Sulfur-containing methane directly for reactive absorption enhancement on hydrogen production method from methane steam reformation

A methane water vapor and absorption enhancement technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of consuming large equipment, manpower and energy resources, and achieve the goal of reducing the pretreatment process, reducing emissions, and shortening the process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

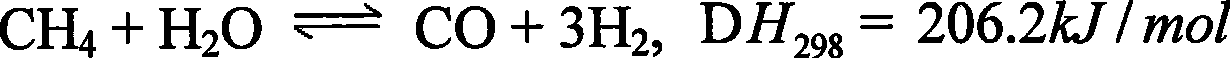

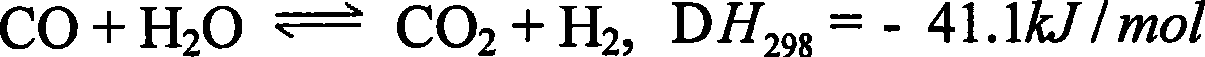

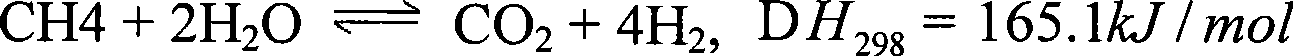

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Preparation of composite catalyst RSER-1, the weight percentage of each component is NiO 20%, CaO 30%, Al 2 o 3 50%. Get 5g composite catalyst, pack in the fixed-bed reactor, heat up and CaCO 3 Decomposed into the active absorption component CaO, and with H 2 reduction. At a reaction temperature of 600°C and normal pressure, water vapor and methane containing 200ppm of hydrogen sulfide are introduced, the molar ratio of water to carbon is 4, and the product gas is condensed to remove water vapor, and the gas composition is analyzed online by gas chromatography to be 96.3% hydrogen, CO 2 2.0%, methane conversion rate 87.0%.

Embodiment 2

[0047] Preparation of composite catalyst RSER-2, the weight percentage of each component is NiO 15%, CaO 25%, Al 2 o 3 37%, SiO 2 twenty three%. Get 5g composite catalyst, pack in the fixed-bed reactor, heat up and CaCO 3 Decomposed into the active absorption component CaO, and with H 2reduction. At a reaction temperature of 600°C and a pressure of 0.2 MPa, water vapor and methane containing 200 ppm of hydrogen sulfide are introduced, the molar ratio of water to carbon is 4, and the product gas is condensed to remove water vapor, and the gas composition obtained by online analysis with a gas chromatograph is hydrogen 94.4 %, the conversion rate of methane is 80.9%.

Embodiment 3

[0049] Preparation of composite catalyst RSER-3, the weight percentage of each component is NiO 30%, CaO 32%, Al 2 o 3 33%. ZnO 5%, get 5g composite catalyst, pack in the fixed-bed reactor, heat up CaCO 3 Decomposed into the active absorption component CaO, and with H 2 reduction. At a reaction temperature of 600°C and a pressure of 0.2 MPa, water vapor and methane containing 200 ppm of hydrogen sulfide are introduced, the molar ratio of water to carbon is 5, and the product gas is condensed to remove water vapor, and the gas composition obtained by online analysis with a gas chromatograph is hydrogen 96.9 %, the conversion rate of methane is 88.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com