Method for preparing aluminum-scandium intermediate alloy by using elpasolite molten salt sinking cathode electrolysis

A technology of potassium cryolite and master alloy, which is applied in the field of preparation of aluminum-scandium master alloy by sinking cathode electrolysis of potassium cryolite molten salt, can solve the problems of high cost, uneven alloy structure, small application range, etc., and achieve the goal of saving production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A method for preparing an aluminum-scandium master alloy by sinking cathode electrolysis of potassium cryolite molten salt, comprising the following steps:

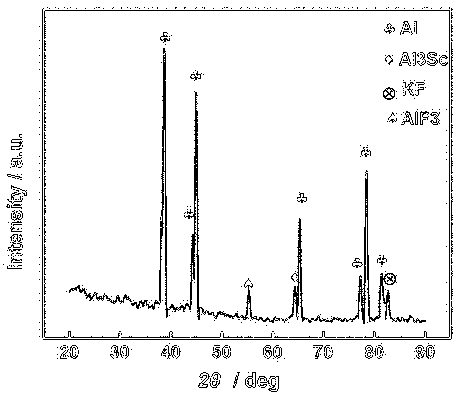

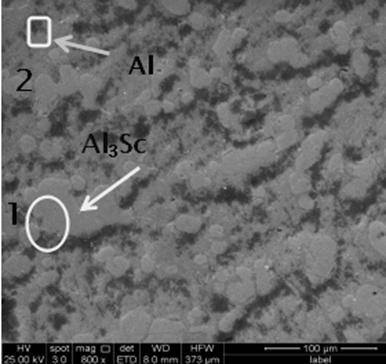

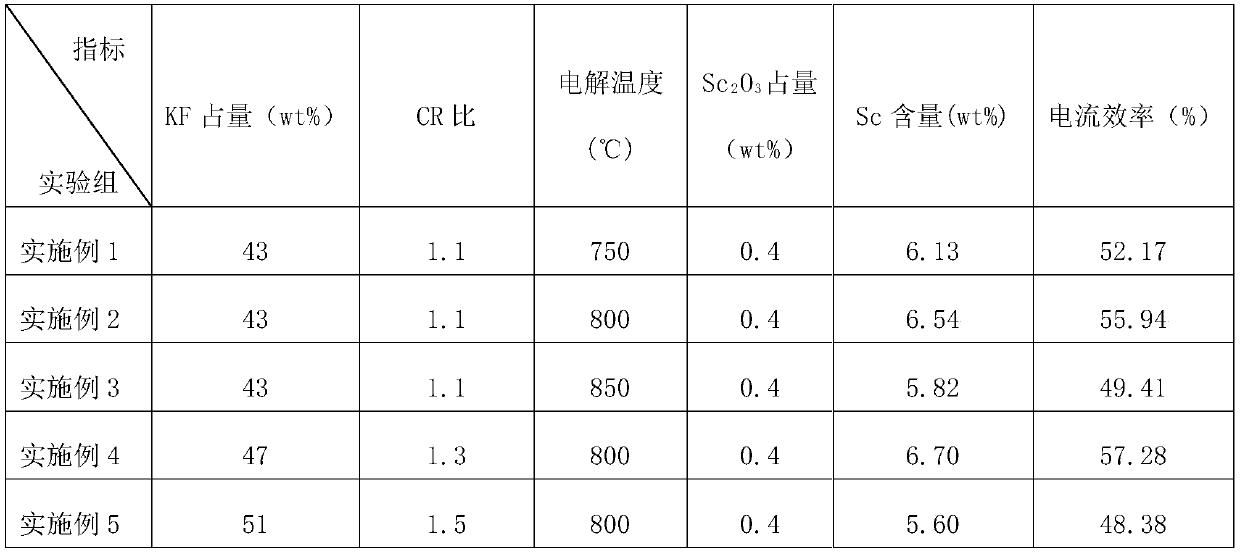

[0024] (1) Weigh the raw materials separately: K 3 AlF 6 (KF and AlF 3 ), Sc 2 o 3 , aluminum ingot, guarantee K 3 AlF 6 The CR ratio is: 1.1-1.5, the current efficiency of the present invention and the Sc content in the product are all better, and the molten salt is initially 100% K 3 AlF 6 (KF and AlF 3 ), the content of aluminum ingot is 5-8wt% of the total amount of molten salt (the input amount of aluminum ingot can be changed arbitrarily, and generally has no effect on the result); and the weighed K 3 AlF 6 (KF and AlF 3 ), Sc 2 o 3 , Aluminum ingots are dried and preheated at 300°C for 2-3 hours for later use. Preheating the raw materials can activate the raw materials on the one hand, and on the other hand can effectively reduce the heating and melting temperature in step (2), thereby reducing p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com