Apparatus for non-aqueous catalytic synthesis and self-separation of 1-amino-2-propanol, and process thereof

An isopropanolamine and self-separation technology, which can be used in molecular sieve catalysts, preparation of organic compounds, preparation of amino hydroxy compounds, etc., can solve the problems of limiting the large-scale application of high-pressure supercritical methods, consuming large amounts of energy, and tedious operations. Reasonable design, reduced generation, good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of described solid catalyst is as follows:

[0036] 1) Synthesis of titanium silicon molecular sieve

[0037] Tetraethyl orthosilicate was used as the silicon source, tetrabutyl titanate was used as the titanium source, tetrapropylammonium hydroxide was used as the template, and SiO 2 · aTPAOH · bTiO 2 · cH 2 O forms a gel, wherein a=0.2, b=0.02;

[0038] Under stirring conditions, mix water, ethyl orthosilicate, tetrabutyl titanate and tetrapropyl ammonium hydroxide, stir in a constant temperature water bath at 80°C for 30 hours, add deionized water during the stirring process to maintain the mixture composition;

[0039] Put the mixed solution into a stainless steel autoclave with a polytetrafluoroethylene internal scale, crystallize at 200°C for 5 days, wash the crystallized powder to neutrality and dry it, then put it into a resistance furnace and heat it up to Calcined at 560°C for 8 hours, cooled to room temperature to obtain titanium s...

Embodiment 1

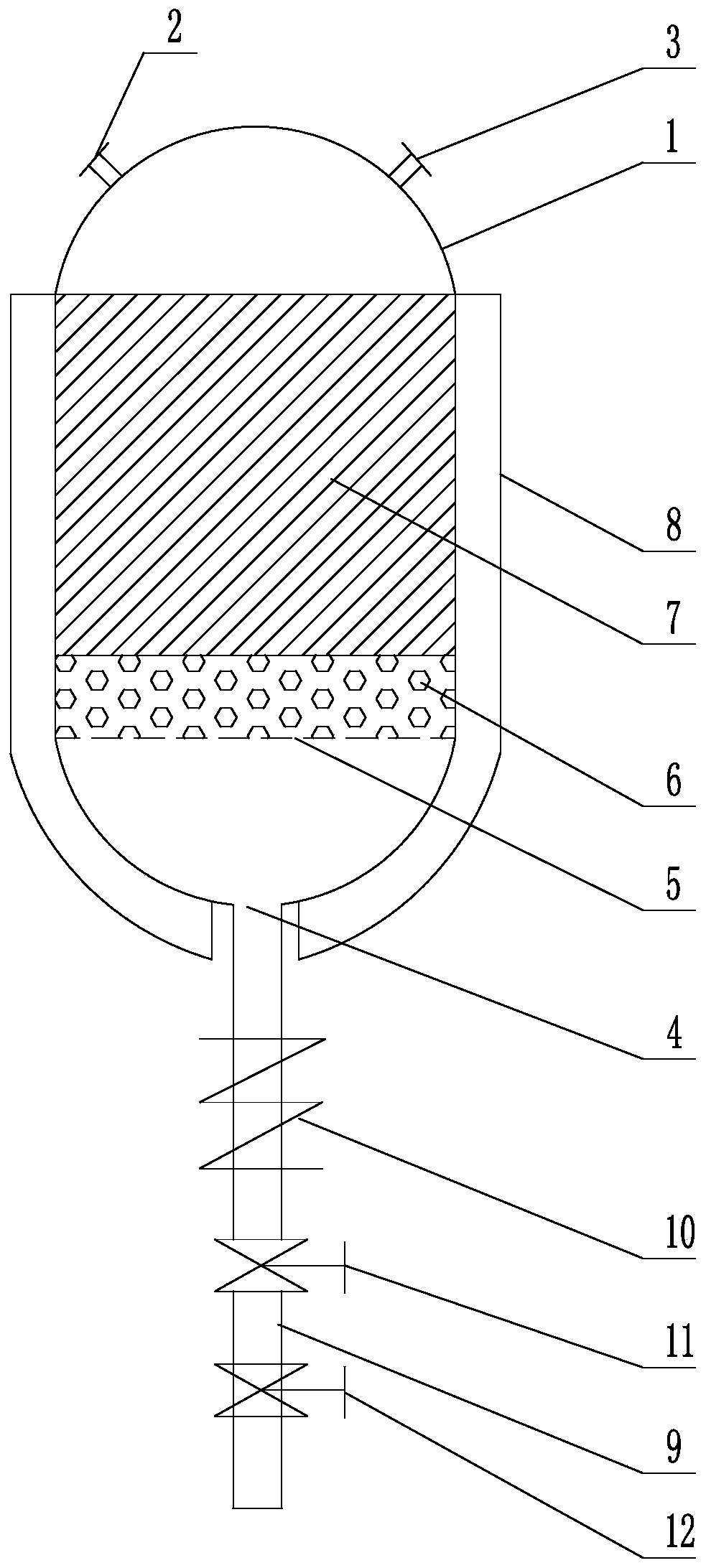

[0043] Such as figure 1 As shown, the non-aqueous catalytic synthesis-isopropanolamine self-separation device includes a reactor 1, a propylene oxide inlet 2 and an ammonia inlet 3 are arranged at the top of the reactor 1, and a discharge port 4 is arranged at the bottom of the reactor 1, The inside of the reactor 1 is provided with orifice plate 5, ceramic ball 6 and solid catalyst 7 sequentially from bottom to top, the outside of the reactor 1 is provided with a jacket 8, the discharge port 4 is connected with the buffer pipe 9, and the outside of the buffer pipe 9 is provided with a cooling plate The pipe 10 and the buffer pipe 9 are provided with a valve A11 and a valve B12.

[0044] The top of the reactor 1 is also provided with a temperature measuring device and a pressure measuring device.

[0045] The technique of described non-aqueous catalytic synthesis-isopropanolamine self-separation device, concrete steps are as follows:

[0046]1) Load the solid catalyst into t...

Embodiment 2

[0051] The structure of the device is the same as in Example 1.

[0052] The technique of described non-aqueous catalytic synthesis-isopropanolamine self-separation device, concrete steps are as follows:

[0053] 1) Load the solid catalyst into the reactor, raise the temperature to 200°C, and pass nitrogen gas for 10 minutes;

[0054] 2) Continuously feed propylene oxide and ammonia gas into the reactor through the propylene oxide inlet and the ammonia gas inlet to react, the molar ratio of ammonia gas to propylene oxide is 5:1, and the flow rate of ammonia gas: 80mL / min;

[0055] 3) The temperature of the buffer tube is controlled at 60°C, and the isopropanolamine produced by the reaction is extracted from the end of the buffer tube. During the reaction, valve A is opened and valve B is closed. When the product is extracted, valve A is closed and valve B is opened. .

[0056] The purity of the extracted monoisopropanolamine product is 98.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com