Device and method for removing dust from converter gas by dry method

A technology for dry dust removal and converter gas, applied in the direction of manufacturing converters, improving process efficiency, improving energy efficiency, etc., can solve problems such as electrostatic precipitator explosion, electrostatic precipitator blow up, affecting production, etc., to improve safety , the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

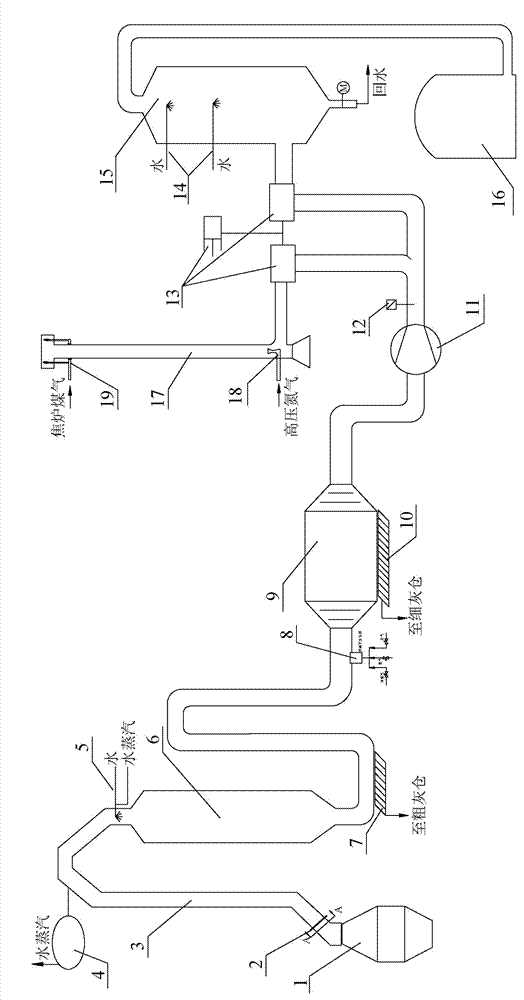

[0029] Example: Assume that the converter steelmaking cycle is 40min, of which 0-10min is the preparation stage before blowing, 11-32min is the blowing stage, of which 16-28min is the gas recovery stage, and 33-40min is the tapping stage, then the converter gas The working process of the dry dust removal device is as follows:

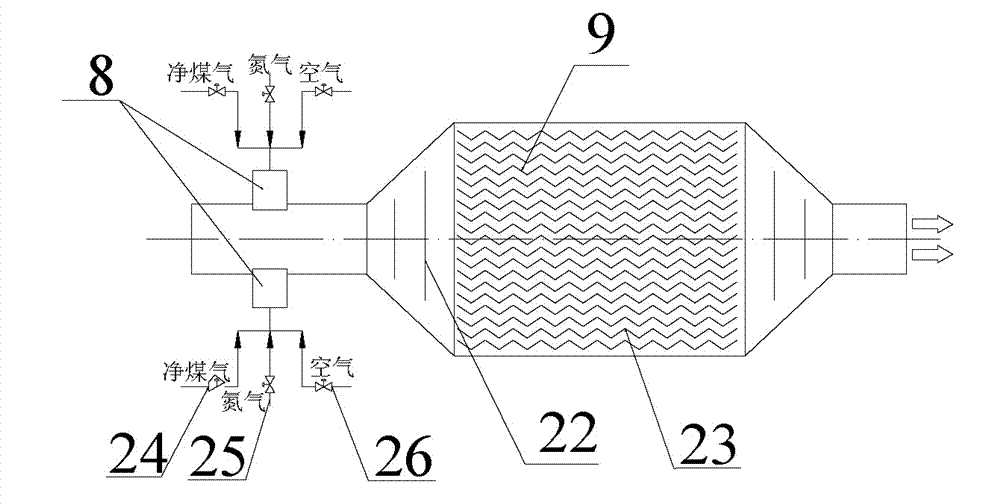

[0030] 1) 0-10min, the vaporization cooling flue is not fed with compressed air, the anion generator 8 is in the low pressure working mode, the compressed air is fed inside, and the electrostatic precipitator 9 is in the long vibration cycle;

[0031] 2) 11-15 minutes, a proper amount of compressed air is introduced into the vaporization cooling flue, the anion generator 8 is in the high-voltage working mode, and nitrogen gas is injected into it, and the electrostatic precipitator 9 is in the short vibration cycle;

[0032] 3) 16-28 minutes, the vaporization cooling flue is not fed with compressed air, the anion generator 8 is in the high-voltage working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com