Low-temperature non-calcination preparation method of pollucite

A cesium garnet, calcination-free technology, applied in the directions of aluminum silicate, silicate, etc., can solve the problems of difficult capture and collection of Cs airborne substances, high temperature volatilization of Cs, and high synthesis temperature, which is beneficial to environmental protection and avoids high temperature. The effect of volatilization and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

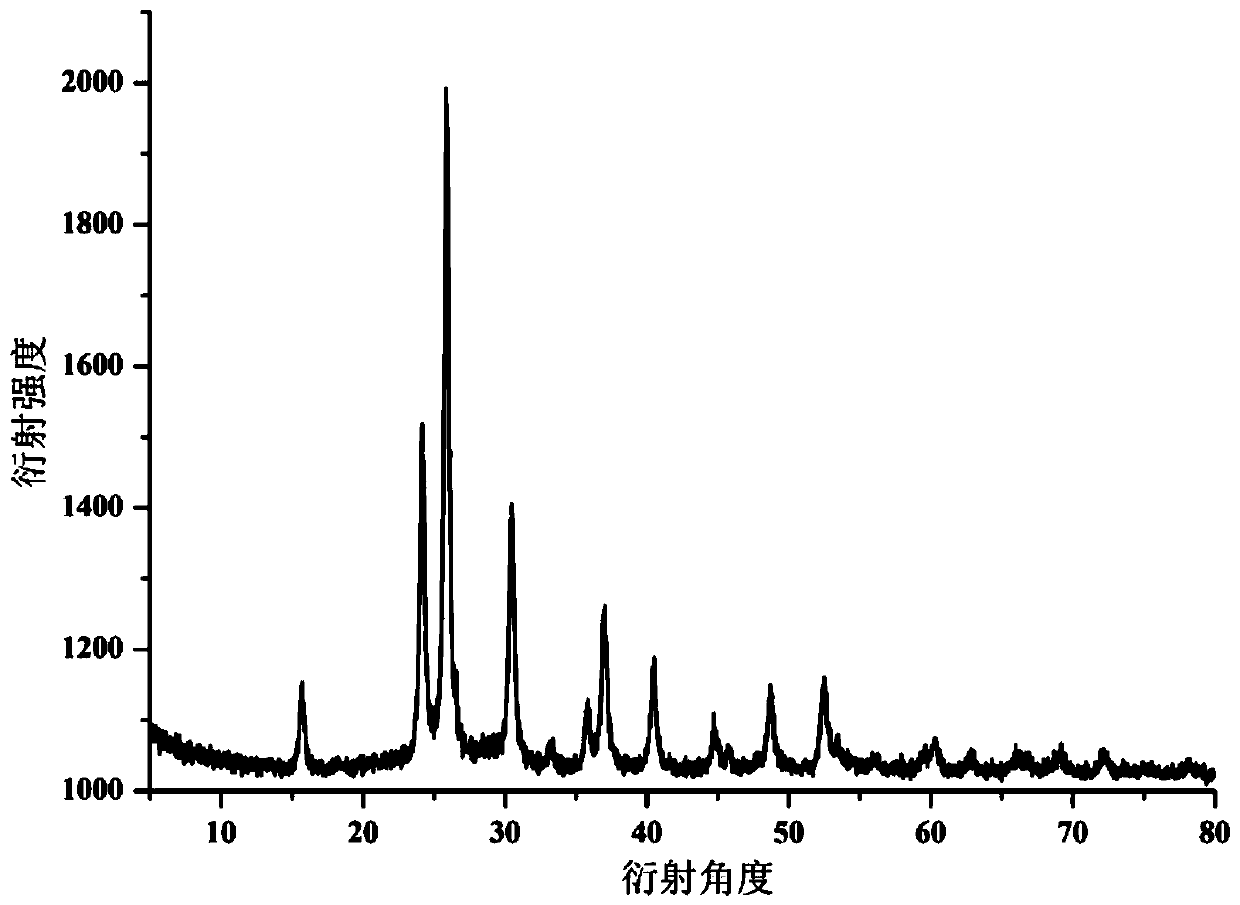

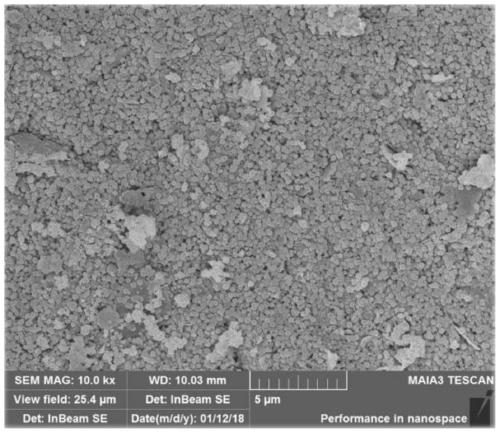

[0020] A low-temperature non-calcining preparation method of cesium garnet, the steps are: weighing aluminum-silicon raw materials and cesium hydroxide, mixing to obtain solid powder, so that the molar ratio of Cs:Al:Si=1:1:2; Mix evenly with water not exceeding 10% of the solid powder mass to obtain a water-containing solid mixture; the water-containing solid mixture is pressed into a tablet machine at 3-5MPa, and the demoulded sample is placed in a blast drying oven at 105 °C The dried sample was placed in an autoclave reactor, crystallized in a water vapor environment at a temperature of 120 °C for 24 h, and then cooled to take out the sample to obtain cesium garnet.

Embodiment 2

[0022] A low-temperature non-calcining preparation method of cesium garnet, the steps are: weighing aluminum-silicon raw materials and cesium hydroxide, mixing to obtain solid powder, so that the molar ratio of Cs:Al:Si=1:1:2; Mix evenly with water not exceeding 10% of the solid powder mass to obtain a water-containing solid mixture; the water-containing solid mixture is pressed into a tablet machine at 3-5MPa, and the demoulded sample is placed in a blast drying oven at 105 °C The dried sample was placed in an autoclaved reactor, crystallized in a water vapor environment at a temperature of 140 °C for 20 h, and then cooled to take out the sample to obtain cesium garnet.

Embodiment 3

[0024] A low-temperature non-calcining preparation method of cesium garnet, the steps are: weighing aluminum-silicon raw materials and cesium hydroxide, mixing to obtain solid powder, so that the molar ratio of Cs:Al:Si=1:1:2; Mix evenly with water not exceeding 10% of the solid powder mass to obtain a water-containing solid mixture; the water-containing solid mixture is pressed into a tablet machine at 3-5MPa, and the demoulded sample is placed in a blast drying oven at 105 °C The dried sample was placed in an autoclaved reactor, crystallized in a water vapor environment at a temperature of 160 °C for 16 h, and then cooled to take out the sample to obtain cesium garnet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com