Application of gas-liquid contact reaction device to fluorination of perfluoropolyether acid

A reaction device, gas-liquid contact technology, applied in chemical methods, chemical instruments and methods, chemical/physical/physical-chemical stationary reactors for reacting liquids and gaseous media, etc., can solve the problem of low fluorination conversion rate, The problem of low utilization rate of fluorinating agent gas can achieve the effect of less by-products, safe and stable reaction, and beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

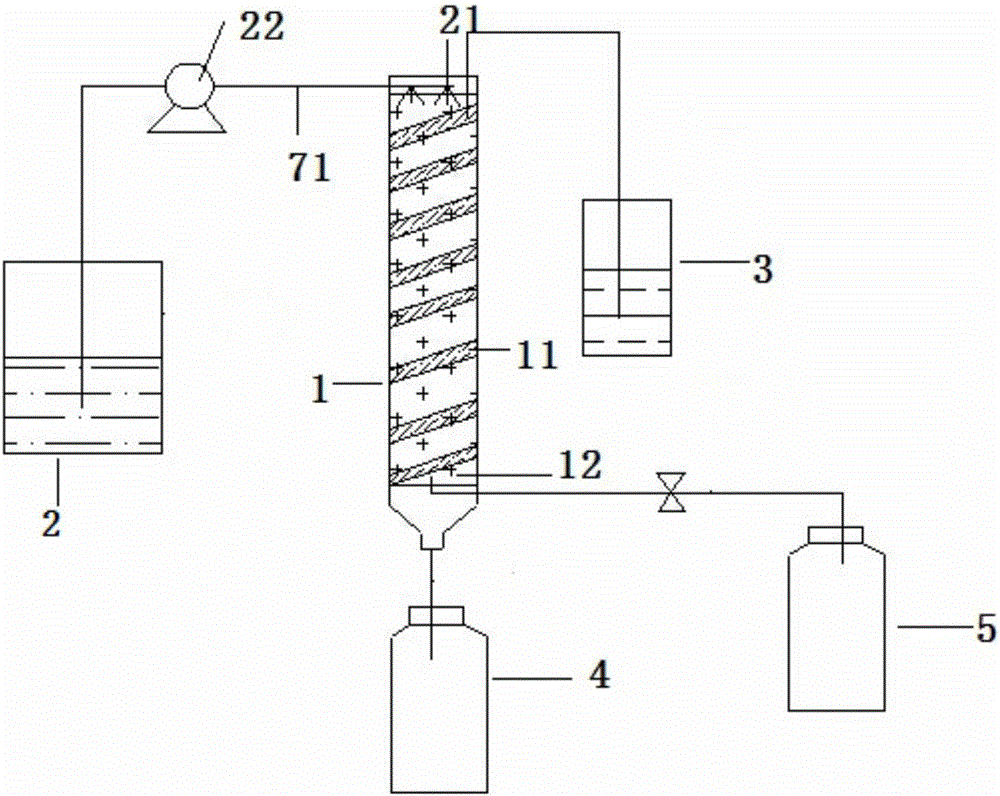

Method used

Image

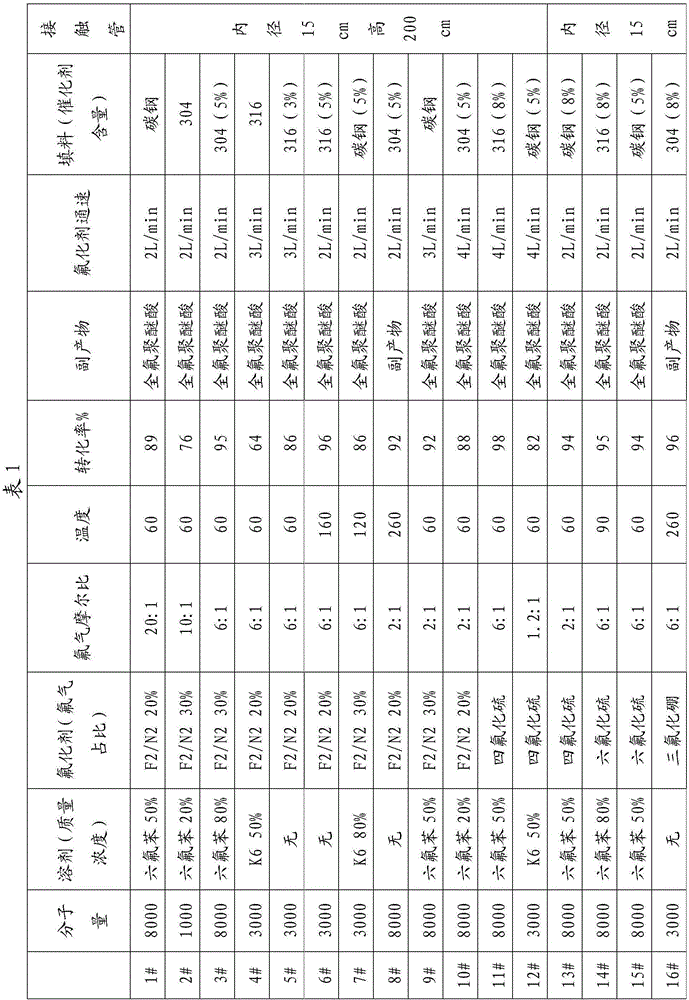

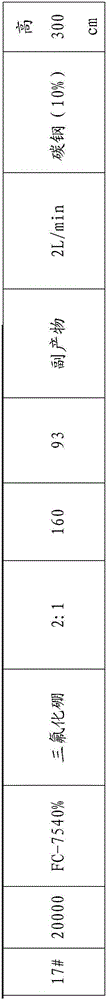

Examples

Embodiment 1

[0037] Fluorinated perfluoropolyether acid comprises the following steps:

[0038] 1) Turn on the power supply connected to the heating belt to heat the contact tube, and the heating temperature is 60°C;

[0039] 2) Open the air inlet bottle and blow into the air inlet at the bottom of the contact tube with a fluorine concentration of 20% F2 / N2 from the air inlet at a speed of 2L / min, and open the liquid pump simultaneously to remove the With hexafluorobenzene as the mass fraction of the solvent, the perfluoropolyether acid solution with a weight average molecular weight of 50% and a weight average molecular weight of 8000g / mol is pumped into the shower head to spray the filler in the contact tube; The gas mole ratio of perfluoropolyether was 20:1 for fluorination experiments.

[0040] 3) The product generated after the reaction between the fluorinating agent gas and the perfluoropolyether acid flows into the product collection bottle through the liquid outlet;

[0041] 4) D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com