Cold-mixed concrete and preparation method thereof

A concrete and cold mix technology, applied in the field of building materials, can solve the problems of high VOC, low utilization rate of steel slag, and poor interface adhesion of hot mix asphalt concrete, so as to improve road performance, improve poor high and low temperature performance, enhance The effect of interfacial adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

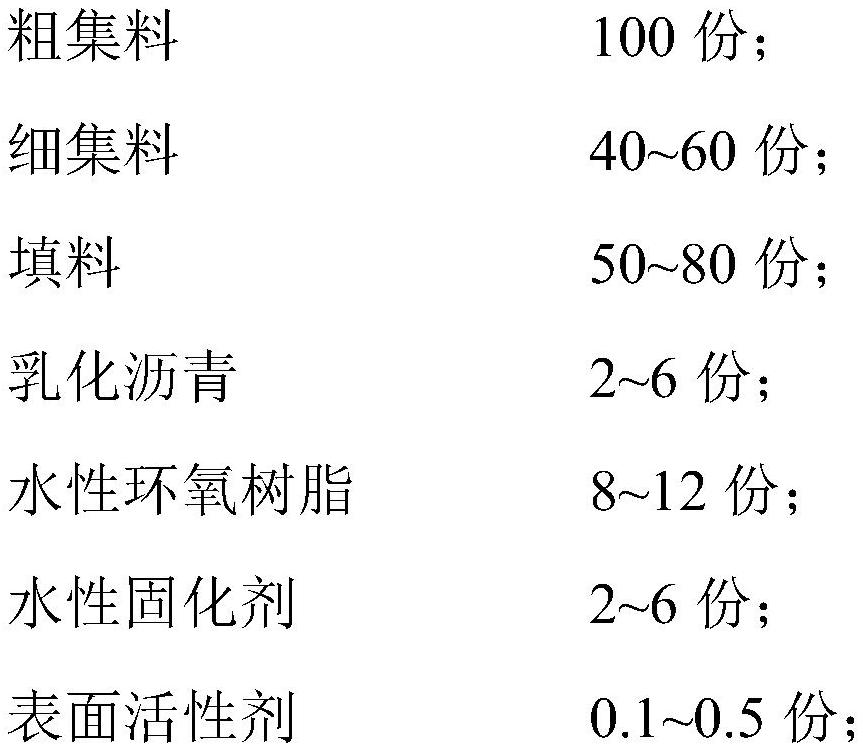

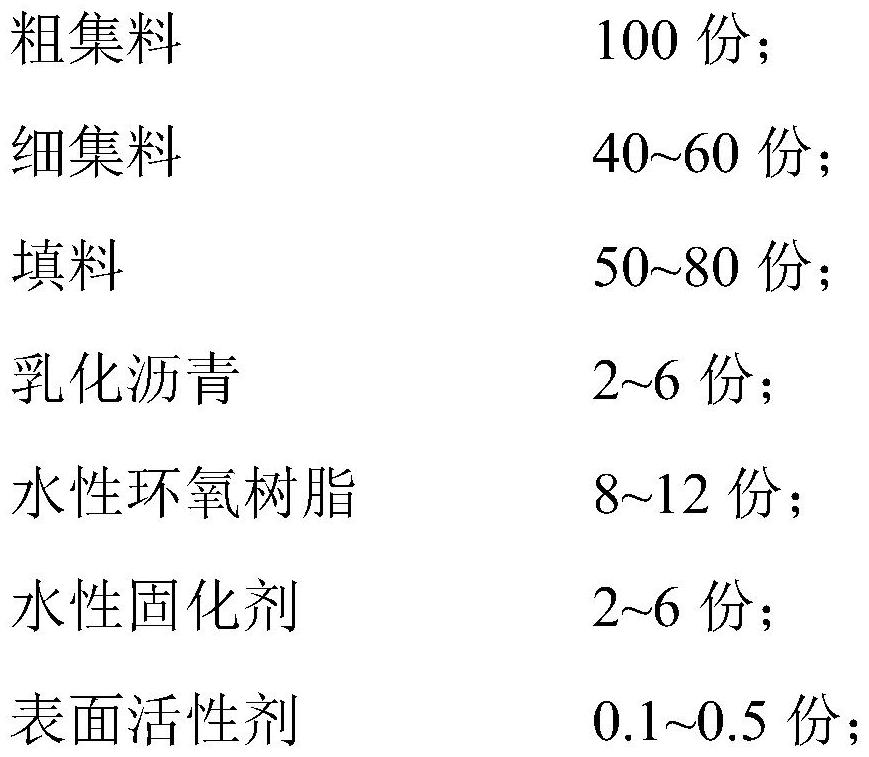

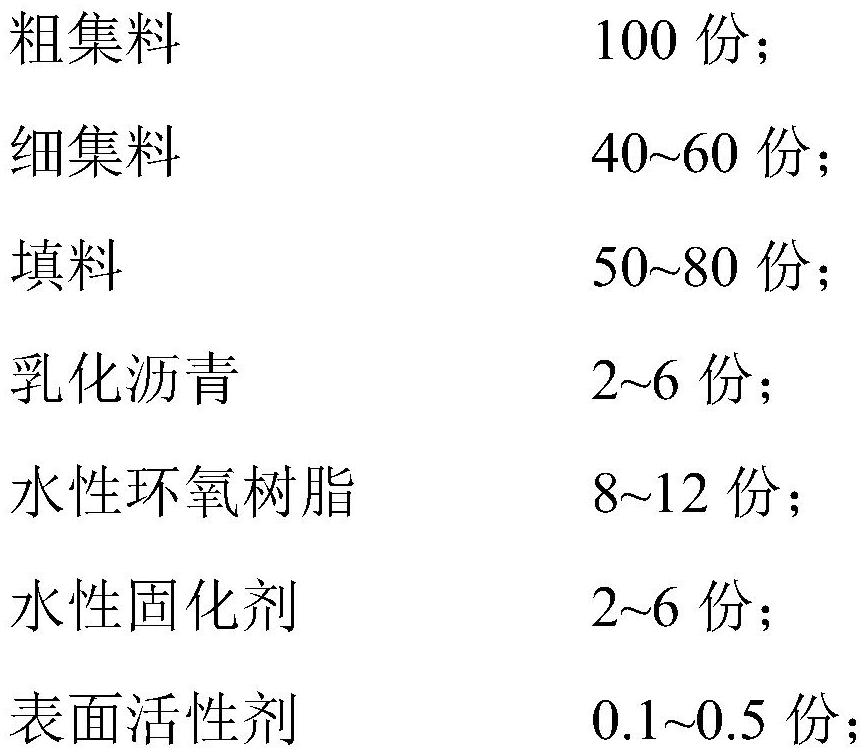

[0032] The second aspect of the embodiment of the present application provides a method for preparing cold-mix concrete, comprising the steps of:

[0033] 100 parts of coarse aggregate, 40-60 parts of fine aggregate, 50-80 parts of filler, 2-6 parts of emulsified asphalt, 8-12 parts of water-based epoxy resin, 2-6 parts of water-based curing agent It is mixed with 0.1-0.5 parts of surfactant to obtain cold-mixed concrete; wherein, the coarse aggregate and the fine aggregate are selected from steel slag.

[0034] The preparation method of cold-mix concrete provided by the second aspect of the present application belongs to the cold-mix process. At room temperature, 100 parts of coarse aggregate, 40-60 parts of fine aggregate, 50-80 parts of filler, 2-6 parts The emulsified asphalt, 8-12 parts of water-based epoxy resin, 2-6 parts of water-based curing agent, and 0.1-0.5 parts of surfactant are mixed to obtain cold-mix concrete. The preparation method provided in the embodiment...

Embodiment 1

[0047] A kind of cold mix concrete, comprises following preparation steps:

[0048] ① According to the mass ratio of coarse aggregate: fine aggregate: filler: emulsified asphalt: water-based epoxy resin: water-based curing agent: surfactant is 100:40:50:2:8:2:2:0.1 (among them, water-based The ratio of epoxy resin to curing agent is selected according to product performance), select coarse aggregate, fine aggregate, filler, emulsified asphalt, water-based epoxy resin, water-based curing agent and surfactant, and set aside.

[0049] Among them, the coarse aggregate is steel slag, the maximum nominal particle size is 13.2mm, and the performance index meets the requirements of coarse aggregate for asphalt mixture in "Technical Specifications for Construction of Highway Asphalt Pavement" (JTG F40-2004). The fine aggregate is steel slag, the maximum nominal particle size is 4.75mm, and the performance index meets the requirements of fine aggregate for asphalt mixture in the "Techni...

Embodiment 2

[0052] A kind of cold mix concrete, comprises following preparation steps:

[0053] ①Coarse aggregate by mass ratio: fine aggregate: filler: emulsified asphalt: water-based epoxy resin: water-based curing agent: surfactant = 100:45:55:3:9:3:3:0.2 (among them, water-based The ratio of epoxy resin to curing agent should be selected according to the product performance), select coarse aggregate, fine aggregate, filler, emulsified asphalt, water-based epoxy resin, water-based curing agent and surfactant, and set aside.

[0054] Among them, the coarse aggregate is steel slag, the maximum nominal particle size is 13.2mm, and the performance index meets the requirements of coarse aggregate for asphalt mixture in "Technical Specifications for Construction of Highway Asphalt Pavement" (JTG F40-2004). The fine aggregate is steel slag, the maximum nominal particle size is 4.75mm, and the performance index meets the requirements of fine aggregate for asphalt mixture in the "Technical Spec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com