Preparation method of nitrogen-doped yolk-shaped carbon sphere/graphene composite material

A composite material and nitrogen doping technology, applied in the field of new energy electronic materials, can solve problems such as not achieving the desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

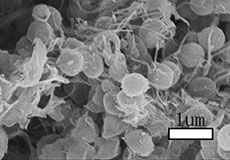

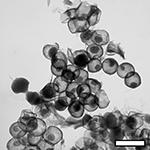

Image

Examples

Embodiment 1

[0032] Ultrasonicate 160 ml of deionized water and 60 ml of absolute ethanol to obtain a uniform mixed solution, pour it into a three-necked bottle, add 0.8 ml of ammonia water, and put the three-necked bottle into 0 o C in a cold bath with stirring. Add 1.8 g of resorcinol to the three-necked flask, and stir to dissolve. Take a 50ml beaker, add 2 g melamine and 4.5238 g formaldehyde to it, put 60 o C in a water bath and stirred until the solution was clear, then poured into a three-neck flask and continued to stir. After 10 min, 2.5 ml of formaldehyde solution was added dropwise to the bottle, and stirred for 24 h. The product was alternately washed 4 times with deionized water and absolute ethanol, and then the product was freeze-dried. After the drying is completed, weigh 0.2 g of the product, and 200 ml of the concentration is 1mg ml -1 Graphite oxide dispersion solution was blended, and after stirring for 4 hours, 1.2 g KOH was weighed, dissolved in 50 ml deionized wa...

Embodiment 2

[0034] Ultrasonicate 160 ml of deionized water and 60 ml of absolute ethanol to obtain a uniform mixed solution, pour it into a three-necked bottle, add 0.8 ml of ammonia water, and put the three-necked bottle into 0 o C in a cold bath with stirring. Add 1.8 g of resorcinol to the three-necked flask, and stir to dissolve. Take a 50ml beaker, add 2 g melamine and 4.5238 g formaldehyde to it, put 60o C in a water bath and stirred until the solution was clear, then poured into a three-neck flask and continued to stir. After 10 min, 2.5 ml of formaldehyde solution was added dropwise to the bottle, and stirred for 24 h. The product was alternately washed 4 times with deionized water and absolute ethanol, and then the product was freeze-dried. After the drying is completed, the powder is placed in a tube furnace for pre-carbonization, and the carbonization temperature is 300 o C, holding time 1 h. Weigh 0.4 g product, and 200 ml concentration is 1mg ml -1 Graphite oxide dispers...

Embodiment 3

[0038] Ultrasonicate 160 ml of deionized water and 60 ml of absolute ethanol to obtain a uniform mixed solution, pour it into a three-necked bottle, add 0.8 ml of ammonia water, and put the three-necked bottle into 0 o C in a cold bath with stirring. Add 1.8 g of resorcinol to the three-necked flask, and stir to dissolve. Take a 50ml beaker, add 2 g melamine and 4.5238 g formaldehyde to it, put 60 o C in a water bath and stirred until the solution was clear, then poured into a three-neck flask and continued to stir. After 10 min, 2.5 ml of formaldehyde solution was added dropwise to the bottle, and stirred for 24 h. The product was alternately washed 4 times with deionized water and absolute ethanol, and then the product was freeze-dried. After the drying is completed, the powder is placed in a tube furnace for pre-carbonization, and the carbonization temperature is 300 o C, holding time 1 h. Weigh 0.6 g of product and 200 ml to a concentration of 1 mg ml -1 Graphite oxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com