Dichloromethane catalyst and preparation method thereof

A dichloromethane and catalyst technology, applied in the field of dichloromethane catalyst and preparation thereof, can solve the problems of long time consumption, high condition requirements and high cost, and achieve the effects of low cost, simple preparation method and excellent catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

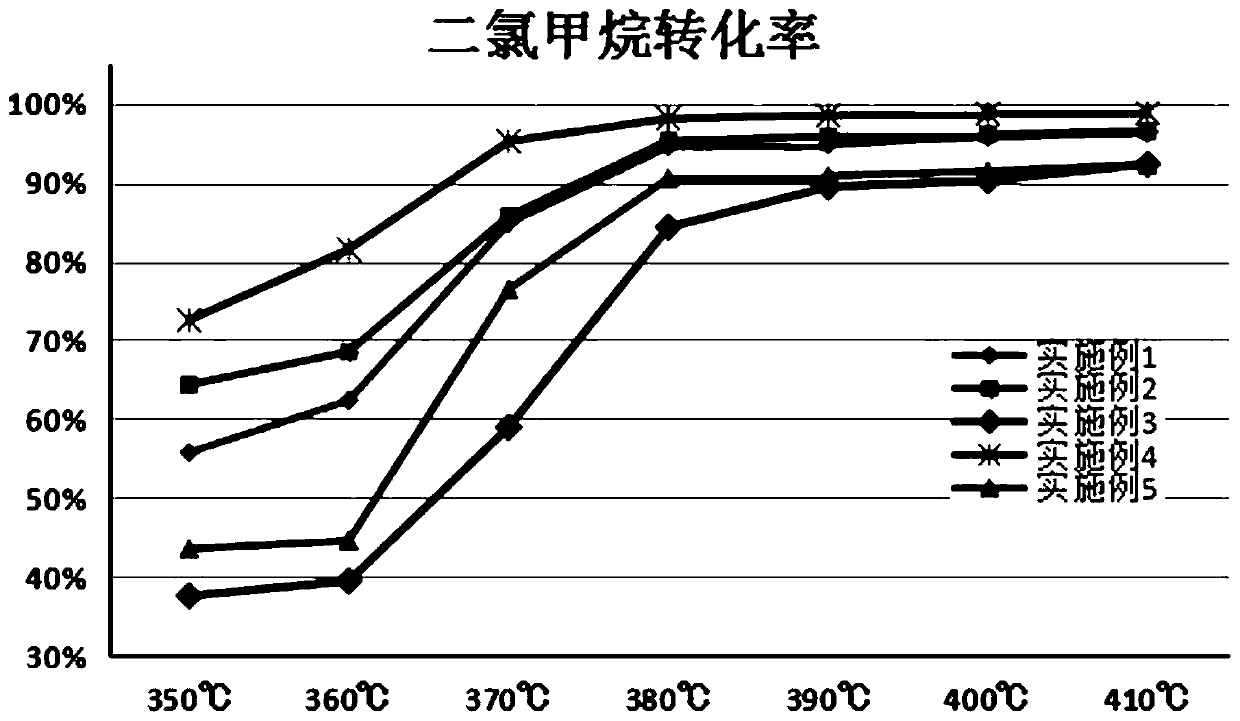

Examples

preparation example Construction

[0030] For realizing above-mentioned object, the present invention also provides a kind of preparation method of dichloromethane catalyst, comprises the following steps:

[0031] Step 1, preparation of transparent aluminum sol; prepare 5-25wt% pseudo-boehmite solution, add HNO3 to adjust pH=2-4, continue stirring and dissolving for 1-3 hours to obtain transparent aluminum sol; or prepare aluminum hydroxide React with phosphoric acid aqueous solution in an oil bath at 70-90°C for 1-3h under stirring. As the reaction proceeds, a transparent sol is gradually obtained from the turbid solution; the mass fraction of the phosphoric acid aqueous solution is 30-65wt%, hydrogen The molar ratio of alumina to phosphoric acid molecules = 1: (1-5); the oil bath here is a heating method, which conducts heat through heat conduction oil, that is, the condition of 70-90 ° C is that the container containing the solution is placed in the oil bath The pot is realized by oil heat conduction; if the...

Embodiment 1

[0042] 1) Weigh 7.5g pseudo-boehmite, add 45g water, add HNO while stirring 3 Adjust pH=3, add 3.5g alumina powder and continue stirring for 3h.

[0043] 2) Take 25cm 3 Cordierite honeycomb ceramics were soaked in the above solution for 5 minutes, then taken out, blown off the excess liquid with an air gun, and baked in a muffle furnace at 450°C for 3 hours.

[0044] 3) Weigh 0.3g of phosphomolybdic acid and 3.0g of chromium nitrate respectively, add them into 75g of water, stir and dissolve for 1 hour.

[0045] 4) Immerse the honeycomb ceramic obtained in 2) into the solution for 5 minutes, take it out, blow off excess liquid with an air gun, put it into a muffle furnace and bake at 500° C. for 3 hours to obtain a molded catalyst.

Embodiment 2

[0047] 1) Weigh 5.5g pseudo-boehmite, add 45g water, add HNO while stirring 3 Adjust pH=3, add 4.5g alumina powder and continue stirring for 3h.

[0048] 2) Take 25cm 3 Cordierite honeycomb ceramics were soaked in the above solution for 5 minutes, then taken out, blown off the excess liquid with an air gun, and baked in a muffle furnace at 450°C for 3 hours.

[0049] 3) Weigh 0.6g of sodium tungstate, 2.5g of chromium nitrate, and 0.3g of chromium oxide respectively, add them into 65g of water, stir and dissolve for 1 hour.

[0050] 4) Immerse the honeycomb ceramic obtained in 2) into the solution for 5 minutes, take it out, blow off excess liquid with an air gun, put it into a muffle furnace and bake at 500° C. for 3 hours to obtain a molded catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com