Micro-channel reactor

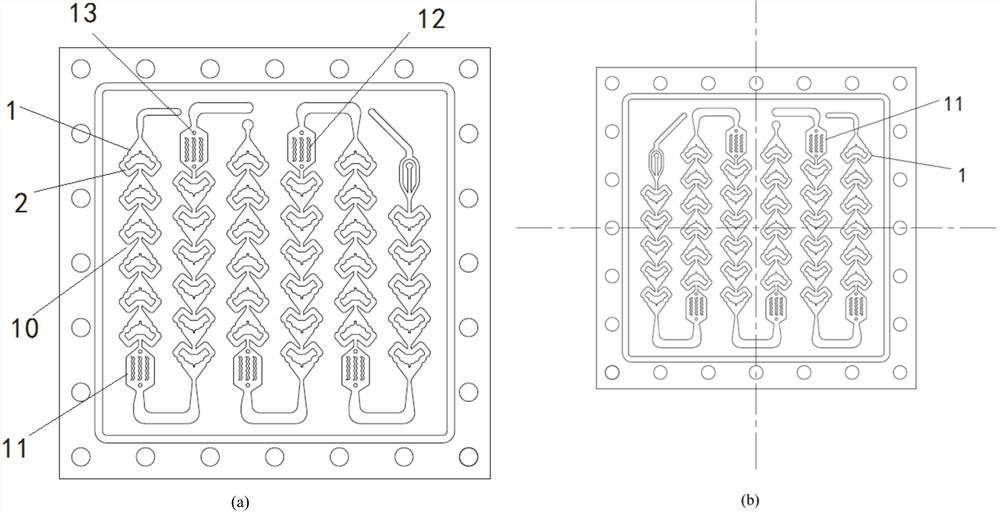

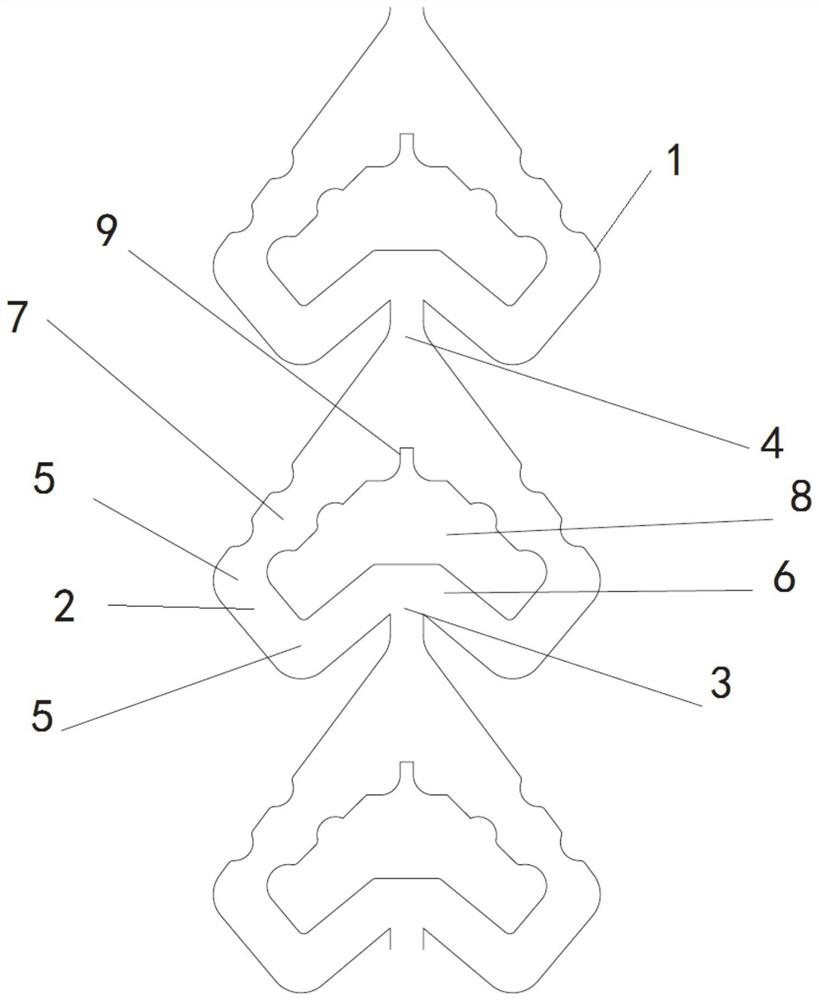

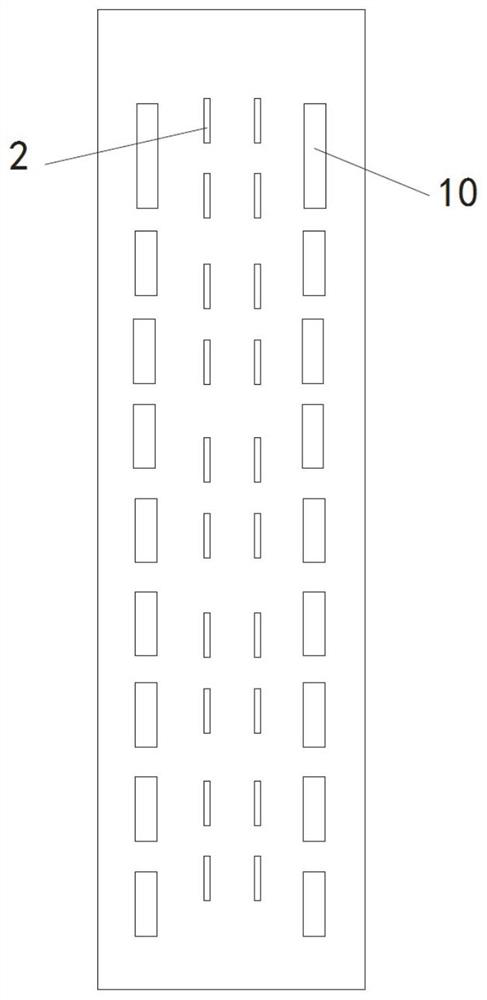

A micro-channel reactor, micro-reactor technology, applied in chemical/physical/physical-chemical reactors, chemical instruments and methods, chemical/physical/physical-chemical processes, etc., can solve the problem of small liquid holding volume, increased by-products, Improve enterprise costs and other issues, to achieve the effect of reducing process reaction conditions, improving mass transfer and heat transfer efficiency, and reducing enterprise costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1—nitration reaction

[0061] The reaction formula is as follows:

[0062]

[0063] The disadvantages of nitration reaction are: large heat release, violent reaction, poor selectivity, many by-products, large amount of acid, and cumbersome post-treatment. The tank reactor and microreactor were used to carry out the nitration reaction respectively, and the reaction conditions and effects are shown in Table 3.

[0064] Table 3 Comparison of Nitrification Reaction

[0065] Reactor form Acid dosage (eq) Reaction temperature / ℃ Reaction time Conversion rate / % selectivity / % kettle reaction 1.2 40-45 2h 99 95.2 microreactor 1.08 60 20s 99.8 98.8

[0066] Known by embodiment 1, the advantage of microchannel reactor is: control heat of reaction, shorten reaction time, improve selectivity and yield, reduce the consumption of acid, improve safety.

Embodiment 2

[0067] Embodiment 2—Grignard reaction

[0068] The reaction formula is as follows:

[0069]

[0070] The disadvantages of Grignard reaction are anhydrous and oxygen-free; low reaction temperature and large heat release; tank reaction is easy to get out of control, and the quality of batch reaction products is unstable. Utilize tank reactor and microreactor to carry out Grignard reaction respectively, reaction condition and effect are as shown in table 4.

[0071] Table 4 Comparison of Format Responses

[0072] Reactor form Grignard reagent dosage Reaction temperature / ℃ Reaction time Product content / % selectivity / % kettle reaction 1.2eq -10 30min 97 A small amount of impurities microreactor 1.1eq 20 25s 99 No impurities

[0073] It can be seen from Example 2 that the advantages of the microchannel reactor are: strengthening the mass transfer and heat transfer process, shortening the reaction time, and improving safety.

Embodiment 3

[0074] Embodiment 3—Butyl lithium reaction

[0075] The reaction formula is as follows:

[0076]

[0077] The disadvantages of butyllithium reaction are low-temperature exothermic reaction, large reaction heat, conventional reaction requirements below -70°C, absolute anhydrous and oxygen-free environment, poor selectivity, poor safety, and difficult to realize industrialization. Utilize flask reaction and microreactor to carry out butyllithium reaction respectively, and reaction condition and effect are as shown in table 5. Field experiment picture as Figure 11 shown.

[0078] The comparison of table 5 butyllithium reaction

[0079] Reactor form Feeding method Reaction temperature / ℃ Reaction time Product content / % selectivity / % flask reaction Step by drop -80~-70 5h 99.5% 80~85 microreactor three-step joint investment -30 1min 99.9% 86

[0080] Known by embodiment 3, the advantage of microchannel reactor is: shorten reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com