Waste flue gas denitration catalyst regeneration method and equipment

A technology for denitration catalyst and regeneration equipment, which is applied in catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc. To deep cleaning and other issues, to achieve the effect of reducing the amount of new water used, simple assembly, avoiding damage and changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

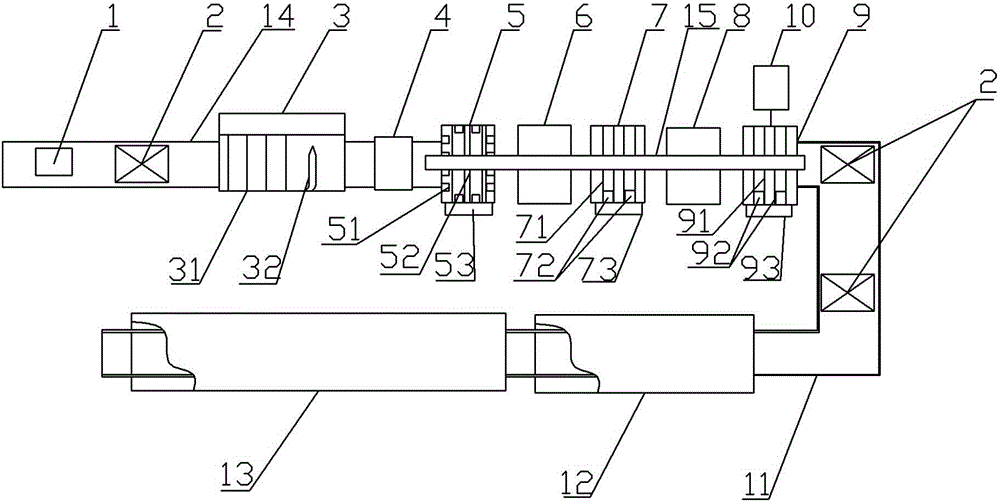

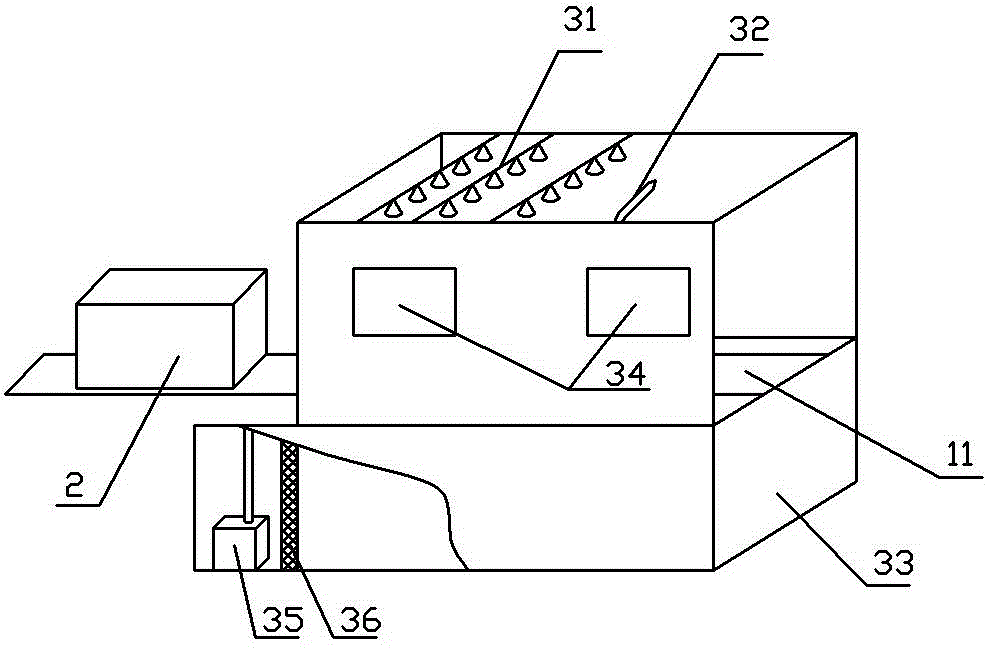

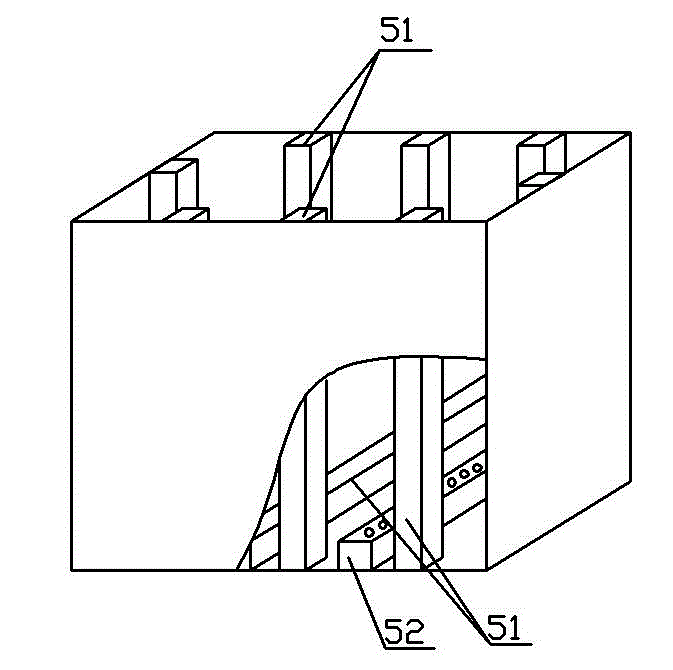

[0035] A waste flue gas denitrification catalyst regeneration equipment, such as Figure 1~3As shown, it includes crawler belt conveying device 14, spray cleaning device 3, ultrasonic cleaning tank 5, deionized water cleaning device 6, pickling tank 7, draining basket 8, activation tank 9, rail conveying device 11, tunnel type Drying furnace 12 and tunnel-type calciner 13, a hoisting adjustment area 4 is also provided between the spray cleaning device 3 and the ultrasonic cleaning tank, and a hoisting device 15 is provided between the end of the rail conveying device 14 and the front end of the rail conveying device 11. The device 11 passes through a tunnel drying furnace 12 and a tunnel calciner 13 .

[0036] A mobile vacuum cleaner 1 is arranged above the front section of the crawler conveyor 14, and the rear section of the crawler conveyor 14 passes through a spray cleaning device 3, and the spray cleaning device 3 includes a sprayer 31 and a high-pressure water gun located...

Embodiment 2

[0051] Adopt the equipment identical with embodiment 1 to carry out regeneration treatment to the SCR denitration catalyst module identical with embodiment 1 specification, comprise the following steps:

[0052] (1) Place the catalyst module 2 on the crawler belt conveyor, use the mobile industrial vacuum cleaner 1 to absorb and remove dust from the catalyst module 2 under negative pressure, and perform artificial through-holes and drilling to remove dust alternately to improve the effect of dust removal;

[0053] (2) Spray cleaning and high-pressure spray gun cleaning: move the catalyst module 2 after dust removal to the spray cleaning device 3 along the crawler conveyor device 14, and first use the cleaning liquid with a spray pressure of 1.3Mpa to pass through the spray cleaning device After the sprayer 31 of 3 cleans the catalyst module 2 on a large area for 5 minutes, then adopts the high-pressure spray gun 32 to manually clean the catalyst module 5 minutes on a point-to-p...

Embodiment 3

[0059] Adopt the equipment identical with embodiment 1 to carry out regeneration treatment to the SCR denitration catalyst module identical with embodiment 1 specification, comprise the following steps:

[0060] (1) Place the catalyst module 2 on the crawler belt conveyor, use the mobile industrial vacuum cleaner 1 to absorb and remove dust from the catalyst module 2 under negative pressure, and perform artificial through-holes and drilling to remove dust alternately to improve the effect of dust removal;

[0061] (2) Spray cleaning and high-pressure spray gun cleaning: move the catalyst module 2 after dust removal to the spray cleaning device 3 along the crawler conveyor device 14, and first use the cleaning liquid with a spray pressure of 0.5Mpa to pass through the spray cleaning device 3. After the sprayer 31 of 3 cleans the catalyst module in a large area for 40 minutes, then use the high-pressure spray gun 32 to manually clean the catalyst module for 40 minutes. The weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com