Preparation method for electrode material of super capacitor, application and super capacitor

A supercapacitor and electrode material technology, applied in capacitors, battery electrodes, electrolytic capacitors, etc., can solve the problems of inconvenient industrial production, strong equipment dependence, and complicated manufacturing process, and achieve good supercapacitor performance, low equipment dependence, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

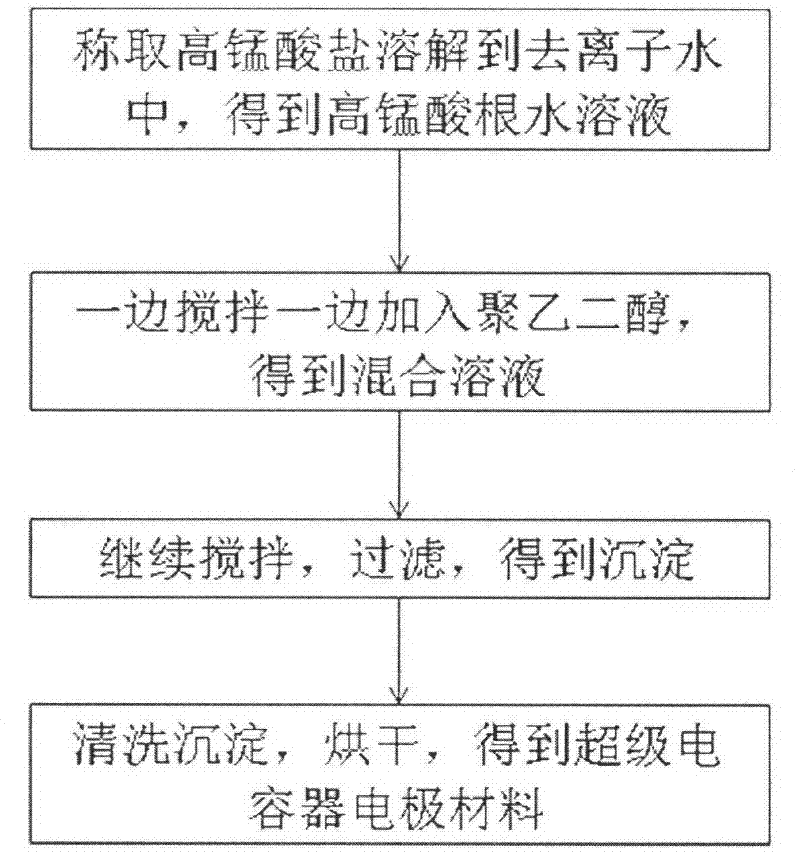

[0039] (1) Weigh 8×10 -3 mol of potassium permanganate was dissolved in 80mL of deionized water to make a solution with a concentration of 0.1mol / L;

[0040] (2) Add 5 mL of PEG2000 to the potassium permanganate solution while stirring to obtain a mixed solution;

[0041] (3) Continue to stir the mixed solution until the color fades, and filter to obtain a precipitate;

[0042] (4) The precipitate was washed 4 times with deionized water, washed with absolute ethanol, and then dried in an oven at 60° C. to obtain a black supercapacitor electrode material.

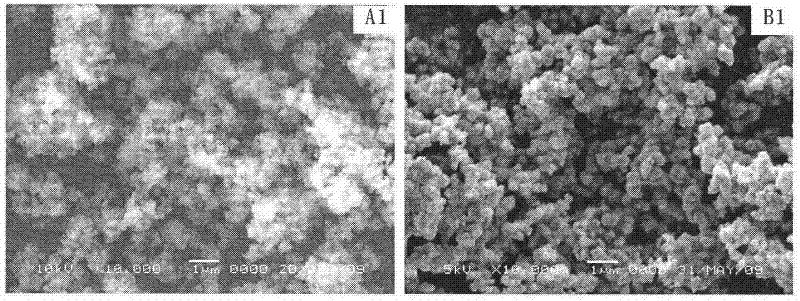

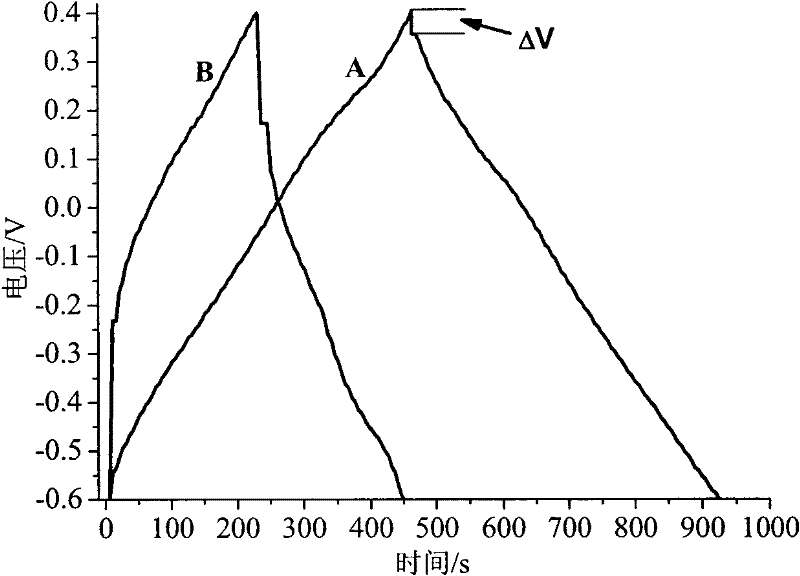

[0043] figure 2It is the SEM figure of the supercapacitor electrode material prepared by Example 1 of the present invention and Comparative Example 1, as figure 2 As shown, A1 is the SEM image of the supercapacitor electrode material prepared in Example 1, and B1 is the SEM image of the supercapacitor electrode material prepared in Comparative Example 1. The particle size of the supercapacitor electrode material in Exa...

Embodiment 2

[0045] (1) Weigh 1.6×10 -3 mol of sodium permanganate was dissolved in 80mL of deionized water to make a solution with a concentration of 0.02mol / L;

[0046] (2) Add 2 mL of PEG400 to the sodium permanganate solution while stirring to obtain a mixed solution;

[0047] (3) Continue to stir the mixed solution until the color fades, and filter to obtain a precipitate;

[0048] (4) The precipitate was washed 5 times with deionized water, and then dried in an oven at 80° C. to obtain a black supercapacitor electrode material.

Embodiment 3

[0050] (1) Weigh 6.4×10 -3 mol of potassium permanganate was dissolved in 80mL of deionized water to make a solution with a concentration of 0.08mol / L;

[0051] (2) Add 4 mL of PEG6000 to the potassium permanganate solution while stirring to obtain a mixed solution;

[0052] (3) Continue to stir the mixed solution until the color fades, and filter to obtain a precipitate;

[0053] (4) The precipitate was washed three times with deionized water, washed with absolute ethanol, and then dried in an oven at 100° C. to obtain a black supercapacitor electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com