An all-solid-state lithium-sulfur/sodium-sulfur battery with halide as electrode active material and catalyst

A technology for electrode active materials and positive electrode active materials, which is applied in the field of lithium-sulfur or sodium-sulfur batteries, can solve the problems of low positive electrode active material loading, poor cycle performance, and low energy density, so as to improve the utilization rate of active materials and increase energy. Density, effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

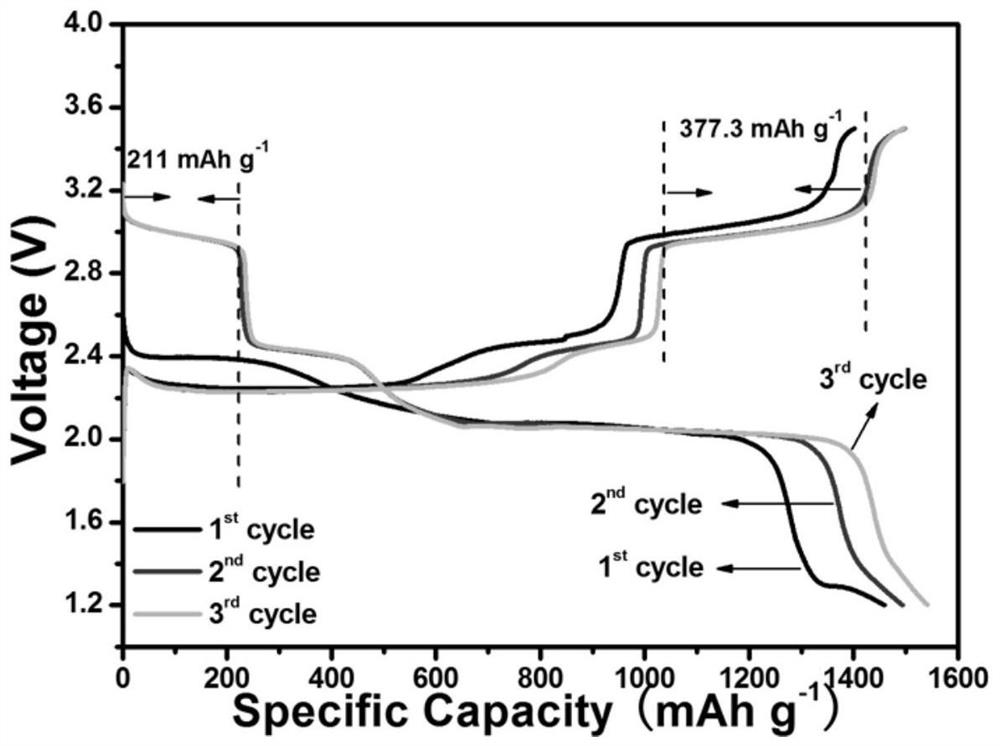

Embodiment 1

[0036] Preparation of positive electrode: 0.7g elemental sulfur and 0.2g Super P were magnetically stirred in 10mL acetonitrile at 25°C for 10min to obtain mixture 1, 0.1g PEO (molecular weight 4000000) was dissolved in acetonitrile solvent, and the above mixture 1 was added after ultrasonication for 10min. Then it is coated on an aluminum foil and placed in an oven at 50°C, and dried with a volatile solvent for 24 hours to obtain a positive electrode.

[0037] Preparation of electrolyte membrane 1: Dissolve 0.08gMIL-53(Al), 0.02gLiI and 0.5gLiTFSI in 60mL of acetonitrile, stir for 10h, add 0.4gPEO, stir for 24h, evaporate the solvent at room temperature for 8h, and obtain polymer electrolyte membrane 1 .

[0038] Preparation of electrolyte membrane 2: Dissolve 0.08g MIL-53(Al) and 0.7g LiTFSI in 20mL of acetonitrile, stir for 12h, add 0.4gPEO, stir for 24h, evaporate the solvent at room temperature for 8h, and obtain polymer electrolyte membrane 2.

[0039] The prepared posi...

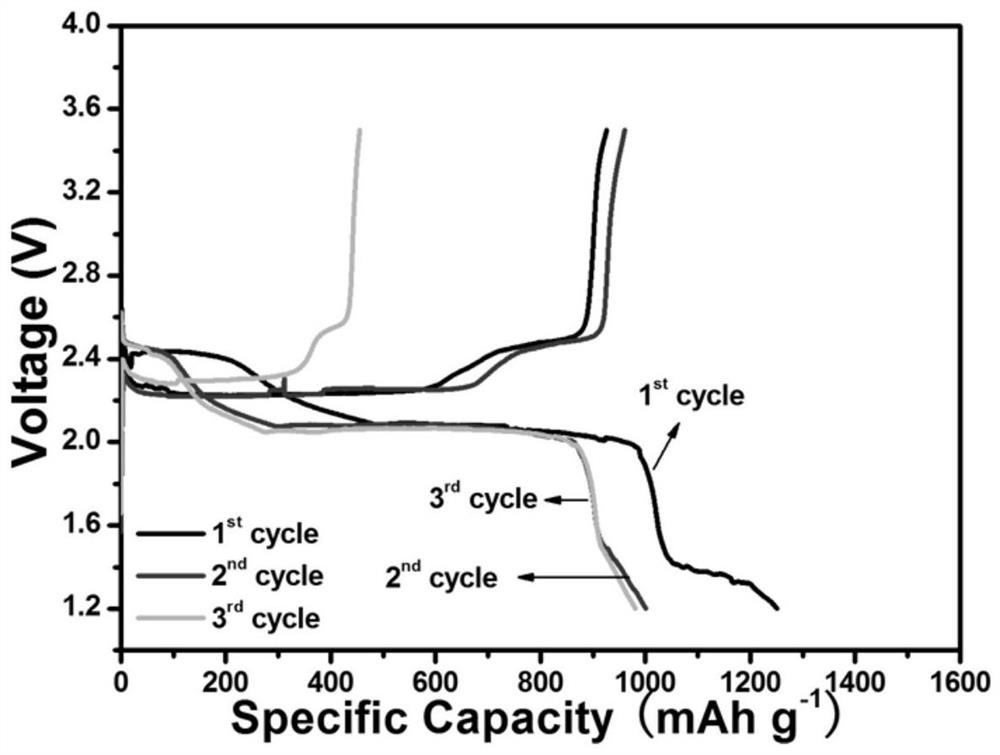

Embodiment 2

[0041] Preparation of positive electrode: 0.7g elemental sulfur and 0.2g Super P were magnetically stirred in 10mL acetonitrile at 25°C for 10min to obtain mixture 1, 0.1g PEO (molecular weight 4000000) was dissolved in acetonitrile solvent, and the above mixture 1 was added after ultrasonication for 10min. Then it is coated on an aluminum foil and placed in an oven at 50°C, and dried with a volatile solvent for 24 hours to obtain a positive electrode.

[0042] Preparation of electrolyte membrane 1: Dissolve 0.08gMIL-53(Al) and 0.7gLiTFSI in 20mL of acetonitrile, stir for 12h, add 0.4gPEO, stir for 24h, evaporate the solvent at room temperature for 8h, and obtain polymer electrolyte membrane 1.

[0043] Preparation of electrolyte membrane 2: Dissolve 0.08g MIL-53(Al) and 0.7g LiTFSI in 20mL of acetonitrile, stir for 12h, add 0.4gPEO, stir for 24h, evaporate the solvent at room temperature for 8h, and obtain polymer electrolyte membrane 2.

[0044] The prepared positive electro...

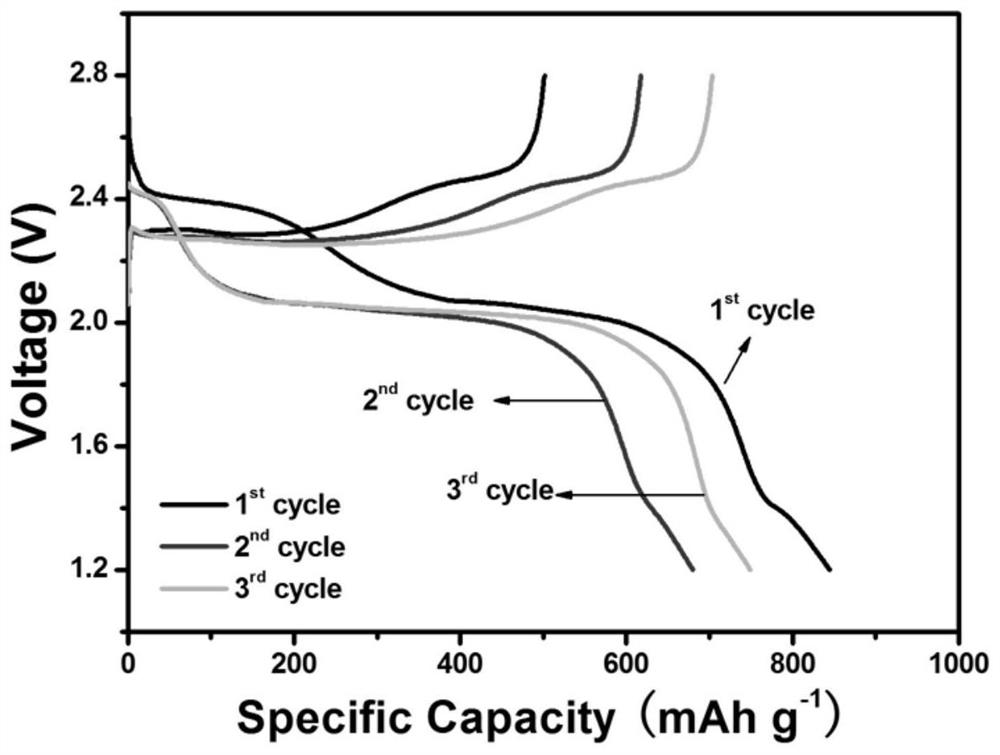

Embodiment 3

[0046] Preparation of positive electrode: 0.7g elemental sulfur and 0.2g Super P were magnetically stirred in 10mL acetonitrile at 25°C for 10min to obtain mixture 1, 0.1g PEO (molecular weight 4000000) was dissolved in acetonitrile solvent, and the above mixture 1 was added after ultrasonication for 10min. Then it is coated on an aluminum foil and placed in an oven at 50°C, and dried with a volatile solvent for 24 hours to obtain a positive electrode.

[0047] Preparation of electrolyte membrane 1: Dissolve 0.08g of MIL-53(Al), 0.02g of LiI and 0.5g of LiTFSI in 60mL of acetonitrile, stir for 10h, add 0.4g of PEO, stir for 24h, and evaporate the solvent at room temperature for 8h to obtain a polymer electrolyte membrane 1.

[0048] Preparation of electrolyte membrane 2: Dissolve 0.08g MIL-53(Al) and 0.7g LiTFSI in 20mL of acetonitrile, stir for 12h, add 0.4gPEO, stir for 24h, evaporate the solvent at room temperature for 8h, and obtain polymer electrolyte membrane 2.

[0049...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com