Method for producing nano-ITO powder with plasma electrical arc one-step method

A plasma arc and plasma technology, applied in chemical instruments and methods, inorganic chemistry, gallium/indium/thallium compounds, etc., can solve the problems affecting target sintering, long cycle, long time, etc., to achieve enhanced gasification effect, Good dispersibility and the effect of improving evaporation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

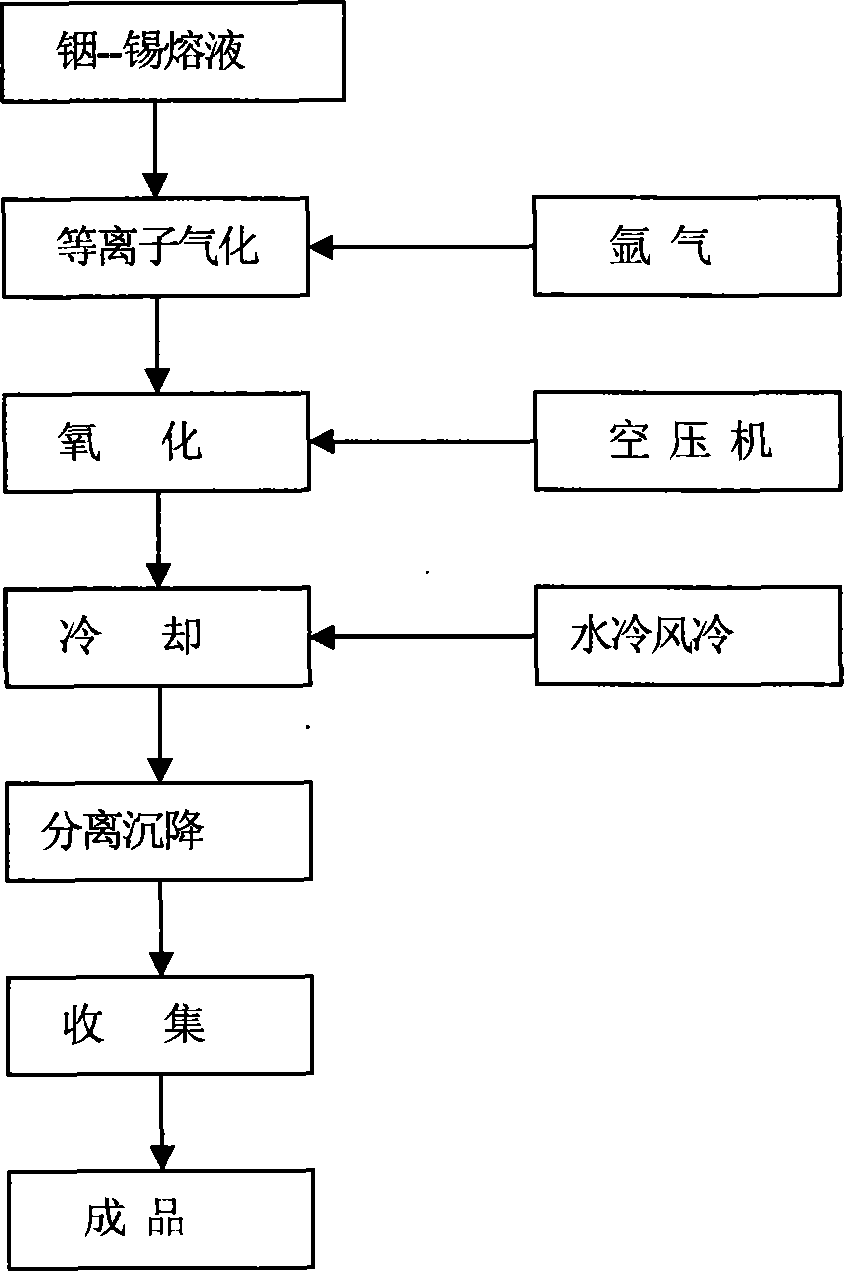

Method used

Image

Examples

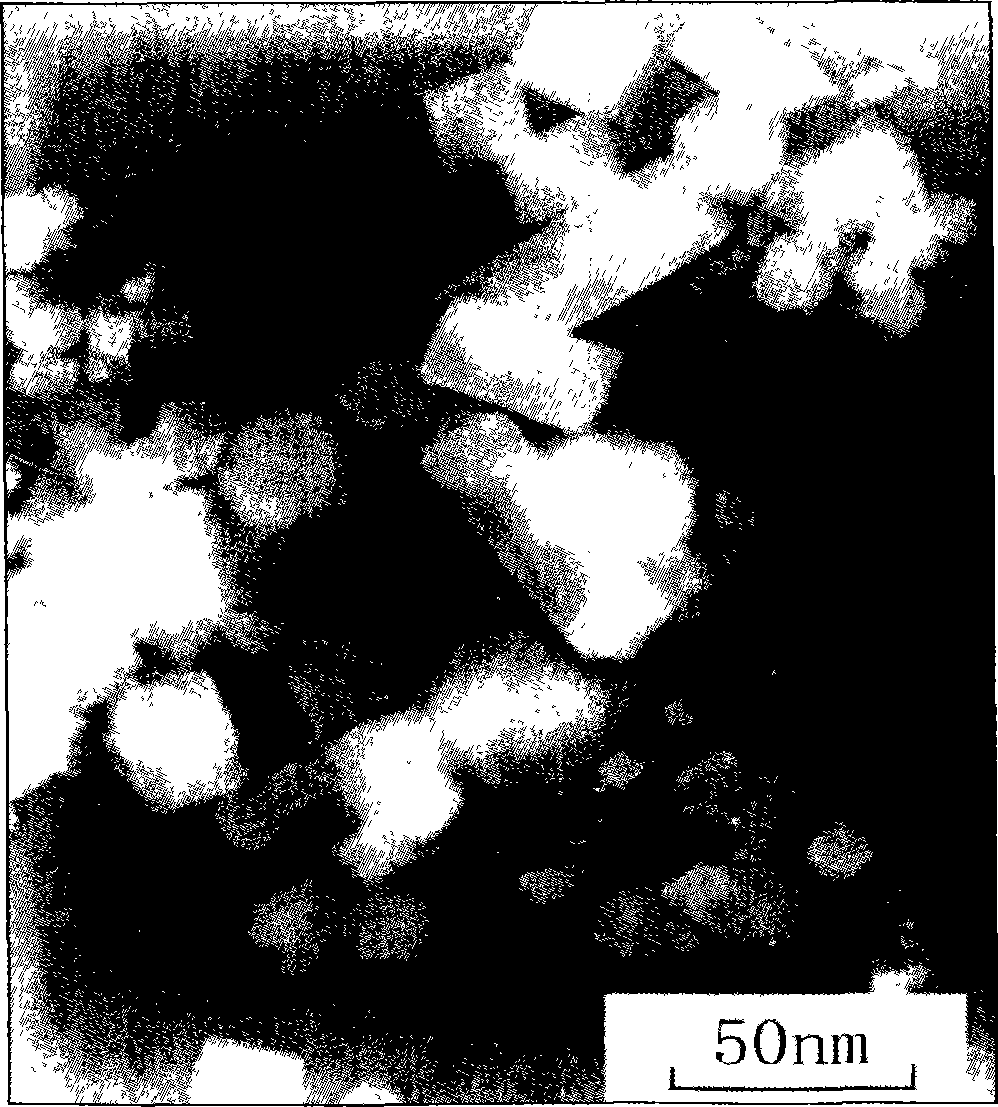

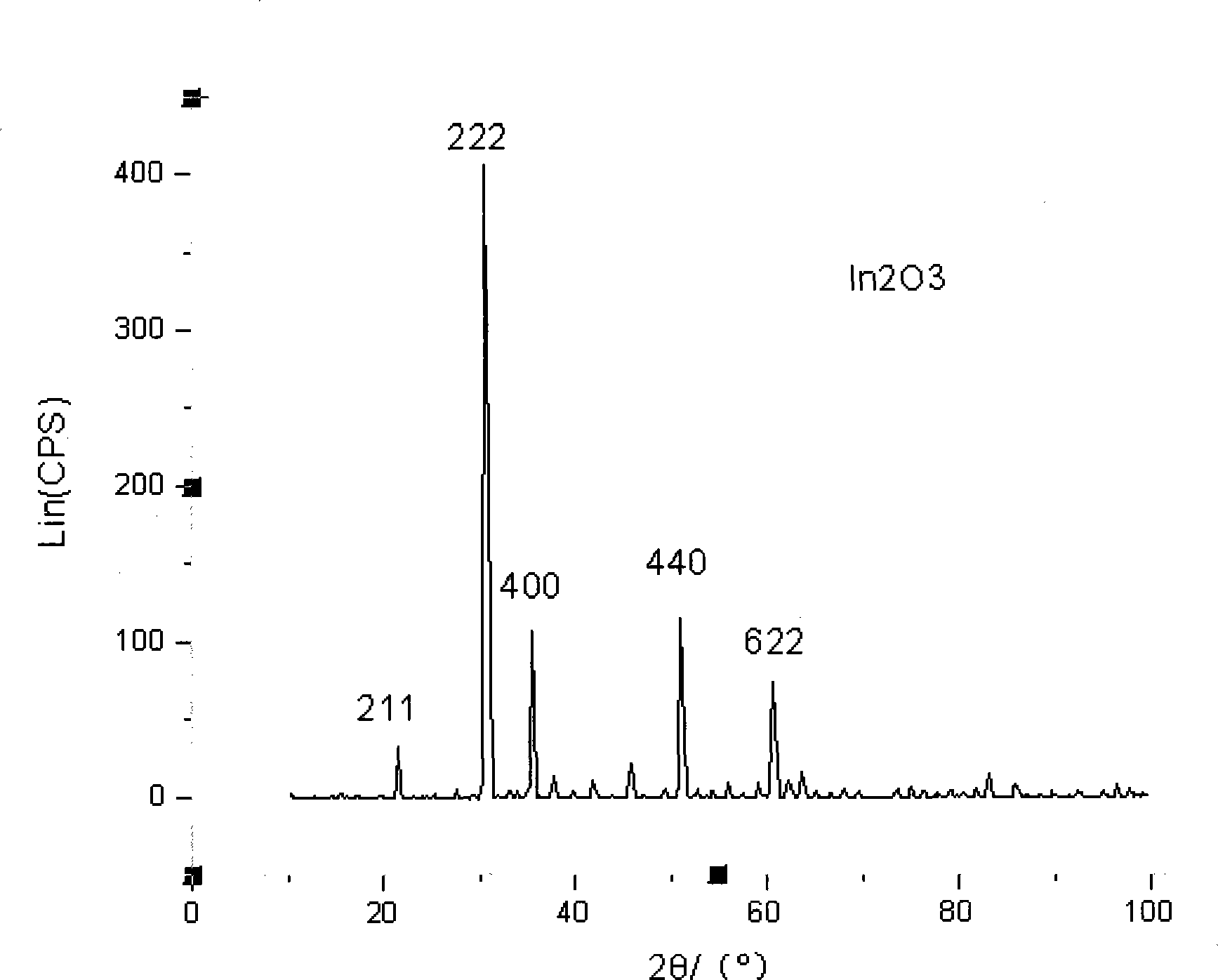

Embodiment 1

[0018] Weigh 100g of pure metal In, Sn11.062g (weight ratio: In:Sn=9.04:1) to make alloy melt, use Ar as the plasma working gas, control voltage at 60V, current at 100A, at about 1.5g / min The alloy is fed into the crucible of the plasma reaction chamber at a high speed, and the alloy raw material is used as the positive electrode. The high-frequency igniter is ignited between the positive electrode and the negative electrode of the plasma gun nozzle to form an arc, and the surrounding inert gas is ionized to form a stable plasma. , the raw material is heated and melted by high-temperature plasma, evaporated to form metal vapor, and reacts with oxygen. Since the interlayer of the reactor is cooled by flowing water and cooled by compressed air, a large temperature gradient is formed, resulting in a high supersaturation zone in the metal vapor, and spontaneous nucleation, condensation, and growth from the gas phase. Nanoparticles, enter the collection chamber.

Embodiment 2

[0020] It is basically the same as Example 1, except that the operating voltage of the plasma reaction chamber is 30V, the current is 400A, and the feeding rate is 2.5g / min. Other conditions are the same as Example 1.

Embodiment 3

[0022] It is basically the same as Example 1, except that the operating voltage of the plasma reaction chamber is 40V, the current is 300A, and the feeding rate is 2.5g / min. Other conditions are the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com