Patents

Literature

69results about How to "Suitable for industrial mass production applications" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waste flue gas denitration catalyst regeneration method and equipment

InactiveCN104888869AAvoid damageAvoid changeDispersed particle separationCatalyst regeneration/reactivationTunnel kilnPtru catalyst

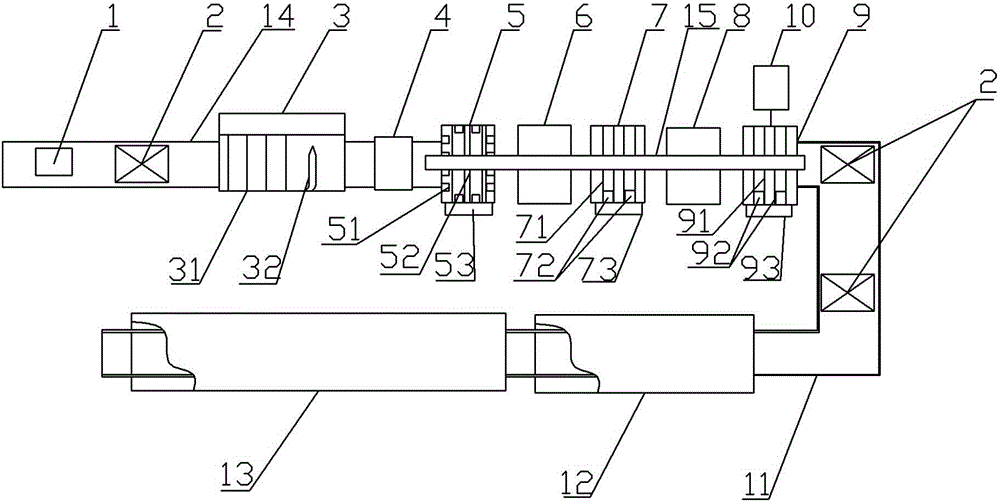

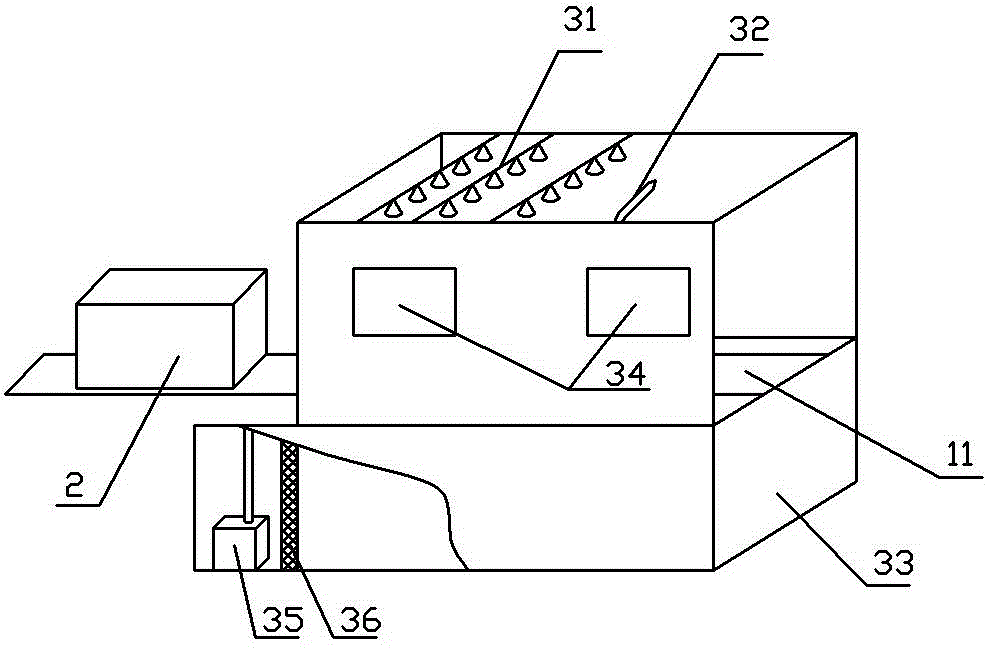

The invention discloses a waste flue gas denitration catalyst regeneration method, and belongs to the field of air pollution control. The method comprises the following steps: (1) removing dust through vacuum adsorption; (2) spray-cleaning and cleaning using a high-pressure spray gun; (3) washing with deionized water after ultrasonic cleaning; (4) draining off after acid pickling; (5) soaking with an activation solution, wherein the activation solution is an aqueous solution of a precursor of V2O5-WO3 or V2O5-MoO3, the weight percentage of metal oxides in the V2O5-WO3 activation solution is as follows: 0.8-5.0% of V2O5, 0.3-1.0% WO3 and the balance of water, the weight percentage of metal oxides in the V2O5-MoO3 activation solution is as follows: 0.8-5.0% of V2O5, 0.15-1.0% of MoO3 and the balance of water; (6) drying and calcining. The invention also discloses waste flue gas denitration catalyst regeneration equipment which includes a tracked conveying device, a spray cleaning device, an ultrasonic cleaning tank, a deionized water cleaning device, a pickling tank, a drain basket, an activation tank, a rail transport device, a tunnel kiln and a tunnel calciner, which are sequentially arranged.

Owner:河南博苑新未来环保科技有限公司 +1

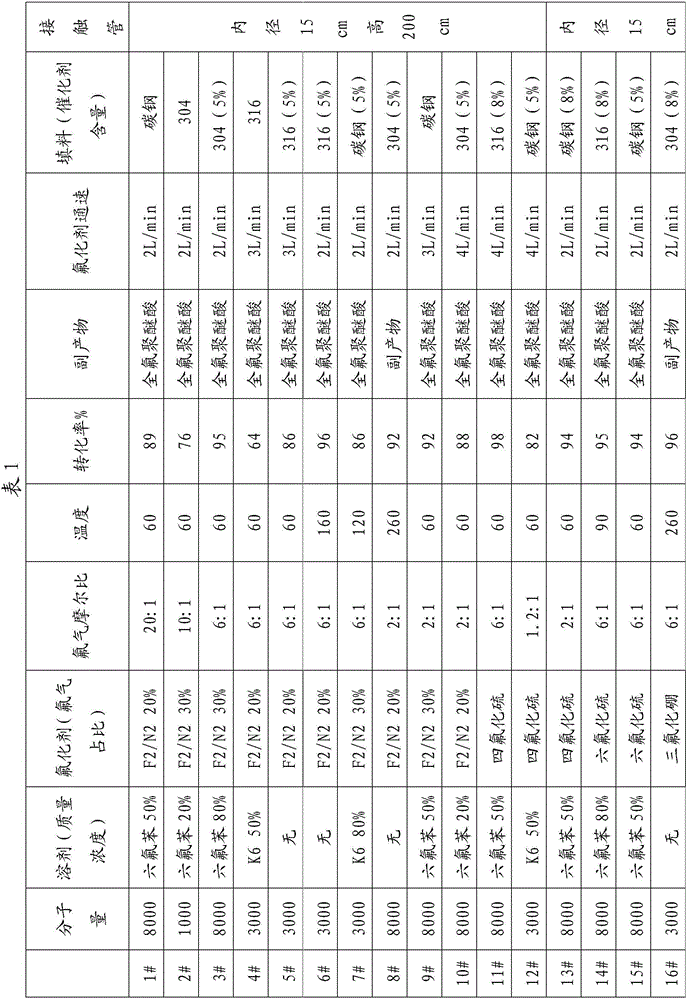

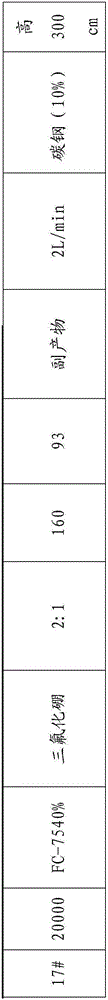

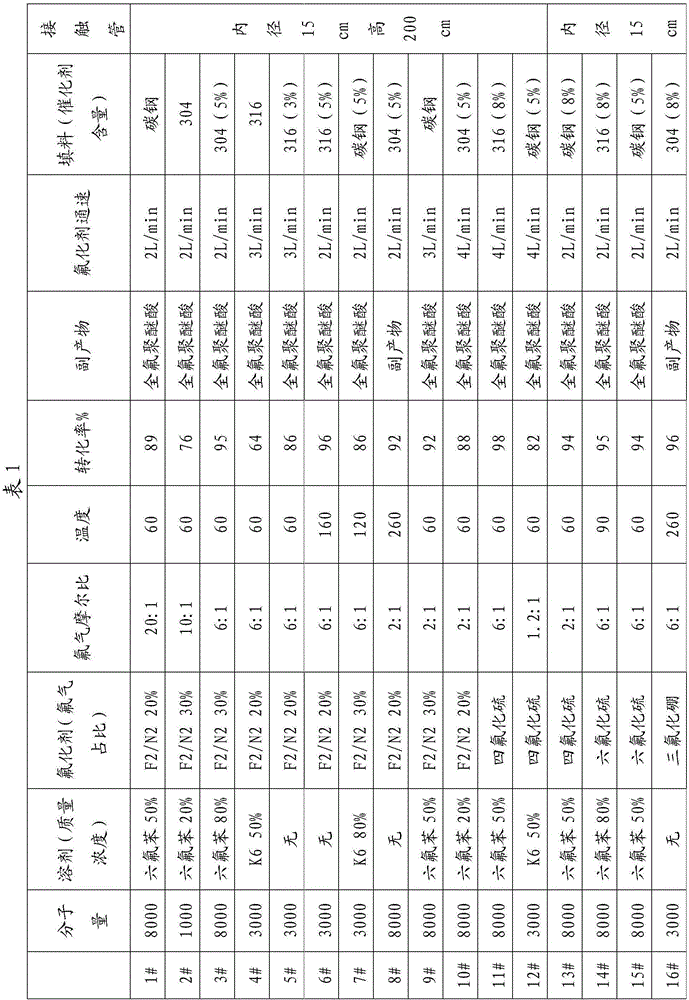

Fluorination method for end groups of perfluoropolyether acid

The invention belongs to the field of fluorine chemical synthesis and particularly relates to a fluorination method for end groups of perfluoropolyether acid. The perfluoropolyether acid and a fluorinating agent are taken as raw materials for synthesis in a gas-liquid contact reaction tube with fluorine gas passivated filler as a filling agent, and the filler adopts one or a mixture of carbon steel, stainless steel 304 and stainless steel 316. The perfluoropolyether acid or a solution thereof sprays downwards from the top of the gas-liquid contact reaction tube, a fluorinating agent gas makes sufficient contact with perfluoropolyether continuously from bottom to top through filler gaps in the gas-liquid contact reaction tube, maximized gas-liquid contact is realized, so that the utilization of the fluorinating agent is realized to the greatest extent, and fluorination of the perfluoropolyether is sufficient and complete. Besides, the perfluoropolyether is subjected to continuous fluorination, the problem of kettle-by-kettle fluorination in the prior art is solved, and the operation procedure is simplified. Few by-products are produced during fluorination of the perfluoropolyether, the operation is simple, continuous production can be realized, reactions are safe and stable, and the method is suitable for industrial mass production and application.

Owner:TIANJIN CHANGLU CHEM NEW MATERIAL CO LTD +1

Regeneration method for honeycomb type SCR (Selective Catalytic Reduction) denitration catalyst

InactiveCN103433081ASimple recycling processReduce recycling costsCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsNitrateHoneycomb

The invention discloses a regeneration method for a honeycomb type SCR (Selective Catalytic Reduction) denitration catalyst, and belongs to the technical field of power environment protection. The regeneration method comprises the following steps: 1) dipping a poisoned honeycomb type SCR catalyst into a diluted sulfuric acid solution, carrying out ultrasonic treatment, then taking out and drying; 2) putting the honeycomb type SCR catalyst treated in the step 1 into a cerous nitrate solution, dipping for 1-3 hours and then taking out; 3) roasting the honeycomb type SCR catalyst treated in the step 2, raising the temperature to be 110 DEG C at the speed of no greater than 3 DEG C / min, subsequently preserving the temperature for 3-5 hours, furthermore, raising the temperature to be 300 DEG C at the speed of no greater than 3 DEG C / min, and preserving the temperature for 8-10 hours to obtain the regenerated honeycomb type SCR denitration catalyst. The active precusor substance cerous nitrate used in the regeneration method is wide in source and good in solvability; the activity of the catalyst subjected to regeneration treatment can be recovered to be more than 80% as compared with the activity of the catalyst which is not poisoned; meanwhile, the regeneration process is simplified, the regeneration cost is lowered, and the regeneration method is simple and convenient to operate, environment-friendly and applicable to large-scale industrial production and application.

Owner:HUANENG POWER INT INC +3

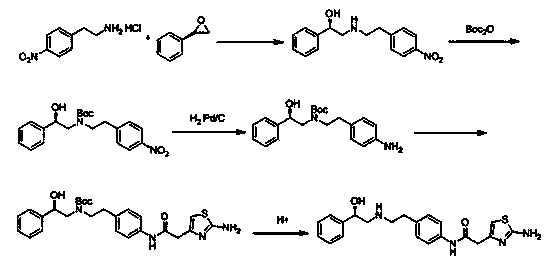

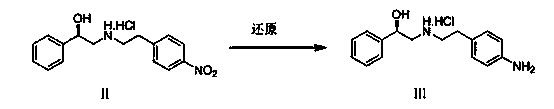

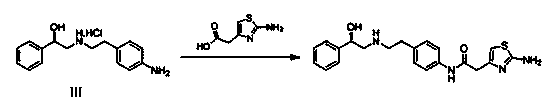

Synthesis method of mirabegron

The invention provides a synthesis method of mirabegron. The synthesis method comprises the following steps: (1) in a tetrahydrofuran solvent and a nitrogen atmosphere, reducing a compound I into a compound II by adopting a reducing agent; (2) in an alcohol solvent and a hydrogen environment, reducing the compound II into a compound III by adopting palladium-on-carbon catalytic hydrogenation; and (3) in a water solvent and under an acidic condition, mixing the compound III with 2-amino-4-thiazole acetic acid, and performing condensation reaction under the action of a condensing agent, to obtain mirabegron. The method has the advantages of being mild in reaction conditions, high in yield and low in cost, and the provided mirabegron is low in the content of impurities, therefore, the synthesis method is suitable for large-scale industrial production.

Owner:安徽联创生物医药股份有限公司

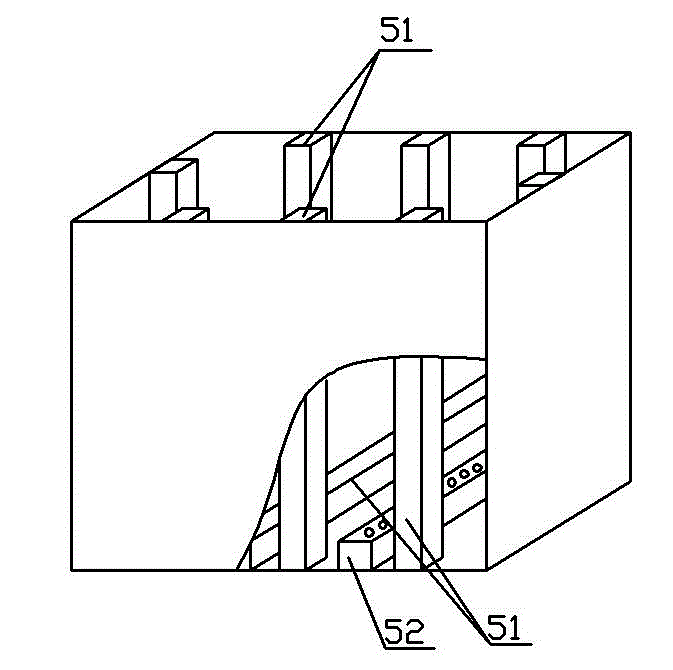

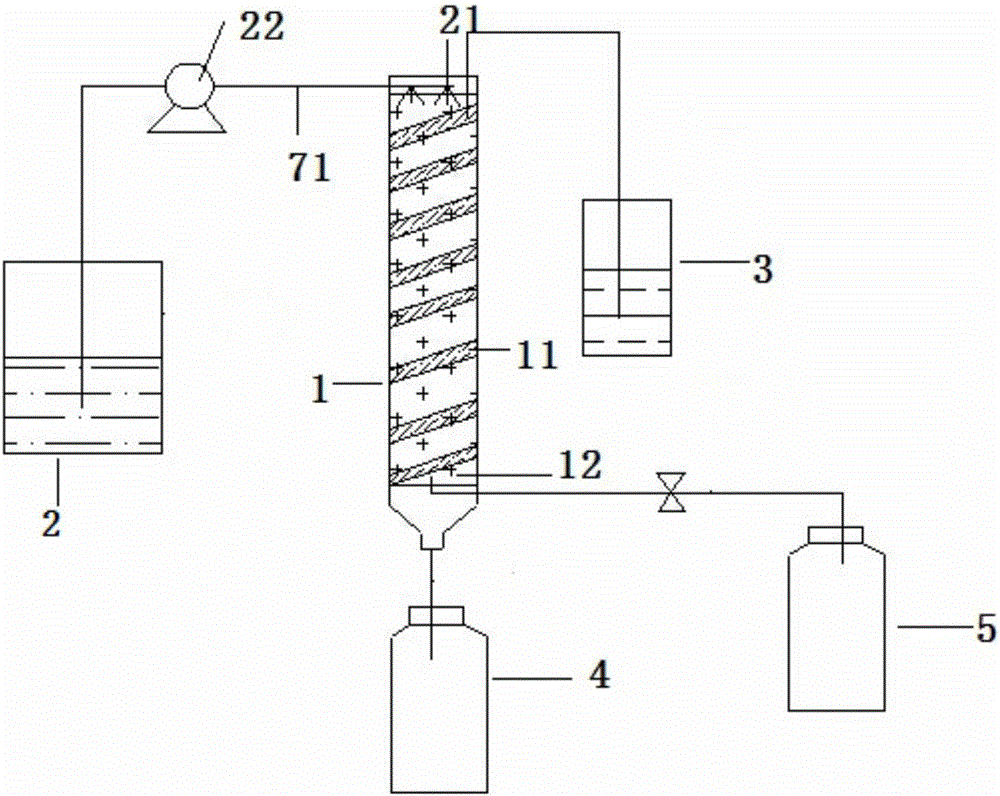

Application of gas-liquid contact reaction device to fluorination of perfluoropolyether acid

ActiveCN106311097AAchieve utilizationFull fluorination reactionChemical/physical/physico-chemical stationary reactorsLiquid-gas reaction processesChemical synthesisPerfluoropolyether

The invention belongs to the field of fluorine chemical synthesis and particularly relates to application of a gas-liquid contact reaction device to fluorination of perfluoropolyether acid. The gas-liquid contact reaction device comprises a gas inlet cylinder for containing fluorinating agent gas, a reaction tube filled with filler, a liquid cylinder, a product collecting cylinder and a tail gas treatment device, wherein a liquid outlet connected with the product collecting cylinder and a gas inlet connected with the gas inlet cylinder are formed in the bottom of the reaction tube, a spray head is arranged at the top end of the reaction tube and is connected with the liquid cylinder through a liquid pump, a gas outlet connected with the tail gas treatment device is formed in the top of the reaction tube, and heating strips are arranged on the outer wall of the reaction tube. The gas-liquid contact reaction device is capable of fluorinating the perfluoropolyether acid by fluorine gas effectively.

Owner:TIANJIN CHANGLU CHEM NEW MATERIAL CO LTD +1

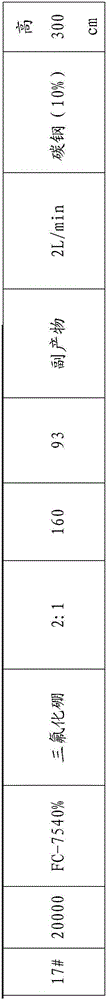

Amphipathic high-molecular polymer, and preparation method and application thereof

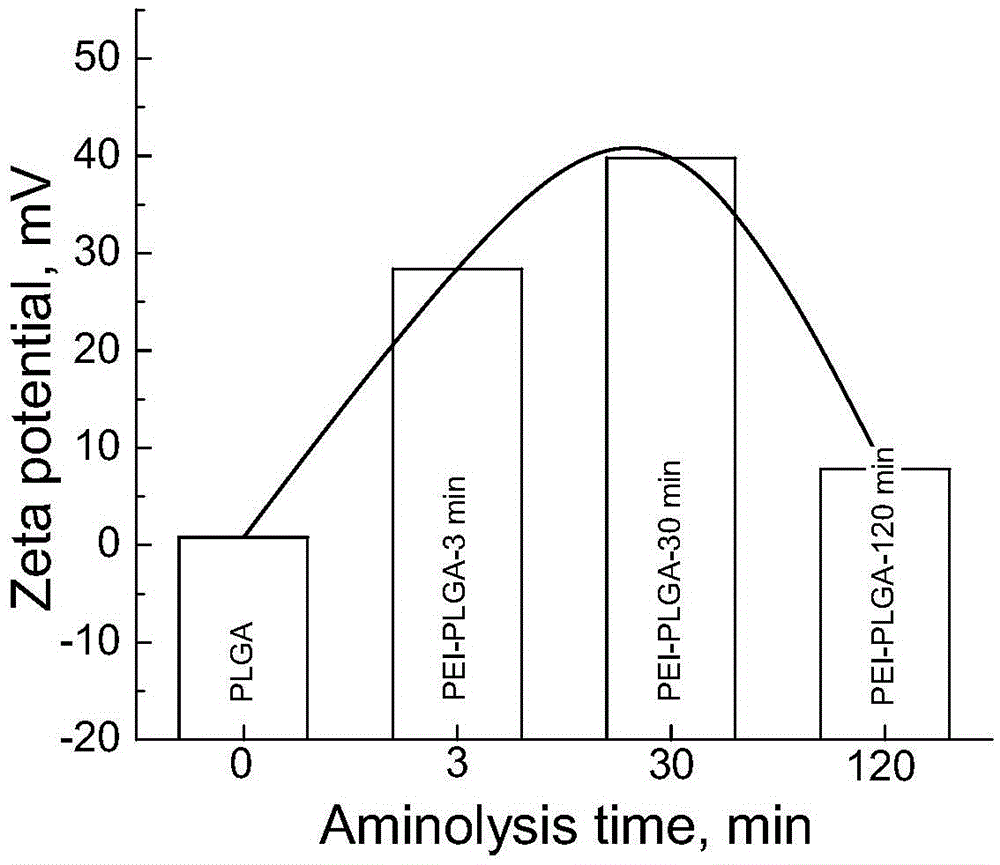

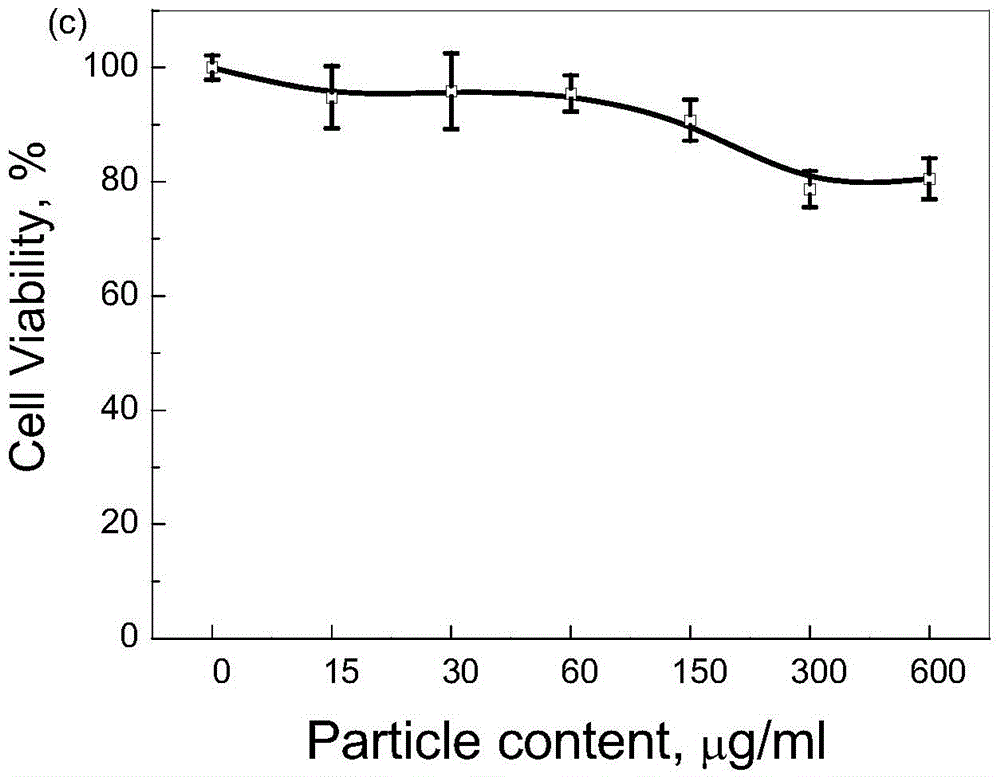

InactiveCN105646887ADegradable and low-cost industrial productionSimple methodGranular deliveryMacromolecular non-active ingredientsPolyesterPolymer science

The invention provides an amphipathic high-molecular polymer, and a preparation method and application thereof. The method comprises the following steps: dissolving a polymer matrix to be modified in an organic solvent, adding an alcoholic solution of a hydrophilic modified material, carrying out thermostatic reaction at 40-80 DEG C for 5-60 minutes to obtain a polymer solution, dialyzing in water, and carrying out freeze-drying, wherein the polymer matrix to be modified comprises one of polylactic acid, polylactic acid copolymer, polyhydroxycarboxylic acid polymer and polyester polymer, and the hydrophilic modified material comprises one of polyethyleneglycol, polypolypeptide, polyethyleneimine, chitosan and polyamine polymer. The one-step method can be used for modifying the polymer molecules without using the toxic heavy metal compound as a catalyst; and thus, the method is simple, and is low in cost. The amphipathic high-molecular polymer has wide application prospects in the aspects of low-cytotoxicity nano microspheres, biological material surface modification and biological drug carrying.

Owner:HUBEI UNIV

Extraction method of star anise oil

The invention provides an extraction method of star anise oil. In the invention, a steam distillation method is adopted before an ethanol extraction method; through the method, residual anise oil in the star anise after steam distillation is extracted by the ethanol extraction method to realize secondary extraction and utilization of active ingredients of star anise; and meanwhile, impurities in the star anise can be effectively removed by steam distillation, so that the purity of the anise oil obtained by ethanol extraction in the later period is increased, and the inherent defects of organic solvent extraction are overcome. The method can remarkably increase the yield of star anise oil and obtain anise oil with relatively good quality; and meanwhile, the method is low in cost, convenient to implement and suitable for industrial large-scale production.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

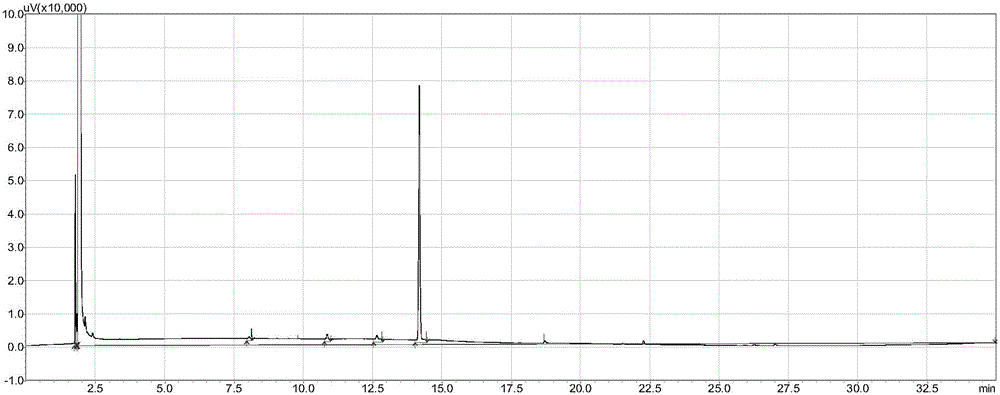

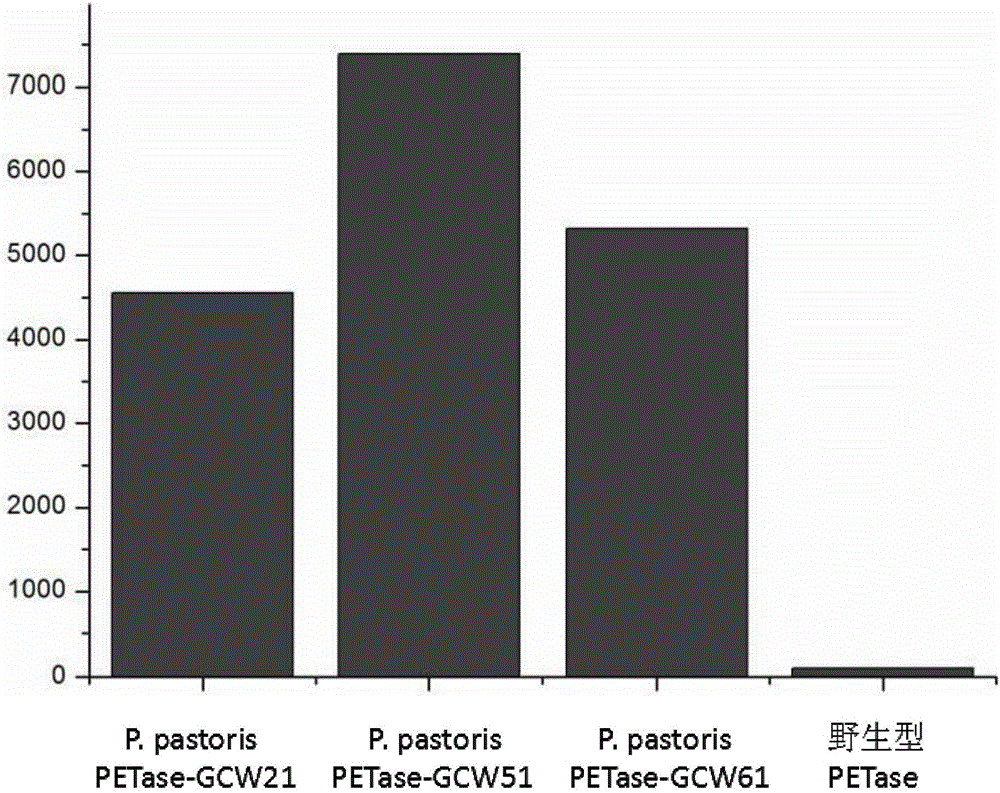

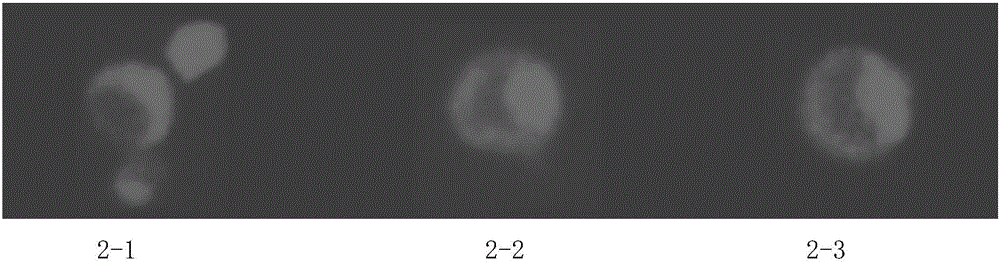

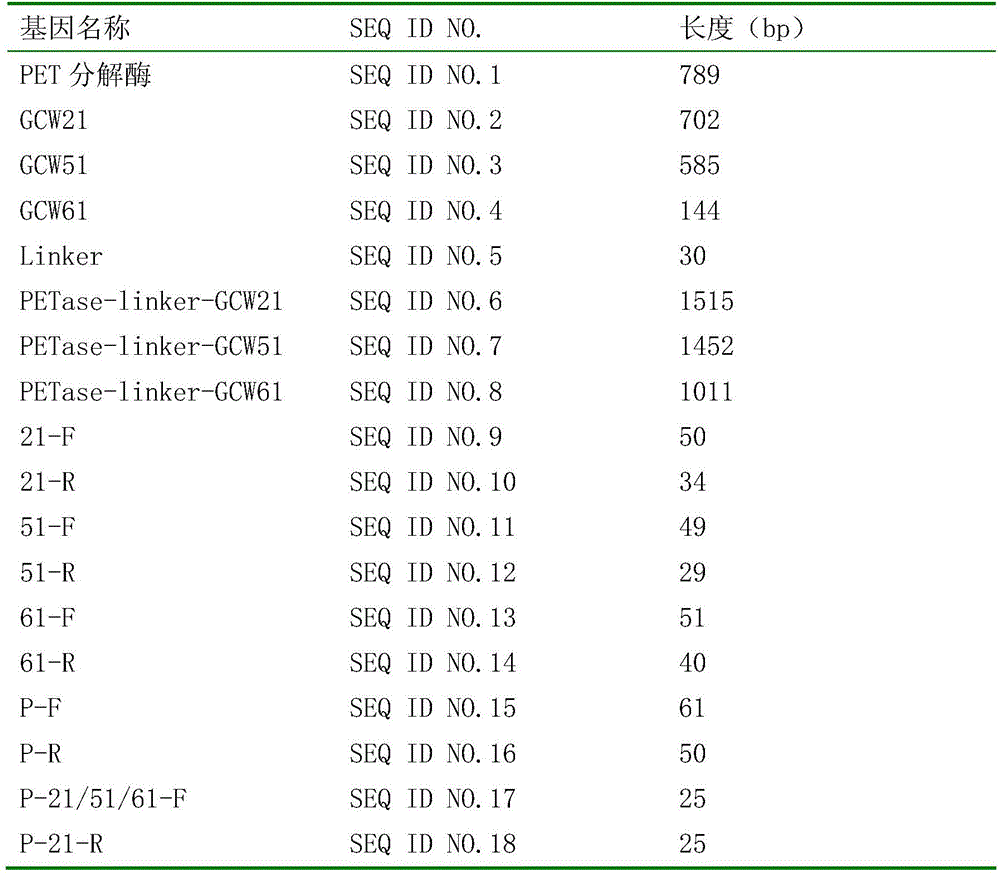

Cell surface exhibition PET decomposing enzyme reorganizable pichia pastoris and structure and application

ActiveCN106497964ALimited ability to produce enzymesIncrease production costFungiHydrolasesPichia pastorisYeast

The invention discloses a cell surface exhibition PET decomposing enzyme reorganizable pichia pastoris and structure and application, comprising the structured steps of 1, chemo synthesizing the nucleotide sequence of ameliorated PET decomposing enzyme as shown in SEQ ID No. 1; cloning the nucleotide sequence of anchoring protein gene from the gene group of GS115 pichia pastoris; 2, utilizing the OverlapPCR to connect the nucleotide sequence of anchoring protein gene and the nucleotide sequence of ameliorated PET decomposing enzyme and obtaining an amalgamation sequence; 3, connecting the amalgamation sequence to an expression load of pichia pastoris, and obtaining a reorganizable expression load; 4, transferring the reorganizable expression load in a host pichia pastoris, and obtaining a reorganizable pichia pastoris of a cell surface exhibition PET decomposing enzyme. The reorganizable pichia pastoris can anchor the PET decomposing enzyme to the cell surface, the enzyme after Immobilization can be used for an entire cell catalyst, compared to the wild grow type, has high stability, is convenient to recover, easy to control and can be repeatedly utilized.

Owner:TIANJIN UNIV

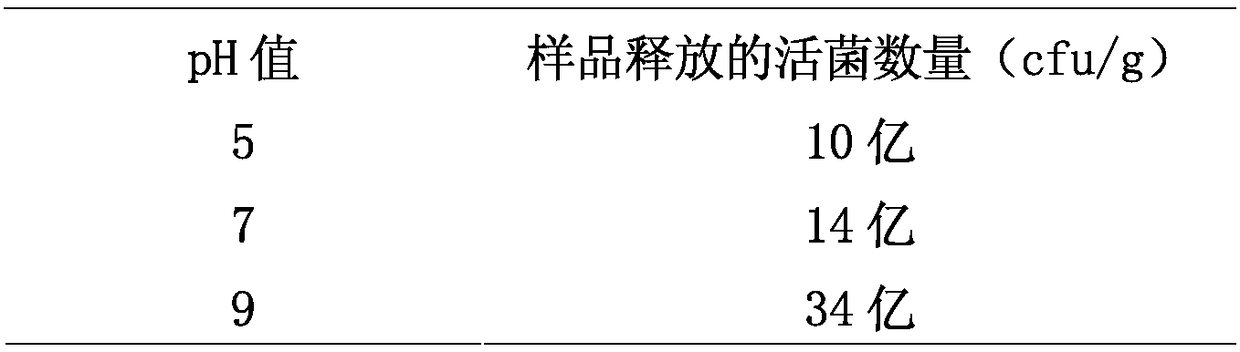

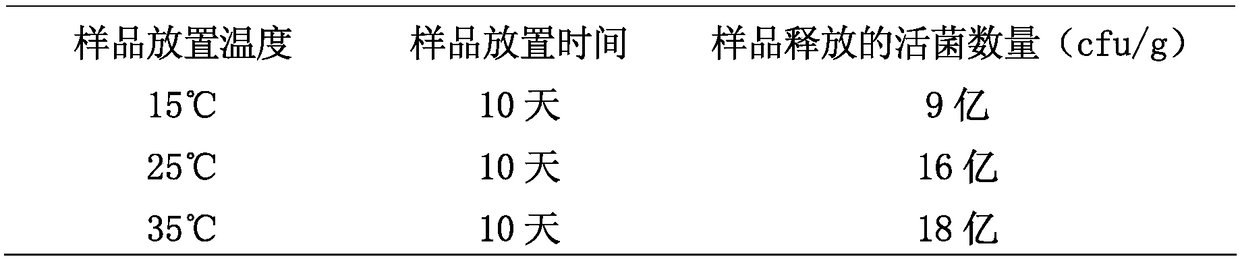

pH sensitive bacillus subtilis fungicide

ActiveCN108977390AOptimizationImprove nutrient availabilityBiocidePlant growth regulatorsFungicideDecomposition

The invention provides a pH sensitive bacillus subtilis fungicide. The fungicide comprises bacillus subtilis and / or spore, dopamine or salt thereof and pH sensitive polymer macromolecules. The dopamine is attached to the surface of the bacillus subtilis, and the surface of the dopamine is coated with the pH sensitive polymer molecules, so that the pH sensitive bacillus subtilis fungicide capable of adjusting the release amount of live bacteria wrapped therein according to the pH vale of the environment can be prepared. In the salinization soil, by applying the pH sensitive bacillus subtilis fungicide provided in the invention, the live bacteria can be rapidly released, so that the soil salinization problem of the soil can be rapidly improved; and by applying the pH sensitive bacillus subtilis fungicide provide in the acidified soil, the release rate of the live bacteria in the fungicide can be effectively retarded, the loss of organic fertilizer generated by the decomposition of live bacteria in the acid soil can be prevented, and the utilization efficiency of the fertilizer can be improved.

Owner:河北丰农有机肥制造有限公司

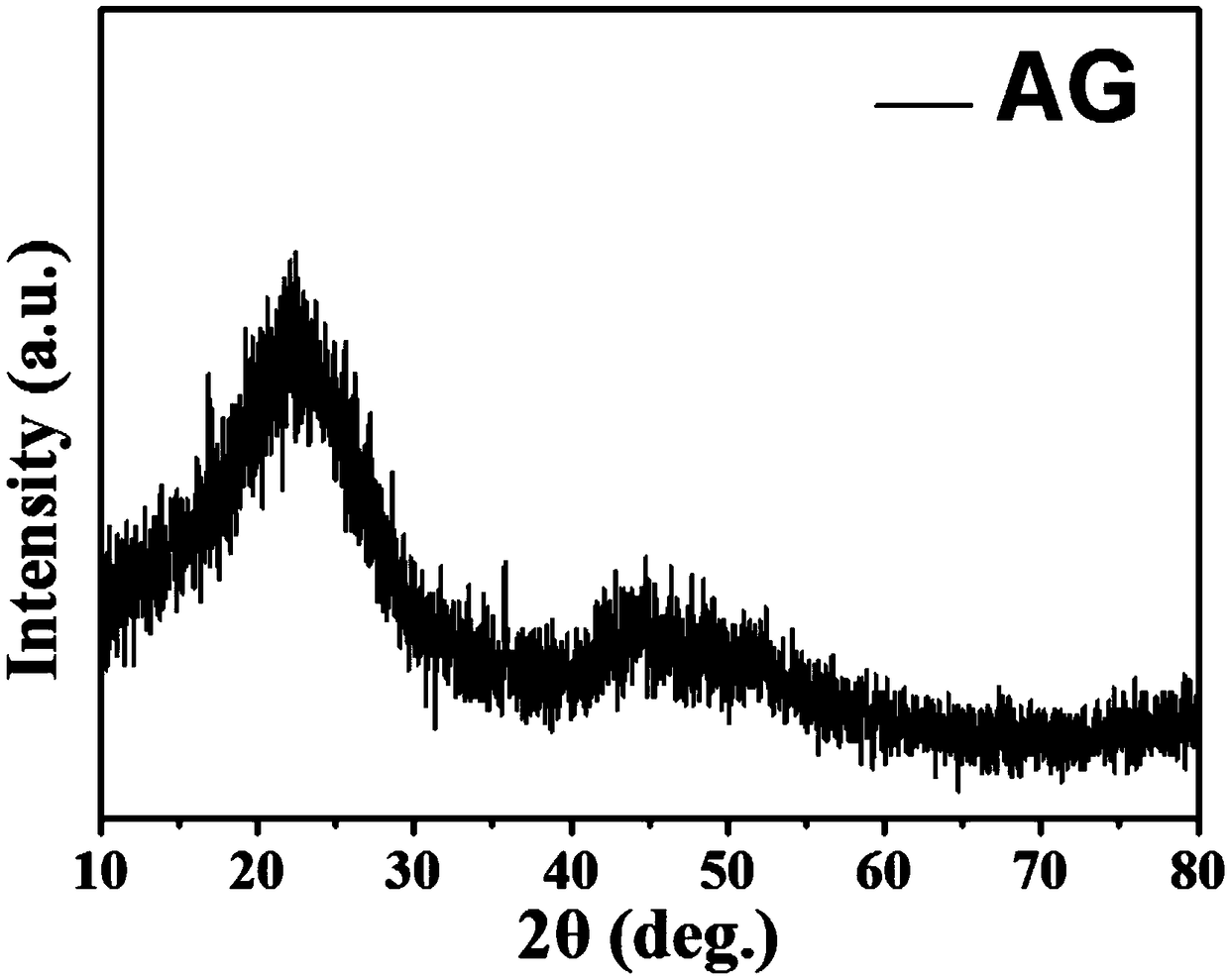

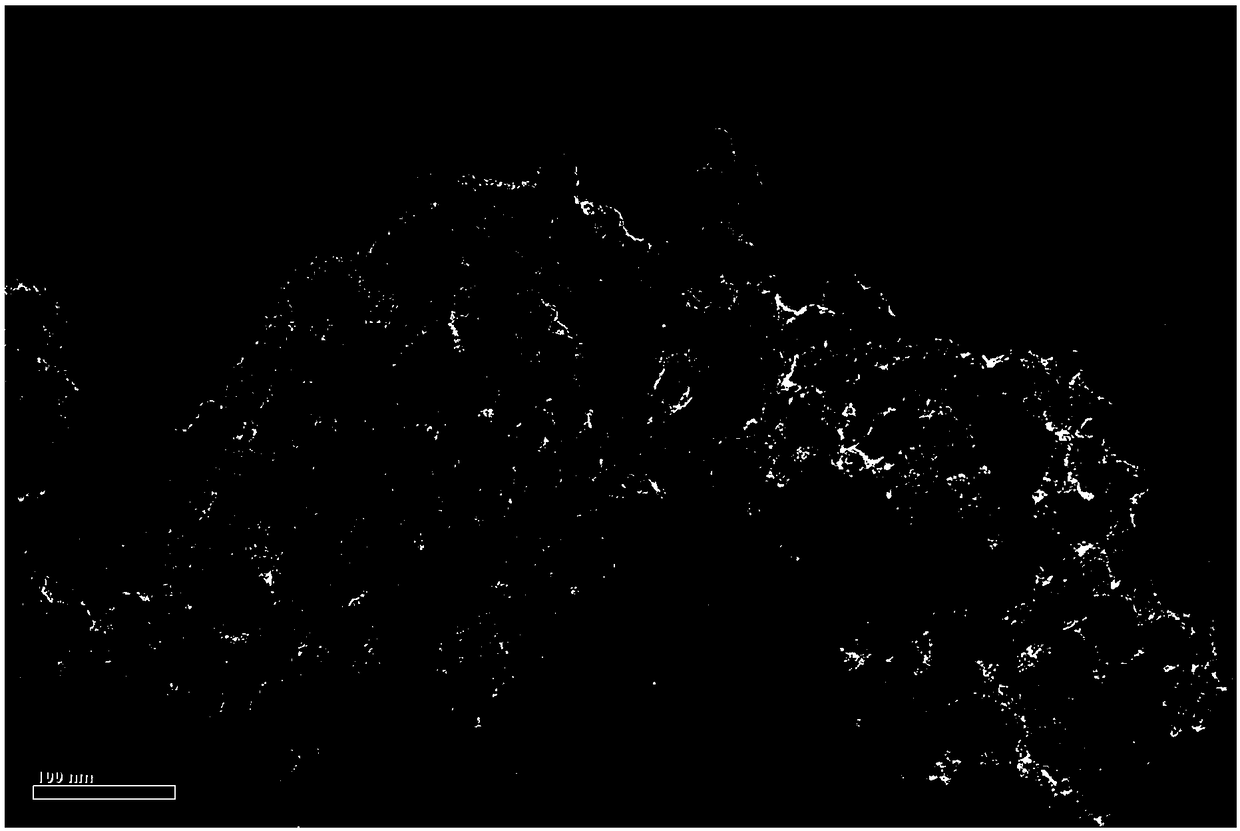

Super-pure carbon aerogel with superhigh specific surface area based on carbon dioxide activating and pore forming and preparation method thereof

ActiveCN108862237AStrong three-dimensional senseHigh specific surface areaPhysical/chemical process catalystsOther chemical processesMicrosphereSorbent

The invention provides a carbon aerogel. The carbon aerogel is of a three-dimensional network structure stacked by carbon particles; the surface of the carbon particle is of a micropore structure; thecarbon aerogel is a super-pure carbon aerogel without metal element impurities. The carbon aerogel has the advantages that a uniform mesopore structure is formed, the stereo feel of the three-dimensional network is strong, the space network structure is stacked by the carbon microspheres, the microspheres are tightly distributed and connected, and the whole structure is complete; the carbon aerogel has the mesopore structure stacked by the carbon microspheres, and the carbon microsphere self has a large amount of micropore structures, so as to enhance the specific surface area of the carbon aerogel, and the BET specific surface area can reach about 1300m<2> / g; the normal-pressure drying method is adopted, the solvent exchange is avoided, the inorganic metal alkaline catalyst is not used,and the super-pure carbon aerogel with good biocompatibility is obtained; the carbon aerogel can be widely applied to the fields of food-level medicine loading, catalyst loading, material adsorbents,energy storage materials and the like.

Owner:UNIV OF SCI & TECH OF CHINA

Method for extracting citric acid with ion exchange resin

InactiveCN101747180AImprove adsorption capacityStrong anti-pollutionCarboxylic compound separation/purificationUltrafiltrationIon exchange

The invention relates to a method for extracting citric acid with ion exchange resin, which comprises the following steps: (1) prefiltering citric acid fermentation liquid: putting the fermentation liquid into a frame filter pre-coated with diatomite to remove thalli and impurities in the fermentation liquid, circulating in a storage tank until effluent liquid is clarified and collecting; (2) filtering citric acid fermentation liquid: treating the effluent liquid the thalli of which is removed through a ultrafiltration membrane with average molecular weight of 4 to 10K to remove the macromolecule impurities; (3) absorbing the citric acid in the fermentation liquid with ion exchange resin fibre: putting the treated liquid into the resin column with ion exchange resin fibre, wherein the filling density of the ion exchange resin fibre is 0.1 to 0.20 kg / L, and the speed thereof is 5 to 30 vv / h; (4) eluting citric acid absorbed by the ion exchange resin fibre: adopting HCI, ammonia water or NaOH with 2 to 3 times column volume and the concentration of 4 to 6 percent to elute with the speed of 5 to 10 vv / h, and collecting eluent; and (5) concentrating and crystallizing the treating fluid containing citric acid, and obtaining finished product. The invention has simple technology and obvious effect.

Owner:天津实发中科百奥工业生物技术有限公司

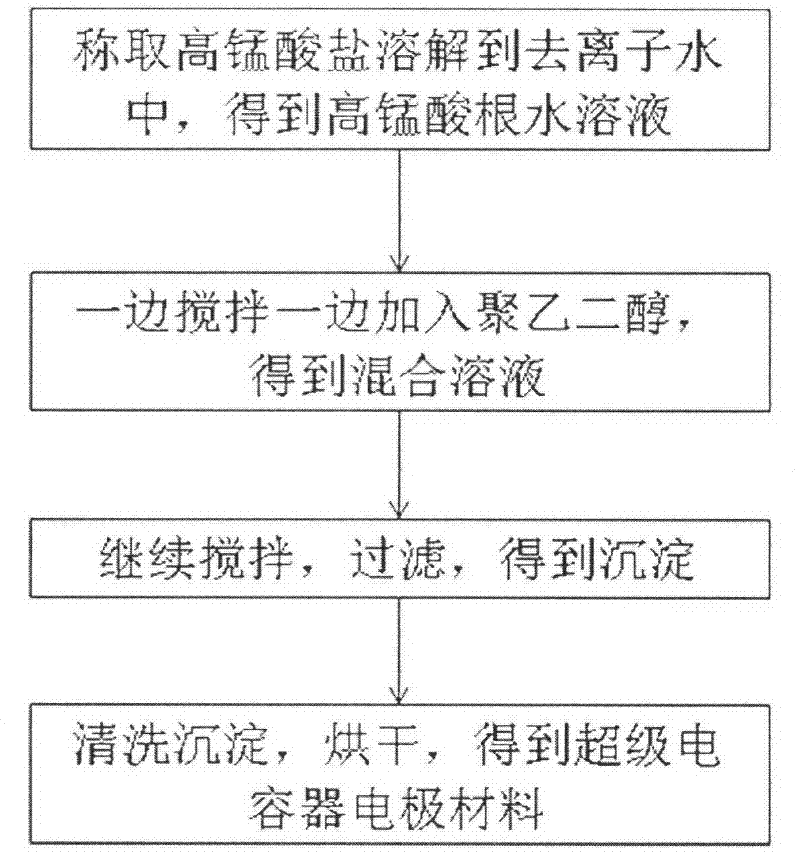

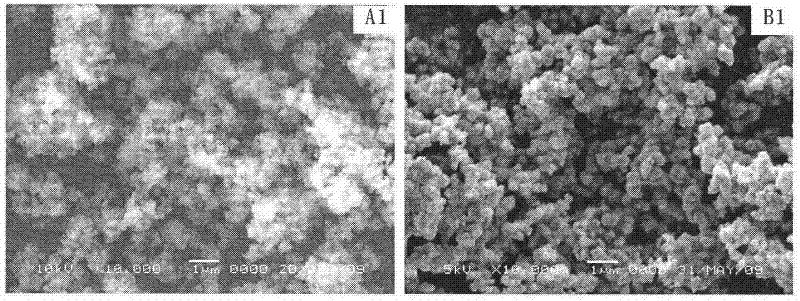

Preparation method for electrode material of super capacitor, application and super capacitor

ActiveCN102456479AHigher specific capacityImprove cycle lifeElectrolytic capacitorsCell electrodesPolyethylene glycolSupercapacitor

The invention discloses a preparation method for an electrode material of a super capacitor. The preparation method comprises the following steps of: preparing an aqueous solution of permanganate at the concentration of 0.02 to 0.20 mol / L, and adding polyethylene glycol with stirring to obtain a mixed solution, wherein the volume ratio of the polyethylene glycol to the aqueous solution of permanganate is 1:8 to 1:40; stirring the mixed solution, and filtering the mixed solution to obtain precipitates; and washing and drying the precipitates to obtain the electrode material of the super capacitor. The preparation method for the electrode material of the super capacitor has the characteristics of simple process, short flow, low dependence on equipment and suitability for large-scale production; and the prepared electrode material of the super capacitor has high performance.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

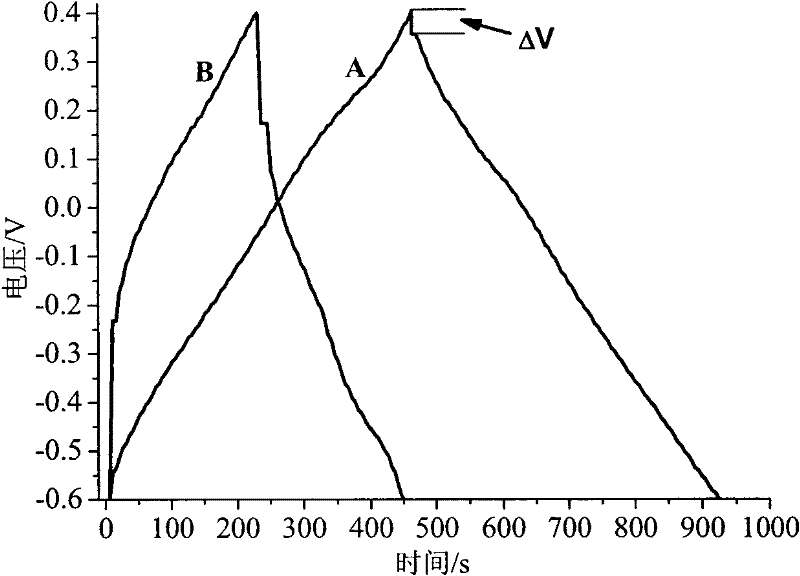

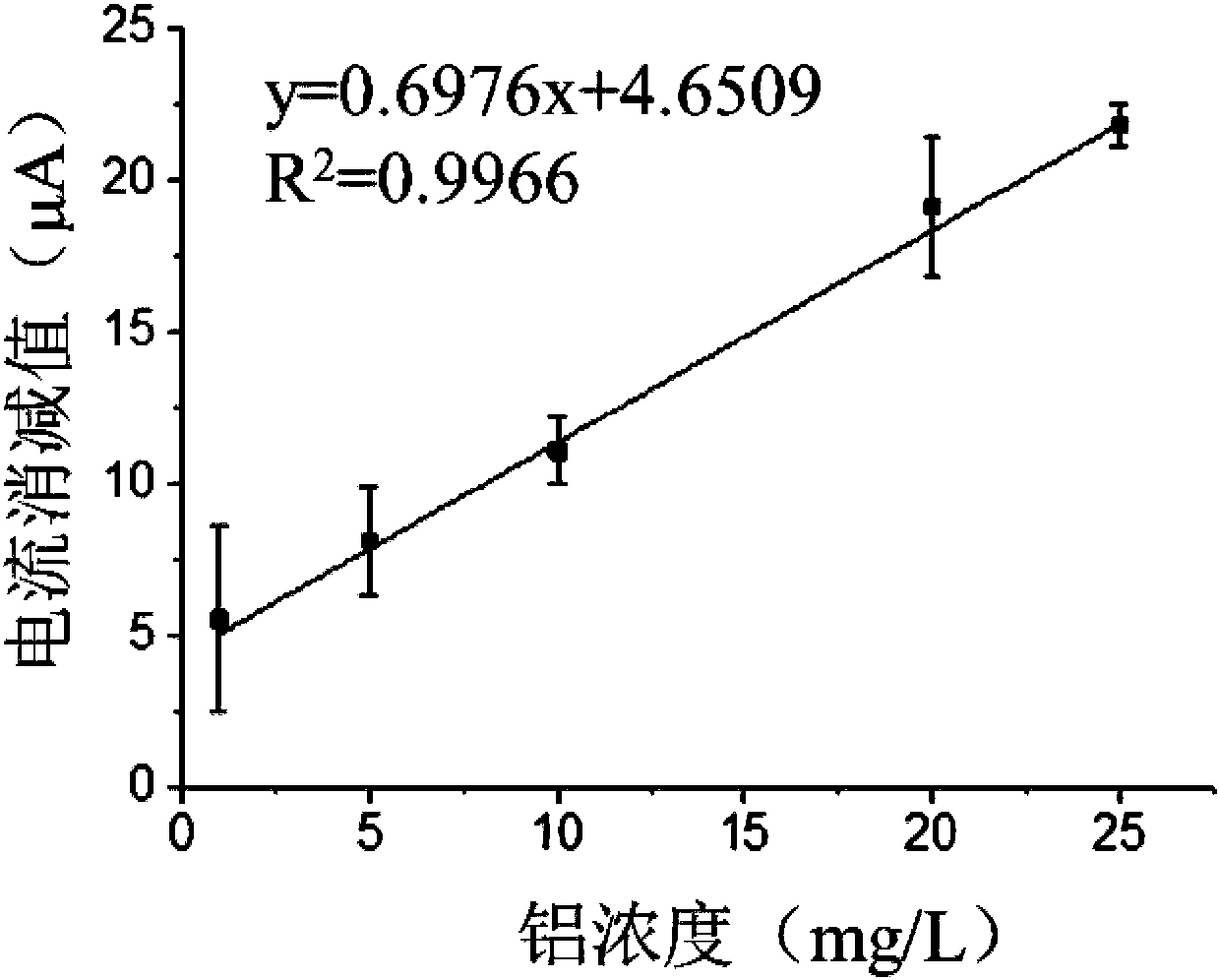

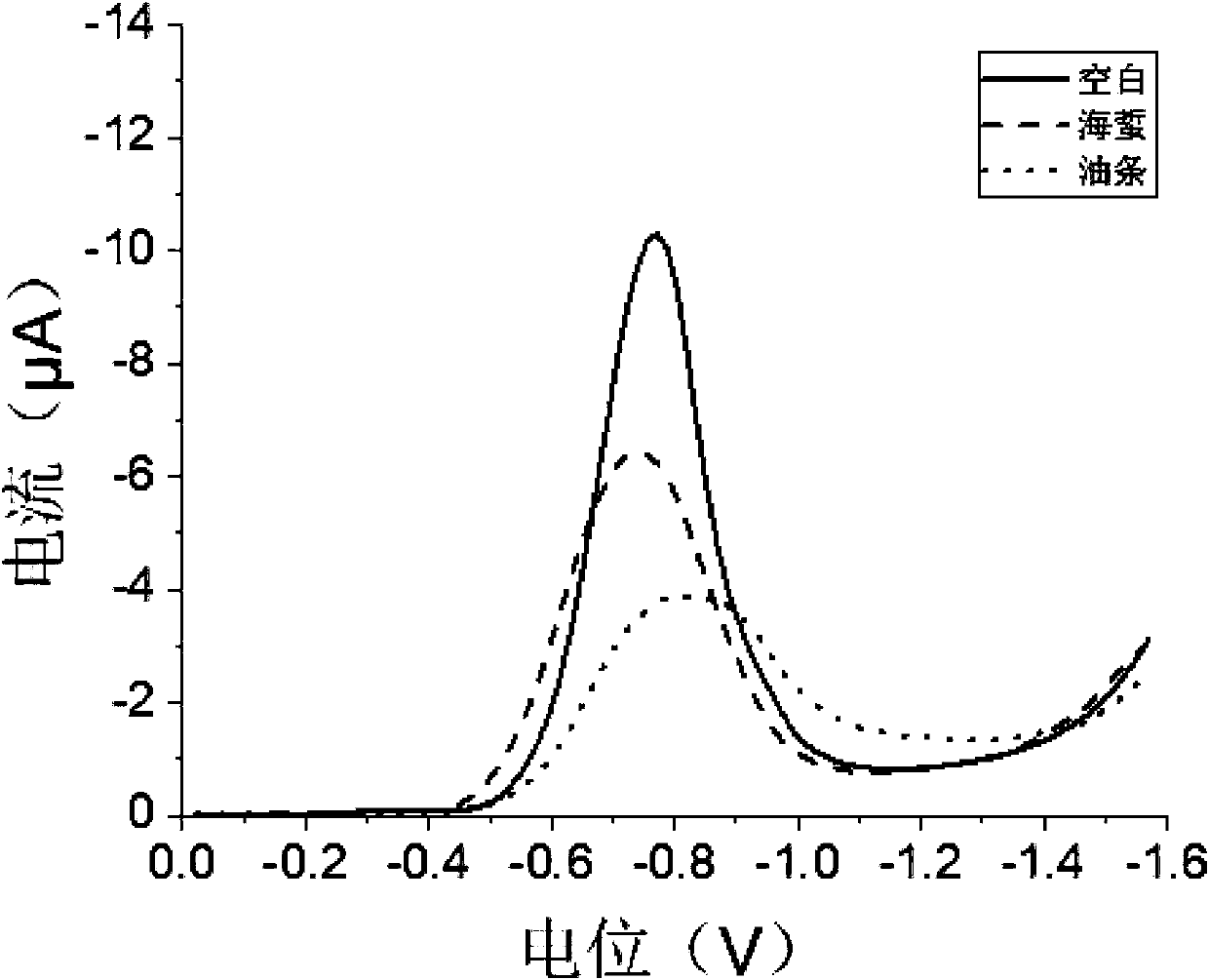

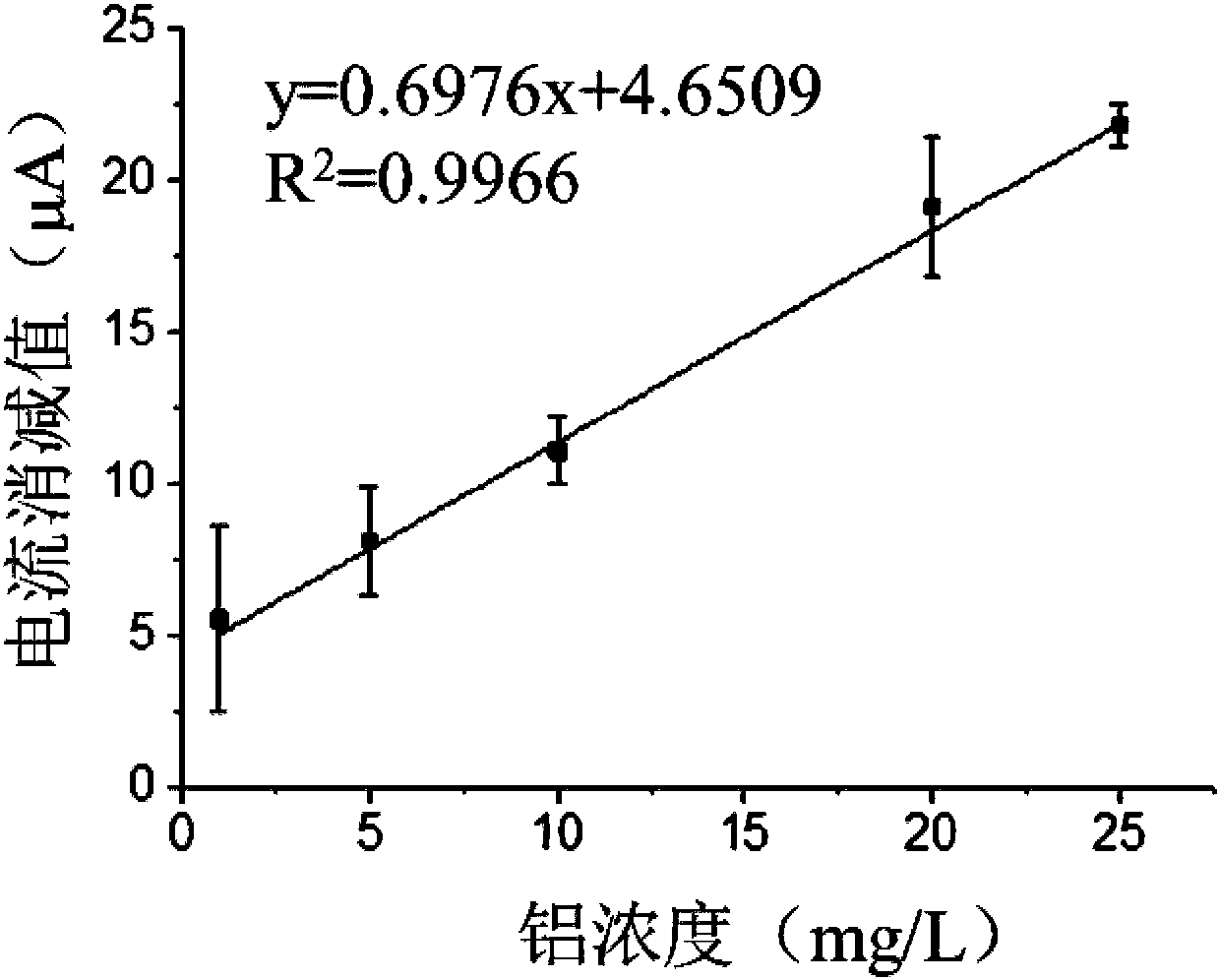

Membrane electrode and preparation method thereof, sensor comprising membrane electrode, electrochemical workstation and application thereof

ActiveCN109991294AHigh sensitivityImprove Sensing PerformanceMaterial electrochemical variablesAluminum IonRelative standard deviation

The invention provides a membrane electrode and a preparation method thereof, a sensor by employing a membrane electrode, an electrochemical workstation and application thereof. The membrane electrodecomprises an electrode and a modified membrane on the surface of the electrode, the modified membrane is a mixture of chitosan and alizarin red S; the modified membrane of the chitosan and the alizarin red S is deposited at the surface of the electrode to allow the obtained membrane electrode to have high sensitivity, high sensing effect and have responsiveness to the current change; the preparation method of the membrane electrode is simple, easy to obtain raw materials, low in cost and easy to implement and can be suitable for industrial large-scale production application; and the sensor comprising the membrane electrode is high in detection sensitivity and good in accuracy; the electrochemical workstation comprising the sensor can achieve the qualitative and quantitative detection of aluminum ions, and is high in sensitivity, small in relative standard deviation and high in accuracy.

Owner:南京腾森分析仪器有限公司

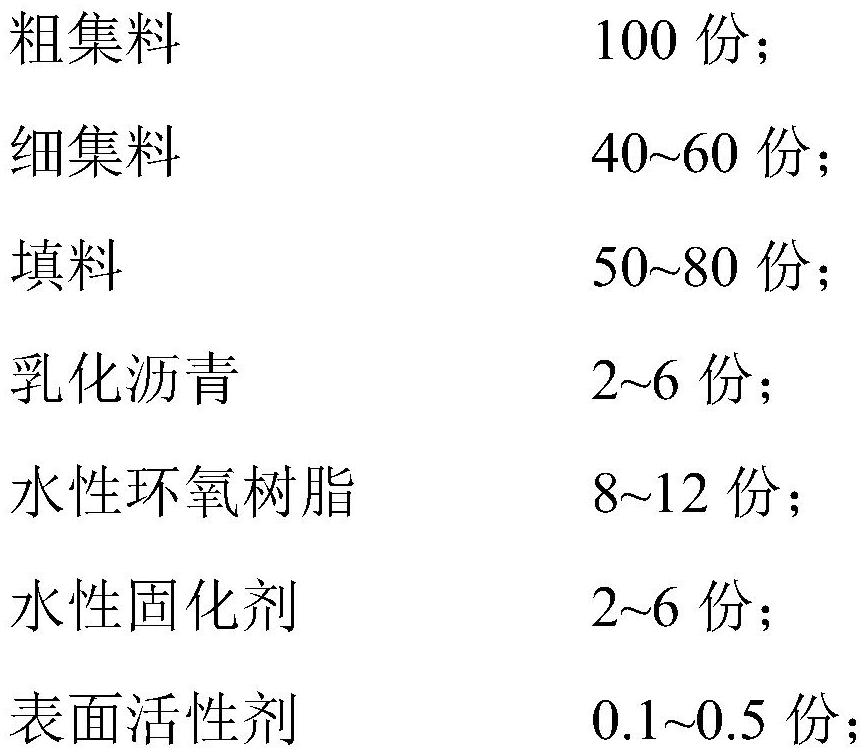

Cold-mixed concrete and preparation method thereof

The invention belongs to the technical field of building materials, and particularly relates to cold-mixed concrete which comprises the following raw material components in parts by weight: 100 partsof coarse aggregate, 40-60 parts of fine aggregate, 50-80 parts of filler, 2-6 parts of emulsified asphalt, 8-12 parts of water-borne epoxy resin, 2-6 parts of a water-borne curing agent and 0.1-0.5 parts of a surfactant, wherein the coarse aggregate and the fine aggregate are selected from steel slag. The cold-mixed concrete does not need to be mixed under the heating condition, and is low in volatile organic compound content, green and environmentally friendly. Through the combined action of the components in specific proportions, the concrete interface bonding force is high, application andconstruction are flexible and convenient, and the formed concrete is high in strength and excellent in high and low temperature performance.

Owner:SHENZHEN TRAFFIC CONSTR ENG TEST & DETECTION CENT

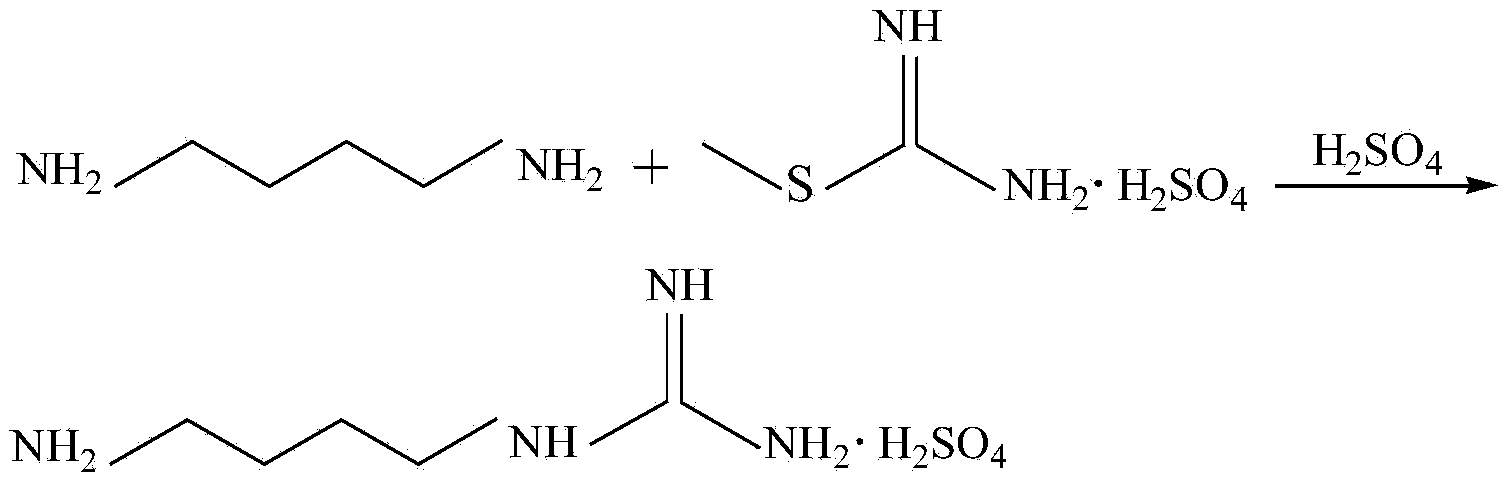

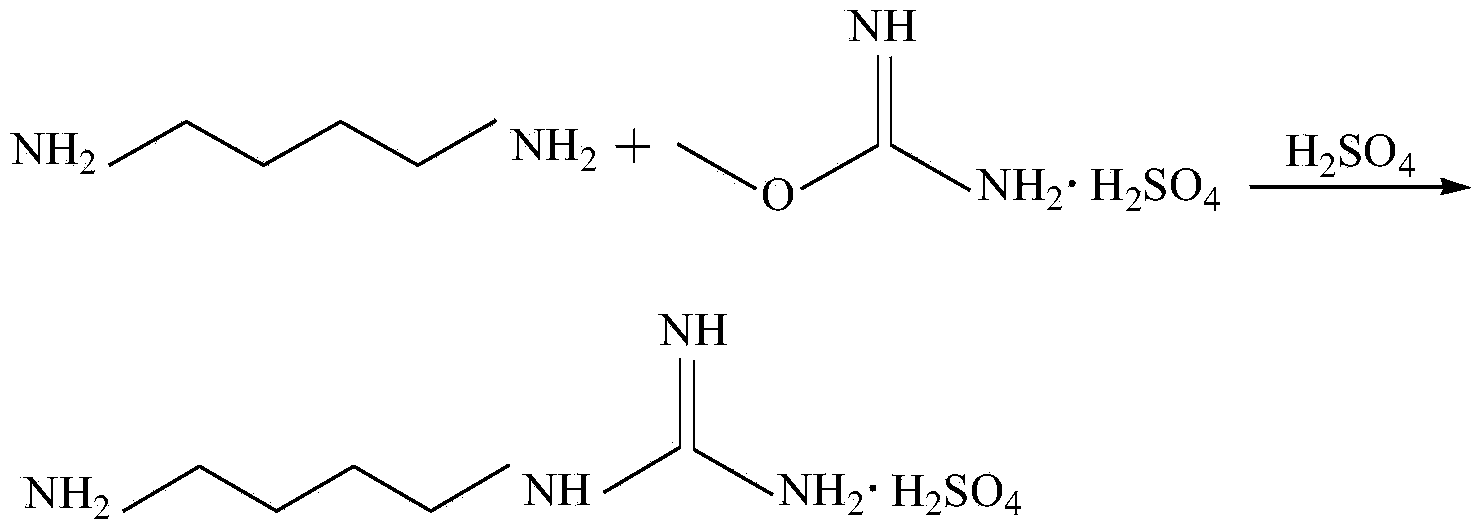

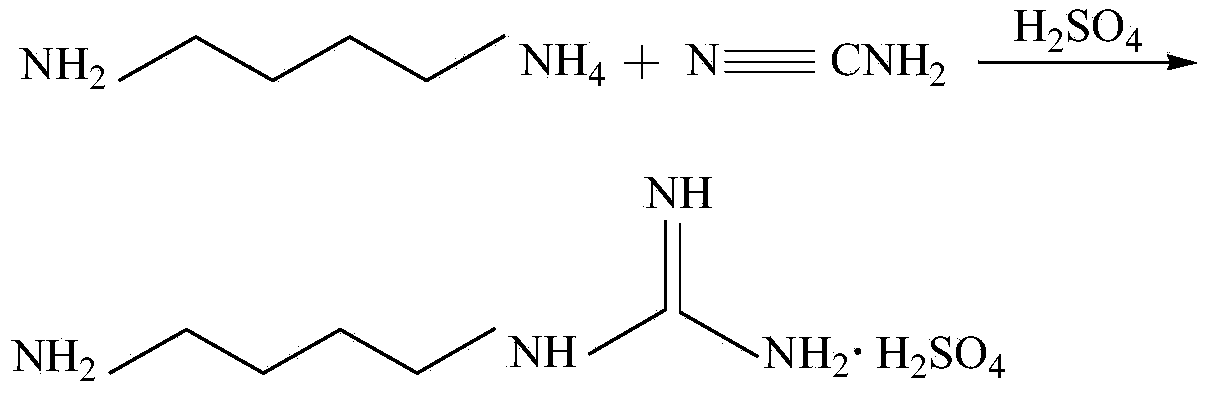

Synthesis method of agmatine sulfate

InactiveCN103755598AImprove protectionMild reaction conditionsOrganic chemistryOrganic compound preparationSynthesis methodsSulfate

The invention provides a synthesis method of agmatine sulfate. The method comprises the steps of carrying out addition reaction by taking 1,4-butanediamine as a raw material and a cyanamide water solution as a guanidination reagent to obtain agmatine, and forming salt with sulfuric acid to obtain agmatine sulfate. The synthesis method disclosed by the invention, by taking cyanamide water solution as the guanidination reagent, is moderate in reaction condition, easy to control, light in pollution, favorable for environmental protection, low in cost, and suitable for industrial production and application on a large scale.

Owner:SHANGHAI XUXIN CHEM

Regeneration method for honeycomb type SCR (Selective Catalytic Reduction) denitration catalyst

InactiveCN103433081BSimple recycling processReduce recycling costsCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsNitrateHoneycomb

The invention discloses a regeneration method for a honeycomb type SCR (Selective Catalytic Reduction) denitration catalyst, and belongs to the technical field of power environment protection. The regeneration method comprises the following steps: 1) dipping a poisoned honeycomb type SCR catalyst into a diluted sulfuric acid solution, carrying out ultrasonic treatment, then taking out and drying; 2) putting the honeycomb type SCR catalyst treated in the step 1 into a cerous nitrate solution, dipping for 1-3 hours and then taking out; 3) roasting the honeycomb type SCR catalyst treated in the step 2, raising the temperature to be 110 DEG C at the speed of no greater than 3 DEG C / min, subsequently preserving the temperature for 3-5 hours, furthermore, raising the temperature to be 300 DEG C at the speed of no greater than 3 DEG C / min, and preserving the temperature for 8-10 hours to obtain the regenerated honeycomb type SCR denitration catalyst. The active precusor substance cerous nitrate used in the regeneration method is wide in source and good in solvability; the activity of the catalyst subjected to regeneration treatment can be recovered to be more than 80% as compared with the activity of the catalyst which is not poisoned; meanwhile, the regeneration process is simplified, the regeneration cost is lowered, and the regeneration method is simple and convenient to operate, environment-friendly and applicable to large-scale industrial production and application.

Owner:HUANENG POWER INT INC +3

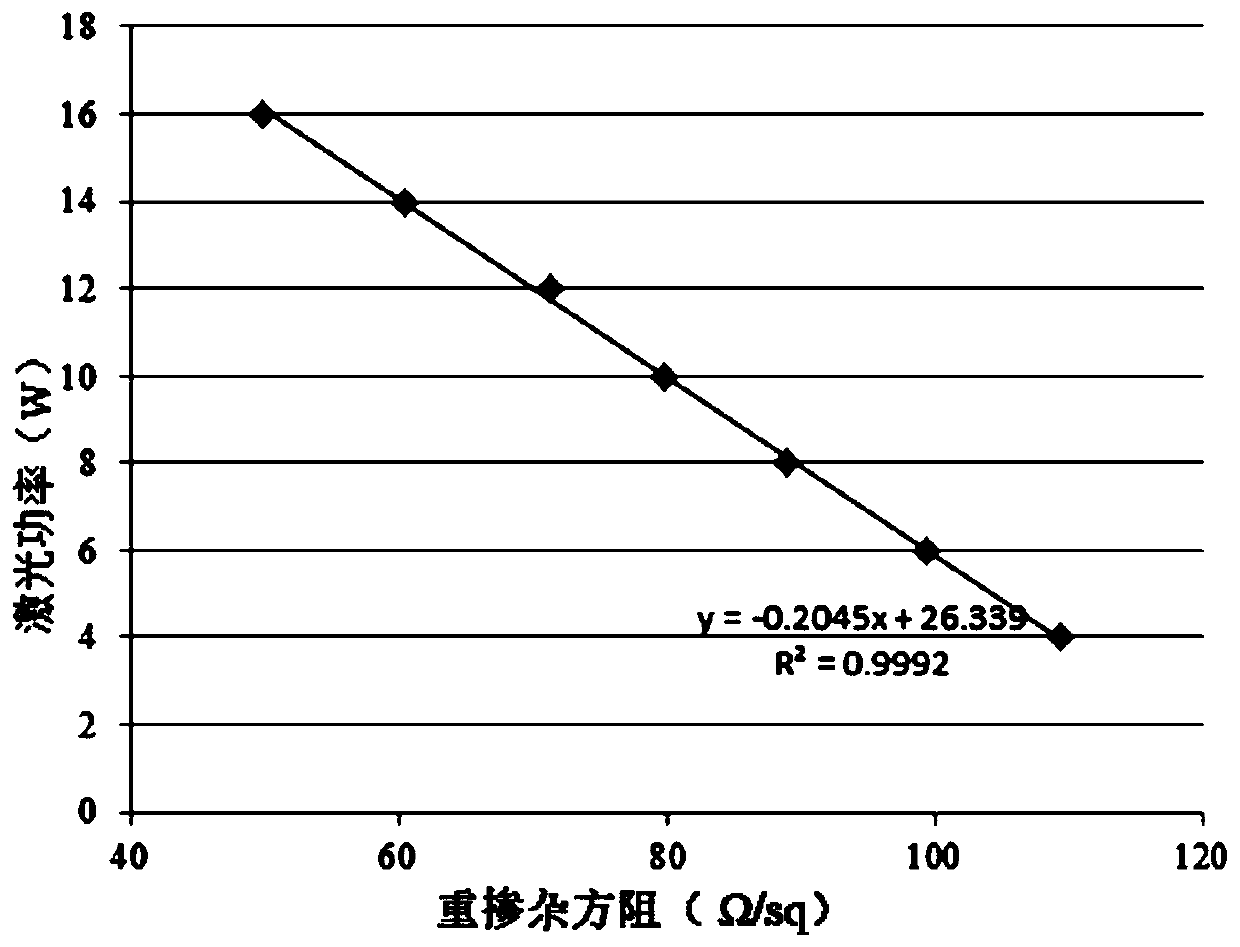

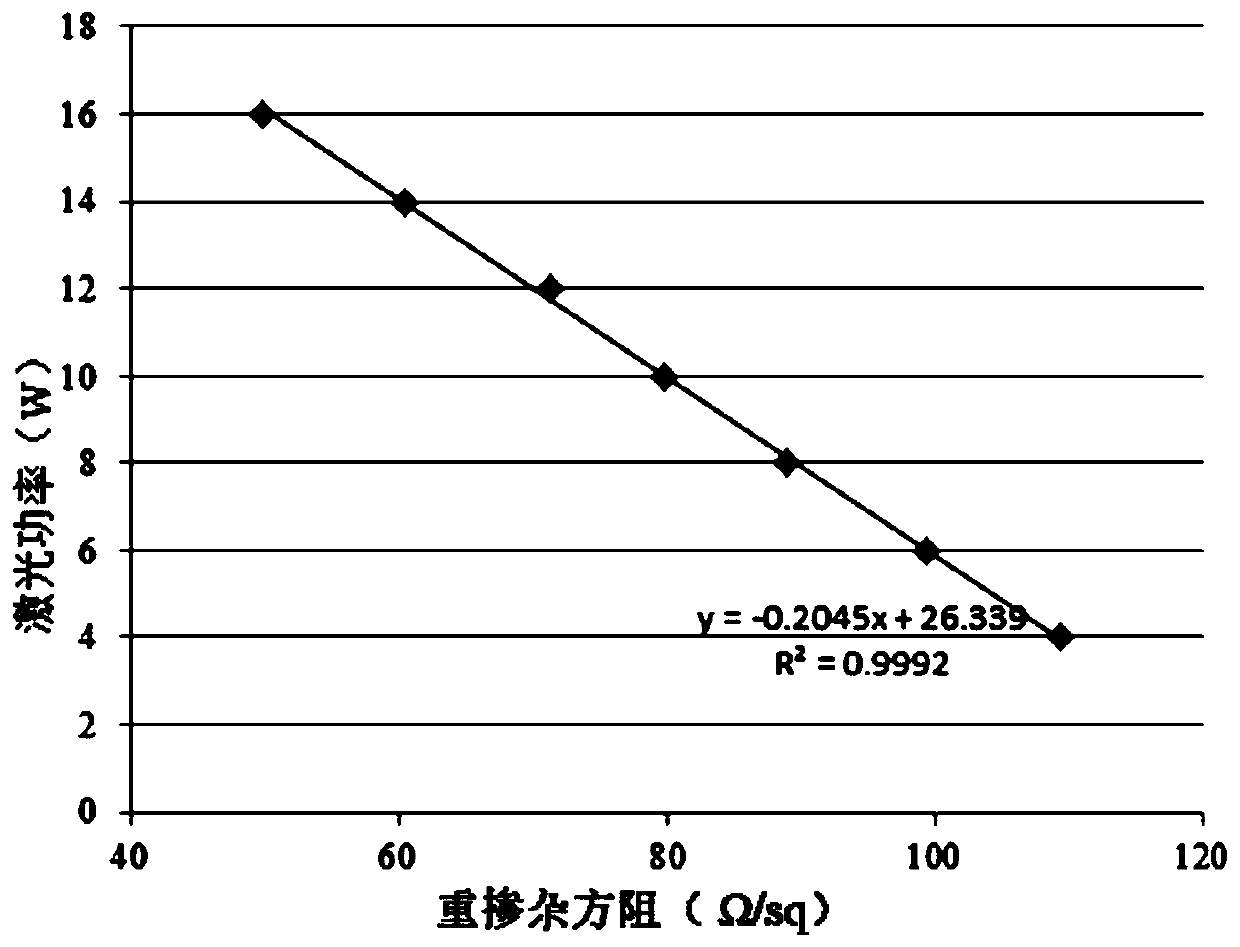

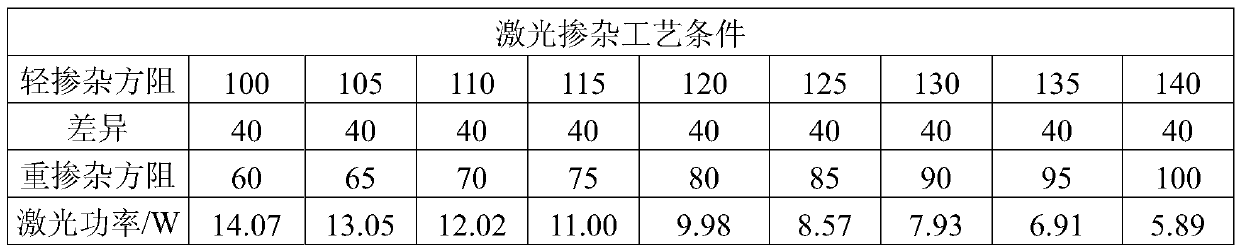

Selective emitter, preparation method thereof, solar cell using selective emitter, and application of solar cell

ActiveCN109713064AIncrease the open circuit voltageIncrease short circuit currentPhotovoltaic energy generationSemiconductor devicesSolar cellProcess conditions

The invention provides a selective emitter, a preparation method of the selective emitter, a solar cell using the selective emitter and an application of the solar cell. The difference between lightly-doped sheet resistance of a light receiving region and heavily-doped sheet resistance of a non-light receiving region of the selective emitter is a fixed value, and the fixed value is 40 + / -10 ohm / sq. The open-circuit voltage and the short-circuit current can be improved and the dead layer effect can be reduced by preparing the selective emitter, so that the light conversion efficiency is improved. The preparation method of the selective emitter is low in price, high in yield, simple in process condition, easy to operate and suitable for industrial large-scale production application. The prepared solar cell has high light conversion efficiency, greatly reduces the production cost, and can be applied to the field of photovoltaics as an energy cell.

Owner:YANCHENG CANADIAN SOLAR INC +1

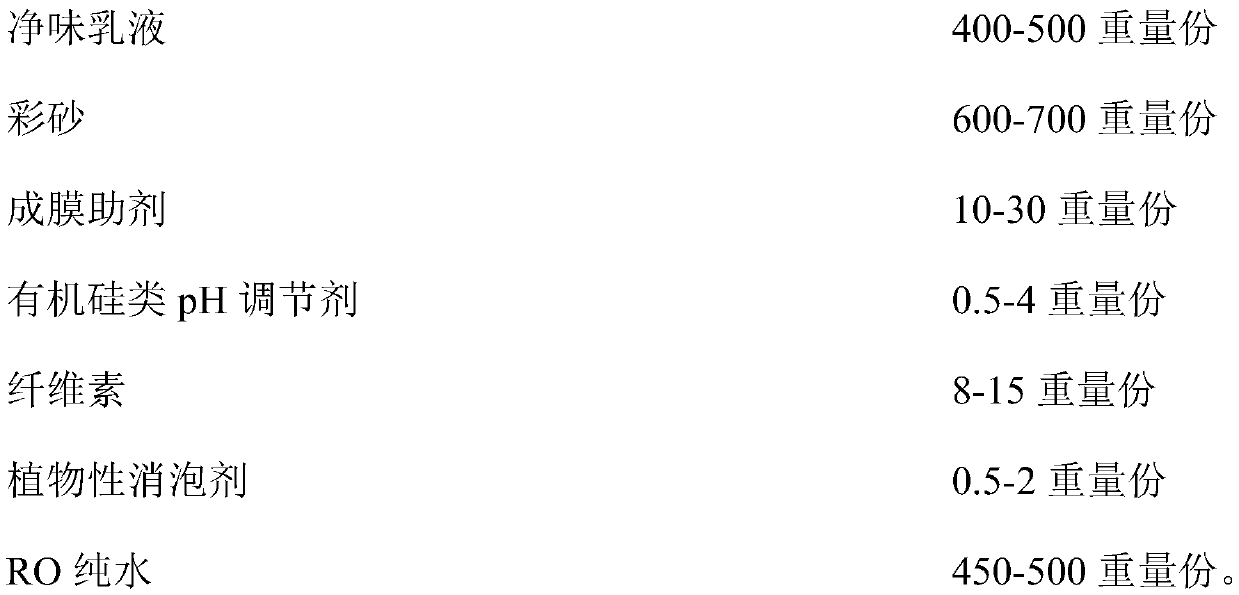

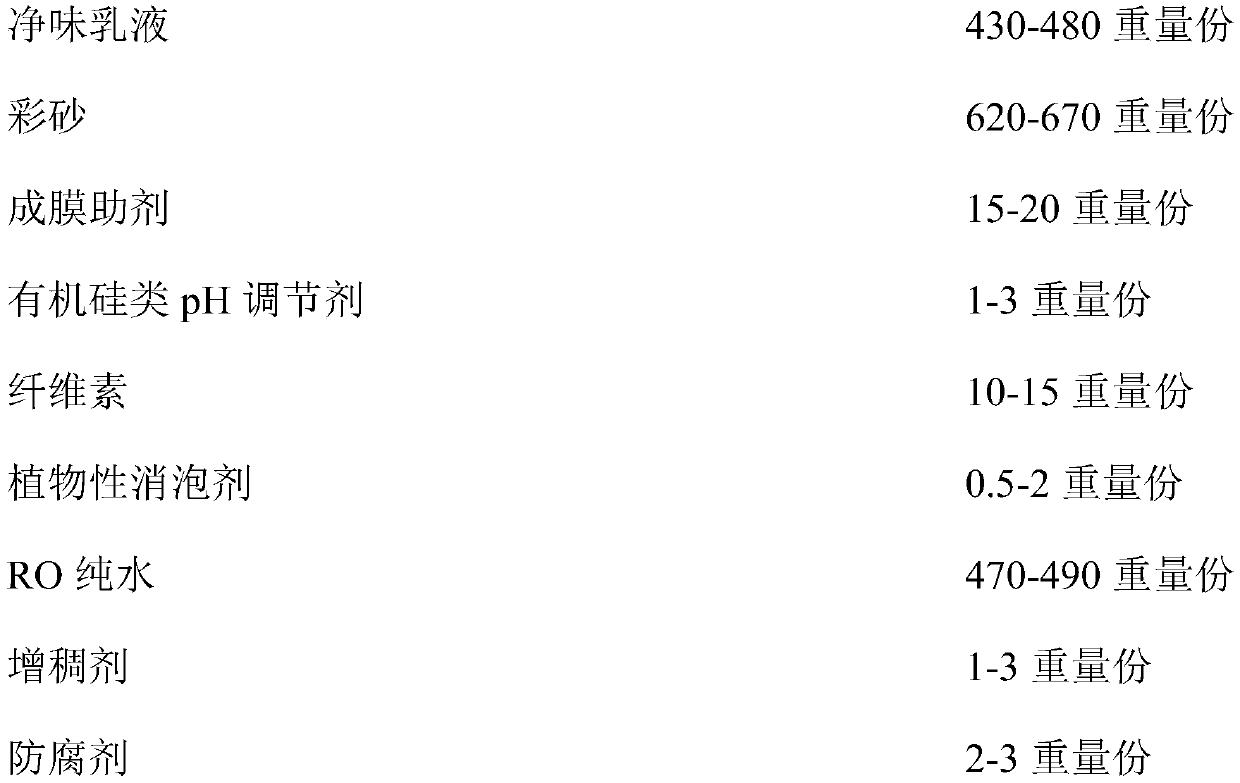

Coating, preparation method and application thereof

The invention provides a coating, a preparation method and an application thereof. The coating comprises the following components in parts by weight: 400-500 parts of odorless emulsion, 600-700 partsof colorful sand, 10-30 parts of coalescing agent, 0.5-4 parts of organic silicon pH regulator, 8-15 parts of cellulose, 0.5-2 parts of plant de-foaming agent and 450-500 parts of RO purified water. The prepared coating has excellent water resistance, appearance and processability; the coating has little odor and is low in content of VOC, SVOC, free formaldehyde and heavy metal; the preparation method is simple; the raw materials are easily acquired and are low in cost; the coating can be used for decorating household or commercial inner walls.

Owner:上海贝塔建筑科技有限公司

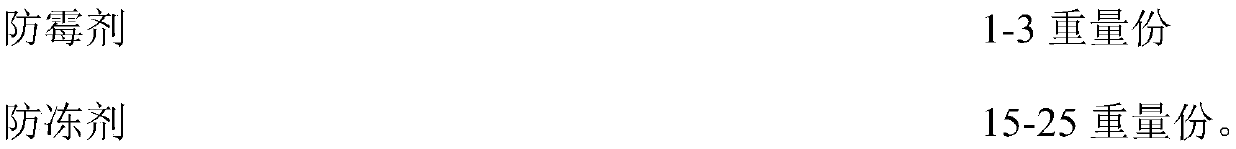

Method for producing iron-containing slag and high zinc materials through cloth bag dedusting ash

InactiveCN108034829AReduce preprocessingSimple operation processProcess efficiency improvementSlagMixed materials

The invention discloses a method for producing iron-containing slag and high zinc materials through cloth bag dedusting ash. The method comprises the steps that a mixed material containing 80%-95% ofthe cloth bag dedusting ash in weight percentage is burnt, restored, oxidized and collected to obtain the high zinc materials and the iron-containing slag. By means of the method for producing the iron-containing slag and the high zinc materials through the cloth bag dedusting ash, the cloth bag dedusting ash is efficiently recovered and processed, the process technological flow is simple, valuable elements in the cloth bag dedusting ash are extracted, the added value of the cloth bag dedusting ash is increased, the method has important practical significance in cleaning production, energy conservation and emission reduction in the iron and steel industry, and the method is suitable for industrialization large-scale production and application.

Owner:杜海东

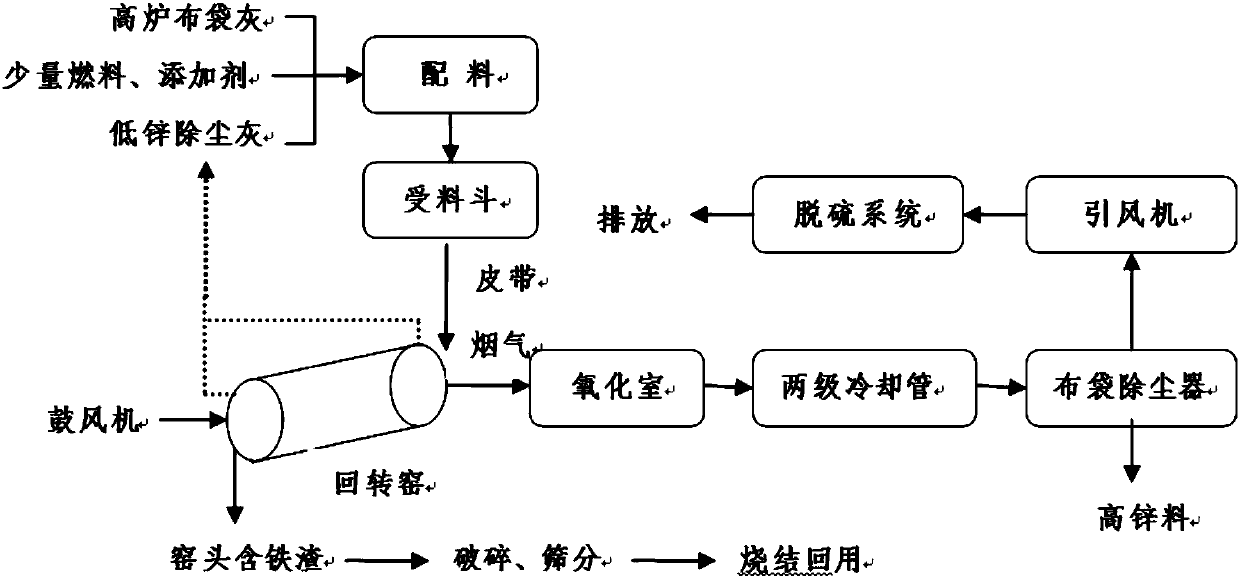

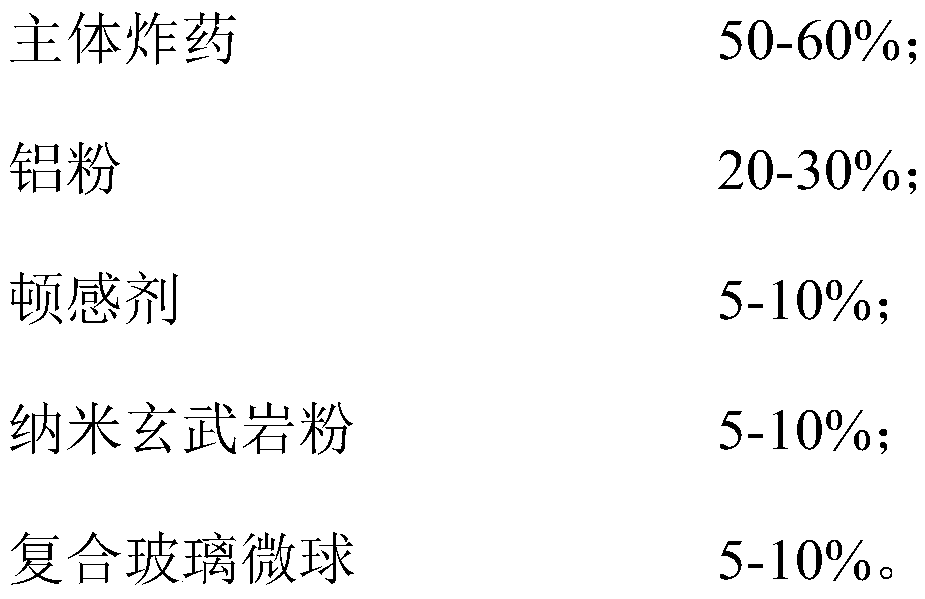

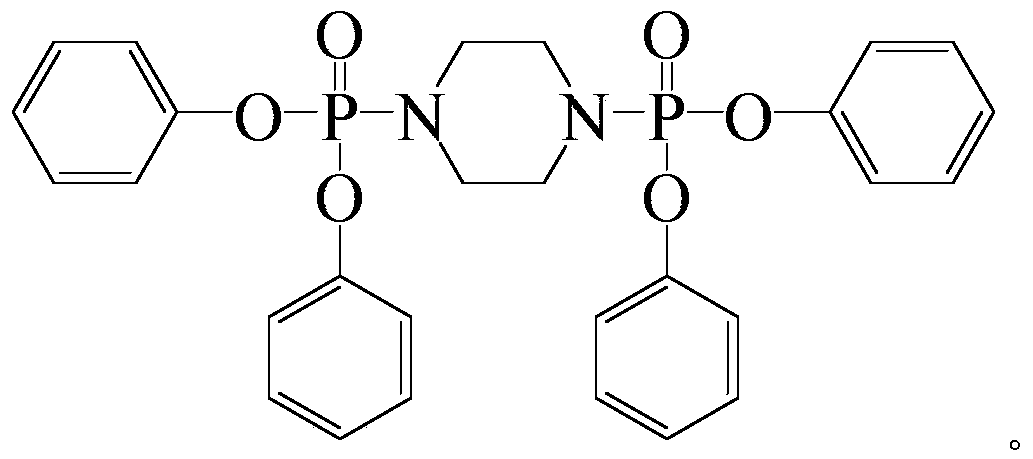

Explosive, and preparation method and application thereof

ActiveCN110218133AReduced explosion rateLow detonation velocityNon-explosive desensitisers/phlegmatisersPressure gas generationFiberExternal energy

The invention discloses an explosive, and a preparation method and an application thereof. The explosive comprises the following components in percentages by weight: 40 to 70% of a main explosive, 10to 30% of aluminum powder, 5 to 15% of a desensitizing agent, 5 to 15% of nanometer basalt powder and 3 to 10% of a composite glass microsphere. According to the invention, through addition of the composite glass microsphere, the explosion rate of the explosive can be reduced through the combined action of silicon dioxide on the surface of the composite glass microsphere and the nanometer basalt powder; meanwhile, under the action of external energy or explosive energy, the silicon dioxide on the surface of the composite microsphere is broken, and a flame retardant located in hollow aluminum fiber can be gradually released; thus, by combination of substances and through combined action, an obtained explosive has low explosion rate and high insensitiveness and flame-retardant performance, can achieve high safety performance and is applicable to the fields of stone mining, etc. The preparation method for the explosive has the advantages of simplicity, easily-available and cheap raw materials, convenient implementation, and applicability to industrial large-scale production application.

Owner:US DIAMOND OIL DRILLING SYST ENG (SHANGHAI) CO LTD

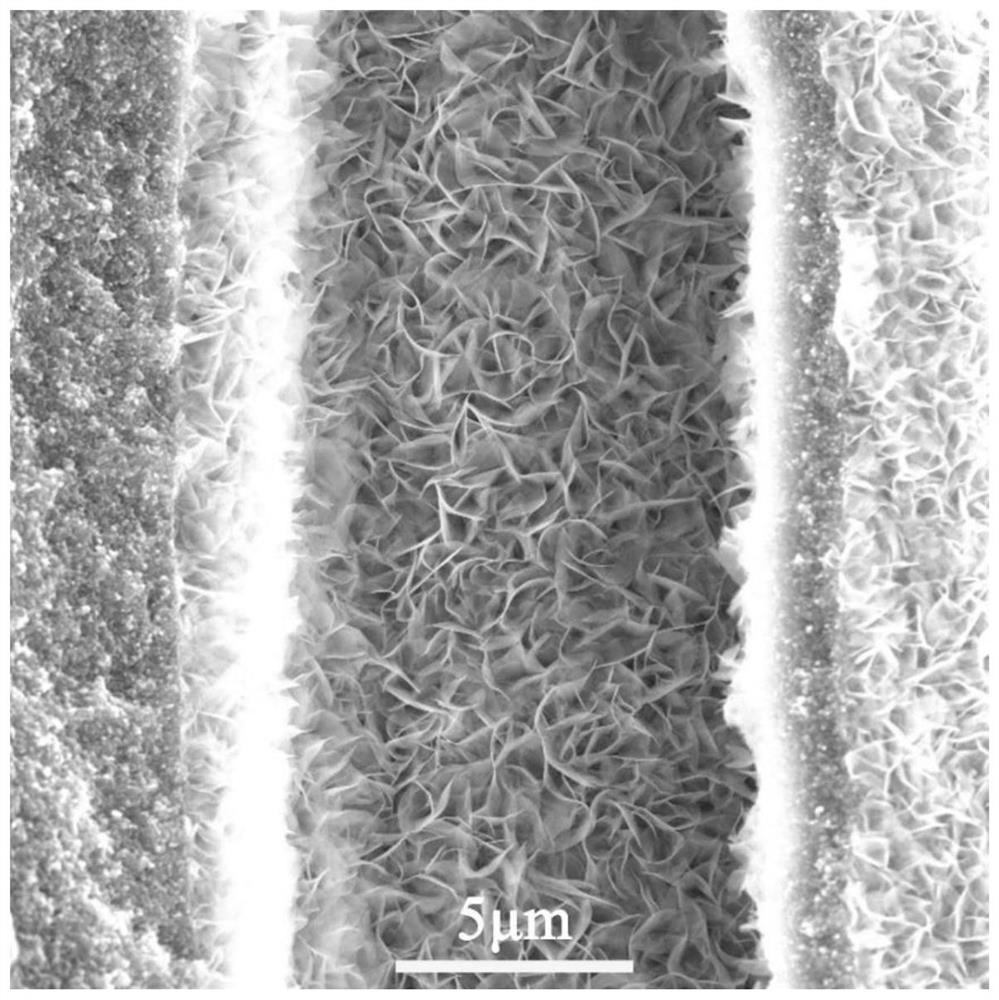

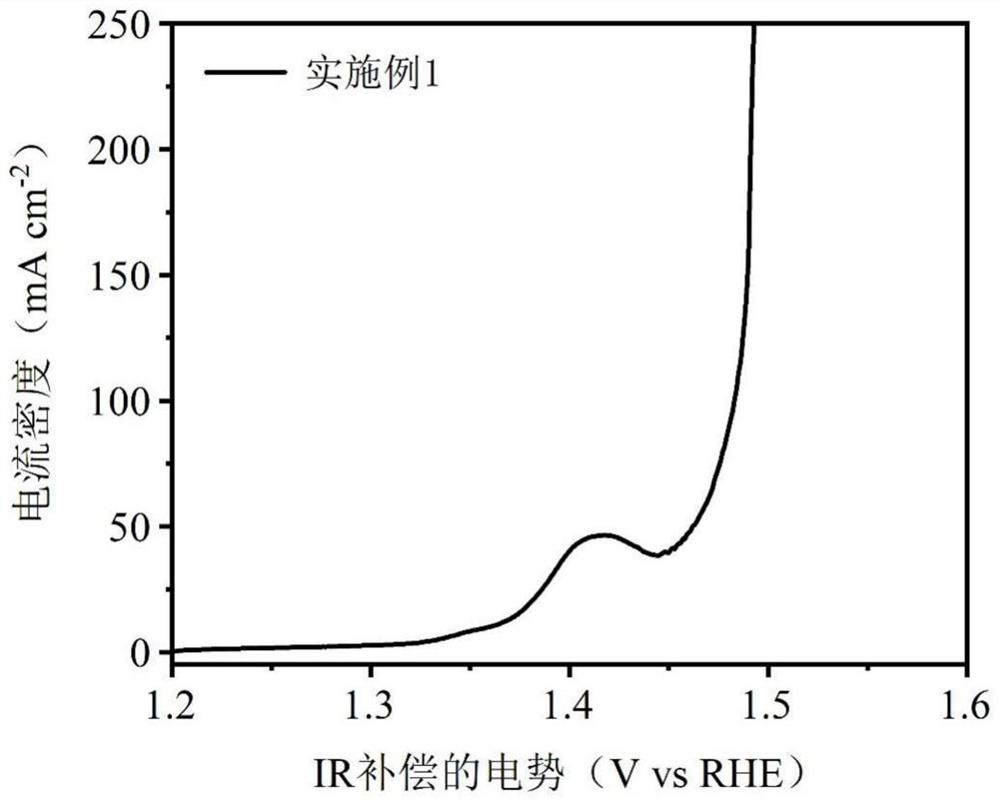

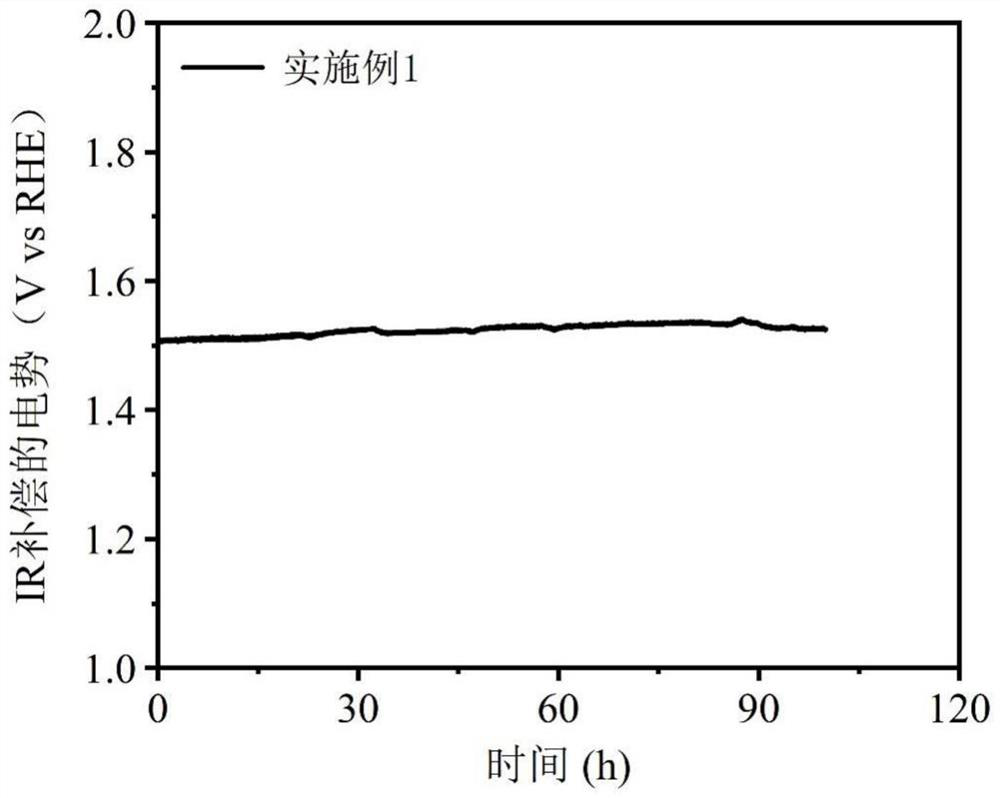

Ferro-nickel hydroxide/ferro-nickel alloy loaded wood-based electrocatalyst, preparation method thereof and water electrolysis hydrogen production catalyst

The invention discloses a ferro-nickel hydroxide / ferro-nickel alloy loaded wood-based electrocatalyst, which comprises a charcoal skeleton with a three-dimensional porous structure and an active substance loaded on the charcoal skeleton, the active substance comprises a ferro-nickel hydroxide / ferro-nickel alloy heterojunction taking ferro-nickel alloy as a bottom layer and ferro-nickel hydroxide as a surface layer. The invention also provides a preparation method of the ferro-nickel hydroxide / ferro-nickel alloy loaded wood-based electrocatalyst and a water electrolysis hydrogen production catalyst. The ferro-nickel hydroxide / ferro-nickel alloy loaded wood-based electrocatalyst has the advantages of high catalytic efficiency, good stability, simple process and the like.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

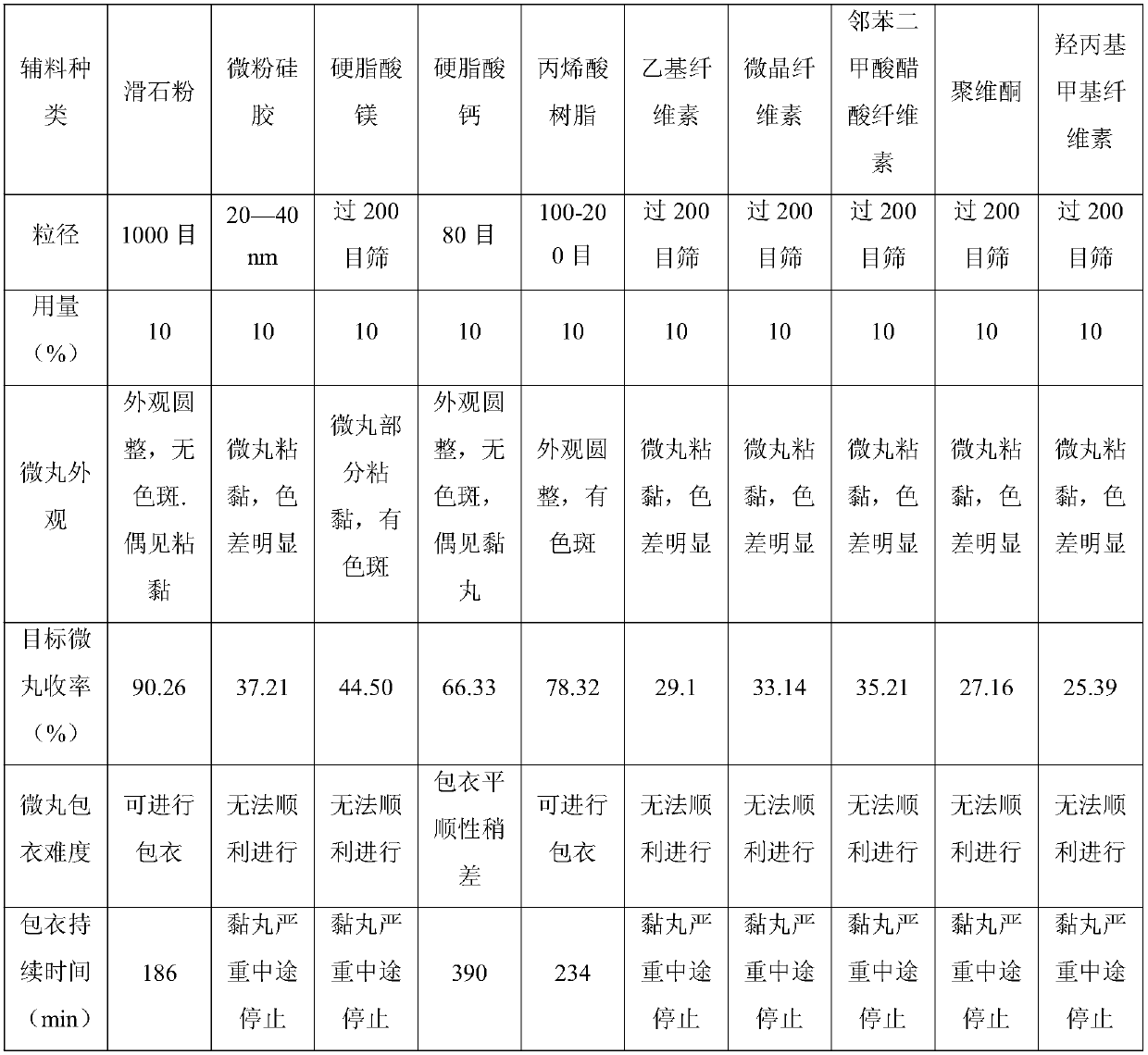

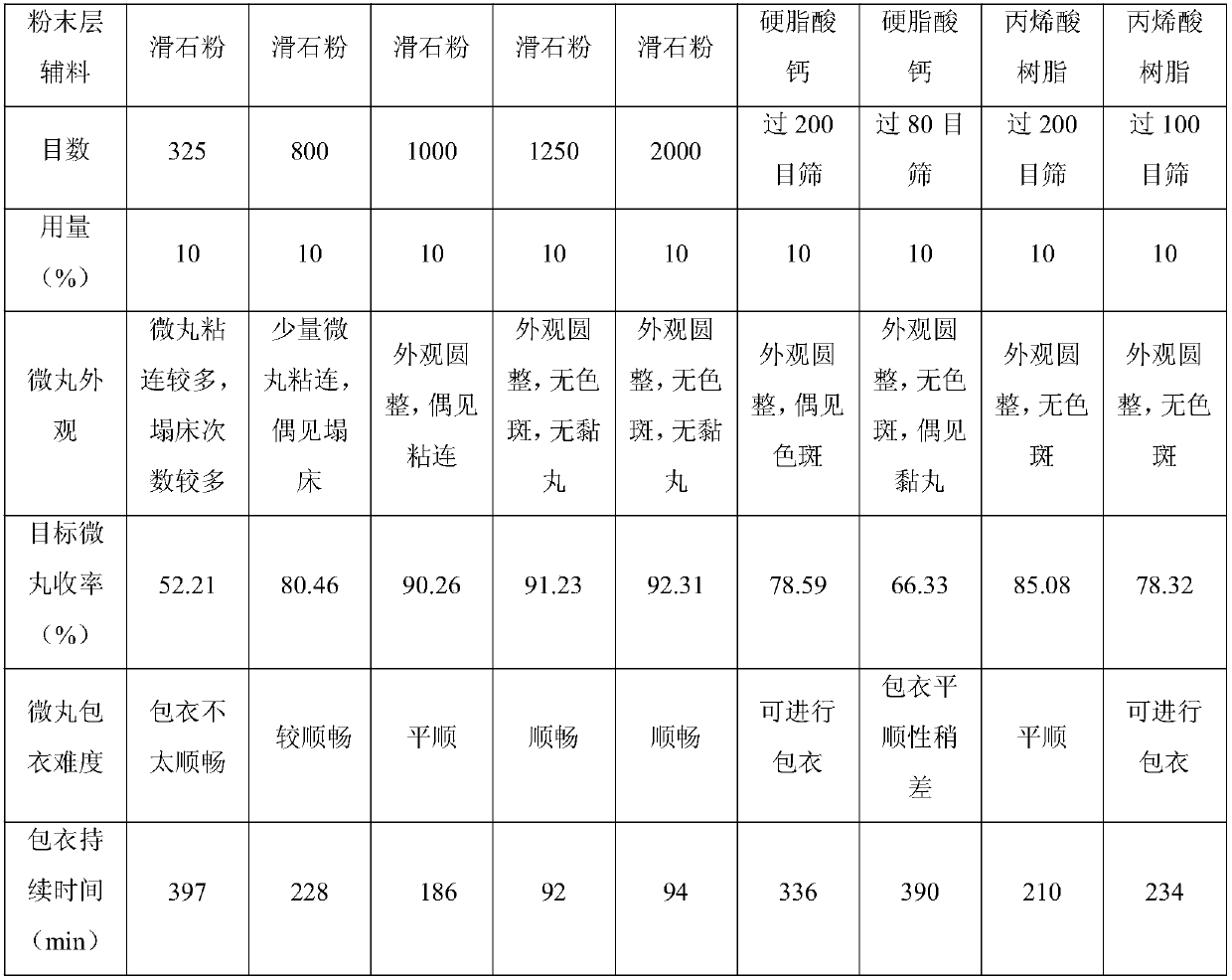

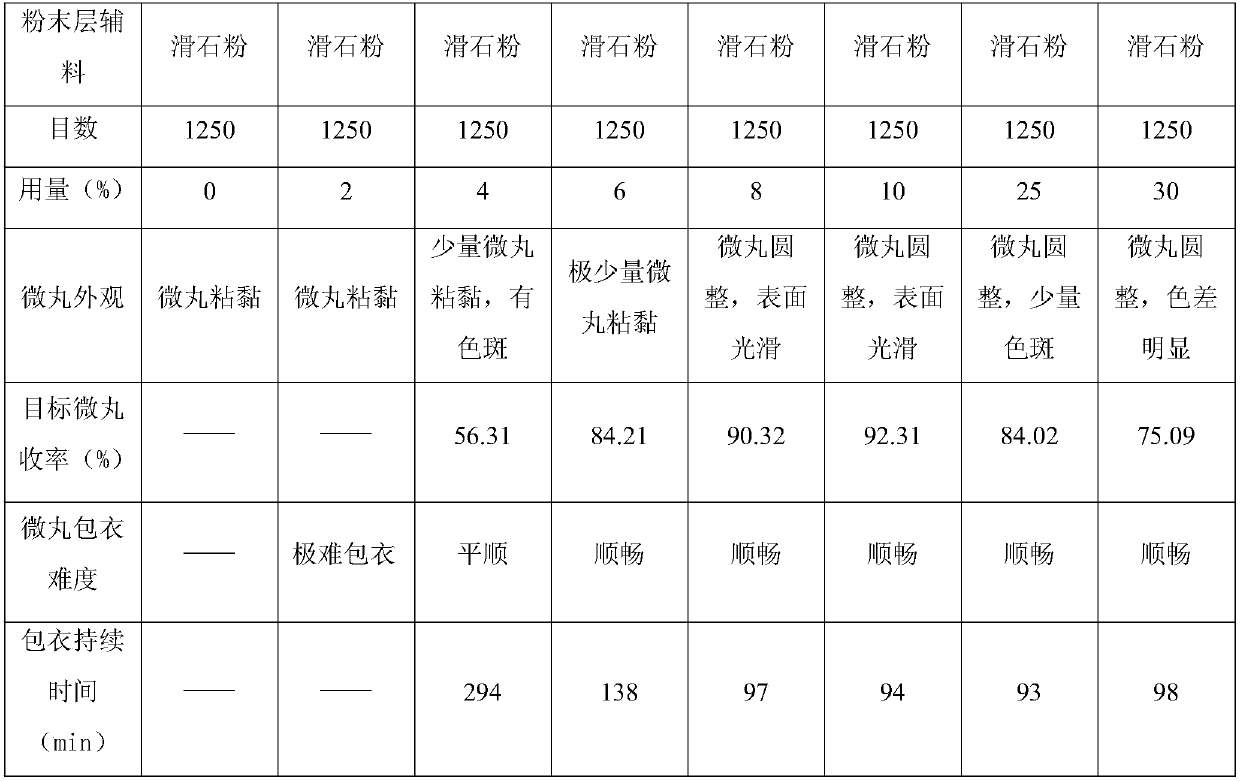

Coating method for traditional Chinese medicine micro-pellets

ActiveCN109925296AHigh pellet rateImprove efficiencyInorganic non-active ingredientsMicrocapsulesFluidized bedExcipient

The invention provides a coating method for traditional Chinese medicine micro-pellets; pharmaceutically acceptable excipients are used for wrapping the surface of micro-pellets containing a traditional Chinese medicine extract with a powder layer, and then coating is performed with a fluidized bed coating technology. The coating method of the traditional Chinese medicine micro-pellets can be usedfor coating various traditional Chinese medicine blank micro-pellets, especially for micro-pellets containing traditional Chinese medicine extracts with large viscosity, can obviously improve the problems of stickiness, bed collapse, chromatic aberration and color spots in the process of fluidized bed coating of traditional Chinese herbal medicine extract micro-pellets, has the advantages of highpelleting rate, good formability, simple operation, low production cost and high efficiency, and is suitable for industrial mass production and application.

Owner:SICHUAN JISHENGTANG PHARMLS

Method for preparing water-soluble PVA resin through photoinduction-reversible addition fragmentation chain transfer polymerization

The invention belongs to the technical field of high polymer material synthesis, and discloses a method for preparing water-soluble PVA resin through photoinduction-reversible addition fragmentation chain transfer polymerization. The method comprises the following steps: (1) adding vinyl acetate, acrylic acid, a chain transfer agent and a photocatalyst into a reactor, carrying out ultrasonic dispersion, and reacting for 24-72 hours under anaerobic or aerobic conditions and light irradiation to obtain a vinyl acetate-acrylic acid copolymer with controllable molecular weight and molecular weightdistribution; and (2) carrying out alcoholysis on the vinyl acetate-acrylic acid copolymer under an alkaline condition to obtain a water-soluble polyvinyl alcohol-acrylic acid copolymer. The raw materials used in the method are rich, cheap and easily available, the reaction condition is mild, the method is simple to operate, the vinyl acetate-acrylic acid copolymer with controllable molecular weight and molecular weight distribution can be obtained, the molecular structure, molecular weight and distribution index of the polyvinyl acetate-acrylic acid copolymer are further controlled, and theapplication range of the water-soluble PVA resin is widened.

Owner:NANCHANG NORMAL UNIV

A kind of extraction method of star anise oil

The invention provides an extraction method of star anise oil. In the invention, a steam distillation method is adopted before an ethanol extraction method; through the method, residual anise oil in the star anise after steam distillation is extracted by the ethanol extraction method to realize secondary extraction and utilization of active ingredients of star anise; and meanwhile, impurities in the star anise can be effectively removed by steam distillation, so that the purity of the anise oil obtained by ethanol extraction in the later period is increased, and the inherent defects of organic solvent extraction are overcome. The method can remarkably increase the yield of star anise oil and obtain anise oil with relatively good quality; and meanwhile, the method is low in cost, convenient to implement and suitable for industrial large-scale production.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Preparation process of slurry for screen printing of sintered NdFeB (neodymium iron boron)

The invention provides a preparation process of slurry for screen printing of sintered NdFeB (neodymium iron boron), and relates to the technical field of screen printing. The process comprises the following steps: crushing fluoride R1F3 and hydride R2H3 into powder, uniformly conducting mixing to obtain a powder mixture, dissolving the powder mixture into a solvent, and then sequentially adding a defoaming agent and macromolecular resin to prepare the heavy rare earth suspension slurry. The slurry prepared by the process has the advantages of strong adhesive force, short drying time after printing, no screen printing plate blockage in printing, substantial improvement of the coercive force of neodymium iron boron, realization of the effects of magnetron sputtering and coating, low equipment cost, and suitableness for industrial batch production.

Owner:ANHUI HANHAI NEW MATERIAL

3D printing method of cobalt alloy

ActiveCN110961622AImprove uniformitySimple stepsAdditive manufacturing apparatusIncreasing energy efficiency3d printManufactured material

The invention discloses a 3D printing method of cobalt alloy. The 3D printing method includes the following steps of firstly, preparing cobalt alloy powder as a raw material for 3D printing; secondly,designing a to-be-printed cobalt alloy device through three-dimensional software; thirdly, performing laser 3D printing forming to prepare a blank; fourthly, performing annealing heat treatment on the blank prepared in the third step to prepare a semi-finished product; fifthly, performing fine machining on the semi-finished product prepared in the fourth step; and sixthly, performing surface treatment and nondestructive testing on the semi-finished product obtained through fine machining in the fifth step to obtain the cobalt alloy. The 3D printing method is simple in step, easy to operate and suitable for industrial large-scale production and application; in the early stage of the operation steps, the uniformity of cobalt alloy crystalline grains is improved; and in the later period, theproduct is stable in structure, and the surface corrosion resistance and wear resistance are improved.

Owner:GEM CO LTD

Multifunctional slow-release organic bacterial fertilizer

InactiveCN108911857AImprove utilization efficiencyImprove nutritional conditions and nutrient availabilityCalcareous fertilisersOrganic fertilisersFertilizerEnvironmental chemistry

The present invention provides a multifunctional slow-release organic bacterial fertilizer. The organic bacterial fertilizer comprises organic matters, bacteria beneficial to plant growth, dopamine ora salt thereof, a high polymer molecule, sodium alginate and Ca<2+>. The dopamine is attached to the surfaces of the organic matters and beneficial bacteria; then the surface of the dopamine is covered with the high polymer molecule; finally, the surface of the high polymer molecule is coated with the sodium alginate and Ca<2+>; and thus the organic bacterial fertilizer capable of maintaining fertilizer with water of soil and slowly releasing live bacteria to a certain extent is prepared. The slow-release organic bacterial fertilizer can effectively maintain the fertilizer with the water of the soil and slowly release the live bacteria, thereby improving the utilization efficiencies of the fertilizer with the water and the living bacteria, improving disease resistance and stress resistance of crops, improving the soil fertility condition sustainably, and realizing efficient reuse of bio-organic waste materials. The provided slow-release organic bacterial fertilizer is simple and environmentally-protective in the preparation technology, free of organic solvents and suitable for industrial mass production applications.

Owner:长沙昱旻信息科技有限公司

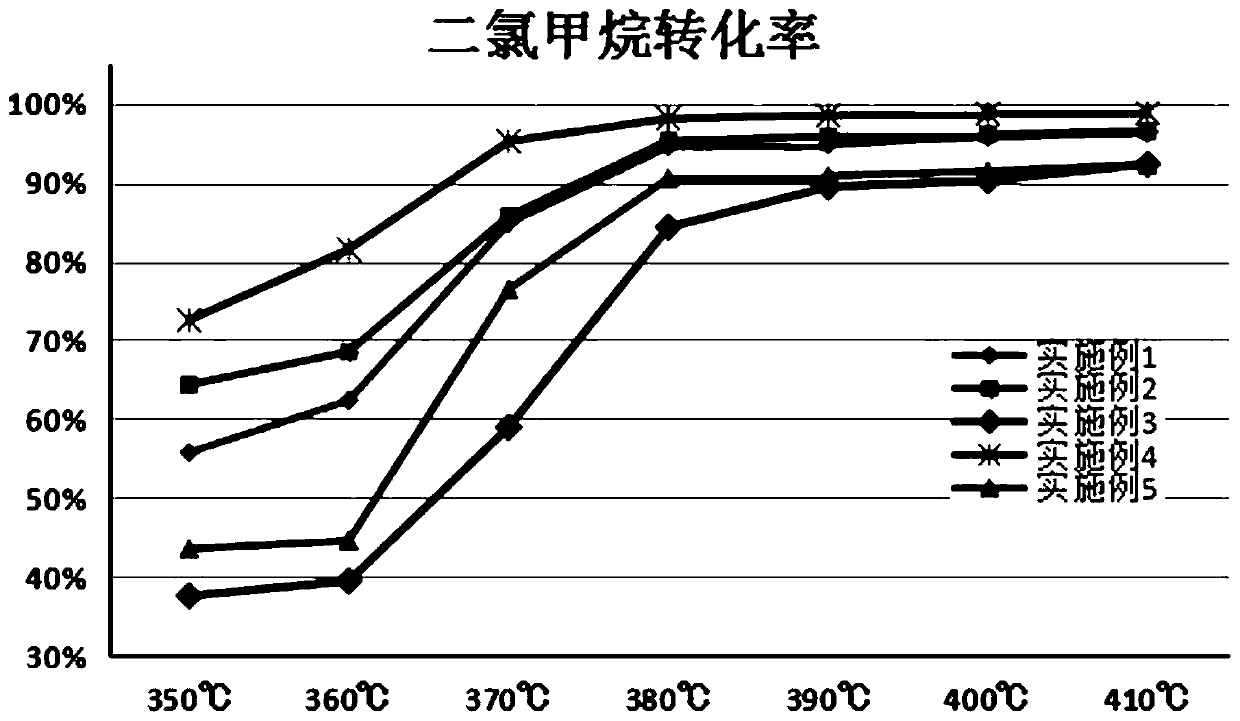

Dichloromethane catalyst and preparation method thereof

ActiveCN110280282AThe preparation method is simple and easySuitable for industrial mass production applicationsMolecular sieve catalystsHeterogenous catalyst chemical elementsDichloromethaneComposite oxide

The invention discloses a dichloromethane catalyst and a preparation method thereof. The dichloromethane catalyst comprises an alumina coating and a porous substrate; the surface of the porous substrate is coated with the alumina coating; a composite oxide precursor salt solution is impregnated on the porous substrate coated with the alumina coating, and then roasted to form the dichloromethane catalyst; the catalyst is prepared under normal pressure conditions; the solidly bonded alumina coating is prepared from alumina sol; composite oxide with catalytic activity can be formed through impregnating and then roasting the composite oxide precursor salt solution. The preparation method of a solution is simple, only needs the processes of impregnation and roasting, and is suitable for industrial large-scale production and application; the composite oxide formed after roasting of the selected specific composite oxide precursor salt solution has excellent catalytic activity on dichloromethane, and the catalytic conversion rate at 380 DEG C can reach 95% or above.

Owner:湖南明瑞环保科技有限公司

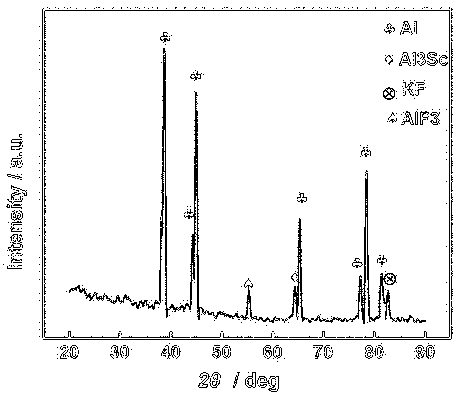

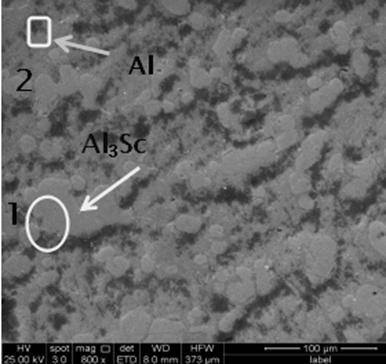

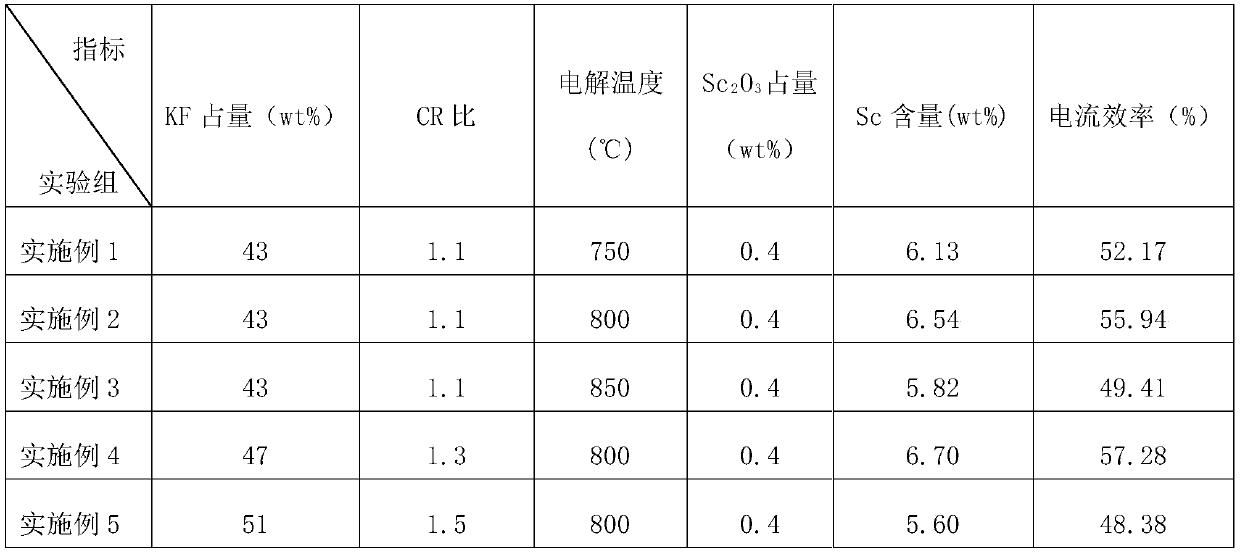

Method for preparing aluminum-scandium intermediate alloy by using elpasolite molten salt sinking cathode electrolysis

The invention discloses a method for preparing an aluminum-scandium intermediate alloy by using elpasolite molten salt sinking cathode electrolysis. The method comprises the following steps of (1), respectively weighing raw materials, specially, a K3AIF6 (KF and AIF3) ), a and an aluminum ingot; (2), putting the K3AIF6 in the step (1) into an electrolytic cell, and heating to increase temperature,adding the aluminum ingot after the K3AIF6 is completely molten, and adding and melting the Sc2O3 after the aluminum ingot is molten; (3), carrying out molten salt electrolysis, a cathode of the molten salt electrolysis is liquid aluminum, an anode is graphite, and sinking a prepared aluminum-scandium intermediate alloy to the bottom of the electrolytic cell. According to the method for preparingthe aluminum-scandium intermediate alloy, a potassium cryolite molten salt system (K3AIF6) is adopted, harmful gas cannot be generated, and the method is relatively environment-protecting; and the method adopts the cheap and easily-available Sc2O3 as an electrolysis raw material, the production cost can be greatly saved, the prepared aluminum-scandium intermediate alloy is sunk to the bottom of the molten salt, and the method is suitable for industrial mass production application.

Owner:GANZHOU FEITENG LIGHT ALLOY CO +1

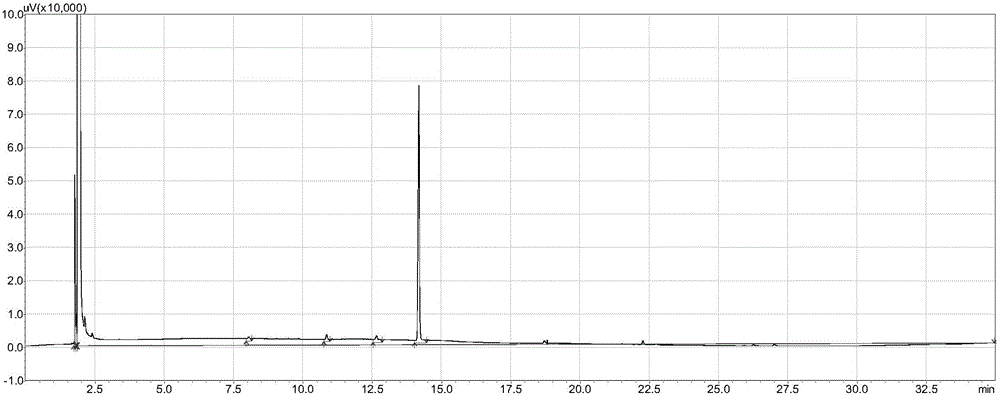

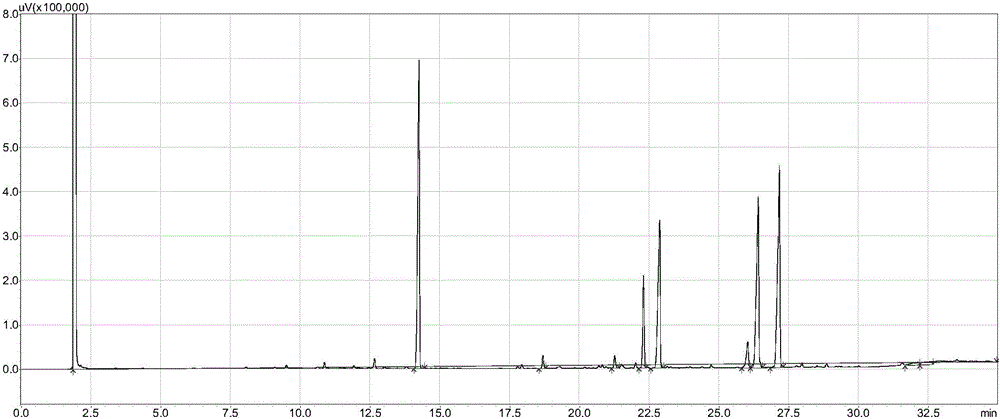

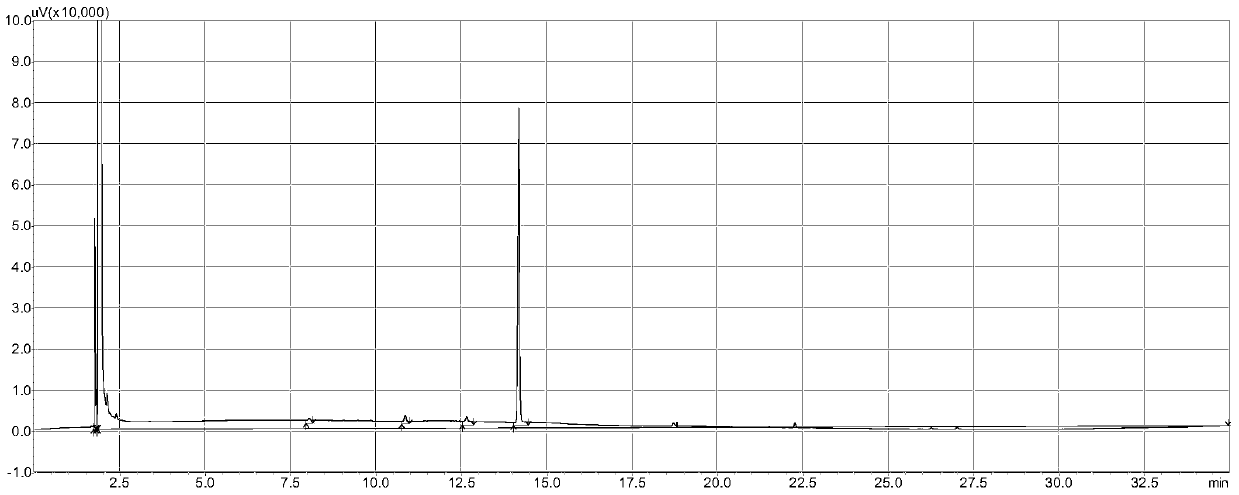

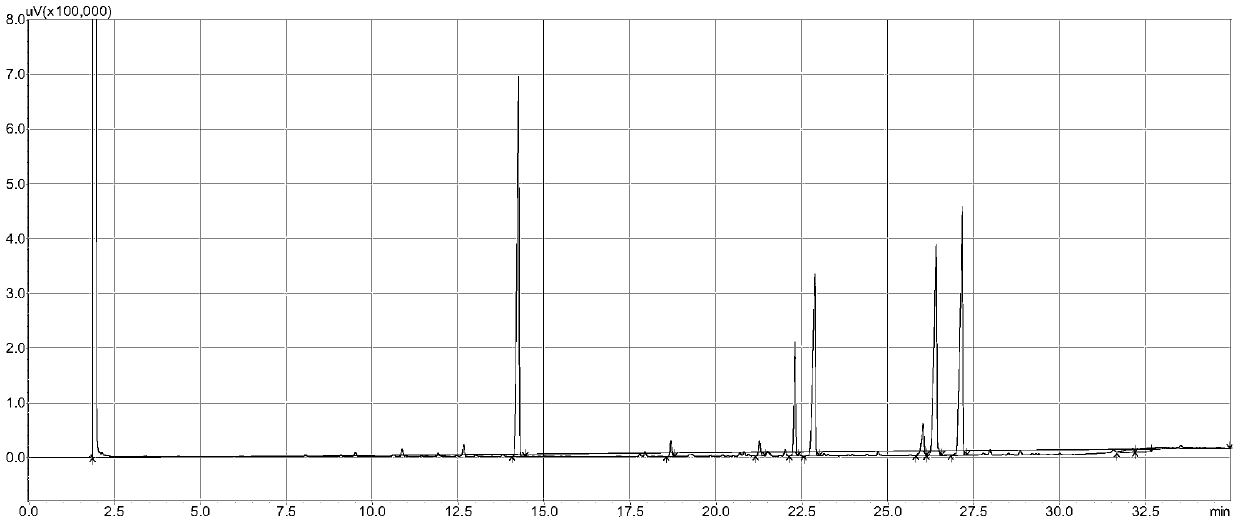

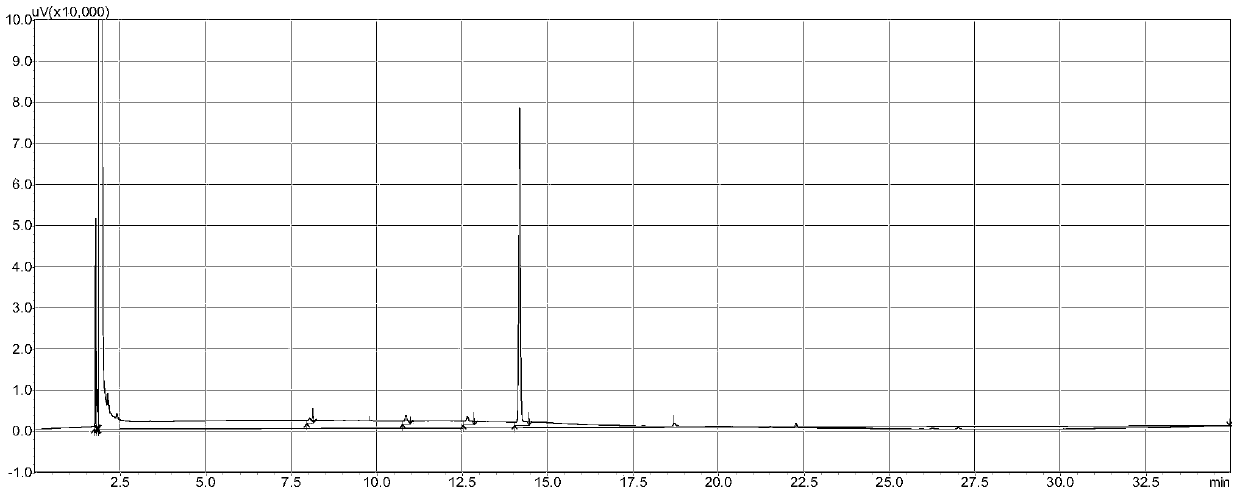

Synthesis method of 8-tert-butyl-2-chloromethyl-1, 4-dioxaspiro [4, 5] decane

InactiveCN111909127AReduce manufacturing costMild reaction conditionsOrganic chemistryCyclohexanoneSpirodecane

The invention discloses a synthesis method of 8-tert-butyl-2-chloromethyl-1, 4-dioxaspiro [4, 5] decane, and the method comprises the following steps: dissolving p-tert-butyl cyclohexanone and epoxy chloropropane in an aprotic solvent, and performing reacting under the catalytic action of Lewis acid to obtain the 8-tert-butyl-2-chloromethyl-1, 4-dioxaspiro [4, 5] decane. According to the method, epoxy chloropropane with lower price is used for replacing 3-chloro-glycerol in a conventional route, so the production cost of the product is reduced; the method has the advantages of mild reaction conditions, high reaction selectivity and few side reaction impurities, and the product can reach high purity and yield, so the method is suitable for large-scale industrial production and application.

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthesis method of 8-tert-butyl-2-chloromethyl-1, 4-dioxaspiro [4, 5] decane Synthesis method of 8-tert-butyl-2-chloromethyl-1, 4-dioxaspiro [4, 5] decane](https://images-eureka.patsnap.com/patent_img/d4161f80-5439-48d5-a1dd-21ebe561bd91/FDA0002051948830000011.png)

![Synthesis method of 8-tert-butyl-2-chloromethyl-1, 4-dioxaspiro [4, 5] decane Synthesis method of 8-tert-butyl-2-chloromethyl-1, 4-dioxaspiro [4, 5] decane](https://images-eureka.patsnap.com/patent_img/d4161f80-5439-48d5-a1dd-21ebe561bd91/BDA0002051948840000021.png)

![Synthesis method of 8-tert-butyl-2-chloromethyl-1, 4-dioxaspiro [4, 5] decane Synthesis method of 8-tert-butyl-2-chloromethyl-1, 4-dioxaspiro [4, 5] decane](https://images-eureka.patsnap.com/patent_img/d4161f80-5439-48d5-a1dd-21ebe561bd91/BDA0002051948840000031.png)