Carbon-coated nickel-based thin-film electrode material and its preparation method and application

A carbon-coated nickel-based, thin-film electrode technology, used in carbon preparation/purification, nanotechnology for materials and surface science, battery electrodes, etc. The preparation method is simple, the performance is good, and the effect of improving the specific capacity value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033]

[0034] Such as figure 1 Shown, the preparation method of carbon-coated nickel-based thin film electrode material of the present invention comprises the steps:

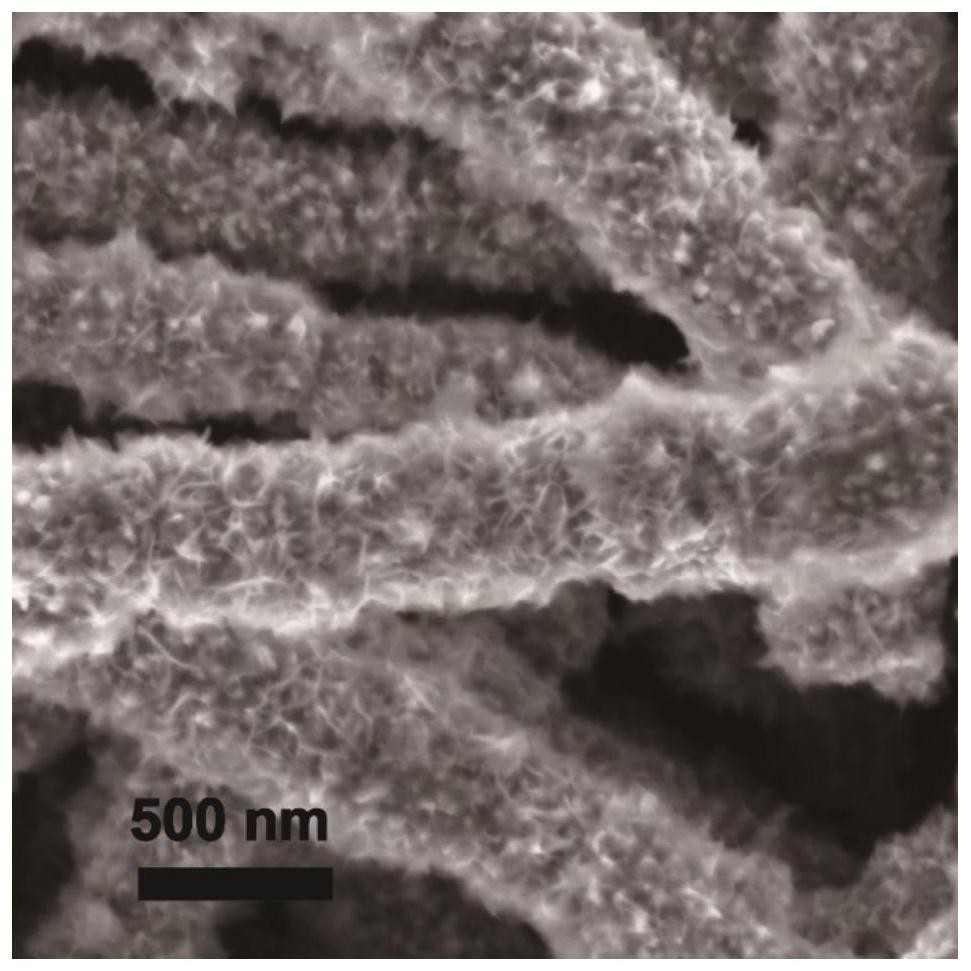

[0035] (1), the preparation of nickel nanowire thin film: uniformly disperse nickel nanowire in the dispersant, dry naturally after vacuum filtration, the filter membrane falls off, then press and slice to obtain nickel nanowire thin film;

[0036] (2), the preparation of nickel / nickel hydroxide film: the nickel nanowire film and hydrogen peroxide solution are mixed and put into the autoclave, after hydrothermal reaction treatment, the product is washed and dried to obtain nickel / nickel hydroxide film;

[0037] (3), preparation of carbon-coated nickel-based thin film electrode material: after mixing nickel / nickel hydroxide film and glucose solution, put it into an oven for hydrothermal reaction, obtain carbon-coated nickel-based thin film electrode material after washing and drying, That is, carbon coated ...

Embodiment 1

[0054] The preparation method of the carbon-coated nickel-based thin film electrode material of the present embodiment comprises the following steps:

[0055] (1) Uniformly disperse the nickel nanowires in 1 wt % polyvinylpyrrolidone ethanol solution, vacuum filter, then dry naturally for 10 minutes, and finally press the nickel nanowires under 10 MPa for 5 minutes to prepare the nickel nanowire film.

[0056] (2) Mix 32mg of nickel nanowire film and 20mL of 15wt% hydrogen peroxide solution into a 50mL polytetrafluoroethylene autoclave, conduct a hydrothermal reaction at 140°C for 12h, and then wash the product with deionized water And dry at 60°C for 6h to obtain a nickel / nickel hydroxide film.

[0057](3) Put 30mg of nickel / nickel hydroxide film into 30mL of 1mg / mL glucose solution, conduct a hydrothermal reaction in an oven at 120°C for 5h, clean up after the reaction, and finally obtain a carbon-coated nickel-based film electrode material .

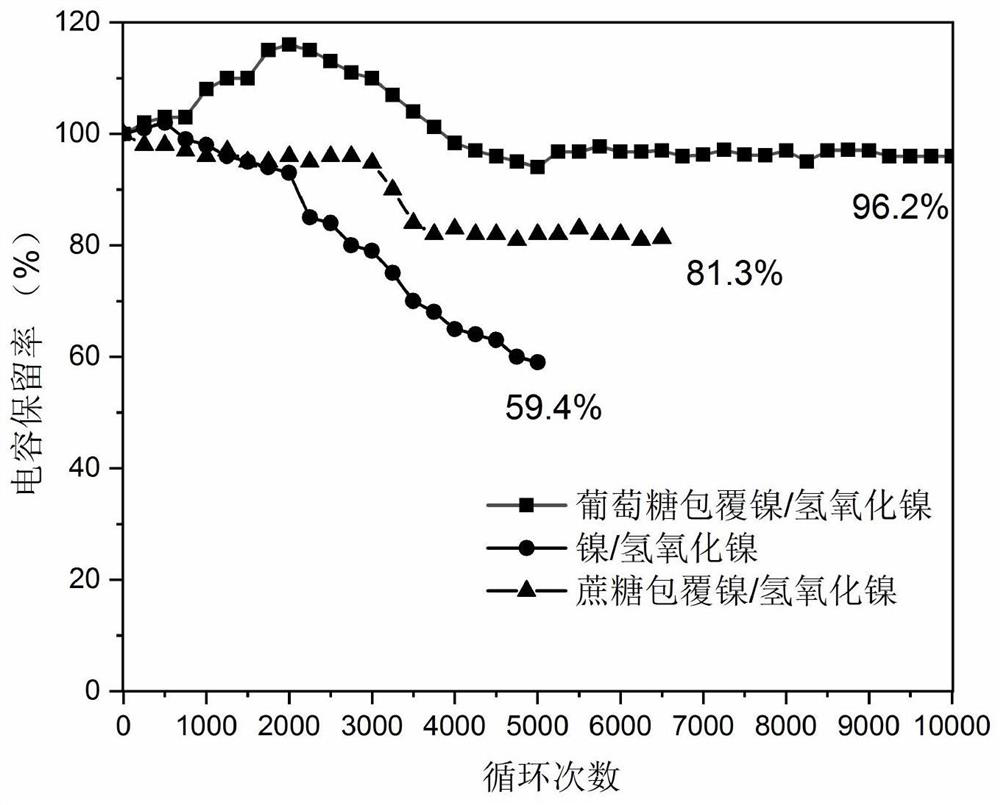

[0058] The prepared electrod...

Embodiment 2

[0060] The preparation method of the carbon-coated nickel-based thin film electrode material of the present embodiment comprises the following steps:

[0061] (1) Uniformly disperse the nickel nanowires in 1 wt % polyvinylpyrrolidone ethanol solution, vacuum filter, then dry naturally for 10 minutes, and finally press the nickel nanowires under 9 MPa for 3 minutes to prepare the nickel nanowire film.

[0062] (2), 50mg of nickel nanowire film and 50mL of 20wt% hydrogen peroxide solution were mixed into a 100mL polytetrafluoroethylene autoclave, hydrothermally reacted at 140°C for 8h, and then the product was washed with deionized water And dry at 65°C for 7h to obtain a nickel / nickel hydroxide film.

[0063] (3) Put 40mg of nickel / nickel hydroxide film into 50mL of 2mg / mL glucose solution, conduct a hydrothermal reaction in an oven at 120°C for 10h, and clean it up after the reaction is over to obtain a carbon-coated nickel-based film electrode material .

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com