Extraction method of star anise oil

A technology of star anise oil and extraction method, which is applied in the directions of essential oils/spices, fat production, etc., which can solve the problems that are not suitable for large-scale industrial production, difficult to separate and purify, and have many impurities in the extract, so as to improve the yield and reduce the production cost , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

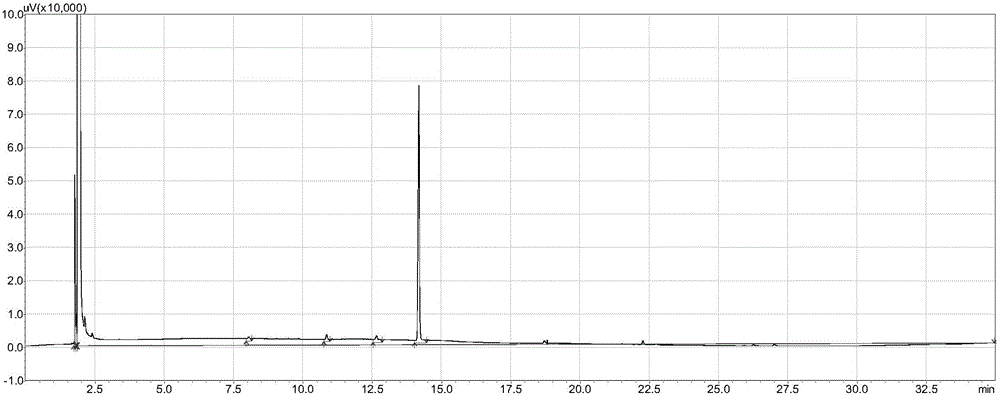

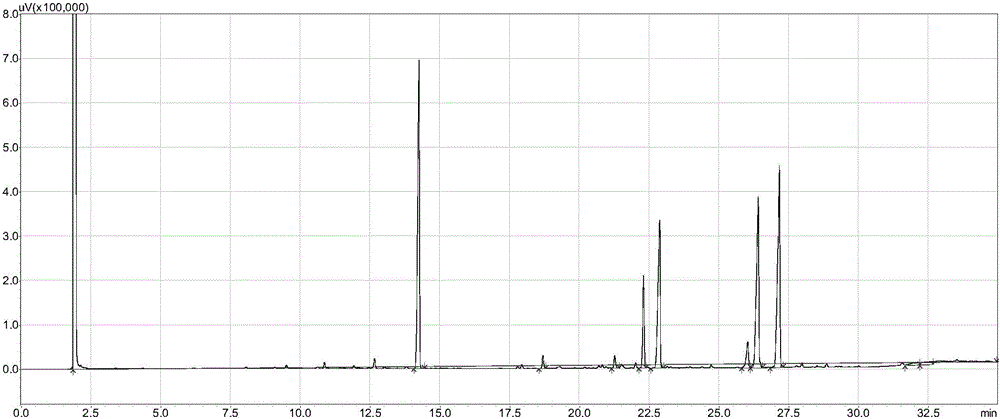

Embodiment 1

[0038] Take the star anise fruit, bake and dry until the water content is 2%, pass through a 60-mesh sieve after being crushed by a pulverizer, weigh 100g of star anise powder with an electronic scale, add 1200mL of water, mix the two, and place it in the steam receiver of the steam distillation device. Start distillation in the bottle, the distillation temperature is 80°C, the distillation time is 5h, remove the impurities in the distillation, collect the effluent, add analytically pure sodium chloride until white sodium chloride solid appears in the water phase, separate the oil and water, absorb In the upper oil layer, 5.74g of star anise essential oil was obtained, which was stored in a brown bottle for later use, and the yield was 5.74%. The water phase in the steam receiving bottle in the steam distillation device was discarded, and the residue in the lower layer was collected and directly poured into a tray for drying. Collect and dry the residue to obtain 71g, place it ...

Embodiment 2

[0040] Take the star anise fruit, bake and dry until the water content is 5%, pass through a 60-mesh sieve after being crushed by a pulverizer, weigh 200g of star anise powder with an electronic scale, add 2200mL of water, mix the two, and place it in the steam receiver of the steam distillation device. Start distillation in the bottle, the distillation temperature is 90°C, the distillation time is 3h, remove the impurities in the distillation, collect the effluent, add analytically pure sodium chloride until white sodium chloride solid appears in the water phase, separate the oil and water, absorb In the upper oil layer, 11.62g of star anise essential oil was obtained, which was stored in a brown bottle for later use, and the yield was 5.81%. The water phase in the steam receiving bottle in the steam distillation device was discarded, and the residue in the lower layer was collected and directly poured into a tray for drying. Collect and dry the residue to obtain 141g, place i...

Embodiment 3

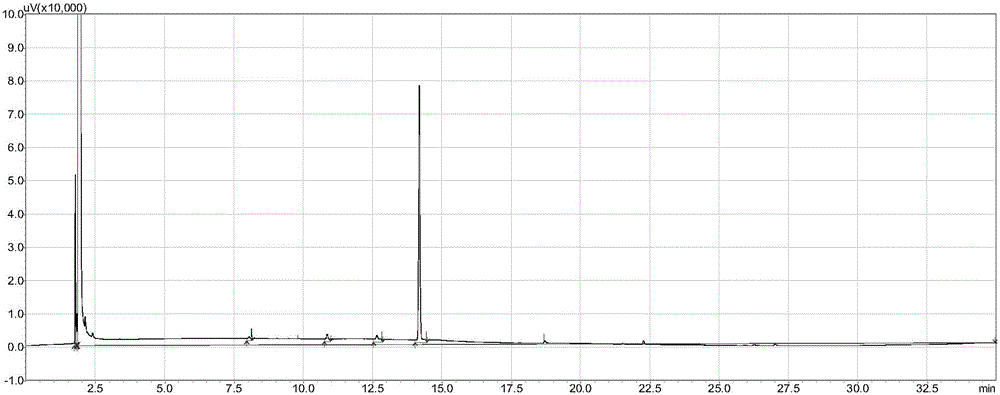

[0042]Take the star anise fruit, bake and dry until the water content is 4%, pass through a 60-mesh sieve after being crushed by a pulverizer, weigh 150g of star anise powder with an electronic scale, add 1500mL of water, mix the two, and place it in the steam receiver of the steam distillation device. Start distillation in the bottle, the distillation temperature is 105°C, and the distillation time is 4h. Remove the impurities in the distillation, collect the effluent, add analytically pure sodium chloride until white sodium chloride solid appears in the water phase, separate the oil and water, and absorb In the upper oil layer, 8.83g of star anise essential oil was obtained, which was stored in a brown bottle for later use, and the yield was 5.89%. The water phase in the steam receiving bottle in the steam distillation device was discarded, and the residue in the lower layer was collected and directly poured into a tray for drying. Collect and dry the residue to obtain 108g, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com