Selective emitter, preparation method thereof, solar cell using selective emitter, and application of solar cell

A solar cell and emitter technology, which is applied in the field of solar cells, can solve the problems of poor selective emitter effect, light conversion efficiency to be improved, and low diffusion square resistance of silicon wafers, so as to improve photoelectric conversion efficiency and short-circuit current and conversion efficiency, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

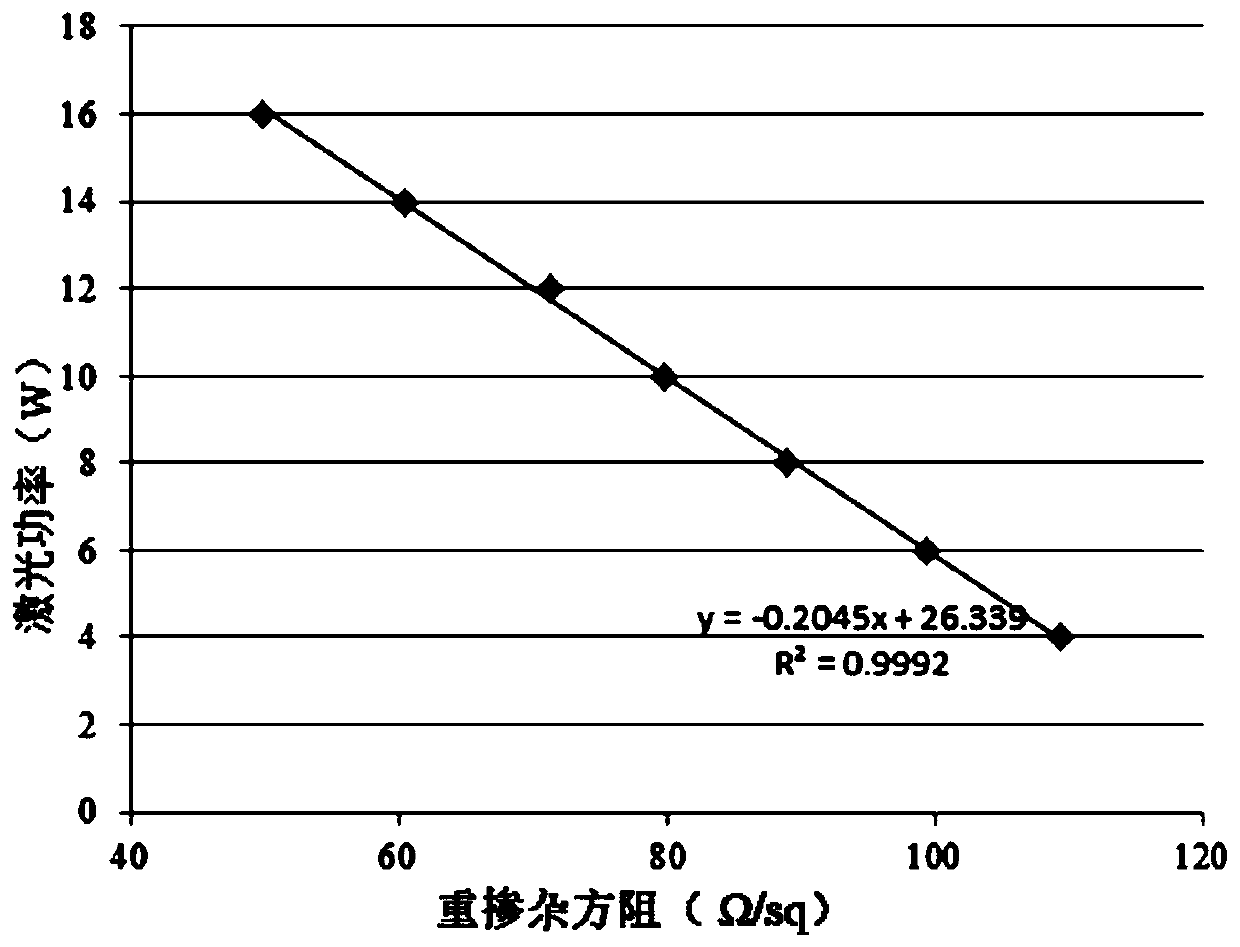

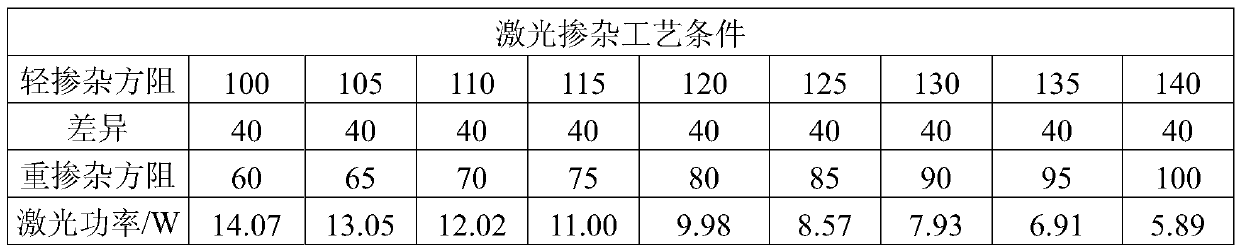

[0041] This embodiment provides a selective emitter, the difference between the lightly doped square resistance of the light receiving region of the selective emitter and the heavily doped square resistance of the non-light receiving region is a fixed value, and the fixed value is 40Ω / sq; where the light doping is tubular diffusion, and the heavy doping is laser doping.

[0042] The preparation method of the selective emitter is as follows:

[0043] (1) Remove the damaged sheet from the silicon wafer, prepare the suede surface, and obtain the pretreated silicon wafer, and then put the pretreated silicon wafer under the condition that the gas is a combination of oxygen, nitrogen and phosphorus oxychloride, and the temperature is 800 ° C. Carry out tubular diffusion, the time of tubular diffusion is 1000s, and obtain a lightly doped silicon wafer with a square resistance of 120±20Ω / sq, wherein during the light doping process, phosphorus oxychloride is carried into the diffusion...

Embodiment 2

[0052] This embodiment provides a selective emitter, the difference between the lightly doped square resistance of the light-receiving region of the selective emitter and the heavily doped square resistance of the non-light-receiving region is a fixed value, and the fixed value is 30Ω / sq; where the light doping is tubular diffusion, and the heavy doping is laser doping.

[0053] The preparation method of the selective emitter is as follows:

[0054] (1) Remove the damaged sheet from the silicon wafer, prepare the suede surface, and obtain the pretreated silicon wafer, and then put the pretreated silicon wafer under the condition that the gas is a combination of oxygen, nitrogen and phosphorus oxychloride, and the temperature is 760 ° C. Carry out tubular diffusion, the time of tubular diffusion is 1200s, and obtain a lightly doped silicon wafer with a square resistance of 120±20Ω / sq, wherein during the light doping process, phosphorus oxychloride is carried into the diffusion...

Embodiment 3

[0061] This embodiment provides a selective emitter, the difference between the lightly doped square resistance of the light receiving region of the selective emitter and the heavily doped square resistance of the non-light receiving region is a fixed value, and the fixed value is 50Ω / sq; where the light doping is tubular diffusion, and the heavy doping is laser doping.

[0062] The preparation method of the selective emitter is as follows:

[0063] (1) Remove the damaged sheet from the silicon wafer, prepare the textured surface, and obtain the pretreated silicon wafer, and then put the pretreated silicon wafer under the condition that the gas is a combination of oxygen, nitrogen and phosphorus oxychloride, and the temperature is 840 ° C. Carry out tubular diffusion, the time of tubular diffusion is 600s, and obtain a lightly doped silicon wafer with a square resistance of 120±20Ω / sq, wherein during the light doping process, phosphorus oxychloride is carried into the diffusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com