Method for producing iron-containing slag and high zinc materials through cloth bag dedusting ash

A technology of bag dust removal and high zinc, which is applied in the direction of improving process efficiency, etc., can solve the problems of insufficient recycling of bag dust removal, cumbersome, long process flow of recycling methods, etc., to achieve significant social benefits, simplify processes, and reduce forecasts. The effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

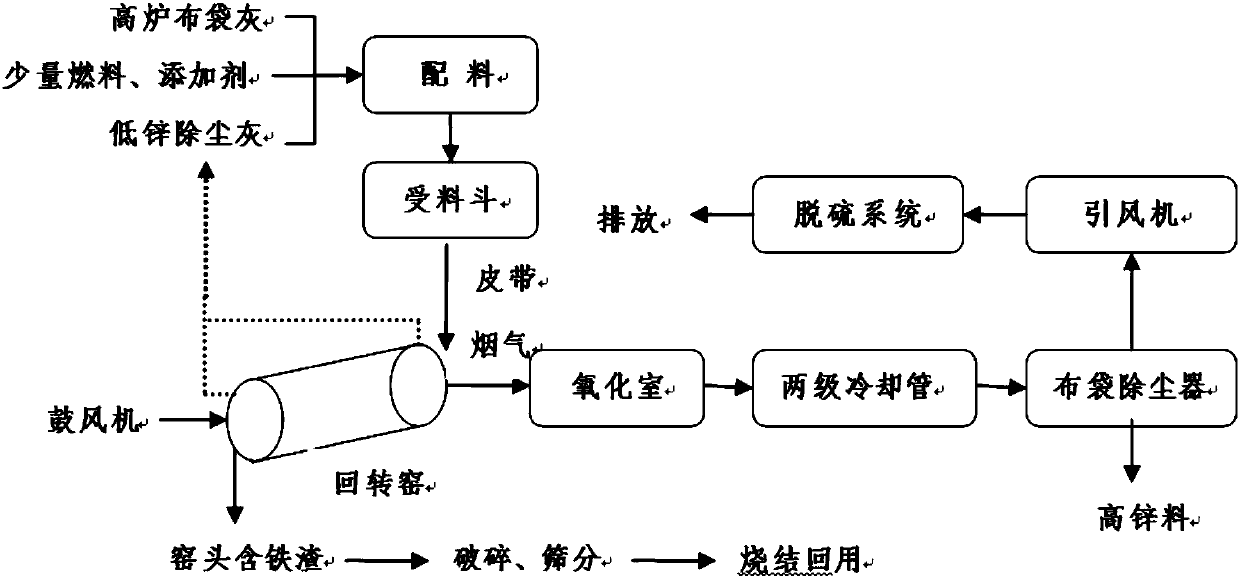

Image

Examples

Embodiment 1

[0043] The length of the rotary kiln used in this embodiment is 38 meters, and the diameter is 2.5m. The rotating speed is adjusted according to the output, and the reaction time of the control charge in the rotary kiln is about 3-4h;

[0044] Mix 85% blast furnace dry bag ash, 10% additives, 3% coke powder and 2% low-zinc dedusting powder evenly, and enter the rotary kiln from the tail of the rotary kiln through the receiving hopper and belt conveyor, and the kiln head is driven by a blower at high speed Air is blown in, the mixture is burned in the rotary kiln, and the average temperature reaches 1230°C, so that the zinc oxide in the bag ash is reduced and enters the flue gas. Lead out to the two-stage cooling pipe, collect the high-zinc material through the bag filter, and the flue gas after the bag filter is desulfurized and then discharged into the atmosphere. The iron-containing slag after the combustion reaction is discharged from the kiln head, and the discharged iron-...

Embodiment 2

[0057] The rotary kiln used in the present embodiment is identical with embodiment 1;

[0058] Mix 87% of blast furnace dry bag ash, 6% of additives, 4% of coke powder and 3% of low-zinc dust removal powder, and enter the rotary kiln from the tail of the rotary kiln through the receiving hopper and belt conveyor, and the kiln head is driven by a blower at high speed The air is blown in, the mixture is burned in the rotary kiln, and the average temperature reaches 1250°C, so that the zinc oxide in the bag ash is reduced and enters the flue gas. Lead out to the two-stage cooling pipe, collect the high-zinc material through the bag filter, and the flue gas after the bag filter is desulfurized and then discharged into the atmosphere. The iron-containing slag after the combustion reaction is discharged from the kiln head, and the discharged iron-containing slag is treated by water quenching, and the treated iron-containing slag is crushed and screened before being used for sinterin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com