Method for preparing highly-pure beta-Sialon ceramic powders

A ceramic powder, high-purity technology, applied in the field of ceramic materials, can solve problems such as high content, high requirements, and inevitable impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

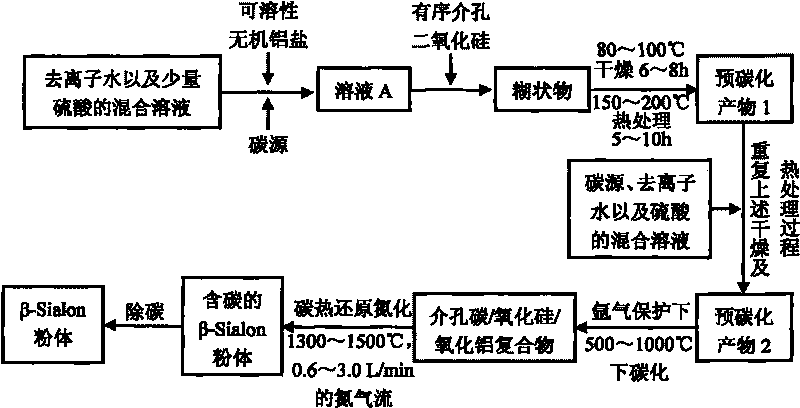

Method used

Image

Examples

Embodiment 1

[0041]The molar ratio of silicon and aluminum in the initial proportion is 1:1, and the molar ratio of silicon and sucrose is 1:0.42. First dissolve 4.45g of anhydrous aluminum trichloride into 10g of deionized water, then add 3.0g of sucrose, stir for a while to completely dissolve the sucrose, then add 0.34g of sulfuric acid, then slowly add 2.0g of SBA-15 to the above solution, stir Evenly, the obtained product was dried at 80°C for 6 hours to allow the water to evaporate completely, and then the temperature was raised to 160°C for 6 hours of heat treatment for pre-carbonization. In the second step, continue to add a solution consisting of 1.8g of sucrose, 0.2g of sulfuric acid and 10g of deionized water to the above-mentioned pre-carbonized product, and repeat the drying at 80°C and heat treatment at 160°C. The third step is to calcine at 800°C for 6 hours under the protection of argon with an argon flow rate of 0.2 L / min to complete the entire carbonization process and ob...

Embodiment 2

[0043] The molar ratio of silicon and aluminum in the initial proportion is 1:1, and the molar ratio of silicon and sucrose is 1:0.5. First dissolve 4.45g of anhydrous aluminum trichloride into 10g of deionized water, then add 3.6g of sucrose, stir for a while to completely dissolve the sucrose, then add 0.4g of sulfuric acid, then slowly add 2.0g of SBA-15 to the above solution, stir Evenly, the obtained product was dried at 80°C for 6 hours to allow the water to evaporate completely, and then the temperature was raised to 160°C for 6 hours of heat treatment for pre-carbonization. In the second step, continue to add a solution consisting of 2.16g of sucrose, 0.24g of sulfuric acid and 10g of deionized water to the above-mentioned pre-carbonized product, and repeat the drying at 80°C and heat treatment at 160°C. The third step is to calcine at 800°C for 6 hours under the protection of argon with an argon flow rate of 0.2 L / min to complete the entire carbonization process and o...

Embodiment 3

[0045] The molar ratio of silicon and aluminum in the initial proportion is 1:1, and the molar ratio of silicon and sucrose is 1:0.58. First dissolve 4.45g of anhydrous aluminum trichloride into 10g of deionized water, then add 4.2g of sucrose, stir for a while to completely dissolve the sucrose, then add 0.48g of sulfuric acid, then slowly add 2.0g of SBA-15 to the above solution, stir Evenly, the obtained product was dried at 80°C for 6 hours to allow the water to evaporate completely, and then the temperature was raised to 160°C for 6 hours of heat treatment for pre-carbonization. In the second step, continue to add a solution consisting of 2.52g of sucrose, 0.3g of sulfuric acid and 10g of deionized water to the above-mentioned pre-carbonized product, and repeat the drying at 80°C and heat treatment at 160°C. The third step is to calcine at 800°C for 6 hours under the protection of argon with an argon flow rate of 0.2 L / min to complete the entire carbonization process and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com