Ferro-nickel hydroxide/ferro-nickel alloy loaded wood-based electrocatalyst, preparation method thereof and water electrolysis hydrogen production catalyst

A technology of iron hydroxide and electrocatalyst, applied in the direction of electrolysis components, electrolysis process, electrodes, etc., can solve the problems of large accumulation, non-renewable, uneven dispersion of active substances, etc., and achieve low cost, simple preparation process and ingenious design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

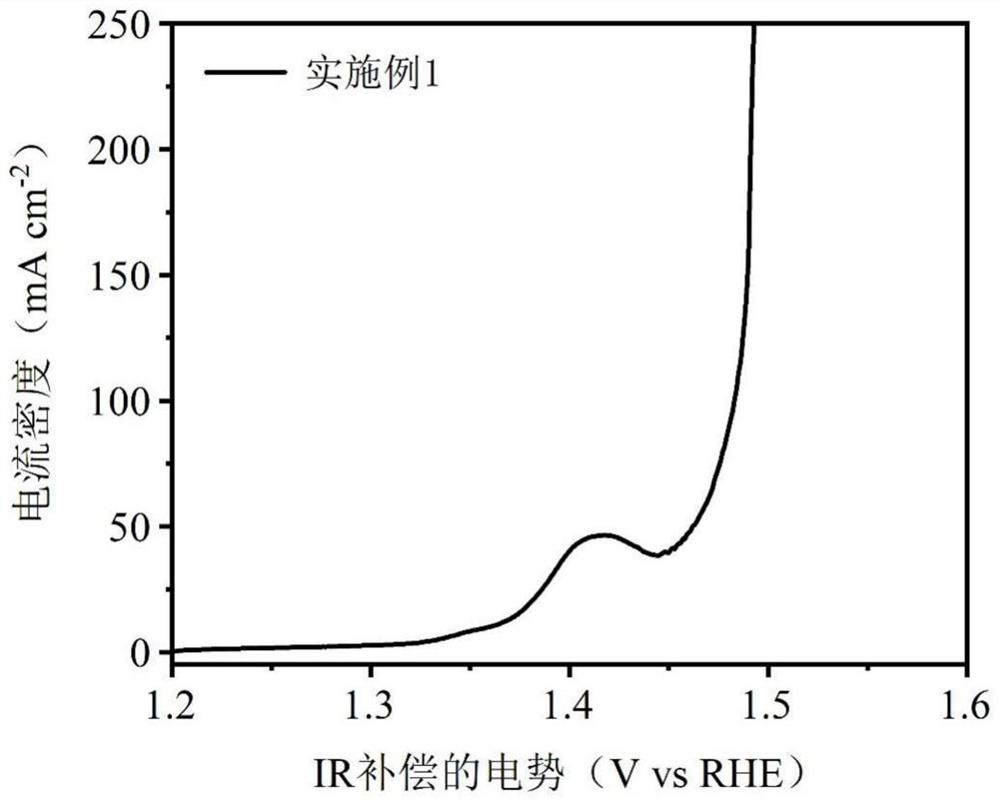

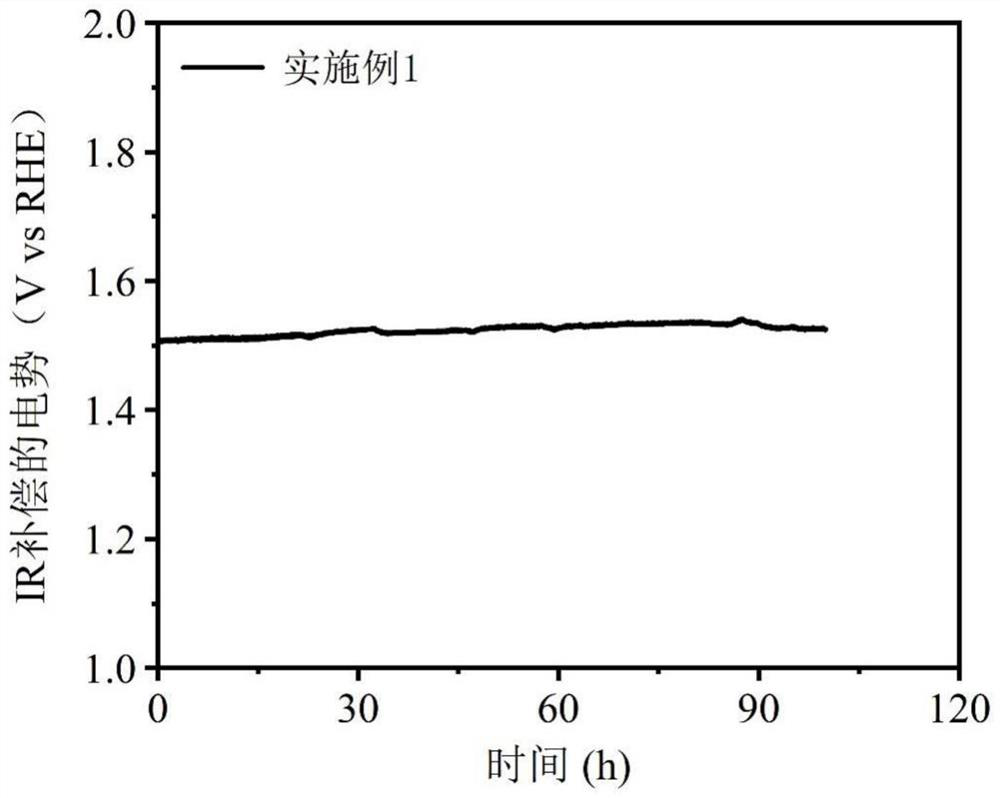

Embodiment 1

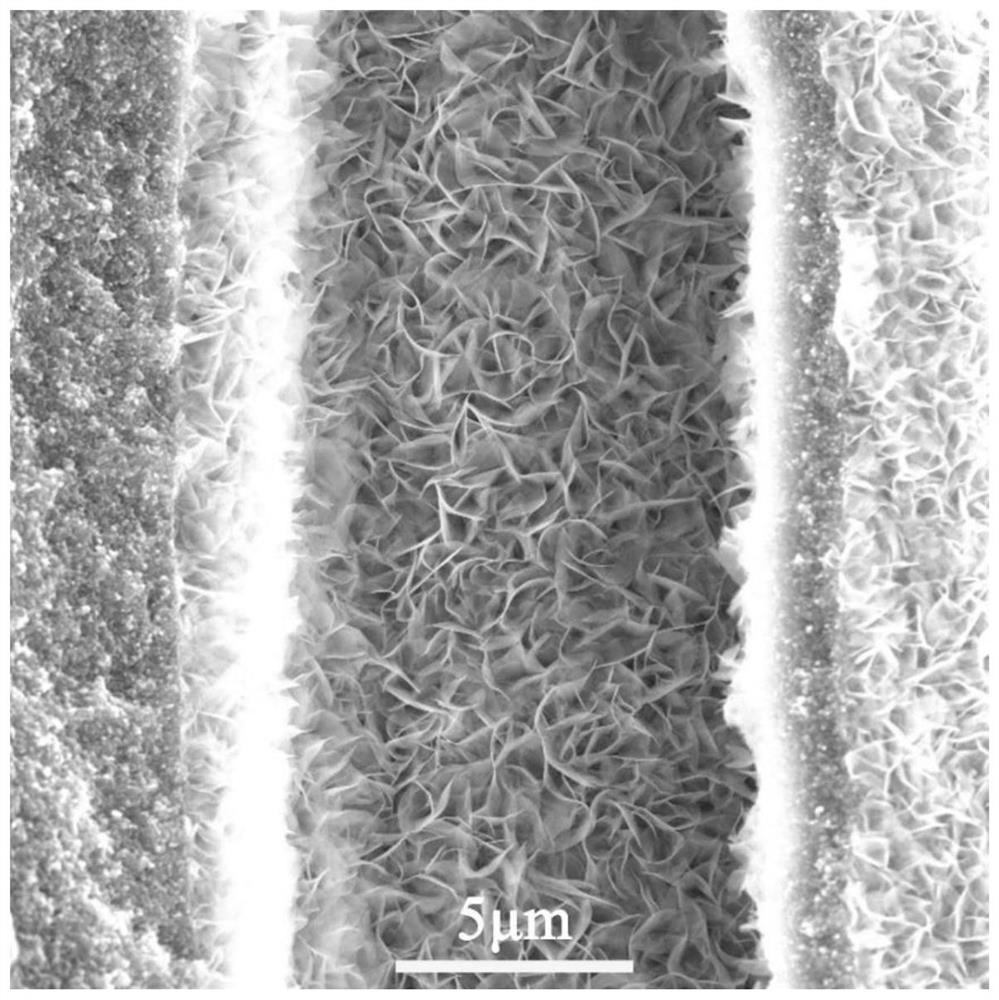

[0039] A wood-based electrocatalyst loaded with nickel-iron hydroxide / nickel-iron alloy. The electrocatalyst uses carbonized wood with a three-dimensional hierarchical porous structure and vertically oriented channels as a charcoal skeleton, and the charcoal skeleton is uniformly and firmly loaded with nickel-iron hydroxide. / Nickel-iron alloy heterojunction (nickel-iron alloy as the bottom layer and nickel-iron hydroxide as the surface layer). The specific surface area of the wood-based electrocatalyst is 100-200m 2 / g, the size of the active material is 100-150nm, and the loading rate of the active material is 0.2-10%.

[0040] The preparation method of the wood-based electrocatalyst of the above-mentioned loaded nickel-iron hydroxide / nickel-iron alloy comprises the following steps:

[0041] (1) Cut a large piece of poplar wood so that its size is 2.0cm×0.8cm×1mm (length×width×height), and weigh 0.05g.

[0042] (2) Add the wood chips in step (1) to the ferronickel nitra...

Embodiment 2

[0049] A wood-based electrocatalyst loaded with nickel-iron hydroxide / nickel-iron alloy. The electrocatalyst uses carbonized wood with a three-dimensional hierarchical porous structure and vertically oriented channels as a charcoal skeleton, and the charcoal skeleton is uniformly and firmly loaded with nickel-iron hydroxide. / nickel-iron alloy heterojunction.

[0050] The preparation method of the wood-based electrocatalyst of the above-mentioned loaded nickel-iron hydroxide / nickel-iron alloy comprises the following steps:

[0051] (1) Cut a large piece of poplar wood so that its size is 2.0cm×0.8cm×1mm (length×width×height), and weigh 0.05g.

[0052] (2) Add the wood chips in step (1) to the ferronickel nitrate solution (a total of 0.400g of nickel nitrate hexahydrate and ferric nitrate nonahydrate, the molar ratio of nickel ions to iron ions in the solution is 1.25:1), and put Vacuum impregnation was carried out in a vacuum drying oven, and the impregnation temperature was...

Embodiment 3

[0058] A wood-based electrocatalyst loaded with nickel-iron hydroxide / nickel-iron alloy. The electrocatalyst uses carbonized wood with a three-dimensional hierarchical porous structure and vertically oriented channels as a charcoal skeleton, and the charcoal skeleton is uniformly and firmly loaded with nickel-iron hydroxide. / nickel-iron alloy heterojunction.

[0059] The preparation method of the wood-based electrocatalyst of the above-mentioned loaded nickel-iron hydroxide / nickel-iron alloy comprises the following steps:

[0060] (1) Cut a large piece of poplar wood so that its size is 2.0cm×0.8cm×1mm (length×width×height), and weigh 0.05g.

[0061] (2) Add the wood chips in step (1) to the ferronickel nitrate solution (a total of 0.400 g of nickel nitrate hexahydrate and ferric nitrate nonahydrate, the molar ratio of nickel ions to iron ions in the solution is 0.5:1), and put Vacuum impregnation was carried out in a vacuum drying oven, and the impregnation temperature was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com