Coating, preparation method and application thereof

A technology of paint and odor-cleaning emulsion, applied in the direction of coating, etc., can solve the problems of low odor and VOC of interior wall colored sand paint, undisclosed taste of imitation stone paint of interior wall, reduce VOC content and odor, etc., to increase appearance performance and processability, increase the film-forming effect, and the effect of low VOC content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

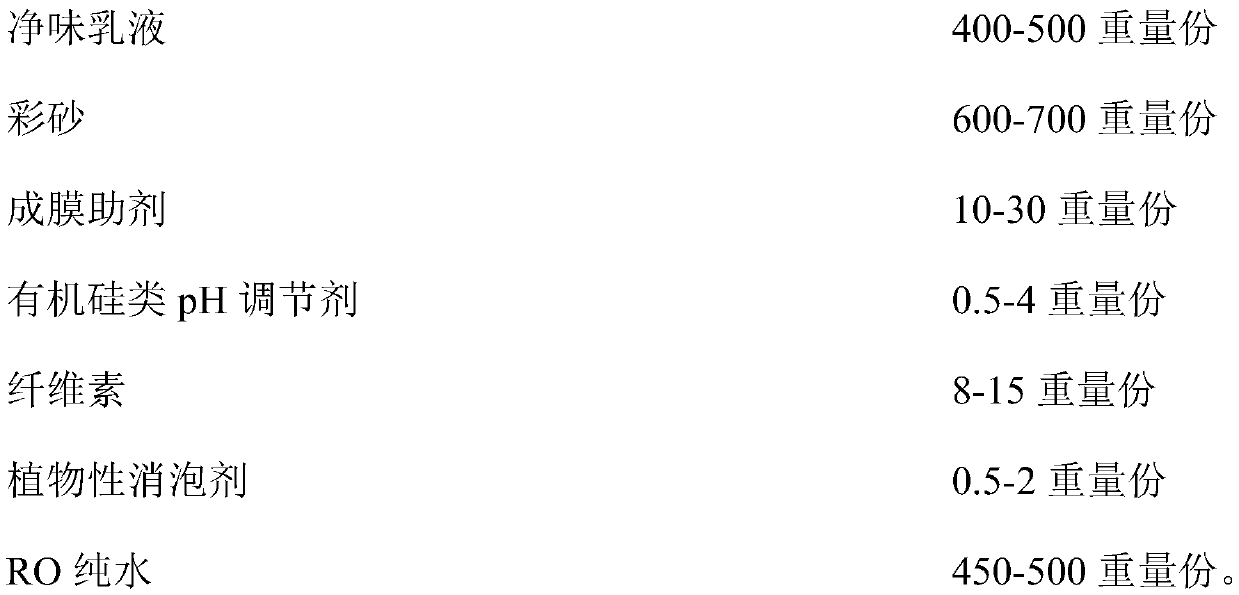

[0065] The present embodiment provides a kind of coating, and described coating comprises following components by weight:

[0066]

[0067] The odor-cleaning emulsion is ECO338, the film-forming aid is OE300, the organic silicon pH regulator is BS198, the vegetable defoamer is San Nopco 5000v defoamer, and the cellulose is hypromellose The combination of methyl cellulose and hydroxyethyl cellulose, the mass ratio of hydroxypropyl methyl cellulose and hydroxyethyl cellulose is 2:1, the colored sand is artificial colored sand, and the mesh number of artificial colored sand is 30 The antifreeze is FT100.

[0068] Described preparation method comprises the steps:

[0069] (1) Mix RO water, plant-type defoamer, preservative, fungicide and antifreeze at a stirring rate of 450rpm to obtain mixture A;

[0070] (2) Dissolving the cellulose in the film-forming aid to obtain a solution, and then adding the obtained solution to the mixture A obtained in step (1), and mixing at a stir...

Embodiment 2

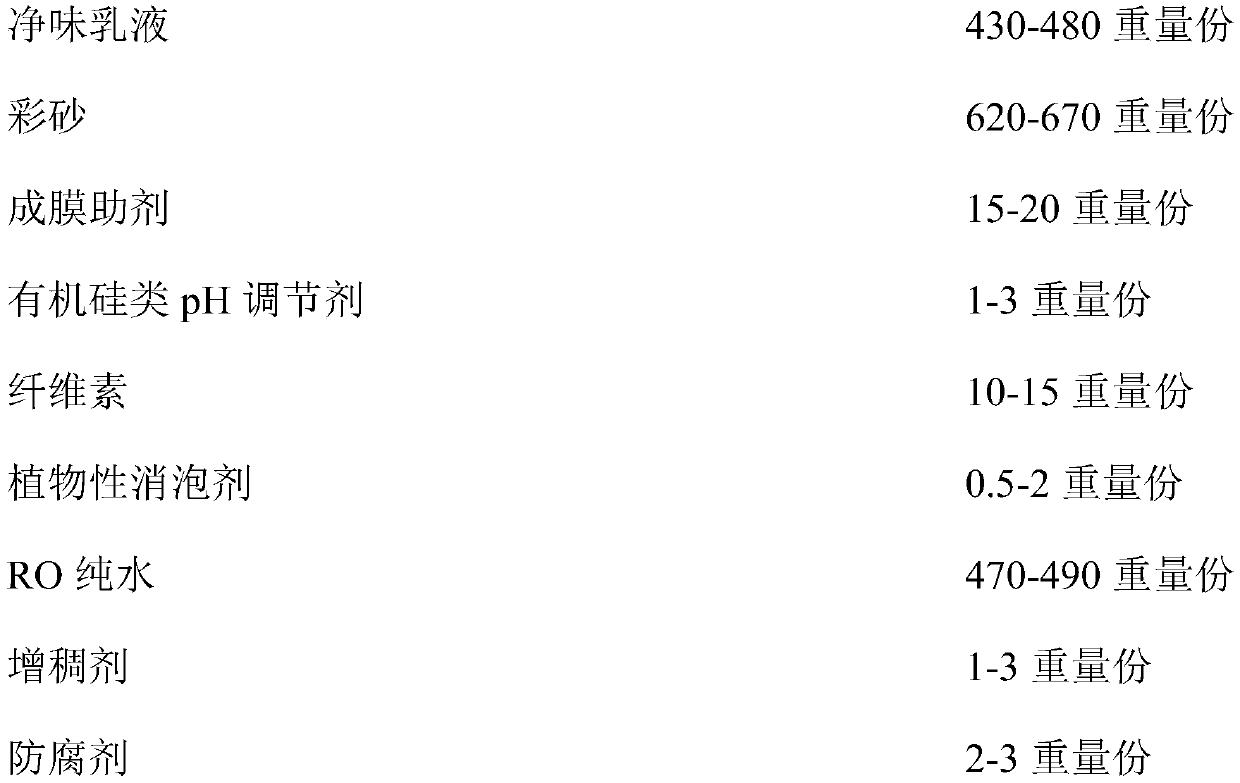

[0074] The present embodiment provides a kind of coating, and described coating comprises following components by weight:

[0075]

[0076]

[0077] The odor-cleaning emulsion is RS-959JW, the film-forming aid is OE300, the organic silicon pH regulator is BS198, the vegetable defoamer is San Nopco 1230v defoamer, and the cellulose is hydroxypropyl The combination of methyl cellulose and hydroxyethyl cellulose, the mass ratio of hydroxypropyl methyl cellulose and hydroxyethyl cellulose is 1:1, the colored sand is artificial colored sand, and the mesh number of artificial colored sand is It is 16 mesh, and the antifreeze is FT100.

[0078] Described preparation method comprises the steps:

[0079] (1) Mix RO water, plant-type defoamer, preservative, fungicide and antifreeze at a stirring rate of 400rpm to obtain mixture A;

[0080] (2) Dissolving the cellulose in the film-forming aid to obtain a solution, and then adding the obtained solution to the mixture A obtained in...

Embodiment 3

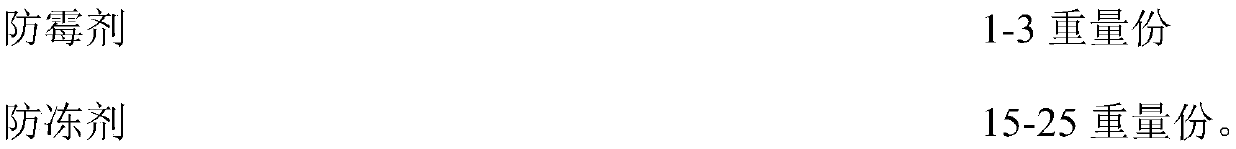

[0084] The present embodiment provides a kind of coating, and described coating comprises following components by weight:

[0085]

[0086]

[0087] The odor-cleaning emulsion is RS-959JW, the film-forming aid is OE300, the organic silicon pH regulator is BS198, the vegetable defoamer is San Nopco 1230v defoamer, and the cellulose is hydroxypropyl The combination of methyl cellulose and hydroxyethyl cellulose, the mass ratio of hydroxypropyl methyl cellulose and hydroxyethyl cellulose is 3:1, the colored sand is artificial colored sand, and the mesh number of artificial colored sand is It is 40 mesh, and the antifreeze is FT100.

[0088] Described preparation method comprises the steps:

[0089] (1) Mix RO water, plant-type defoamer, preservative, fungicide and antifreeze at a stirring rate of 500rpm to obtain mixture A;

[0090] (2) Dissolving the cellulose in the film-forming aid to obtain a solution, and then adding the obtained solution to the mixture A obtained in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com