Temperature triggered handwork furnace coal baking room dust collection desulfurization and denitrification method and device

A technology of desulfurization, denitrification, and hand-fired furnace, which is applied in the direction of separation devices, separation methods, chemical instruments and methods, etc., can solve problems such as flue gas pollution, achieve the effects of reducing emissions, simple devices, and solving flue gas pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

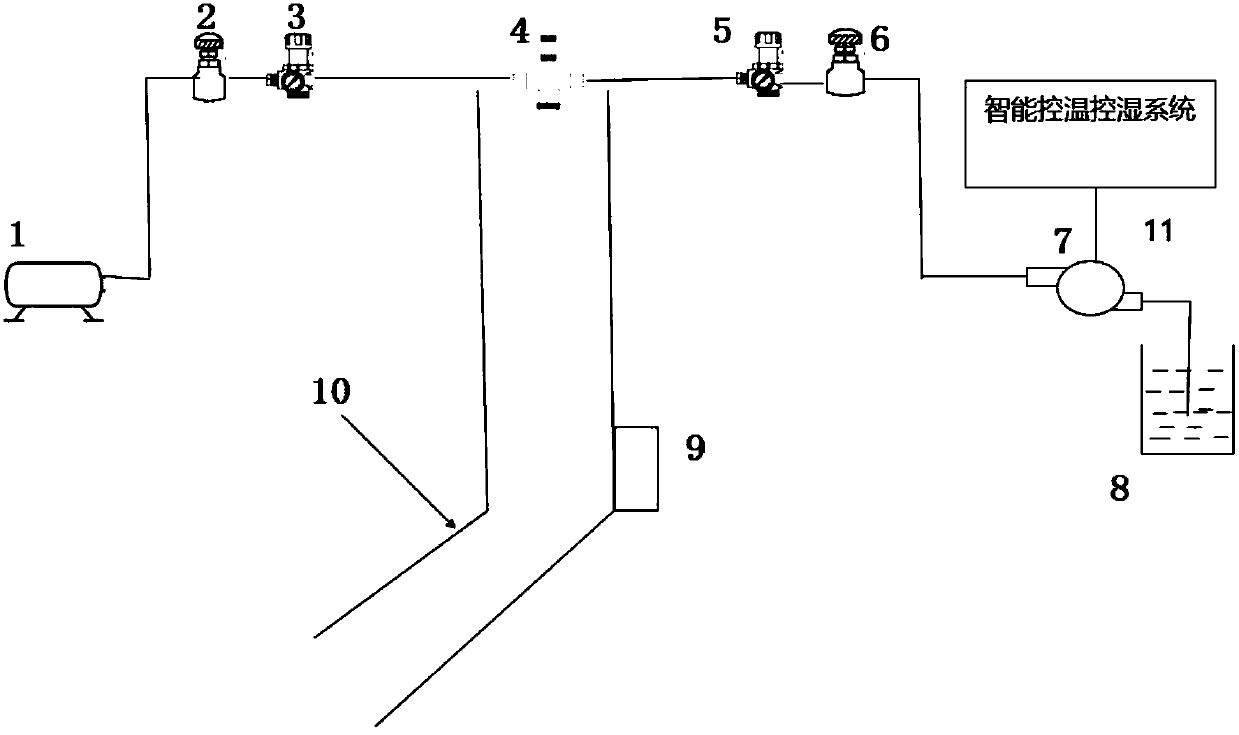

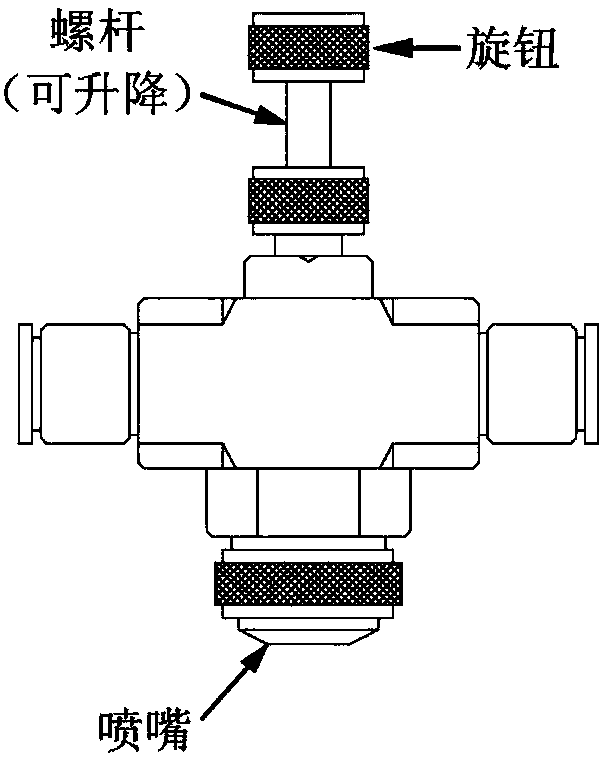

[0042] The invention provides an intelligent nozzle type dust removal and desulfurization device, which comprises the following steps:

[0043] (1) The air path of the nozzle is connected to the air compressor 1, the shut-off valve 2, and the air pressure regulating valve 3 with a pressure gauge in sequence. The air compressor provides compressed air, and the air pressure regulating valve regulates the air flow.

[0044] (2) The liquid path of the nozzle is sequentially connected with the peristaltic pump 7, the shut-off valve 6, and the liquid pressure regulating valve 5 with a pressure gauge. The peristaltic pump is used to provide pressure to the liquid, and the liquid pressure regulating valve regulates the flow of the liquid circuit.

[0045] (3) The control end of the peristaltic pump is connected with the intelligent temperature and humidity control system 11 that comes with the barn.

[0046] (4) When the smoke concentration in the chimney is too high or the flow rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com