Explosive, and preparation method and application thereof

A technology of explosives and weight percentage, applied in the direction of explosives, non-explosive/non-thermal agent components, non-explosive desensitizers/passivators, etc., can solve the problem of incompatibility between energy performance and low vulnerability performance, detonation velocity reduction, explosive machinery Low sensitivity and other issues, to achieve the effects of large-scale industrial production and application, low detonation velocity, improved stuttering performance and flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

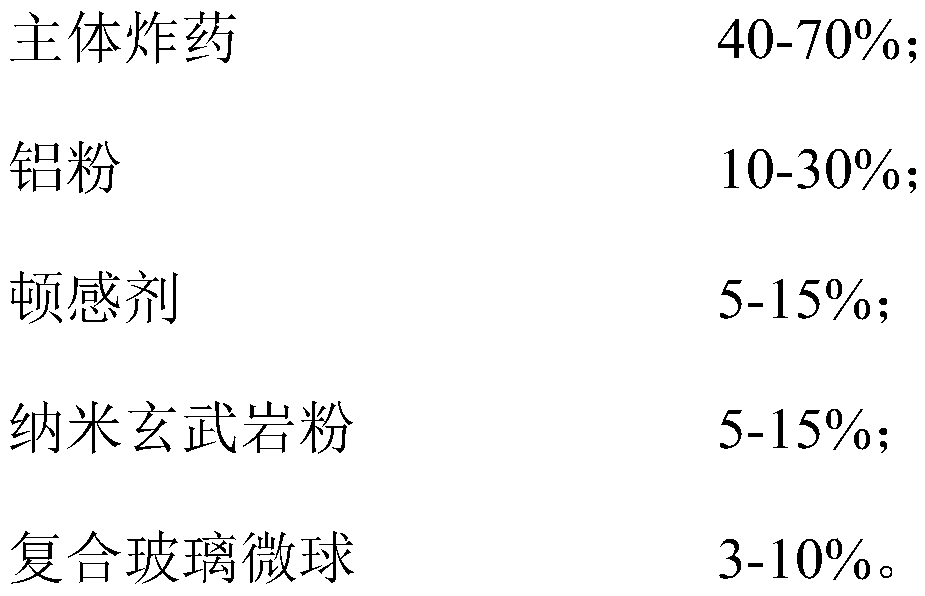

[0054] This embodiment provides a kind of explosive, and described explosive comprises the following components by weight percentage:

[0055]

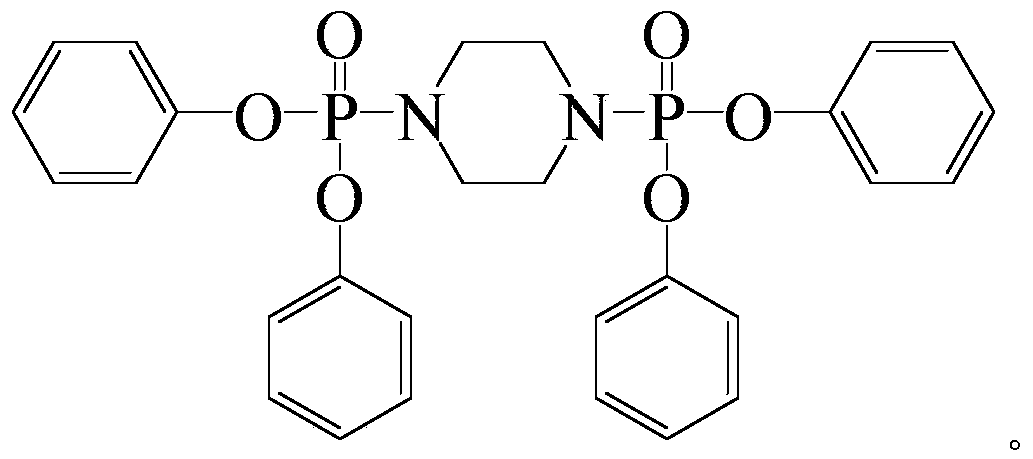

[0056] Among them, the main explosive is N,N'-bis(fluoro-dinitroethyl)-3,4-dinitrate ammonium furazan; the mesh number of aluminum powder is 500 mesh; the shock agent is stearic acid and polyethylene A combination of waxes, the mass ratio of the two is 3:1; the particle size of the nano-basalt powder is 50nm; the composite glass microspheres include silica and composite fibers coated inside the silica, and the composite fibers include hollow cores Aluminum fiber and the flame retardant inside the hollow aluminum fiber, the flame retardant has the following structure:

[0057]

[0058] This embodiment also provides a preparation method of explosives, the preparation method comprising the steps of:

[0059] (1) Mix the main explosive and the shock agent in ethanol at a temperature of 30°C for 20 minutes to obtain a diluent;

[0...

Embodiment 2

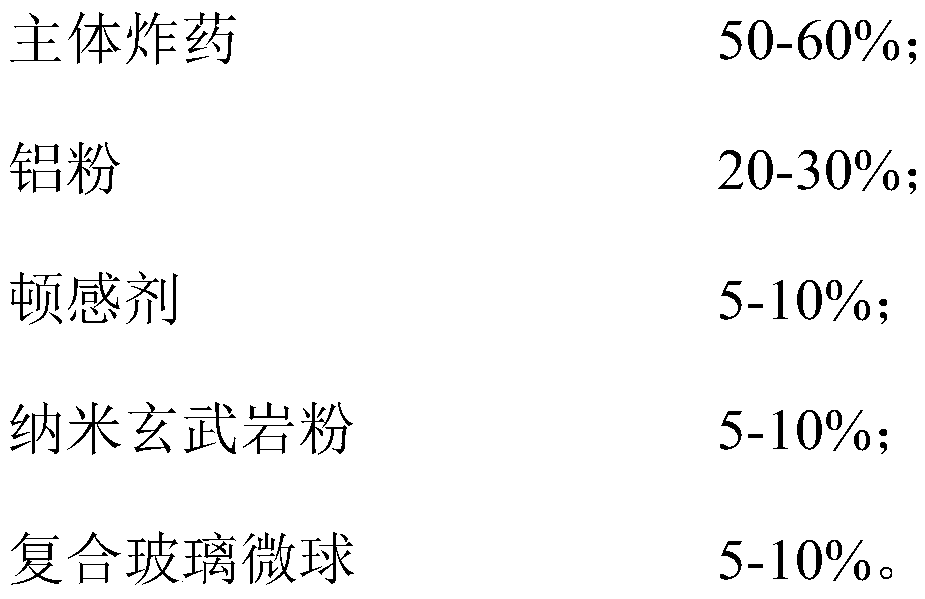

[0063] This embodiment provides a kind of explosive, and described explosive comprises the following components by weight percentage:

[0064]

[0065] Among them, the main explosive is N,N'-bis(fluoro-dinitroethyl)-3,4-dinitrate ammonium furazan; the mesh number of aluminum powder is 100 mesh; the shock agent is stearic acid and polyethylene The combination of waxes, the mass ratio of the two is 1:1; the particle size of nano basalt powder is 100nm; the composite glass microspheres include silica and composite fibers coated inside the silica, and the composite fibers include hollow cores Aluminum fiber and the fire retardant inside the hollow aluminum fiber, the structure of the fire retardant is the same as in Example 1.

[0066] This embodiment also provides a preparation method of explosives, the preparation method comprising the steps of:

[0067] (1) Mix the main explosive and the shock agent in ethanol at a temperature of 10°C for 30 minutes to obtain a diluent;

...

Embodiment 3

[0071] This embodiment provides a kind of explosive, and described explosive comprises the following components by weight percentage:

[0072]

[0073] Among them, the main explosive is N,N'-bis(fluoro-gem-dinitroethyl)-3,4-dinitrate ammonium furazan; the mesh number of aluminum powder is 1000 mesh; the shock agent is stearic acid and polyethylene The combination of waxes, the mass ratio of the two is 5:1; the particle size of nano basalt powder is 10nm; the composite glass microspheres include silica and composite fibers coated inside the silica, and the composite fibers include hollow cores Aluminum fiber and the fire retardant inside the hollow aluminum fiber, the structure of the fire retardant is the same as in Example 1.

[0074] This embodiment also provides a preparation method of explosives, the preparation method comprising the steps of:

[0075] (1) Mix the main explosive and the shock agent in ethanol at a temperature of 40°C for 10 minutes to obtain a diluent;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com