Recycled sintered brick aggregate C30-containing concrete and preparation method thereof

A technology for concrete and sintered bricks, which is applied in the field of C30 concrete containing recycled sintered brick aggregates and its preparation, and can solve problems affecting the fluidity and strength of concrete mixtures, low strength and ductility of recycled concrete specimens, and resource utilization of construction waste Low efficiency and other issues, to achieve the effect of improving microstructure and durability, increasing the number of effective collisions, and improving stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Testing of working performance of C30 concrete containing recycled sintered brick aggregate:

[0023] A C30 concrete containing recycled fired brick aggregate, composed of the following raw materials by weight: cement 494.22kg, recycled fired brick coarse aggregate 765.99kg, natural coarse aggregate 327.85kg, fine aggregate 589.98kg, water 250.97kg, water ash The ratio is 0.51.

[0024] The cement is P.O 42.5R ordinary Portland cement.

[0025] The particle size of the coarse aggregate of recycled fired bricks d 1 5mm-10mm, volume density is 1032kg / m 3 , the crushing index is 15.2%, the water absorption rate is 12%, and the water content rate is 5.26%.

[0026] In the regenerated sintered brick coarse aggregate, the regenerated sintered brick aggregate accounts for 45%-65% of the total mass of the regenerated aggregate.

[0027] The natural coarse aggregate includes limestone gravel, and the particle size d of the natural coarse aggregate is 2 5mm-16mm, ...

Embodiment 2

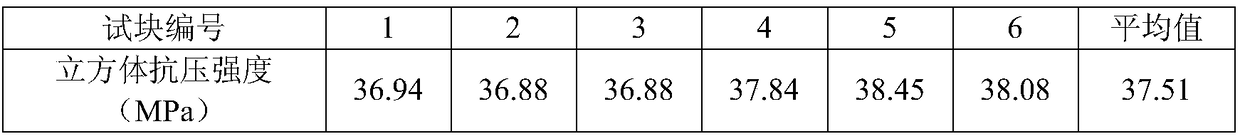

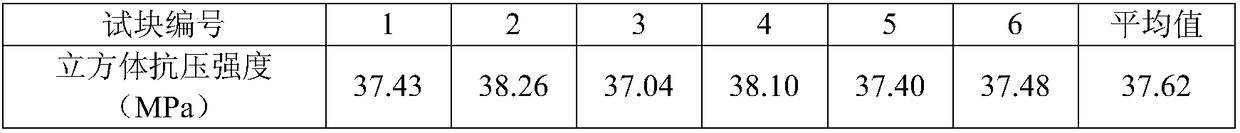

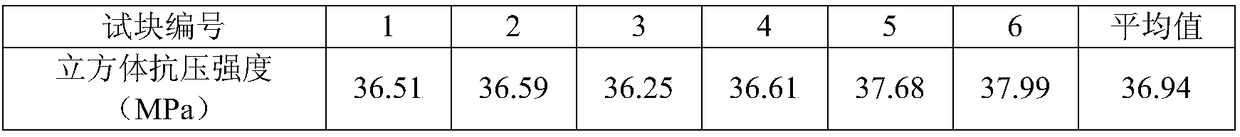

[0036] Embodiment 2: Containing recycled sintered brick aggregate C30 concrete compressive strength test:

[0037] Put the cube test block of compressive strength in the C30 concrete containing recycled sintered brick aggregate obtained in the embodiment of the present invention, let it stand for 24 hours in an environment with a temperature of 20 ± 5°C, and finally move it to the concrete standard curing room for curing. The age of standard curing for 28d. After reaching the curing age, according to the provisions of GB / T50081-2002 "Standards for Test Methods of Mechanical Properties of Ordinary Concrete", the test blocks were taken out for compression tests. The test results are shown in Table 1. It can be seen from the test results that the prepared C30 concrete containing recycled fired brick aggregate meets the standard requirements of concrete.

[0038] Table 1 Strength test results of concrete containing recycled fired brick aggregate

[0039]

Embodiment 3

[0040] Example 3: Testing of working performance of C30 concrete containing recycled sintered brick aggregate:

[0041] A C30 concrete containing recycled fired brick aggregate, composed of the following raw materials by weight: cement 635.37kg, recycled fired brick coarse aggregate 730.95kg, natural coarse aggregate 310.05kg, fine aggregate 570.95kg, water 292.26kg, water ash The ratio is 0.46.

[0042] The cement is P.O 42.5R ordinary Portland cement.

[0043] The particle size of the coarse aggregate of recycled fired bricks d 1 5mm-10mm, volume density is 1140kg / m 3 , the crushing index is 17.3%, the water absorption rate is 14.8%, and the water content rate is 6.52%.

[0044]In the regenerated sintered brick coarse aggregate, the regenerated sintered brick aggregate accounts for 45%-65% of the total mass of the regenerated aggregate.

[0045] The natural coarse aggregate includes limestone gravel, and the particle size d of the natural coarse aggregate is 2 5mm-16mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com