Composite silica gel column and pretreatment method for analyzing organic pollutants in samples

A composite silica gel column and organic pollutant technology, which is applied in the direction of analyzing materials, material separation, measuring devices, etc., can solve the problems of difficult and time-consuming and labor-intensive analysis of multiple types of pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

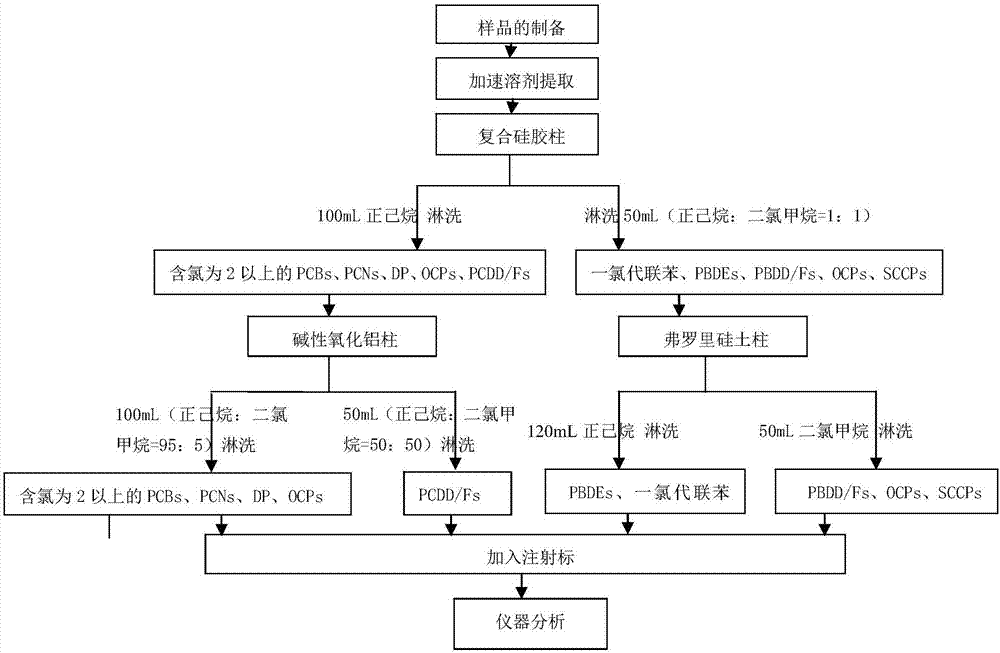

Method used

Image

Examples

Embodiment 1

[0100] Extraction of samples

[0101] After the dried sediment (sample) is picked out of the stones or plant components, it is ground in a porcelain mortar until it becomes a uniform powder. Estimate the degree of pollution and weigh an appropriate amount of sample, generally not less than 1g. For samples with high concentration, use the extract to reduce weighing errors. Biological samples should be recorded in wet and dry weight to calculate moisture content and determine fat content for normalization of data.

[0102] Take an appropriate amount of ground sample and add 13 C-labeled isotope internal standard, mix well, then add anhydrous sodium sulfate to mix, equilibrate for 12h, carry out accelerated solvent extraction (ASE, ASE300, Dionex, USA) with n-hexane and dichloromethane mixed solvent (volume ratio 1:1) ), the temperature is 100℃, the pressure is 1.03×10 7 Pa, the static extraction time is 5min, and the cycle is 3 times), the extract is rotary evaporated to 1-2m...

Embodiment 2

[0104] Environmental samples for pretreatment of sediment

[0105] Sediment: Before analysis, freeze-dry the sediment sample with a freeze dryer for at least 48 hours, grind it through an 80-mesh sieve, and store it in the dark until the analysis of persistent organic matter.

[0106] Take an appropriate amount of ground sample and add 13C-labeled isotope internal standard, mix well, then add anhydrous sodium sulfate to mix, equilibrate for 12h, carry out accelerated solvent extraction (ASE, ASE300, Dionex, USA) with n-hexane and dichloromethane mixed solvent (volume ratio 1:1) ), the temperature is 100℃, the pressure is 1.03×10 7 Pa, the static extraction time is 5min, and the cycle is 3 times), the extract is rotary evaporated to 1-2mL, and the sample to be tested is purified.

[0107] During the purification process of the sediment extract, if the sulfur content is high (generally the color is yellow), the sulfur-containing fraction can be concentrated to 1-2mL, and the a...

Embodiment 3

[0109] Pretreatment of environmental samples as biological samples

[0110] Biological sample pretreatment: Rinse with ultrapure water, put it into a homogenizer for high-speed homogenization, put it in a stainless steel box covered with aluminum foil paper after it becomes a paste, put it in the refrigerator to freeze and then freeze and dry for at least 48 hours , Grind to sample particle size <1mm.

[0111] Take 2g sample and add 13 C-labeled isotope internal standard, mix well, then add 2g of anhydrous sodium sulfate to mix, equilibrate for 12h, carry out accelerated solvent extraction (ASE, ASE300, Dionex, USA, temperature is 100°C, pressure is 1.03×10 7 Pa, static extraction time is 5min, cycled 3 times), transfer the extract and rotary evaporate to 1-2mL, load the sample on the column head, and elute with 100mL (n-hexane:dichloromethane=1:1).

[0112] Choose the step of removing fat according to the situation. The filling method of the acidic silica gel column (ie t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com