reaction efficiencyOrganic compound preparationCarbonyl compound preparationSolventKetone

The invention discloses a method for continuously and efficiently preparing 2, 6, 6-trimethyl-2-cyclohexene-1, 4-diketone by oxidation. The method includes the steps: (1) performing reaction of raw material liquid and oxygen-containing gas in a spraying and mixing manner to obtain reaction liquid; (2) performing gas-liquid separation on the reaction liquid, adjusting temperature of a liquid phase,and performing reaction of the liquid phase and the oxygen-containing gas in a spraying and mixing manner to obtain reaction liquid; (3) repeating process of the step (2) until reaction is complete to obtain 2, 6, 6-trimethyl-2-cyclohexene-1, 4-diketone liquid. The oxygen-containing gas in the step (2) is a gas phase acquired by gas-liquid separation or newly prepared gas. The raw material liquidcomprises a catalyst, a reaction raw material and a solvent. By the aid of a gas and liquid mixing and spraying mode, the mixing effect of the reaction liquid, the gas and the catalyst is greatly superior to that of a mechanically stirred reactor, bubbles are more uniformly dispersed and sufficiently contact, ideal mass transfer effects are achieved, and reaction is accelerated.

Owner:SHANDONG NHU VITAMIN CO LTD +1

Preparation method of 5-chloro-3-trichloromethyl-1,2,4-thiadiazole

InactiveCN104672174AAchieving Continuous ResponseEasy to separateOrganic chemistryTrichloroacetonitrileReaction temperature

The invention discloses a preparation method of 5-chloro-3-trichloromethyl-1,2,4-thiadiazole. The preparation method comprises the following steps: by taking trichloroacetonitrile as a raw material, firstly synthesizing trichloro-acetamidine, and then preparing thiadiazole to achieve continuous reaction. By adopting the preparation method disclosed by the invention, separation processes of an intermediate trichloro-acetamidine can be reduced; a single solvent is used in the whole reaction so as to ensure that continuous production of two-step reaction can be achieved; a liquid ammonia mode is changed into a production mode of introducing ammonia gas into the solvent, and the reaction temperature is improved to adapt to the industrial production; the trichloro-acetamidine intermediate does not need to be treated additionally, and can be directly applied to the next reaction to ensure that purification and refining processes can be reduced; the quality and yield of products can be significantly improved, and the production cost can be reduced; and greater industrial production values can be achieved.

Owner:NANJING QIZHENG CHEM

Production method of beta-alanine

InactiveCN108383742AAchieving Continuous ResponseImprove conversion rateOrganic compound preparationAmino-carboxyl compound preparationAlcoholRoom temperature

The invention belongs to the technical field of chemistry, and particularly relates to a production method of beta-alanine. The method comprises the following steps of leading an ammonia-water mixtureand alanine respectively into a pipeline reactor to perform continuous reaction, and then performing deamination, dehydration, alcohol precipitation and crystallization treatment on reaction productsto obtain the beta-alanine; in a normal temperature state, the ammonia-water mixture at least comprises NH4<+> and CO3<2->; the method provided by the invention is simple, safe, and high in both reaction selectivity and product yield.

Owner:安徽省恒锐新技术开发有限责任公司

Preparation method of expanded graphite

ActiveCN106744926AThoroughly oxidizedHigh intercalation efficiencyCarbon compoundsSodium chloratePhosphoric acid

The invention relates to the field of new materials and discloses a preparation method of expanded graphite. The method comprises the following steps of preparing a first mixed solution which is prepared from sodium chlorate, perchloric acid and phosphoric acid; adding the first mixed solution to crystalline flake graphite and carrying out stirring reaction at 20-45 DEG C for 15-35 minutes to obtain a first mixed system; preparing a second mixed solution which is prepared from potassium permanganate and perchloric acid; adding the second mixed solution to the first mixed system and carrying out stirring reaction at 20-45 DEG C for 5-15 minutes to obtain a second mixed system; filtering the second mixed solution to take solids and washing until the washing liquid is neutral to obtain a primary product; and putting the primary product into an environment of 850-1,000 DEG C until the volume does not change any more to obtain the expanded graphite. According to the preparation method of the expanded graphite, graphite oxidation is more thorough and the intercalation efficiency is higher. The expanded multiplication rate of the prepared expanded graphite can reach 500-700ml / g; the steps are simple; continuous reaction and a short production cycle can be achieved; and the method is suitable for industrial production.

Owner:北京鼎臣石墨科技有限公司

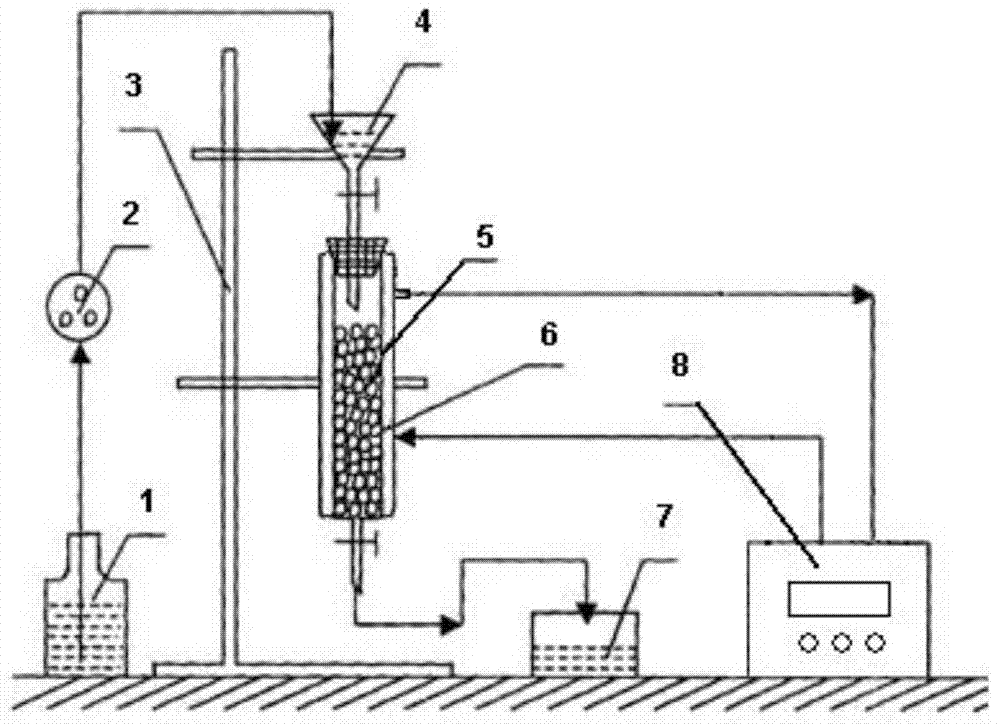

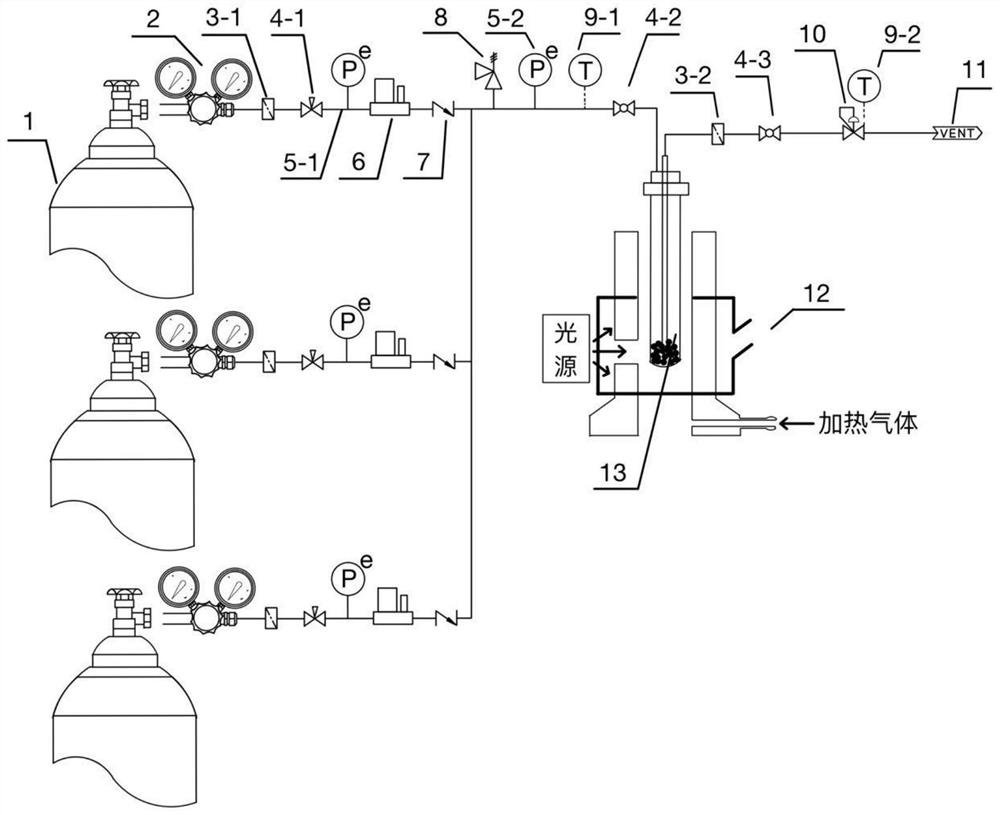

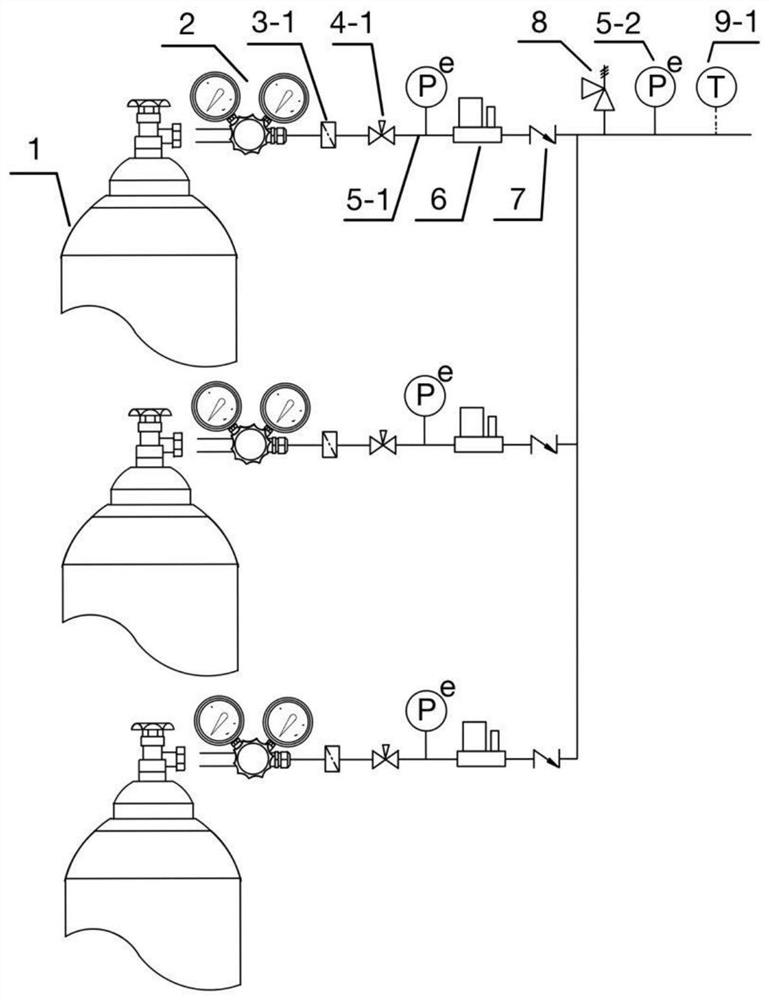

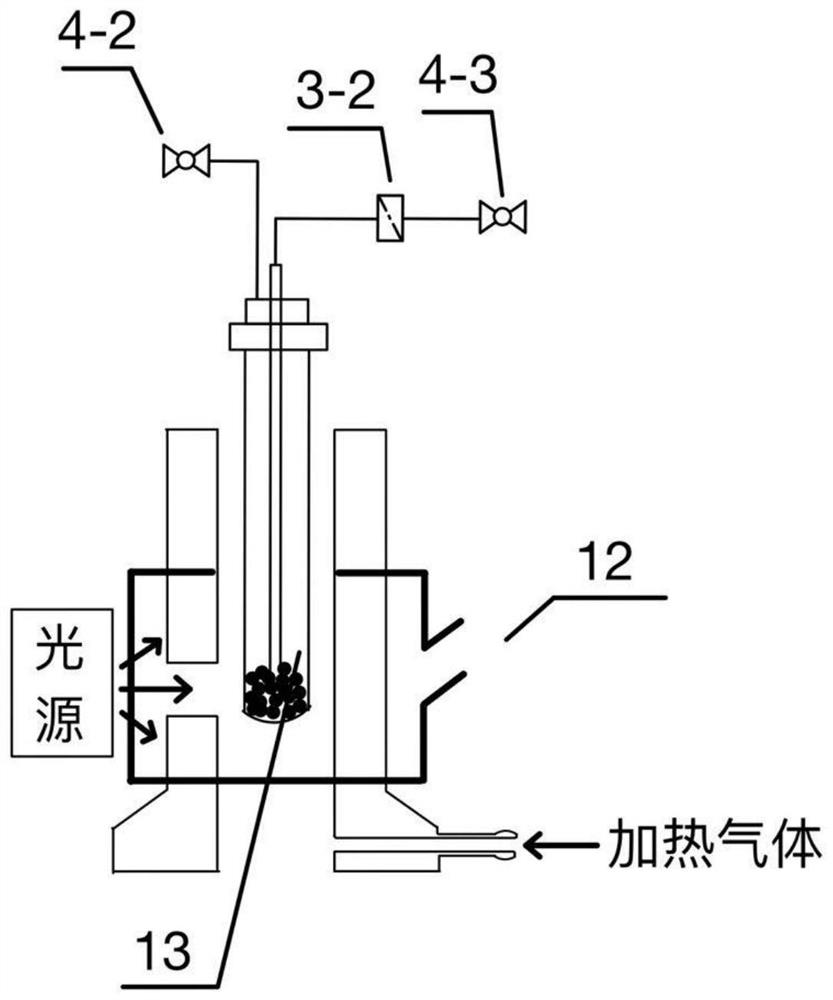

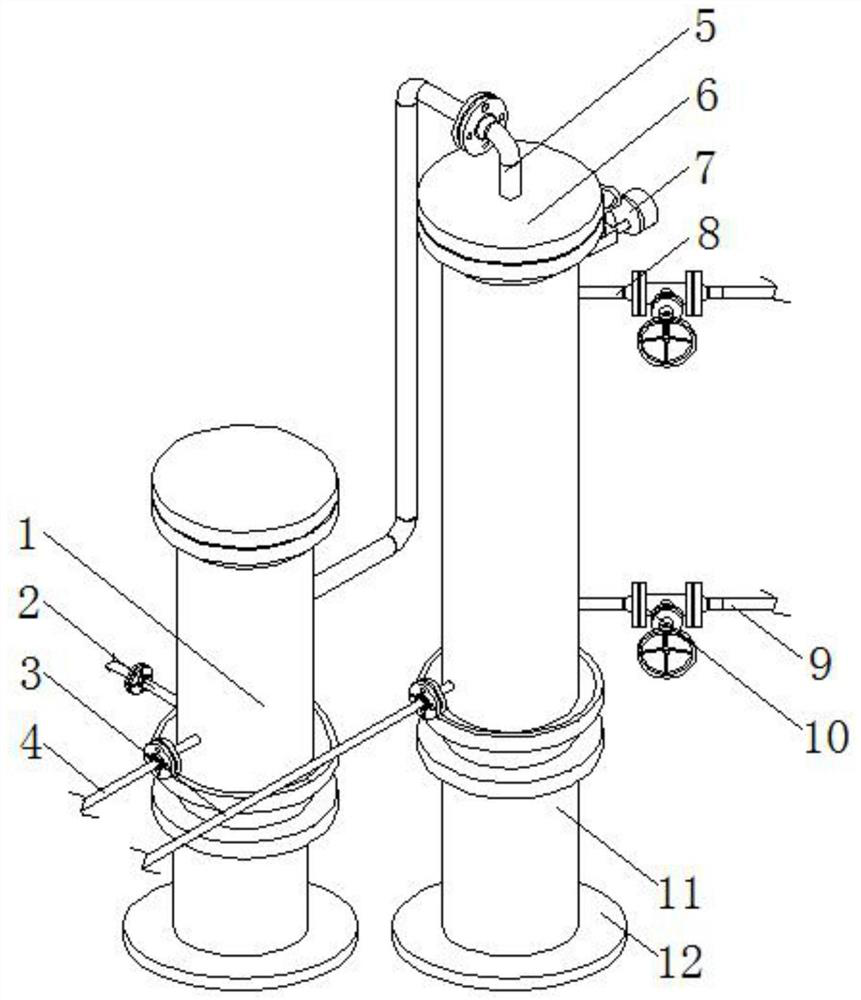

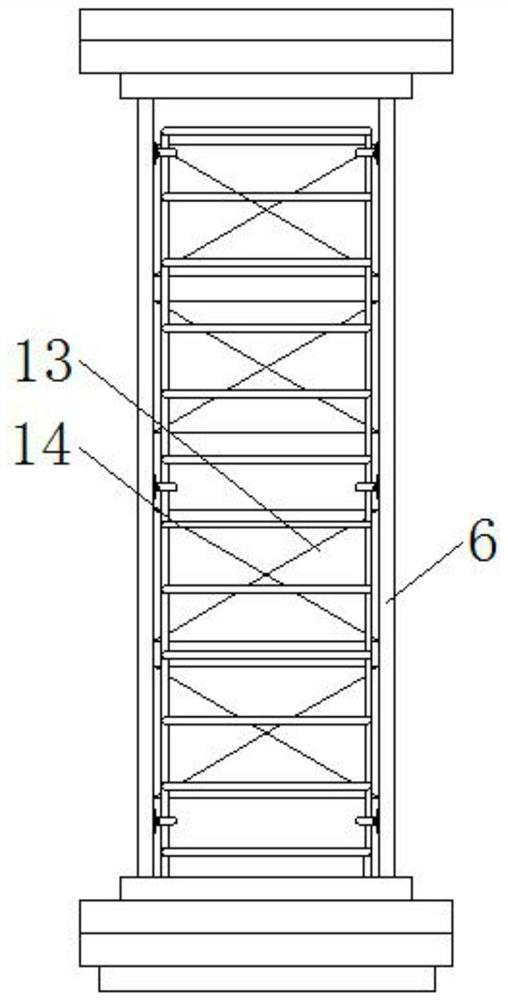

In-situ and quasi-in-situ heterogeneous catalytic electron paramagnetic resonance platform and using method

PendingCN112697832AStrong circulationEasy to controlAnalysis using electron paramagnetic resonanaceDisplay deviceMaterials science

The invention discloses an in-situ and quasi-in-situ heterogeneous catalysis electron paramagnetic resonance platform and a using method. The in-situ and quasi-in-situ heterogeneous catalysis electron paramagnetic resonance platform is composed of a gas distribution system device and an in-situ reaction tank device. The gas distribution system device consists of an external steel cylinder, a pressure reducer, a filter, a needle valve, an electronic pressure gauge, a mass flow meter, a one-way valve, an unloading valve, a temperature measuring point, a ball valve and a back pressure valve, and is assisted by a display panel for accurate control and real-time switching; and the in-situ reaction tank device is composed of a double-layer glass sleeve, a light source and a resonant cavity of the electron paramagnetic resonance spectrometer. The platform is simple to operate and convenient to disassemble, can be operated on the basis of an original electron paramagnetic resonance instrument, and can realize in-situ (the reaction temperature<=250 DEG C) / quasi-in-situ (the reaction temperature >250 DEG C) illumination / heating experimental conditions, and the pressure lower than 10Mpa of a reaction system.

Owner:LANZHOU UNIVERSITY

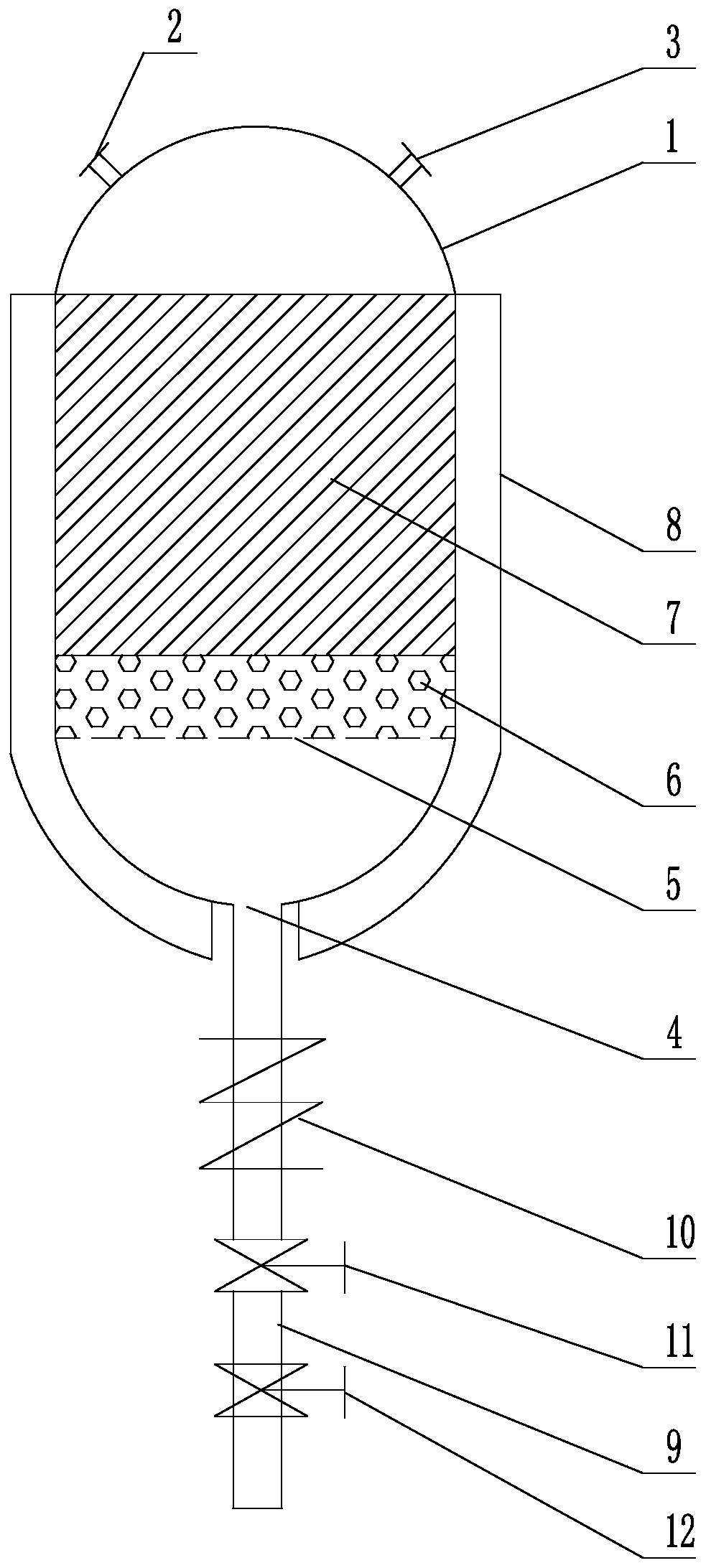

Apparatus for non-aqueous catalytic synthesis and self-separation of 1-amino-2-propanol, and process thereof

InactiveCN110193327ASimple structureReasonable designMolecular sieve catalystsOrganic compound preparation1-Amino-2-propanolMonoisopropanolamine

The invention relates to a 1-amino-2-propanol production process, particularly to an apparatus for non-aqueous catalytic synthesis and self-separation of 1-amino-2-propanol, and a process thereof. Theapparatus comprises a reactor, wherein a propylene oxide inlet and an ammonia gas inlet are arranged on the top portion of the reactor, a material outlet is arranged on the lower portion of the reactor, the interior of the reactor is sequentially provided with a hole plate, a porcelain ball and a solid catalyst from bottom to top, a jacket is arranged on the outer portion of the reactor, the material outlet is connected to a buffer pipe, the outer portion of the buffer pipe is provided with a cooling coil pipe, and the buffer pipe is provided with a valve A and a valve B. The invention further provides the process. According to the present invention, with the apparatus, the continuous reaction can be achieved, only the 1-amino-2-propanol product is extracted, only a very small amount of diisopropanolamine and triisopropanolamine are formed, and the requirements of the 1-amino-2-propanol industrial product can be met without the subsequent separation; and the process using the apparatus is scientific, reasonable, simple and easy-performing.

Owner:山东河清化工科技有限公司

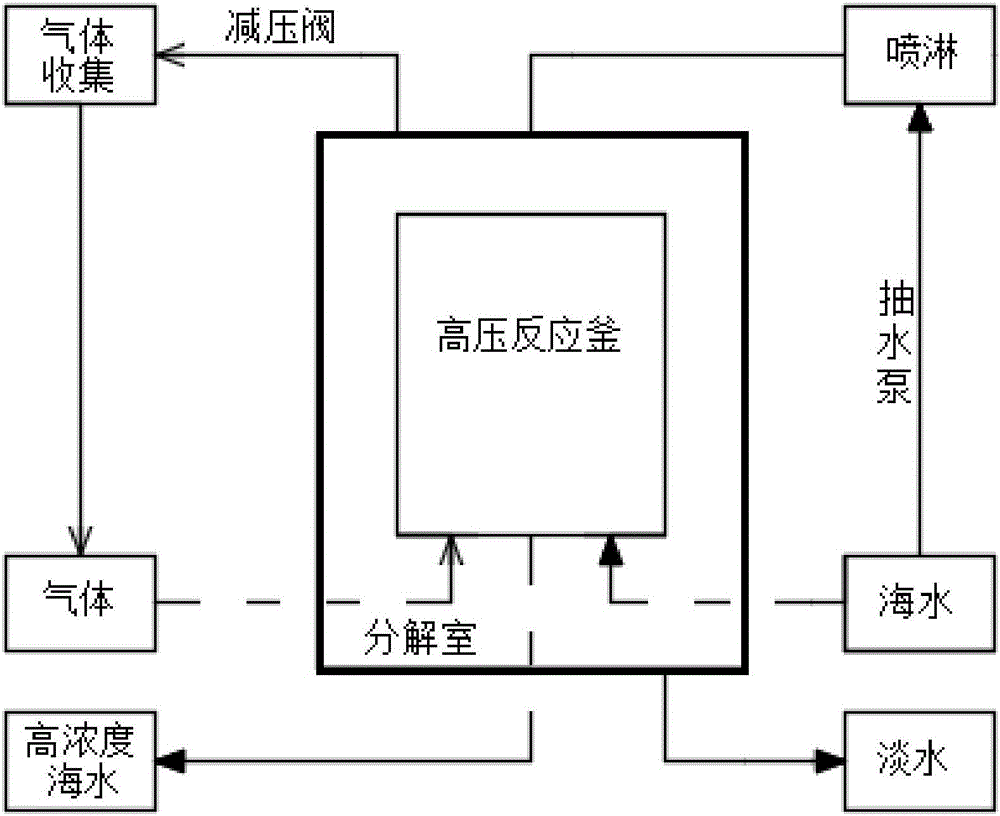

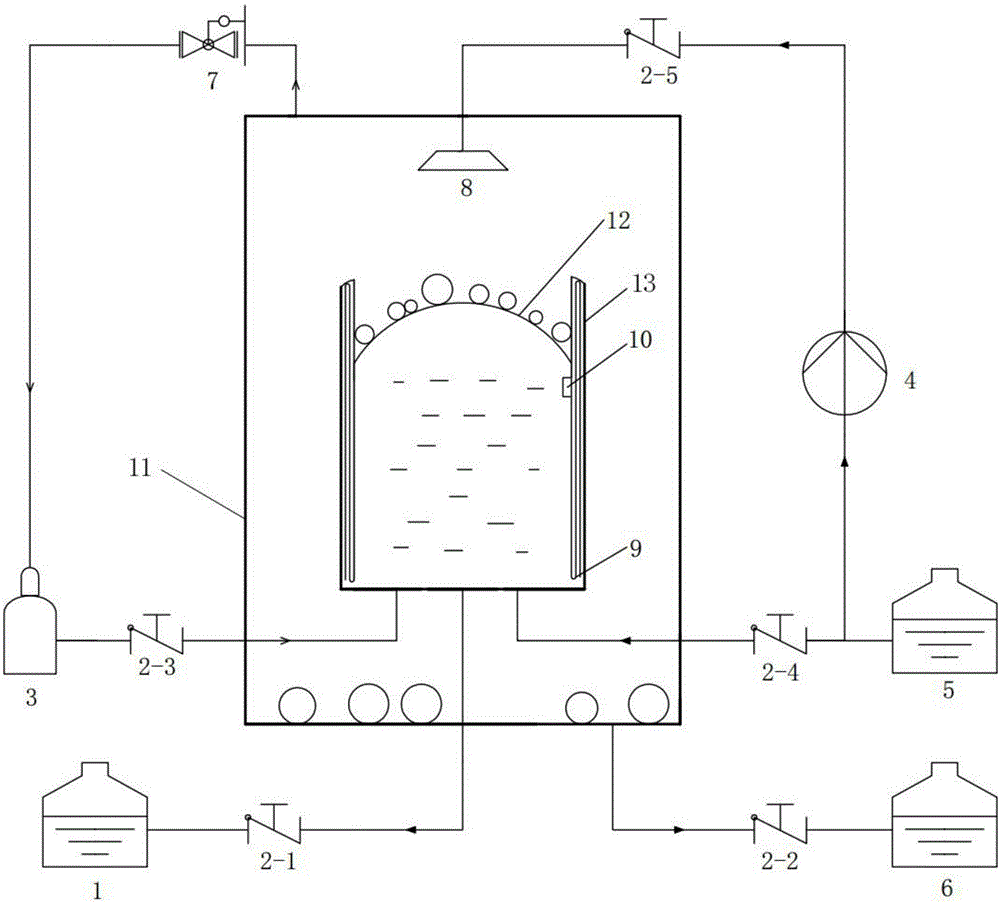

External discharge type continuous hydrate seawater desalination device

ActiveCN106745368AAchieve compactnessReduce energy consumptionSeawater treatmentWater/sewage treatmentHigh concentrationGeneration process

The invention discloses an external discharge type continuous hydrate seawater desalination device, and belongs to the technical field of hydrate seawater desalination. The device comprises a high-pressure reaction kettle, a low-temperature seawater spraying system, a high-concentration seawater recycling system, a hydrate dissociation chamber and a gas intake and collection system. A gas hydration agent and seawater are introduced into the high-pressure reaction kettle to generate a hydrate, the hydrate is lifted out of the water surface for low-temperature seawater spraying by a hard filter screen, meanwhile, high-concentration seawater is discharged, seawater is reintroduced for next-step hydrate generation reaction, then a hydrate is discharged to the outer-layer hydrate dissociation chamber, dissociated fresh water is collected, and the gas hydration agent is collected and recycled, so as to implement highly concentrated production by virtue of a hydrate seawater desalination technology. At the same time of low-temperature seawater spraying, the high-concentration seawater is discharged and the seawater is reintroduced into the high-pressure reaction kettle to start a next-step hydrate generation process to implement continuous reaction for hydrate seawater desalination, so that the device is more compact in structure and more complete in function, and the economy is improved.

Owner:DALIAN UNIV OF TECH

A method for the selective hydrogenolysis of lignin catalyzed by a nickel-based material supported by zirconium phosphate

ActiveCN108558608BHigh selectivityLow priceOrganic compound preparationCatalyst activation/preparationPtru catalystPhosphoric acid

The invention discloses a method for the selective hydrogenolysis of lignin catalyzed by a nickel-based material supported by zirconium phosphate; and the hydrogenolysis method prepares monophenolic chemicals. The method uses renewable biomass as a raw material, adds a nickel-based catalyst to the alcohol solution reaction medium, and adjusts the ratio of phosphorus to zirconium in the catalyst carrier and the reaction temperature. 2 Under the conditions of pressure and 1-5h reaction time, the raw materials are selectively catalytically hydrogenated to form high value-added monophenolic chemicals. The ratio of carrier phosphorus to zirconium in the nickel-based catalyst is 1:(1-3), and the Ni load is 5wt%-25wt%. The conversion rate of lignin in the present invention is higher than 85.1%, the yield of monophenol is higher than 13.0%, and the selectivity of 4-ethylphenol is higher than 38.3%. . The obtained small molecule products can be used as high value-added chemicals or as precursors of biomass fuel oil.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of expanded graphite

InactiveCN106672962AGraphite oxidation is completeHigh intercalation efficiencyCarbon compoundsPotassium permanganateSodium chlorate

The invention relates to the field of new materials, and particularly provides a preparation method of expanded graphite. The preparation method comprises the following steps: adding a first mixed solution into crystalline flake graphite, and performing stirring reaction at 20-45 DEG C for 15-35 minutes to obtain a first mixed system, wherein the first mixed solution comprises sodium chlorate and perchloric acid; adding a second mixed solution into the first mixed system, and performing stirring reaction at 20-45 DEG C for 5-15 minutes to obtain a second mixed system, wherein the second mixed solution comprises potassium permanganate and perchloric acid; filtering the second mixed system to obtain solids, and washing until a washing solution is neutral to obtain a primary product; and burning the primary product at 850-1100 DEG C until the volume does not change any more to obtain the expanded graphite. According to the preparation method of expanded graphite, the expanded graphite is prepared through a multi-step intercalation method, so that the oxidation is more thorough, the intercalation efficiency is higher, and the expansion multiplying power of the prepared expanded graphite can be up to 500-800 ml / g. The preparation method has the advantages of simple steps and short production cycle, can realize continuous reaction and is suitable for industrial production.

Owner:北京鼎臣石墨科技有限公司

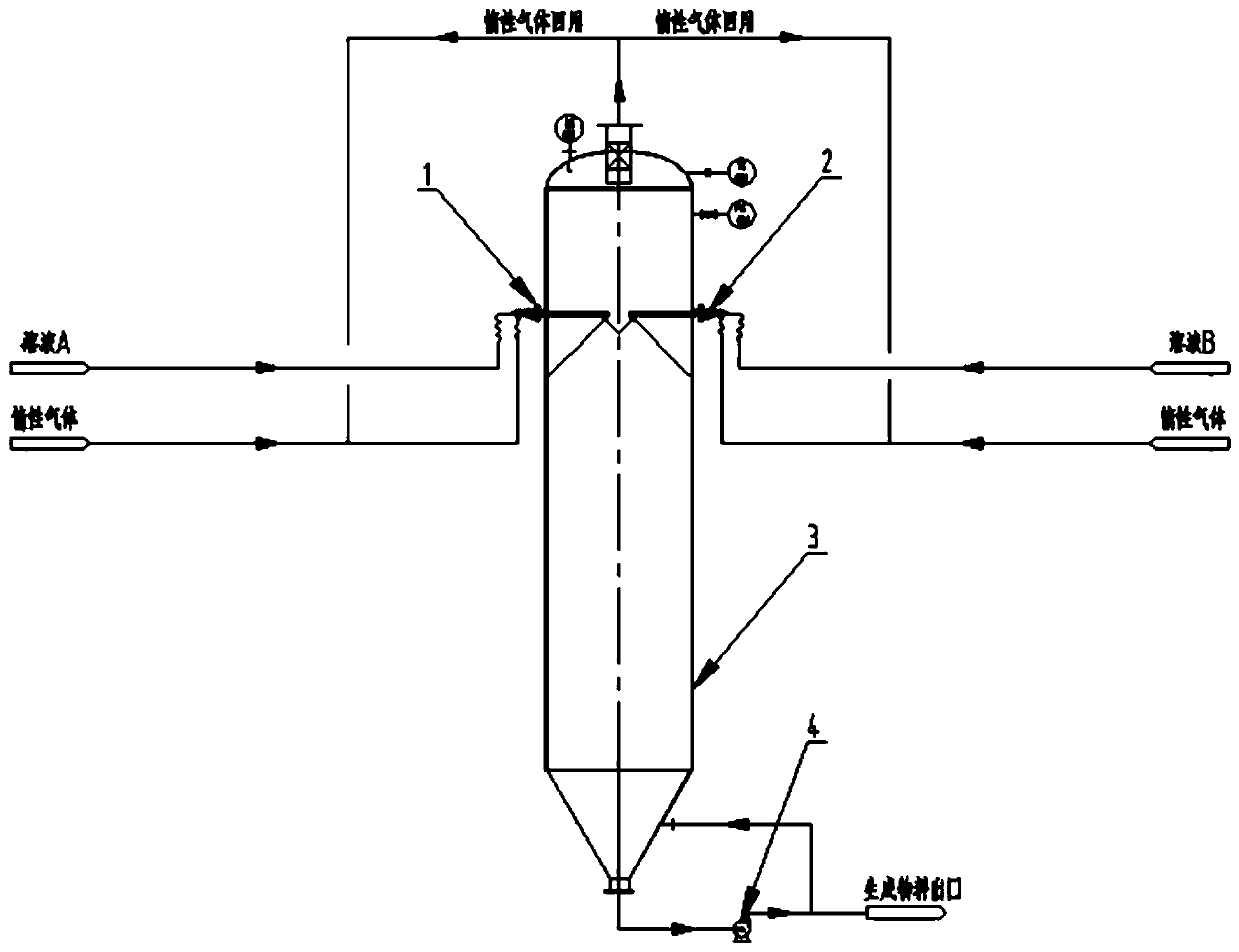

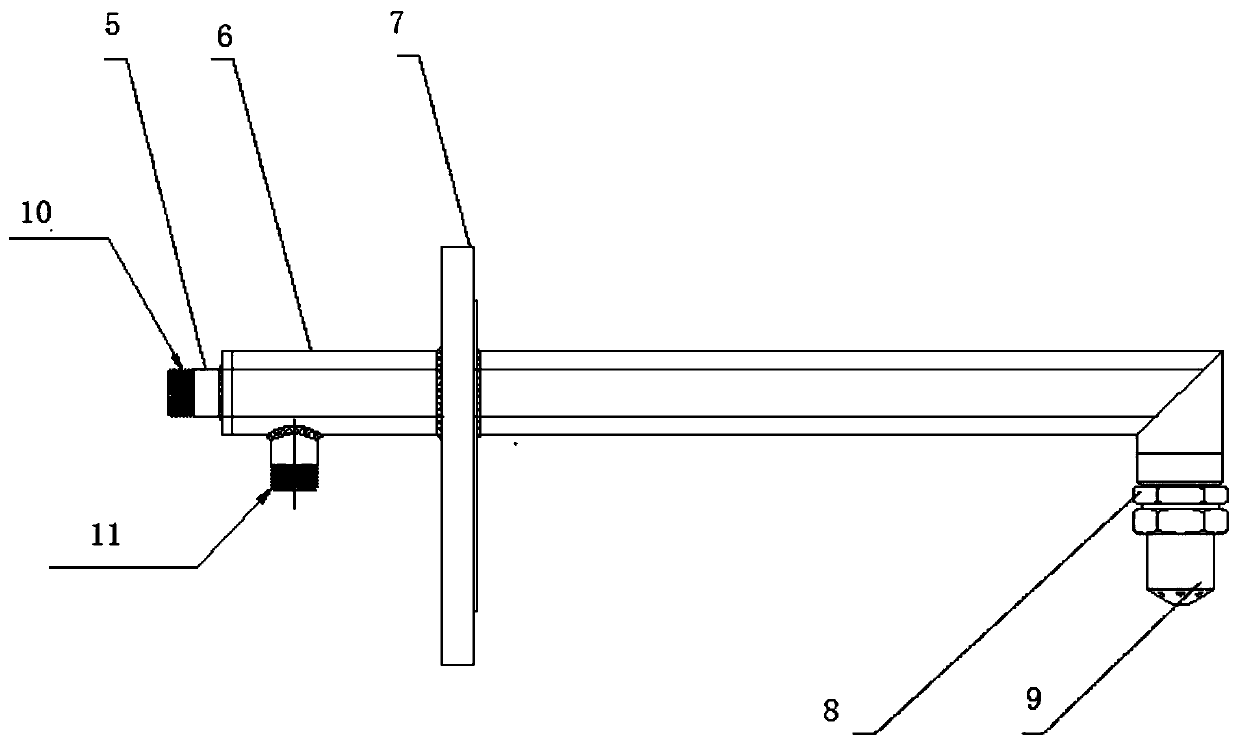

Device and method for spraying continuous reaction

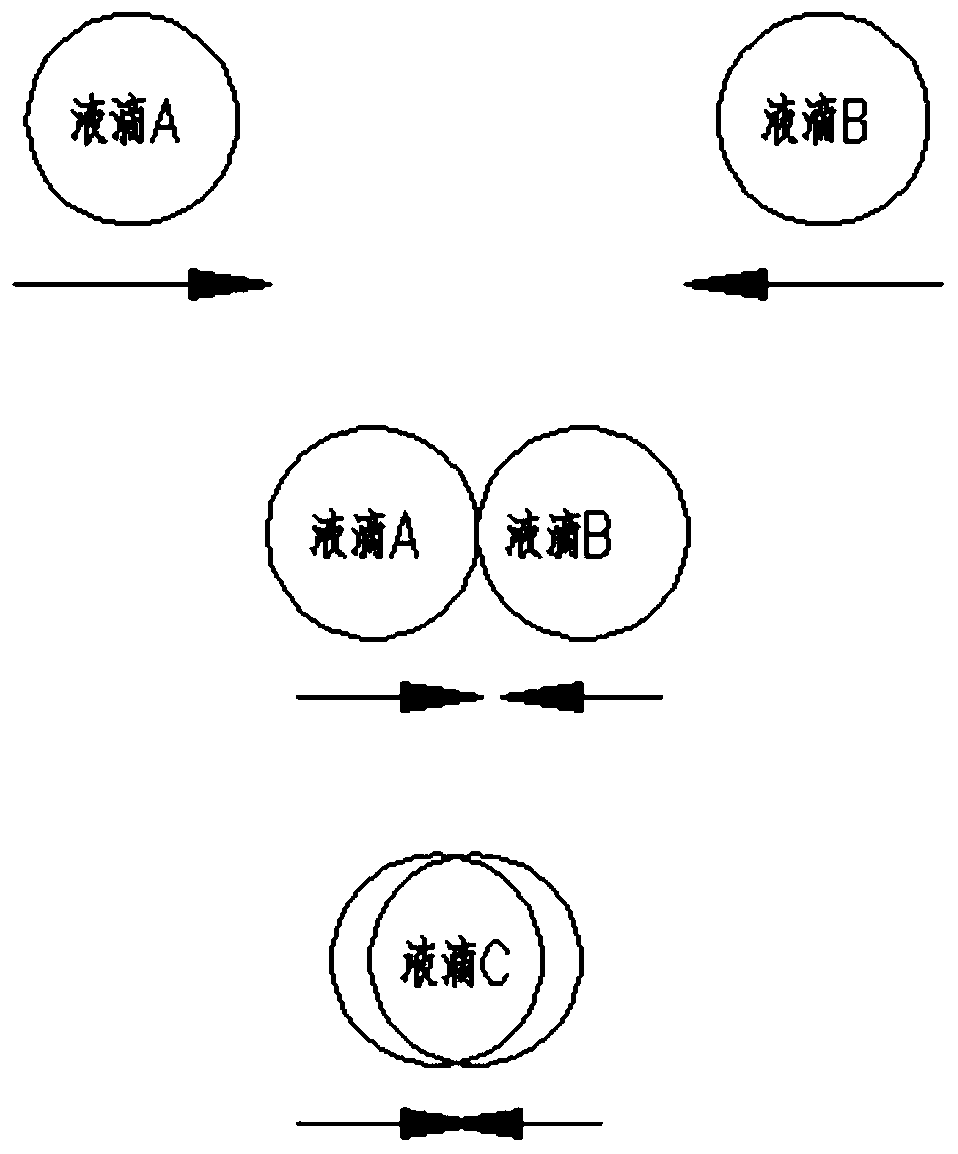

PendingCN110639445AContinuous responseCollision response is fastInert gas productionLiquid-liquid reaction processesRapid mixingConsecutive reaction

The invention provides a spraying continuous reactor. According to the invention, the reactor is provided with fluid spray guns; the principle of high-speed flowing of inert gas is utilized to micronize liquid; rapid dissipation of energy is realized through instantaneous violent impact of two high-speed flowing fluids; so the segregation degree between the two fluids is rapidly reduced, and the purpose of rapid mixing is achieved. The inert gas can carry away most of heat while a collision reaction occurs, so the reaction is facilitated. The impact fluids can be designed into a symmetrical structure or an asymmetric structure. Fluid inlets can be designed to be in a high-pressure nozzle form, and can also be designed to be in a form that two streams of fluids coming from a double-fluid nozzle and conveyed by gas are atomized by the nozzle. After atomization, the two fluids impact each other and are mixed with each other in the reactor. Results of experimental studies show that collision mixing of droplets with droplet diameters in a range of about 200-300 [mu] m is more beneficial for uniform mixing of liquid.

Owner:锦益创典(天津)科技有限责任公司

Preparation and Application of a Supramolecular Polymer Framework Material

InactiveCN107936262BAchieving Continuous ResponseRealize highly sensitive detectionFluorescence/phosphorescenceImidePolymer science

The invention designs and synthetizes a supermolecule polymer framework material. The supermolecule polymer framework material is formed through self assembly in cyclohexanol by using naphthalimide functionalized pillar [5] arene as a subject and bilateral quaternization pillar [5] arene as an object, wherein the mole ratio of the subject to the object is 1:1. Through competitive coordination mechanism, the supermolecule polymer framework material (SOF-AP5-MJP5) and a metal supermolecule polymer framework material (M-SOF-AP5-MJP5) can respectively realize continuous response and high-sensitivity detection to Fe<3+> and H2PO4<->; the recognition performance has important application values in the field of ion recognition.

Owner:NORTHWEST NORMAL UNIVERSITY

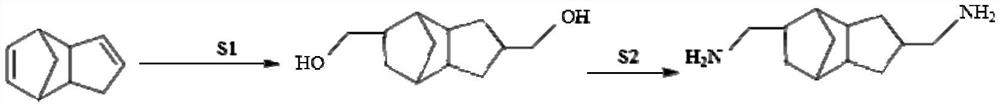

Process for preparing tricyclodecane dimethylamine from dicyclopentadiene and application of tricyclodecane dimethylamine

PendingCN114685281AStrong hydrogenation activityAvoid decompositionOrganic compound preparationHydroxy compound preparationPtru catalystCombinatorial chemistry

The invention relates to the technical field of IPC C07C, in particular to a process for preparing tricyclodecane dimethylamine from dicyclopentadiene and application of the tricyclodecane dimethylamine. The process comprises the following steps: S1, adding dicyclopentadiene, a metal catalyst and a ligand into a reaction device, and reacting to obtain tricyclodecane dimethyl carbinol; s2, reacting the tricyclodecane dimethyl carbinol obtained in the step S1 with mixed gas under the action of a supported catalyst to obtain a tricyclodecane dimethylamine finished product, the mixed gas is a combination of hydrogen and ammonia gas. The method provided by the invention is simple in process route and high in raw material economy, material loss in the separation process is avoided, and the production cost is remarkably reduced.

Owner:广东希必达新材料科技有限公司

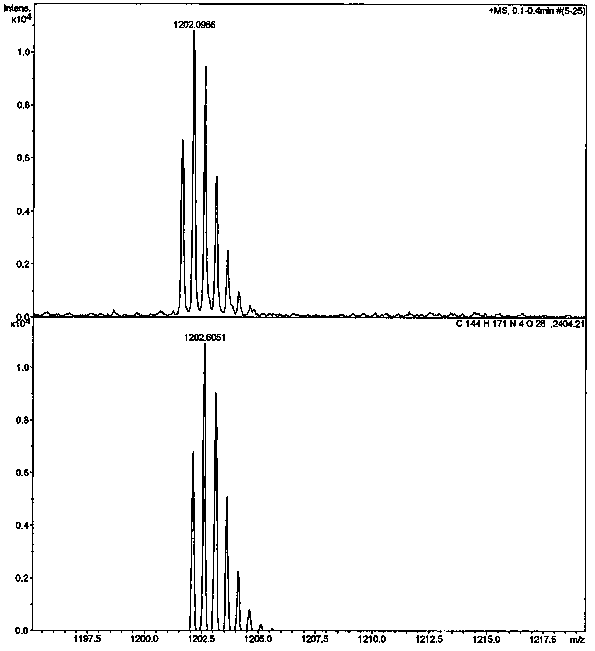

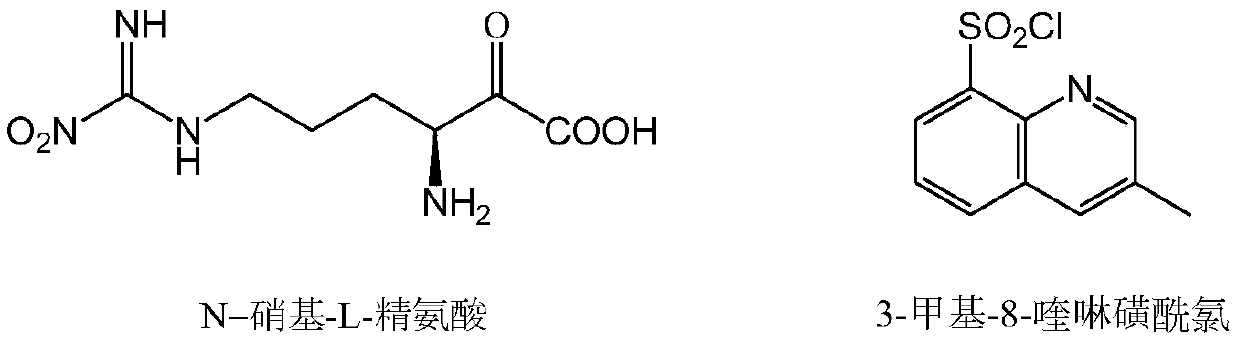

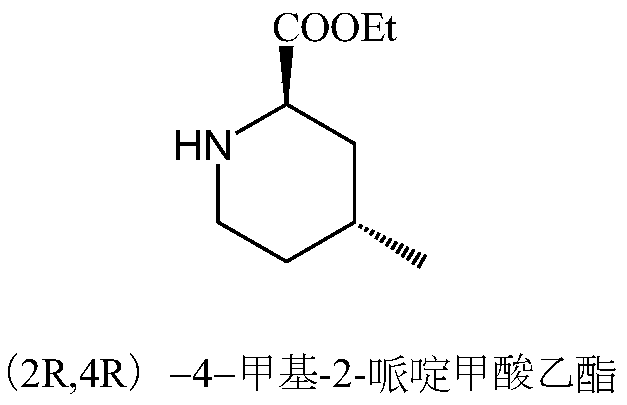

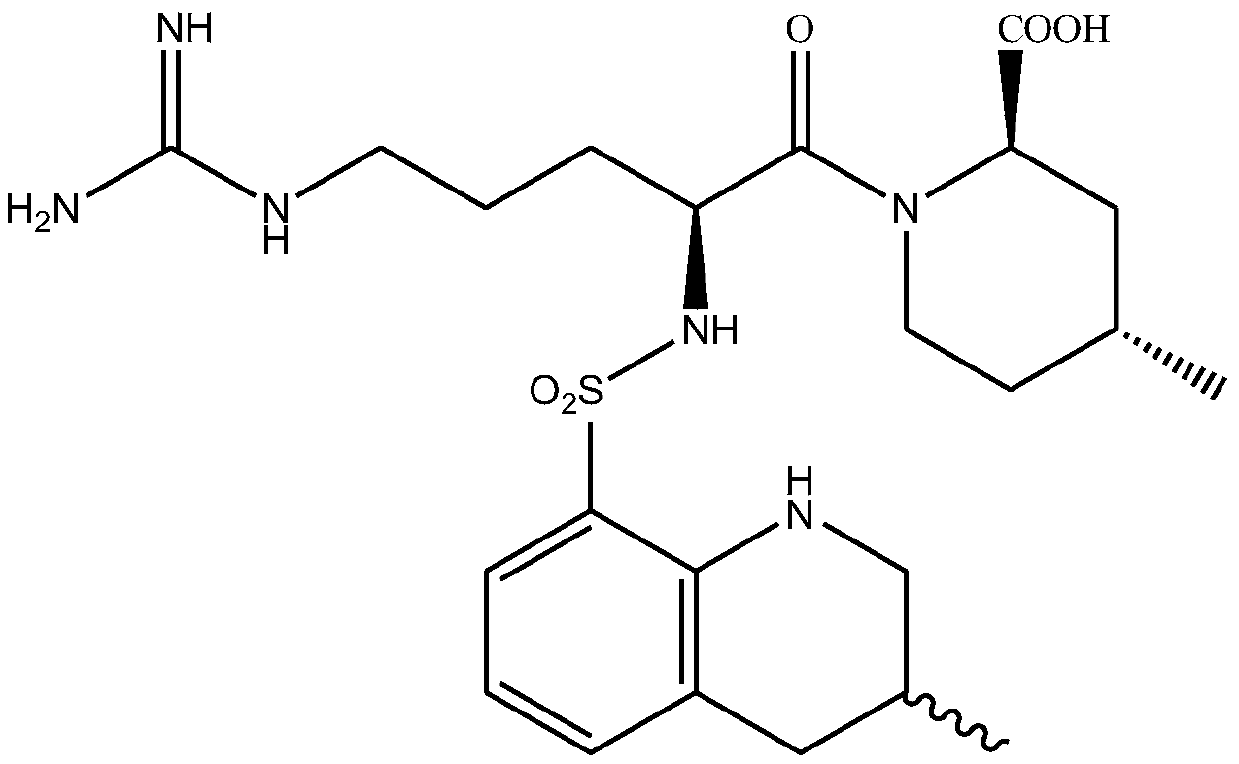

Method for continuously preparing argatroban

PendingCN111471085AReduced handling and purification stepsAchieving Continuous ResponsePeptide preparation methodsPtru catalystArginine

The invention belongs to the technical field of medicines and relates to a method for continuously preparing argatroban. The method comprises the specific processes of achieving N-nitro-L-arginine sulfonylation reaction through a phase transfer catalyst in two phases of water and a solvent; after reaction is completed, directly carrying out condensation on an organic phase without concentration treatment and ethyl (2R,4R)-4-methyl-2-piperidinecarboxylate; after reaction is completed, carrying out hydrolysis reaction on a water phase in an alkaline condition; carrying out hydrogenation reduction by using a microreactor; and finally carrying out refining to obtain argatroban. According to the method, tedious treatment and purification steps of various intermediates are reduced, and continuous reaction is achieved, so that the production efficiency is improved. Meanwhile, almost the same solvent is adopted by a plurality of steps in the reaction process, solvent recovery is facilitated, and the target of waste liquid reduction is achieved. In addition, the microreactor is adopted by the method for carrying out palladium carbon hydrogenation reduction, so that high temperature, high pressure, long reaction time and other problems in the hydrogenation process are avoided to ensure the safety in the production process.

Owner:江巨东

Method for producing nano-ITO powder with plasma electrical arc one-step method

InactiveCN101269834BGood dispersionGrowth inhibitionGallium/indium/thallium compoundsTin oxidesNano sizeGas phase

The invention relates to a method using a plasma arc one step method to prepare nano-size ITO powder. The method is characterized in that In-Sn alloy is continuously sent into a pot of a plasma reaction chamber by a feeding fixed point and fixed amount method, and the plasma reaction chamber uses Ar as a plasma gas, wherein, the working voltage ranges from 30 to 60 V, and the working current ranges from 100 to 400 A; alloyed material is used as a positive pole in the plasma reaction chamber, and a high igniter inflames between the positive pole and the negative pole of a nozzle to form an electric arc; inert gas around ionization forms stable plasma; raw materials are heated and melted by high temperature plasma to evaporate to form metal vapor which reacts with oxygen, and a great temperature grade is formed under the function of flowing water cooling of an inter layer of a reactor, thereby resulting in a high supersaturated zone in the metal vapor; through self nucleation, condensation and growth in a gas phase, nano-size to particle is formed. The nano-size ITO powder made by the method has the advantages of regular grain shape and high powder purity, and the method can realizecontinuous feeding, continuous reaction, and continuous milling. The efficiency is high, and compared with other methods, the method is easier to realize mass production.

Owner:KUNMING UNIV OF SCI & TECH

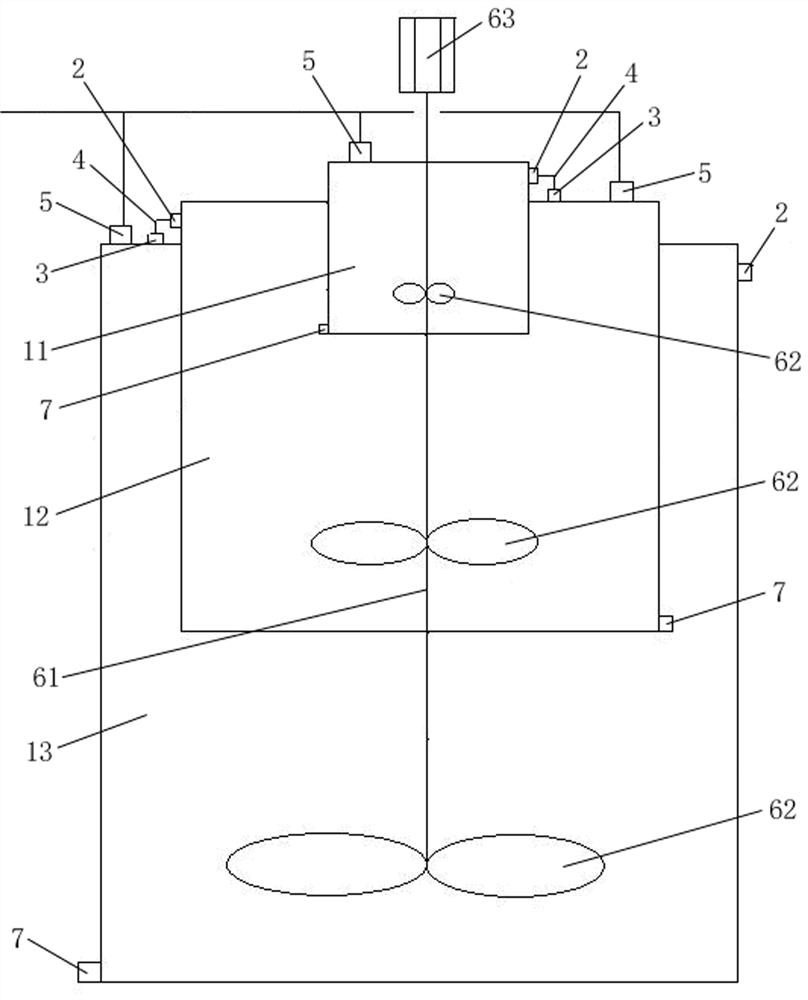

Multi-stage reaction kettle

InactiveCN112316881AIncrease profitEffective control of particle size distributionChemical/physical/physico-chemical stationary reactorsProcess engineeringWaste material

The invention relates to the technical field of reaction kettle design, and discloses a multi-stage reaction kettle which comprises N stages of kettle bodies sequentially sleeved from top to bottom and from inside to outside, an overflow port is formed in the side wall of each stage of kettle body close to the top cover of the kettle body, and the end part of each stage of kettle body provided with the overflow port is used as a non-sleeved end to be exposed outside; each stage of kettle body is provided with a material receiving opening for receiving materials outputted from the overflow opening of the previous stage of kettle body from the second stage of kettle body; and each stage of kettle body is provided with a feeding hole. The overflow ports are formed in all stages of reaction kettles so that continuous reaction is realized, and the yield can be greatly increased; meanwhile, a return pipeline is arranged between the last-stage kettle body and the first-stage kettle body so that the particle size distribution of the product can be effectively regulated and controlled; for the preparation of the ternary precursor, the single-kettle continuous synthesis of the ternary precursor with the same component or different components and narrow core-shell structure distribution becomes possible, the particle size distribution of the ternary precursor is effectively improved, themicro powder in the product is reduced, the utilization rate of small-particle wastes in a reaction system is improved, the production cost is saved, and the product performance is optimized.

Owner:ZHUJI PAWA NEW ENERGY

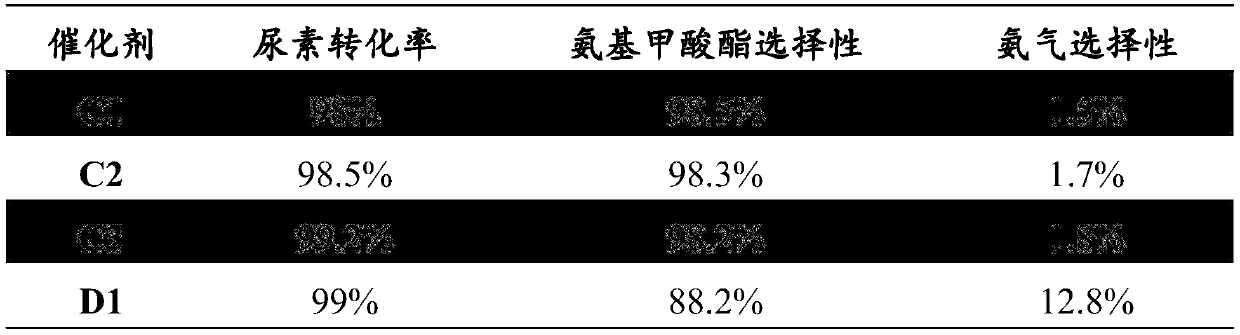

Process for continuously synthesizing carbamate through catalytic rectification

InactiveCN110724071AAchieving Continuous ResponseRealize continuous preparationCarbamic acid derivatives preparationOrganic compound preparationFormic Acid EstersCarbamate

The invention relates to a process for continuously synthesizing carbamate through catalytic rectification. According to the invention, by using a tubular reactor, a composite catalyst is pre-loaded,and a continuous reaction of urea, methanol and dimethyl carbonate can be achieved by controlling a reaction temperature and a raw material flow rate, so that the continuous preparation of carbamate is achieved, wherein the urea conversion rate is more than 98%, the carbamic acid selectivity is more than 98.2%, and the selectivity of the byproduct ammonia is less than 1.8%.

Owner:周玉文

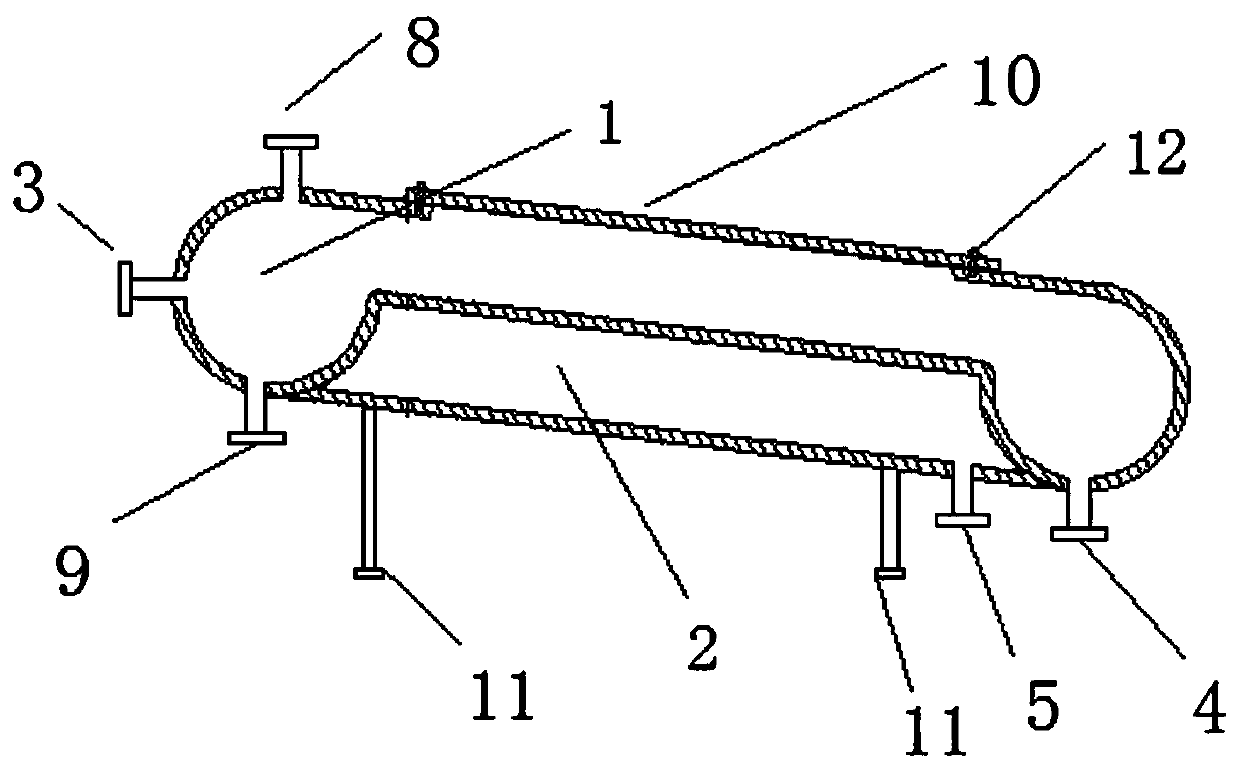

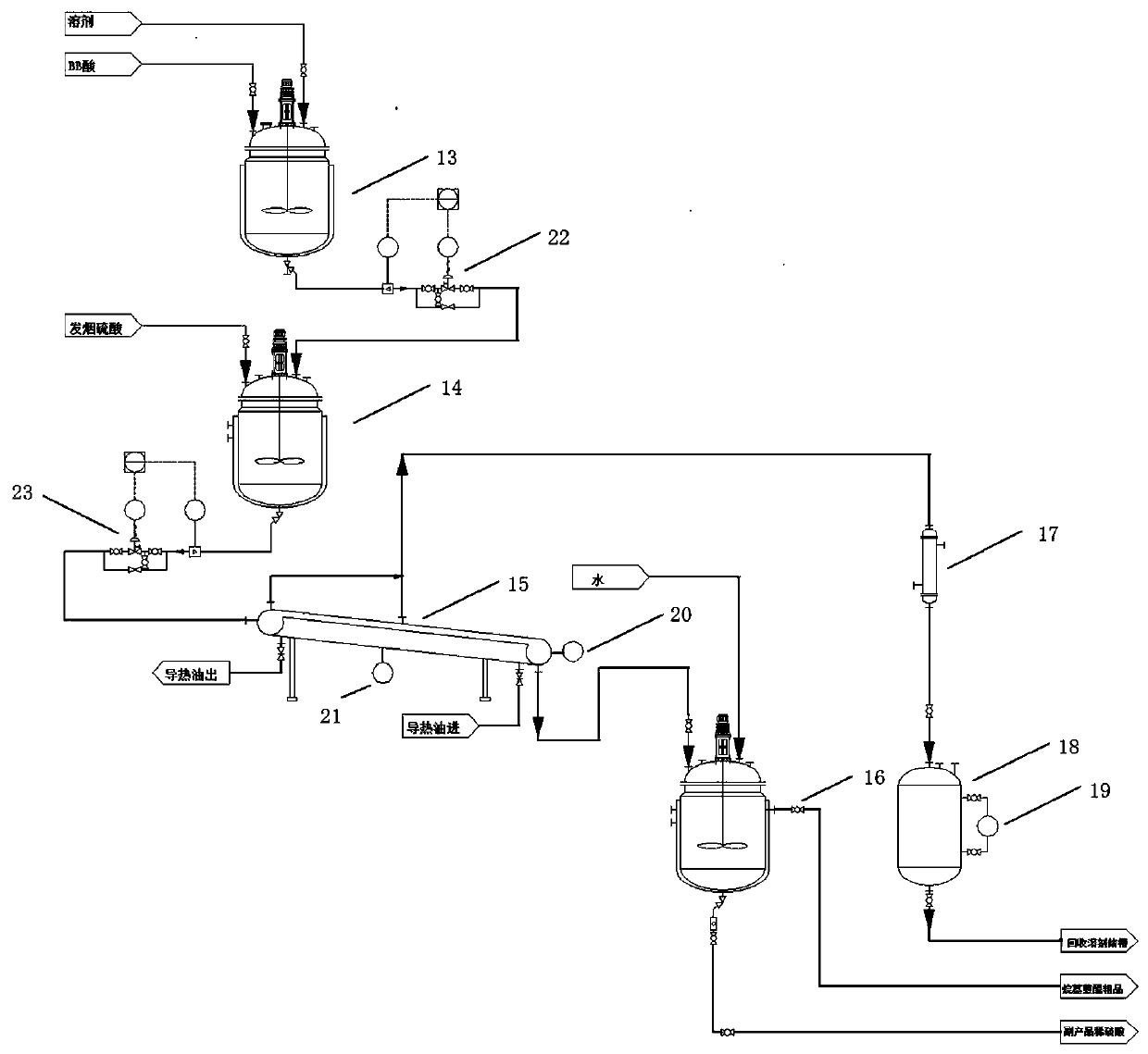

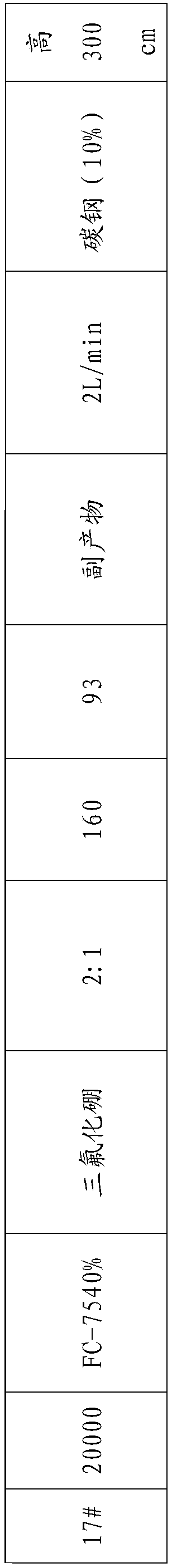

Membrane reactor and process for continuous production of alkyl anthraquinone by using same

PendingCN111558358AImprove heat transfer efficiencyFluid flow resistance is smallOrganic compound preparationQuinone preparationOleumProcess engineering

The invention relates to a membrane reactor and a process for continuous production of alkyl anthraquinone by using the membrane reactor. The process comprises the following steps: fully mixing BB acid and fuming sulfuric acid in proportion, carrying out a ring-closure reaction on the mixed solution at a certain temperature by using the membrane reactor, allowing the reaction solution after the ring-closure reaction to automatically flow into a water precipitation process, and separating to obtain alkyl anthraquinone. The process can realize continuous production, achieves higher production efficiency and lower production energy consumption compared with the prior art, reduces the generation of waste acid, and is beneficial to environmental protection.

Owner:YICHANG SUPENG TECH CO LTD

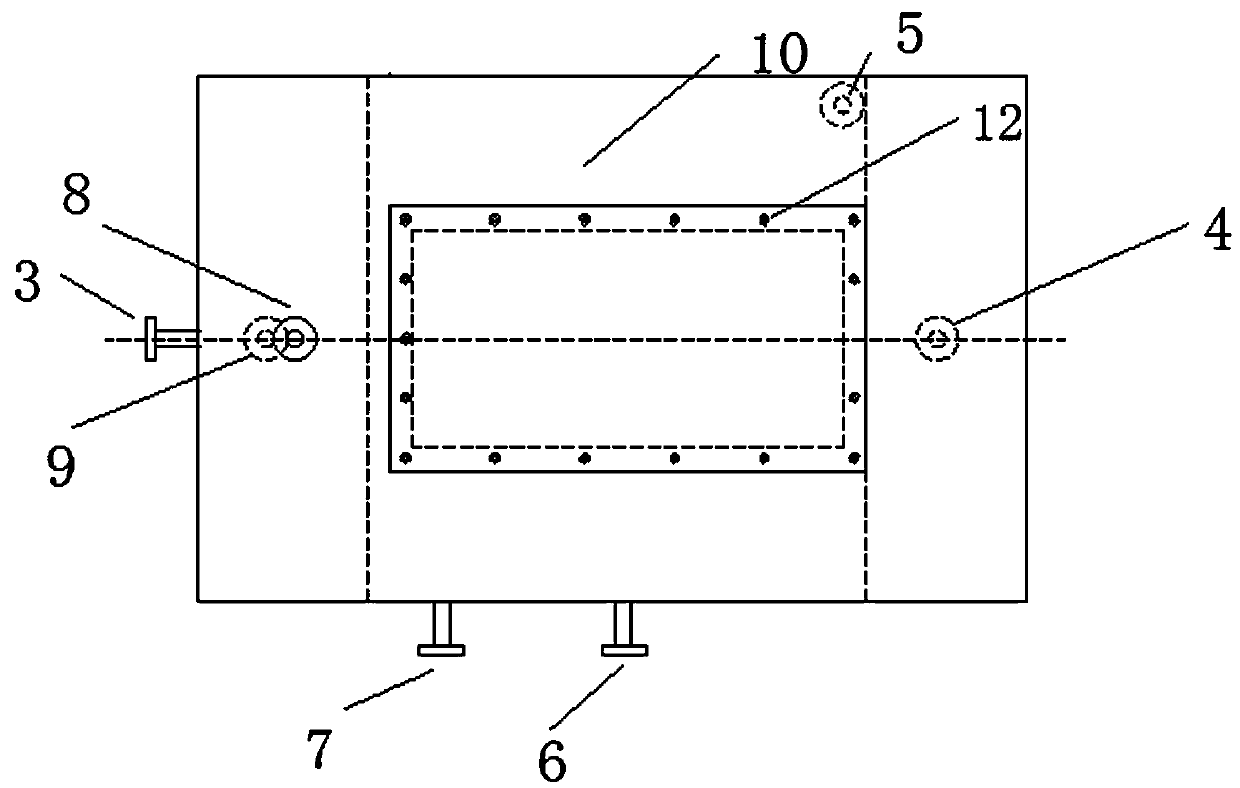

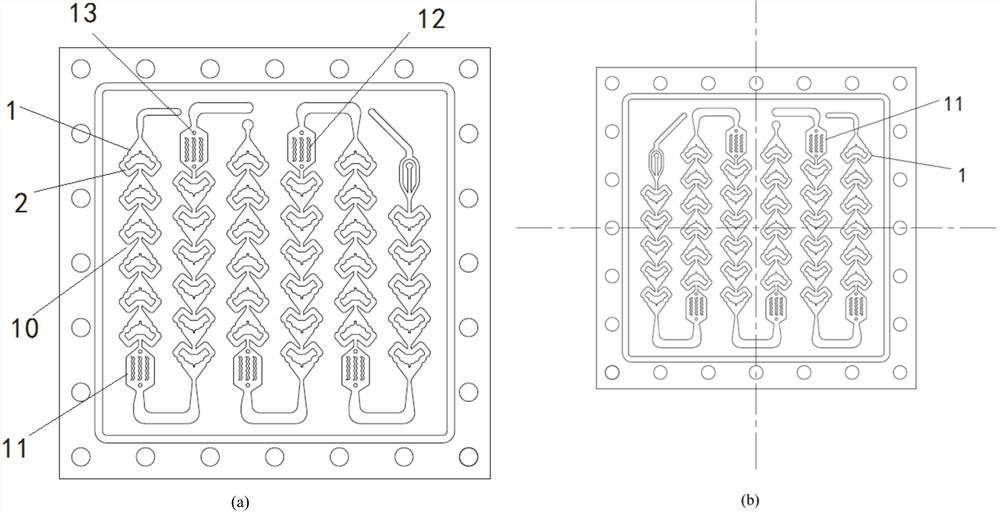

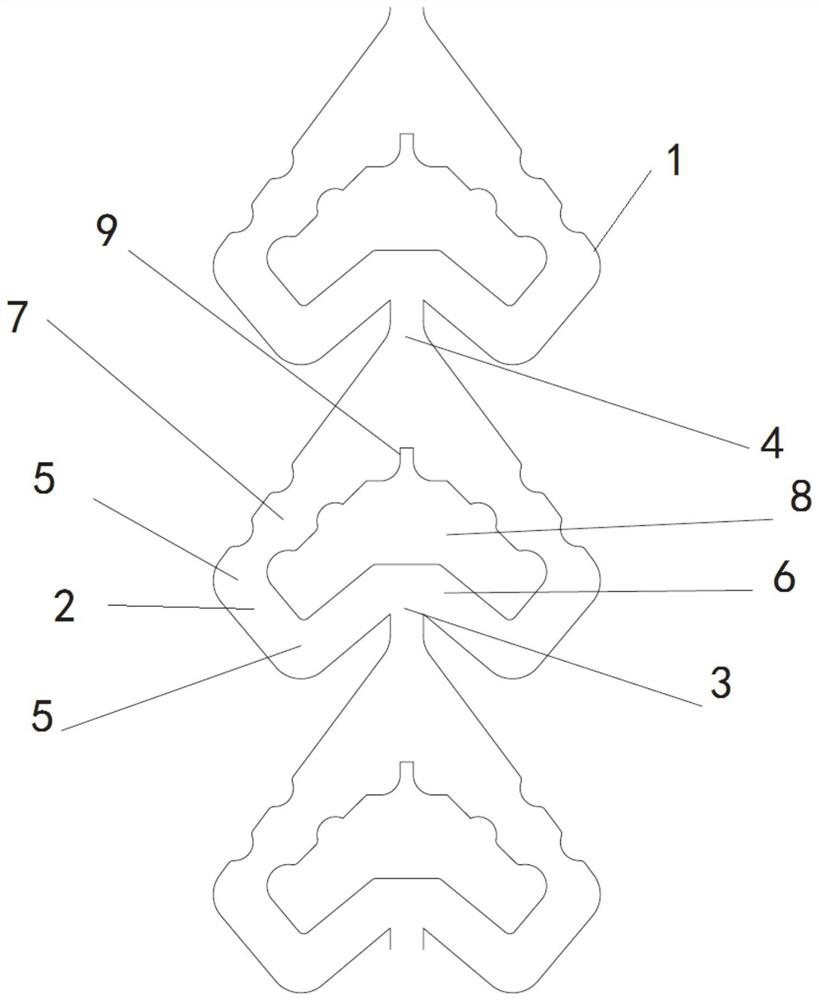

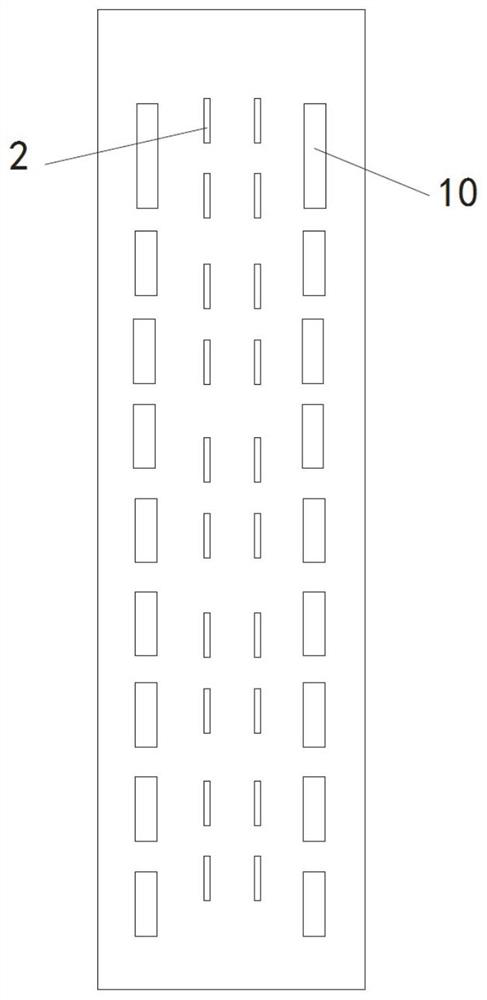

Micro-channel reactor

PendingCN114130326ALow costAdequate responseChemical/physical/physico-chemical microreactorsMicroreactorEngineering

The invention relates to a micro-channel reactor, which comprises a micro-reactor, an annular micro-channel is arranged in the micro-reactor, two opposite ends of the annular micro-channel are respectively a liquid inlet and a liquid outlet, the annular micro-channel has a straight corner structure between the liquid inlet and the liquid outlet, a liquid inlet included angle is formed between the liquid inlet direction of the liquid inlet and the annular micro-channel on two sides, and a liquid outlet included angle is formed between the liquid inlet direction of the liquid inlet and the annular micro-channel on two sides. The liquid inlet included angle is larger than 90 degrees. The mass and heat transfer process is enhanced, the process reaction conditions can be reduced, the reaction of the raw materials is more sufficient, the reaction time is shortened, byproducts in the reaction process can be reduced, the production efficiency of enterprises is improved, the enterprise cost is reduced, and the subsequent environmental protection pressure is reduced. Meanwhile, the research and development period is shortened, and the research and development efficiency is improved.

Owner:山东科加工业技术研究院有限公司

Application of gas-liquid contact reaction device in fluorinated perfluoropolyether acid

ActiveCN106311097BHeating evenlyStable air speedChemical/physical/physico-chemical stationary reactorsLiquid-gas reaction processesChemical synthesisPerfluoropolyether

The invention belongs to the field of fluorine chemical synthesis and particularly relates to application of a gas-liquid contact reaction device to fluorination of perfluoropolyether acid. The gas-liquid contact reaction device comprises a gas inlet cylinder for containing fluorinating agent gas, a reaction tube filled with filler, a liquid cylinder, a product collecting cylinder and a tail gas treatment device, wherein a liquid outlet connected with the product collecting cylinder and a gas inlet connected with the gas inlet cylinder are formed in the bottom of the reaction tube, a spray head is arranged at the top end of the reaction tube and is connected with the liquid cylinder through a liquid pump, a gas outlet connected with the tail gas treatment device is formed in the top of the reaction tube, and heating strips are arranged on the outer wall of the reaction tube. The gas-liquid contact reaction device is capable of fluorinating the perfluoropolyether acid by fluorine gas effectively.

Owner:TIANJIN CHANGLU CHEM NEW MATERIAL CO LTD

High-purity m-phthaloyl chloride/paraphthaloyl chloride continuous reaction system and reaction method thereof

InactiveCN111004111AAchieving Continuous ResponseReduce consumptionOrganic compound preparationCarboxylic compound preparationOrganic synthesisPhysical chemistry

The invention relates to the technical field of organic synthesis systems. The invention relates to a continuous reaction system, in particular to a continuous reaction system of high-purity m-phthaloyl chloride / paraphthaloyl chloride and a reaction method thereof. The device comprises a granulator, a mixing tank and a reaction kettle which are sequentially connected in series, an exhaust port ofthe reaction kettle is externally connected with a condenser; the discharge end of the condenser is communicated with the feed port of the mixing tank; an S-shaped channel is formed in the reaction kettle, a plurality of exhaust pipes penetrate through the S-shaped channel, a tail gas cavity is formed in the upper part of the reaction kettle, the tops of the exhaust pipes are positioned in the tail gas cavity and are communicated with the tail gas cavity, and a plurality of capillary holes are formed in the upper parts of the exhaust pipes positioned in the S-shaped channel. According to the invention, continuous reaction of acyl chloride products is realized, the occupied area of equipment is small, the space is saved, the operation process is simpler than that of an intermittent reaction, the reaction equipment does not have a complex pipeline, and the complexity of the process is reduced. The problem that the pipeline is easy to crystallize is solved, the energy consumption requiredby heat tracing of the process pipeline is saved, and the quality of a continuous reaction product is relatively stable.

Owner:SHANDONG KAISHENG NEW MATERIALS

Device and method for preparing methylsulfonyl fluoride through continuous reaction

ActiveCN112742337AAvoid contactImprove securityDistillation separationChemical/physical/physico-chemical stationary reactorsData displayPhysical chemistry

The invention discloses a device and a method for preparing methylsulfonyl fluoride through continuous reaction. The device comprises a reaction kettle body and a filtering device, bases are fixed at the lower ends of the reaction kettle body and the filtering device, base plates are fixed at the lower ends of the bases, the filtering device and the reaction kettle body are connected through a connecting pipe, one side of the reaction kettle body is connected with a methylsulfonyl chloride conveying pipe and a KF solution input pipe, a filler layer and a liquid distributor are arranged in the reaction kettle body, and one side of the filtering device is connected with a KCl crystal discharging pipe and a mother liquor discharging pipe. According to the device and the method, continuous reaction can be realized, the efficiency is higher than that of an intermittent kettle, anti-corrosion materials under various working conditions can be selected for all parts in a targeted manner, intrinsic safety is realized in the aspects of equipment strength and corrosion prevention, remote data display and automatic operation are realized through a DCS, and personnel contact can be avoided especially under the working condition with highly toxic substances, and the safety is greatly improved.

Owner:PERIC SPECIAL GASES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com