External discharge type continuous hydrate seawater desalination device

A technology for the generation of hydrates and hydrates, which is applied in seawater treatment, water/sewage treatment, water/sludge/sewage treatment, etc. It can solve problems such as affecting the quality of desalinated water, and achieve the effect of complete functions and realization of structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

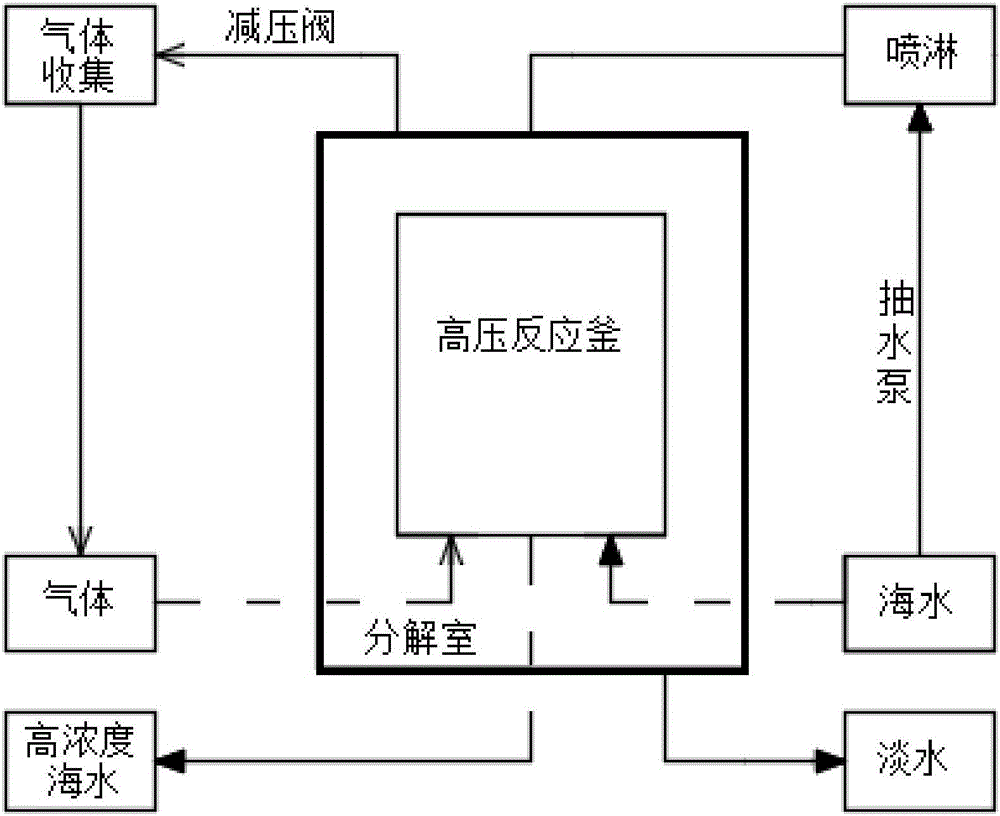

[0017] figure 1 Shown is a block diagram of the working principle of an external discharge continuous hydrate method seawater desalination device. The working process is as follows: gas hydration agent and seawater are passed into the high-pressure reactor 11 to form hydrate, and the filter device 12 lifts the hydrate out of the water surface Low-temperature seawater spraying is carried out. At this time, high-concentration seawater is discharged, and seawater is re-introduced to prepare for the next seawater desalination process. Then the hydrate is discharged to the bottom of the high-pressure reactor 11, and the decomposed freshwater is collected and recycled for gas hydration. Thus, the hydrate seawater desalination technology realizes highly centralized production.

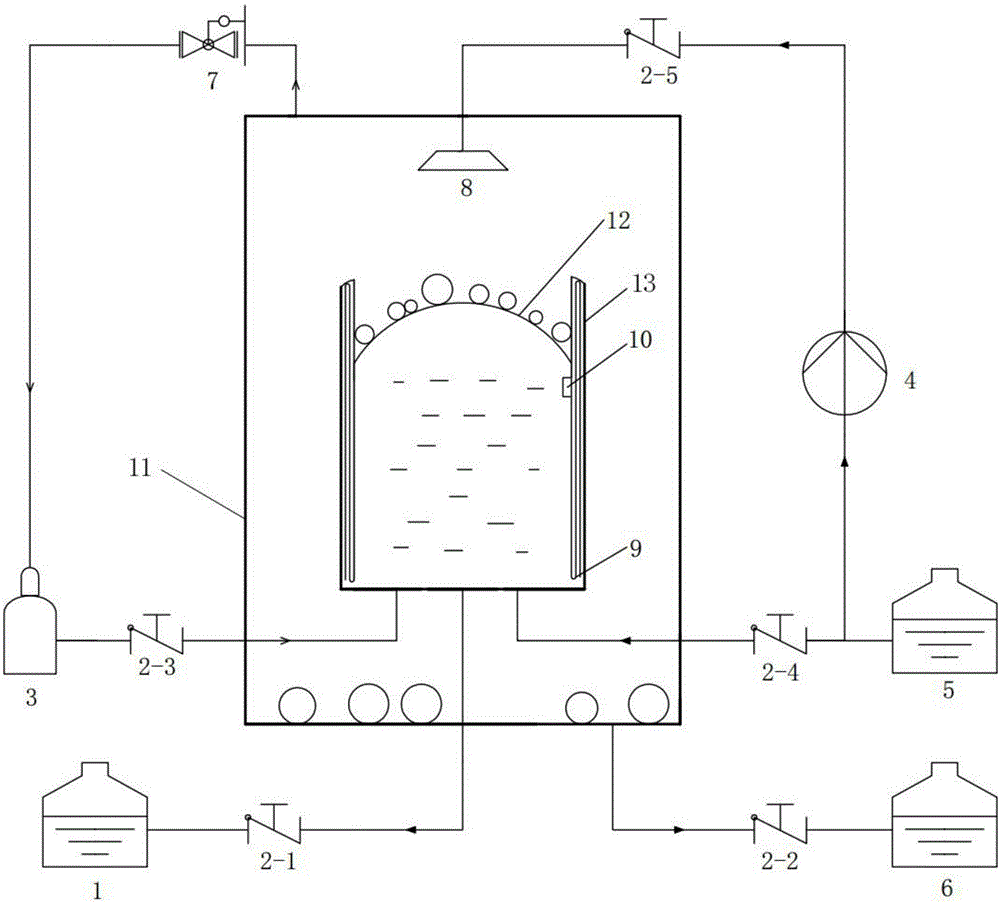

[0018] figure 2 Shown is a structural sch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com