Super-pure carbon aerogel with superhigh specific surface area based on carbon dioxide activating and pore forming and preparation method thereof

A carbon airgel and pore-making technology, applied in the field of airgel, can solve the problems of increased cost and waste of raw materials, and the specific surface area of carbon airgel is not high, so as to avoid high cost and danger, optimize the characteristics of specific surface area and Microscopic pore characteristics, effect of increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] The present invention also provides a kind of preparation method of carbon airgel, comprising the following steps:

[0075] 1) After mixing phenolic compounds, aldehyde compounds, organic basic catalysts and solvents, aging under airtight conditions to obtain solid products;

[0076] 2) drying the solid product obtained in the above steps to obtain a phenolic polymer;

[0077] 3) After the organogel obtained in the above steps is subjected to carbonization treatment and activated pore-forming, carbon airgel is obtained;

[0078] The carbonization treatment and activation pore formation include carbonization treatment followed by activation pore formation, or activation pore formation while carbonization treatment is performed.

[0079] The selection, ratio and parameters of raw materials or products in the above-mentioned preparation method of the present invention, as well as the corresponding optimization principles, etc., unless otherwise specified, are the same as ...

Embodiment 1

[0107] Slowly add 0.3g of resorcinol into 2.7mL of formaldehyde solution, stir at room temperature for 10min, then add 0.005g of hexamethylenetetramine, pour into 20mL of ethanol solution at the same time, and stir evenly. Then the obtained solution was sealed and placed in an oven at 80° C. for 3 days of heat preservation and aging. The aged phenolic gel polymer was taken out and placed in the air for natural drying for 5 hours. Then the phenolic gel was dried in an oven at 80 °C for 2 days. The completely dried phenolic gel was carbonized in a high-temperature furnace filled with argon at 700°C for 4 hours. In order to further obtain carbon aerogels with ultra-high specific surface area, in the final stage of carbonization, carbon dioxide gas is introduced at the same time. Specific surface area of ultrapure carbon aerogels.

[0108] The carbon airgel prepared in Example 1 of the present invention was characterized.

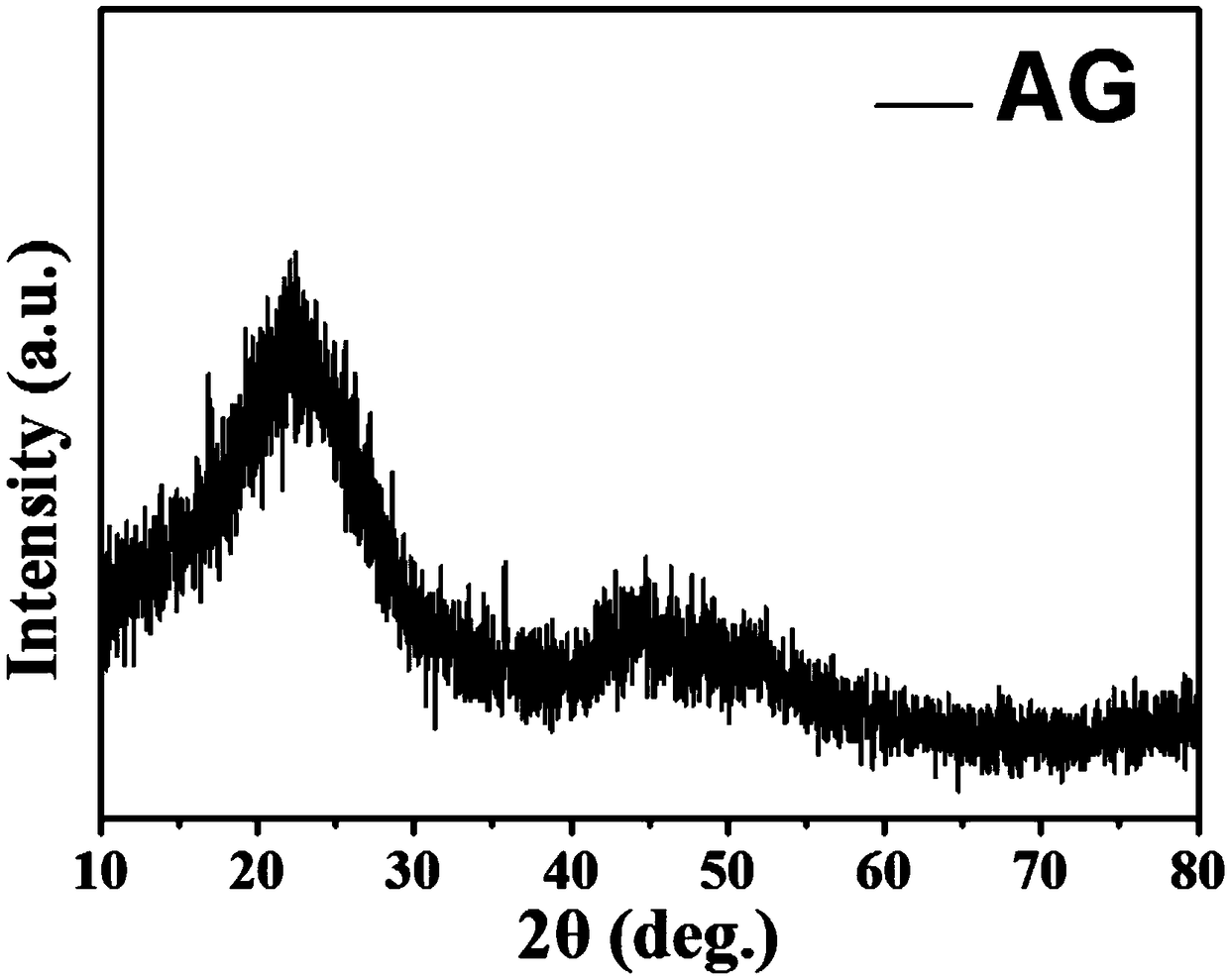

[0109] see figure 1 , figure 1 It is the XRD diff...

Embodiment 2

[0115] Slowly add 0.3g of resorcinol into 5.5mL of acetaldehyde solution, stir at room temperature for 20min, then add 0.005g of hexamethylenetetramine, pour into 15mL of ethanol solution at the same time, and stir evenly. Then the obtained solution was sealed and placed in an oven at 80° C. for 3 days of heat preservation and aging. The aged phenolic gel polymer was taken out and placed in the air for natural drying for 5 hours. Then the phenolic gel was dried in an oven at 80 °C for 2 days. The completely dried phenolic gel was carbonized at 800°C for 2 hours in a high-temperature furnace filled with argon. In order to further obtain carbon aerogels with ultra-high specific surface area, in the final stage of carbonization, carbon dioxide gas is introduced at the same time. Specific surface area of ultrapure carbon aerogels.

[0116] The carbon airgel prepared in Example 2 of the present invention was characterized.

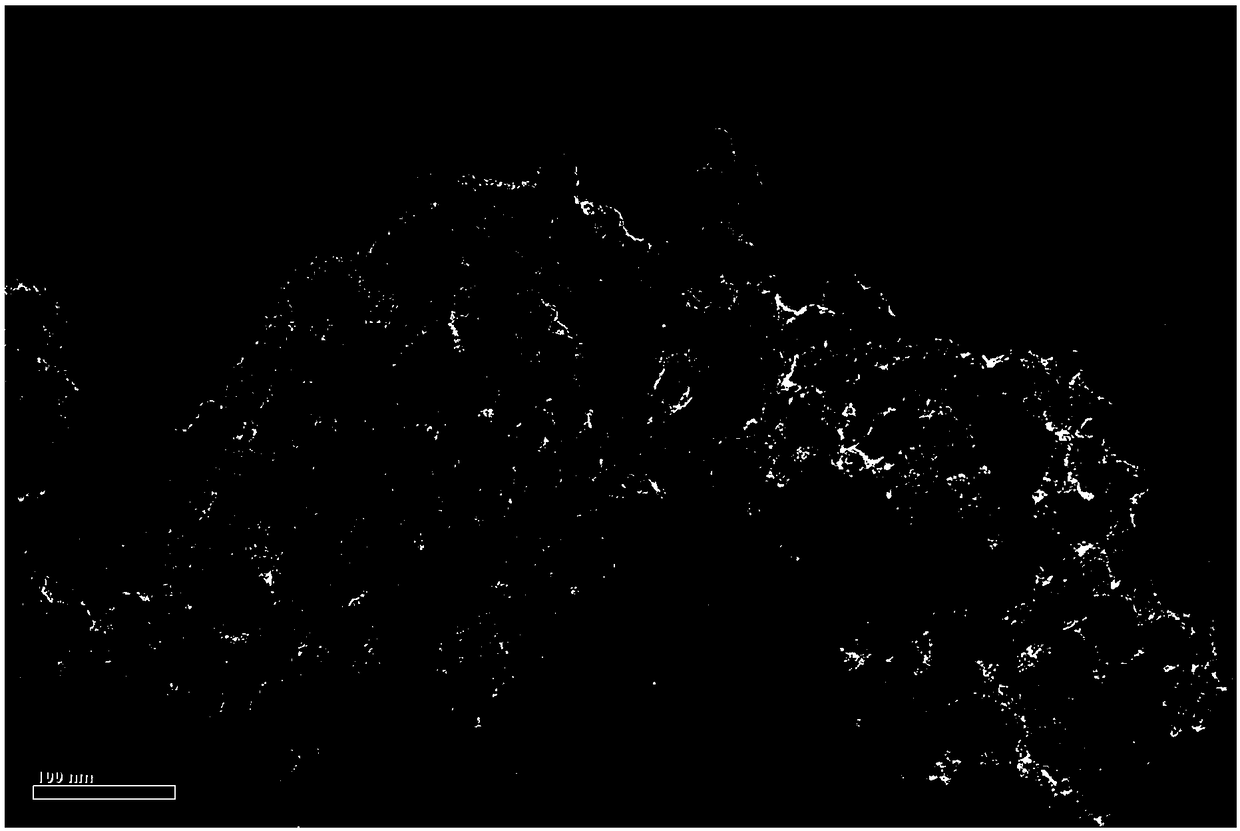

[0117] see image 3 , image 3 Transmission elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com