Amphipathic high-molecular polymer, and preparation method and application thereof

An amphiphilic polymer and polymer technology, which is applied in the field of amphiphilic polymer and its preparation, can solve the problems of many types of chemical reagents, complicated operation steps, inconvenient operation, etc., and achieves low cytotoxicity and low cost. Inexpensive and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

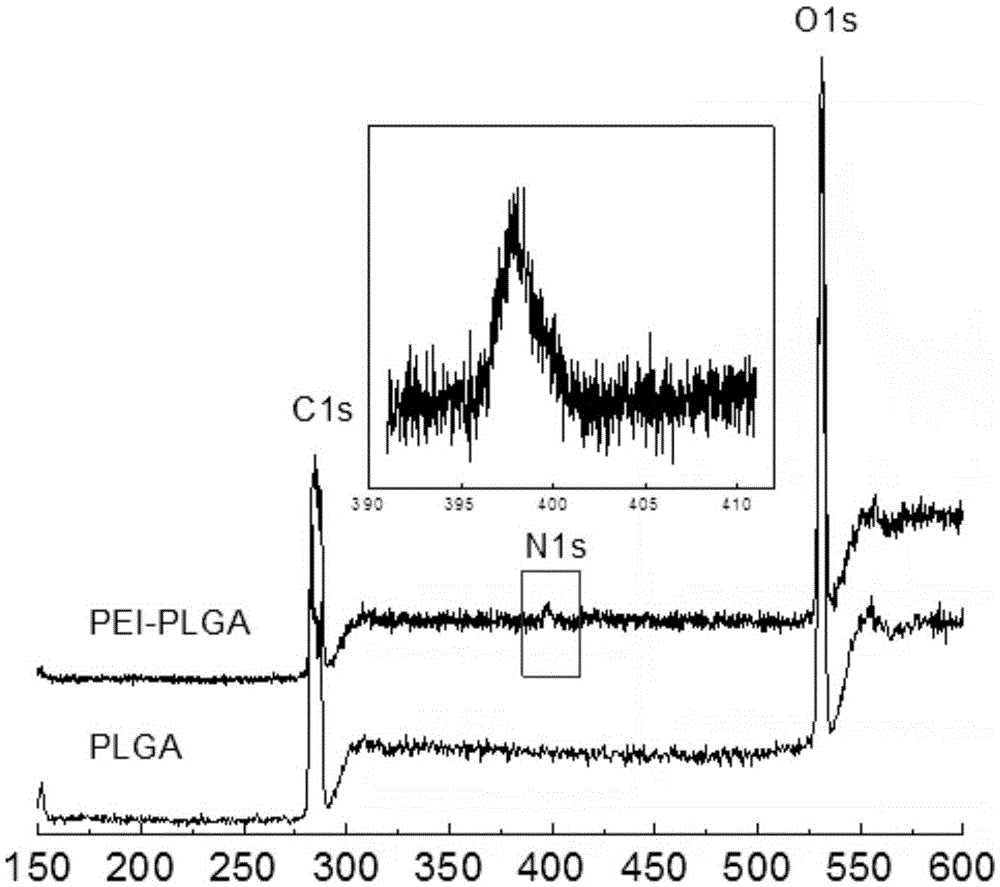

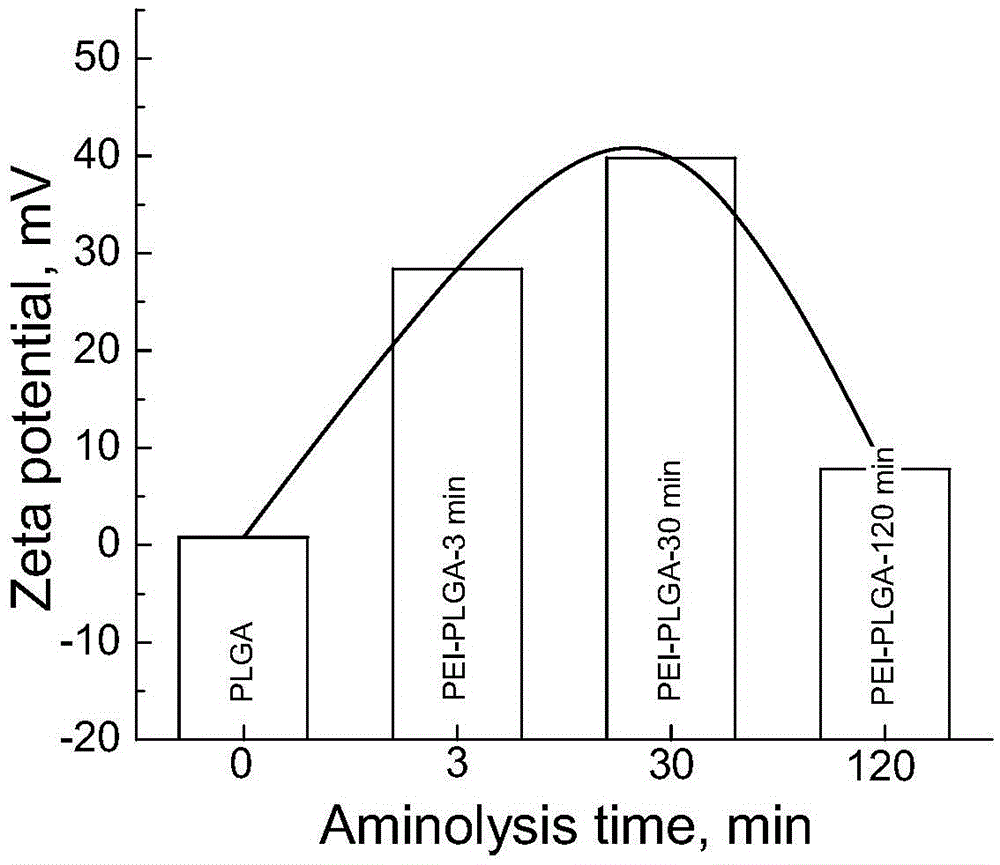

[0039] The synthetic method of polylactic acid-glycolic acid-polyethyleneimine (PEI-PLGA) amphiphilic polymer: Polylactic acid-glycolic acid (PLGA, Mw is about 80,000) is dissolved in anhydrous tetrahydrofuran and added to polyethylene In the isopropanol solution of imine (PEI, Mw about 2000), the two are mixed according to the repeating unit lactic acid (or glycolic acid): ethyleneimine molar ratio of 20:1, and react at a constant temperature of 60°C for 5 minutes to obtain The polymer solution was dialyzed in water, and unreacted small molecules were removed by dialysis with a dialysis membrane with a molecular weight cut-off of 10,000. After lyophilization, a white solid product was obtained for subsequent detection and characterization. figure 1 Be the XPS spectrogram of PEI-PLGA of the present embodiment and PLGA, by figure 1 It can be seen that the appearance of the N peak in the PEI-PLGA polymer is due to the introduction of PEI into the polylactic acid-glycolic acid (P...

Embodiment 2

[0042] The reaction was performed at a constant temperature of 60° C. for 10 minutes, and the other operating steps were the same as in Example 1.

Embodiment 3

[0044] The reaction was performed at a constant temperature of 60° C. for 20 minutes, and the other operating steps were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com