Carbon-coated nickel-based thin film electrode material, preparation method and application thereof

A carbon-coated nickel-based, thin-film electrode technology, applied in the preparation/purification of carbon, nanotechnology for materials and surface science, battery electrodes, etc., can solve the problems of application limitations, poor conductivity and stability, and achieve The preparation method is simple, the performance is good, and the effect of enhancing cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033]

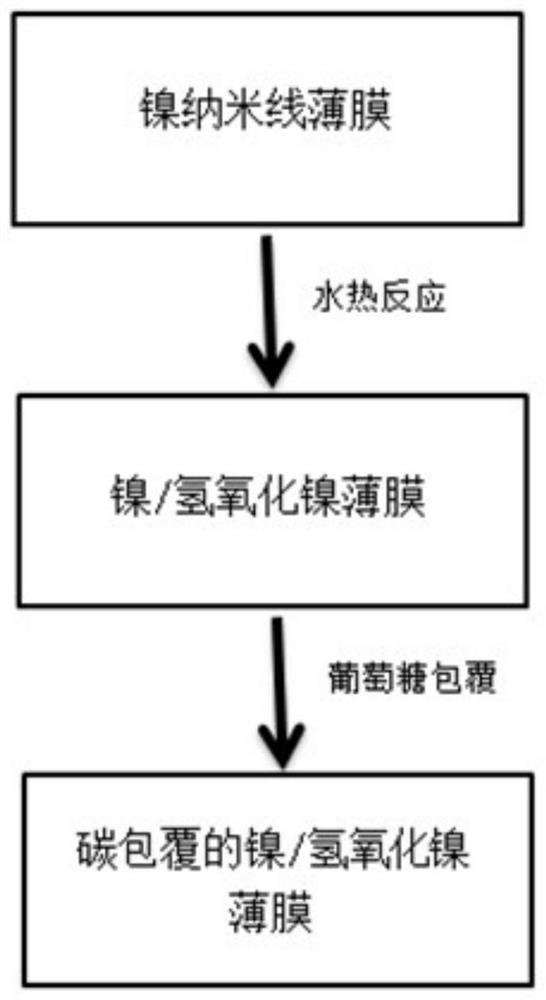

[0034] Such as figure 1 Shown, the preparation method of carbon-coated nickel-based thin film electrode material of the present invention comprises the steps:

[0035] (1), the preparation of nickel nanowire thin film: uniformly disperse nickel nanowire in the dispersant, dry naturally after vacuum filtration, the filter membrane falls off, then press and slice to obtain nickel nanowire thin film;

[0036] (2), the preparation of nickel / nickel hydroxide film: the nickel nanowire film and hydrogen peroxide solution are mixed and put into the autoclave, after hydrothermal reaction treatment, the product is washed and dried to obtain nickel / nickel hydroxide film;

[0037] (3), preparation of carbon-coated nickel-based thin film electrode material: after mixing nickel / nickel hydroxide film and glucose solution, put it into an oven for hydrothermal reaction, obtain carbon-coated nickel-based thin film electrode material after washing and drying, That is, carbon coated ...

Embodiment 1

[0054] The preparation method of the carbon-coated nickel-based thin film electrode material of the present embodiment comprises the following steps:

[0055] (1) Uniformly disperse the nickel nanowires in 1 wt % polyvinylpyrrolidone ethanol solution, vacuum filter, then dry naturally for 10 minutes, and finally press the nickel nanowires under 10 MPa for 5 minutes to prepare the nickel nanowire film.

[0056] (2) Mix 32mg of nickel nanowire film and 20mL of 15wt% hydrogen peroxide solution into a 50mL polytetrafluoroethylene autoclave, conduct a hydrothermal reaction at 140°C for 12h, and then wash the product with deionized water And dry at 60°C for 6h to obtain a nickel / nickel hydroxide film.

[0057](3) Put 30mg of nickel / nickel hydroxide film into 30mL of 1mg / mL glucose solution, conduct a hydrothermal reaction in an oven at 120°C for 5h, clean up after the reaction, and finally obtain a carbon-coated nickel-based film electrode material .

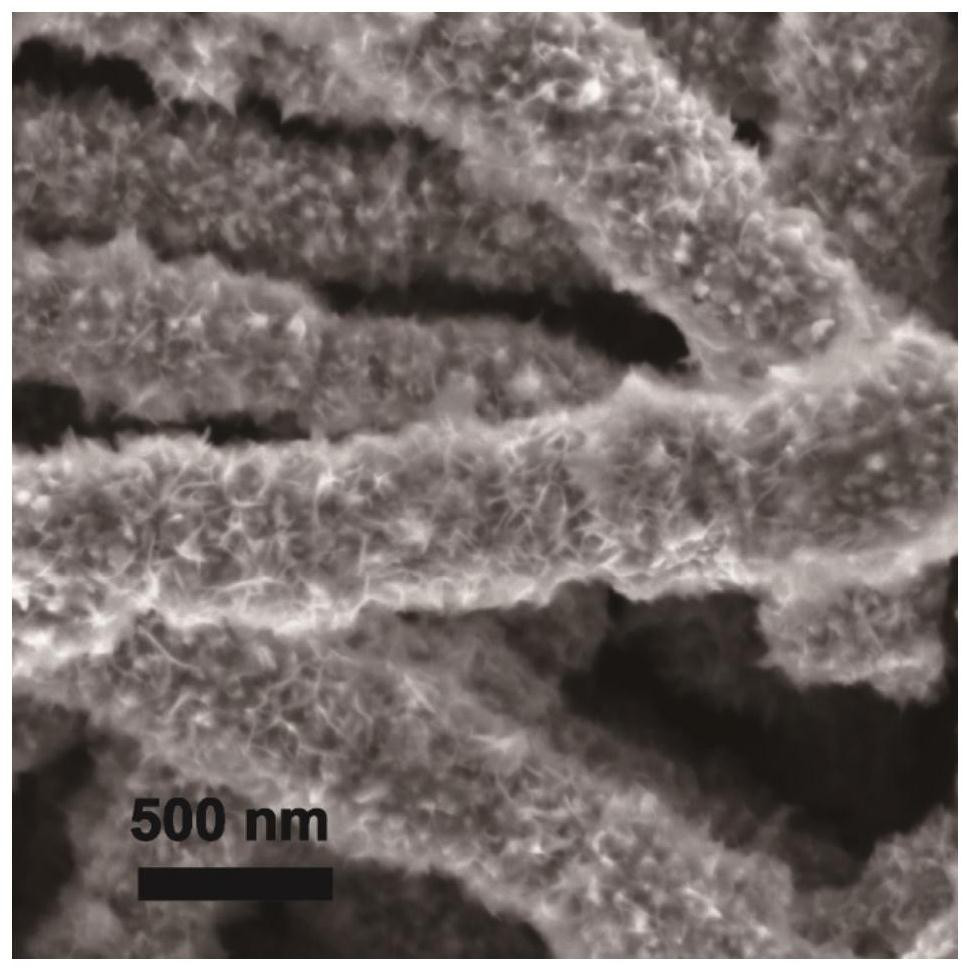

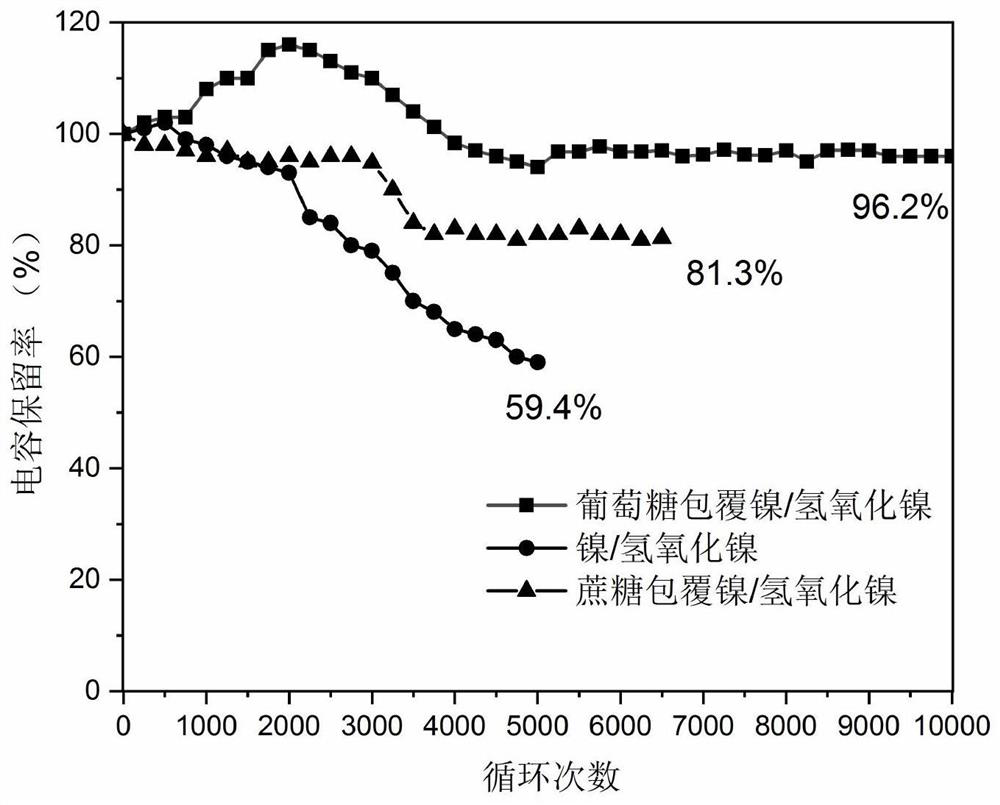

[0058] The prepared electrod...

Embodiment 2

[0060] The preparation method of the carbon-coated nickel-based thin film electrode material of the present embodiment comprises the following steps:

[0061] (1) Uniformly disperse the nickel nanowires in 1 wt % polyvinylpyrrolidone ethanol solution, vacuum filter, then dry naturally for 10 minutes, and finally press the nickel nanowires under 9 MPa for 3 minutes to prepare the nickel nanowire film.

[0062] (2), 50mg of nickel nanowire film and 50mL of 20wt% hydrogen peroxide solution were mixed into a 100mL polytetrafluoroethylene autoclave, hydrothermally reacted at 140°C for 8h, and then the product was washed with deionized water And dry at 65°C for 7h to obtain a nickel / nickel hydroxide film.

[0063] (3) Put 40mg of nickel / nickel hydroxide film into 50mL of 2mg / mL glucose solution, conduct a hydrothermal reaction in an oven at 120°C for 10h, and clean it up after the reaction is over to obtain a carbon-coated nickel-based film electrode material .

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com