Process for continuously synthesizing carbamate through catalytic rectification

A carbamate and process technology, applied in the field of continuous synthesis of carbamate, can solve the problems of high energy consumption for ammonia removal and low urea conversion rate, and achieve good economy, continuous change of reaction parameters, and less back-mixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

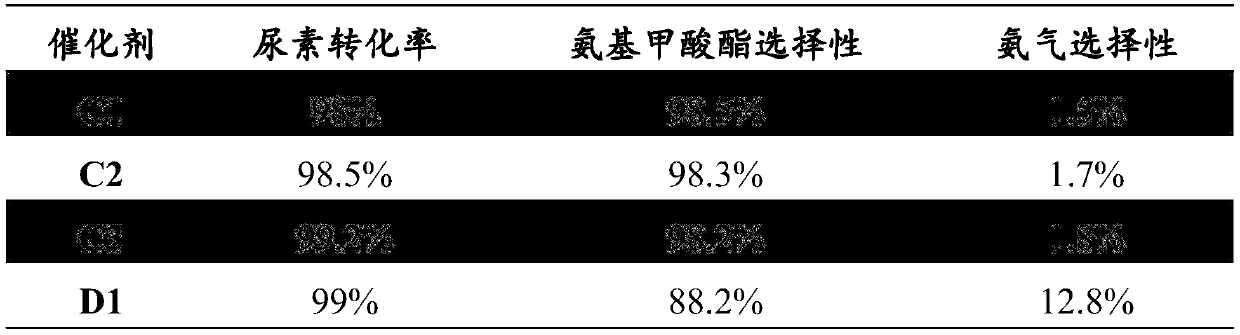

Examples

Embodiment 1

[0027] S1. Dissolve 1 mol of zinc nitrate and 20 mol of zirconium nitrate in 5L of deionized water, stir and mix well, add 500g of alumina carrier, and adjust the pH to 1 with dilute sulfuric acid, ultrasonically disperse for 3 hours, impregnate for 2 hours, and then Drying at 120°C for 5 hours, and finally calcination at 1200°C for 3 hours at a high temperature to obtain a catalyst precursor;

[0028] S2. Add 100g of catalyst precursor and 1.5g of sodium metal into a vacuum grinding reactor, and grind for 4 hours at 300°C to obtain a high-efficiency solid-phase catalyst Na-ZnO-ZrO 2 / γ-Al 2 o 3 , which is catalyst C1.

Embodiment 2

[0030] S1. Dissolve 1mol of zinc chloride and 30mol of zirconium chloride in 6L of deionized water, stir and mix well, add 500g of alumina carrier, and adjust the pH to 1 with dilute sulfuric acid, ultrasonically disperse for 2 hours, and impregnate for 3 hours , followed by drying at 80°C for 10 hours, and finally at 1000°C, high-temperature roasting for 5 hours to obtain a catalyst precursor;

[0031] S2. Add 100g of catalyst precursor and 5g of metal sodium into the vacuum grinding reactor, and grind for 3 hours at 300°C to obtain a high-efficiency solid-phase catalyst Na-ZnO-ZrO 2 / γ-Al 2 o 3 , denoted as catalyst C2.

Embodiment 3

[0033] S1. Dissolve 1mol of zinc nitrate and 50mol of zirconium nitrate in 6L of deionized water, stir and mix well, add 300g of alumina carrier, and adjust the pH to 2. After ultrasonic dispersion for 2 hours, impregnation reaction for 3 hours, then at 120 Drying at ℃ for 5 hours, and finally at 800 ℃, high-temperature roasting for 12 hours to obtain the catalyst precursor;

[0034] S2. Add 100g of the catalyst precursor and 8g of sodium metal into a vacuum grinding reactor, and grind for 3 hours at 200°C to obtain a high-efficiency solid-phase catalyst Na-ZnO-ZrO2 / γ-Al2O3, which is designated as catalyst C3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com