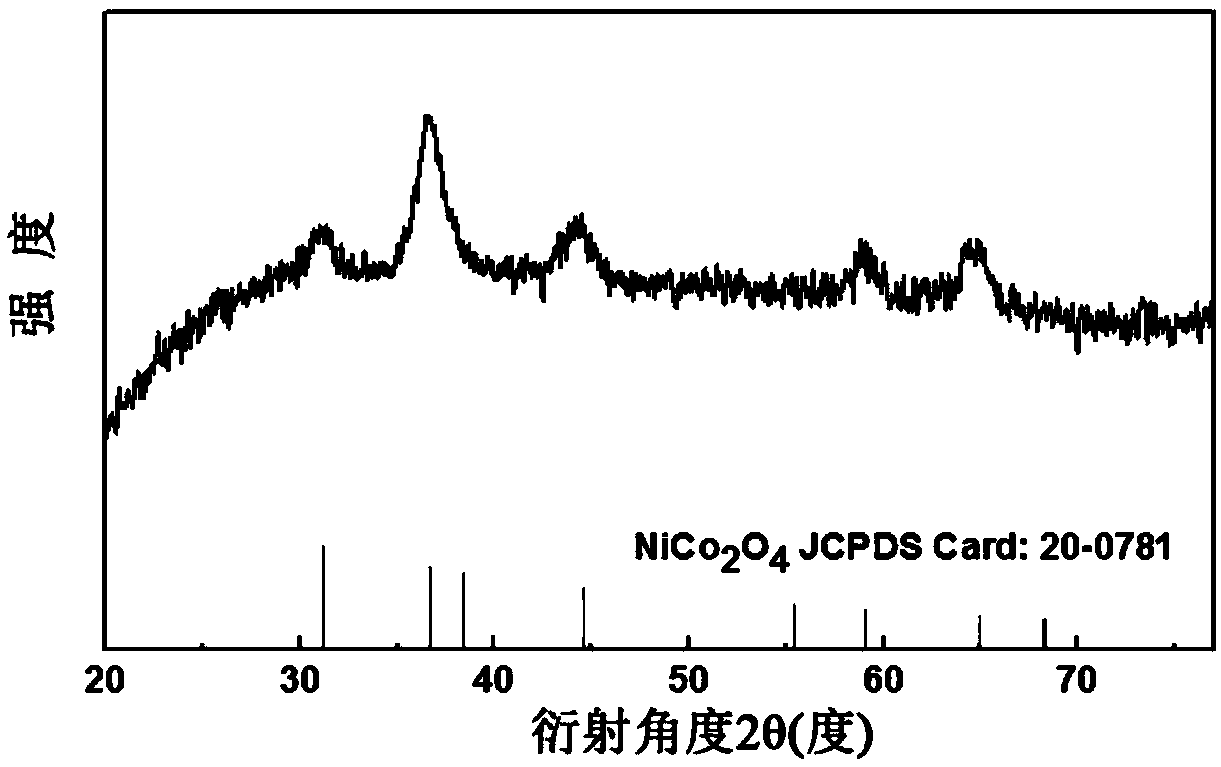

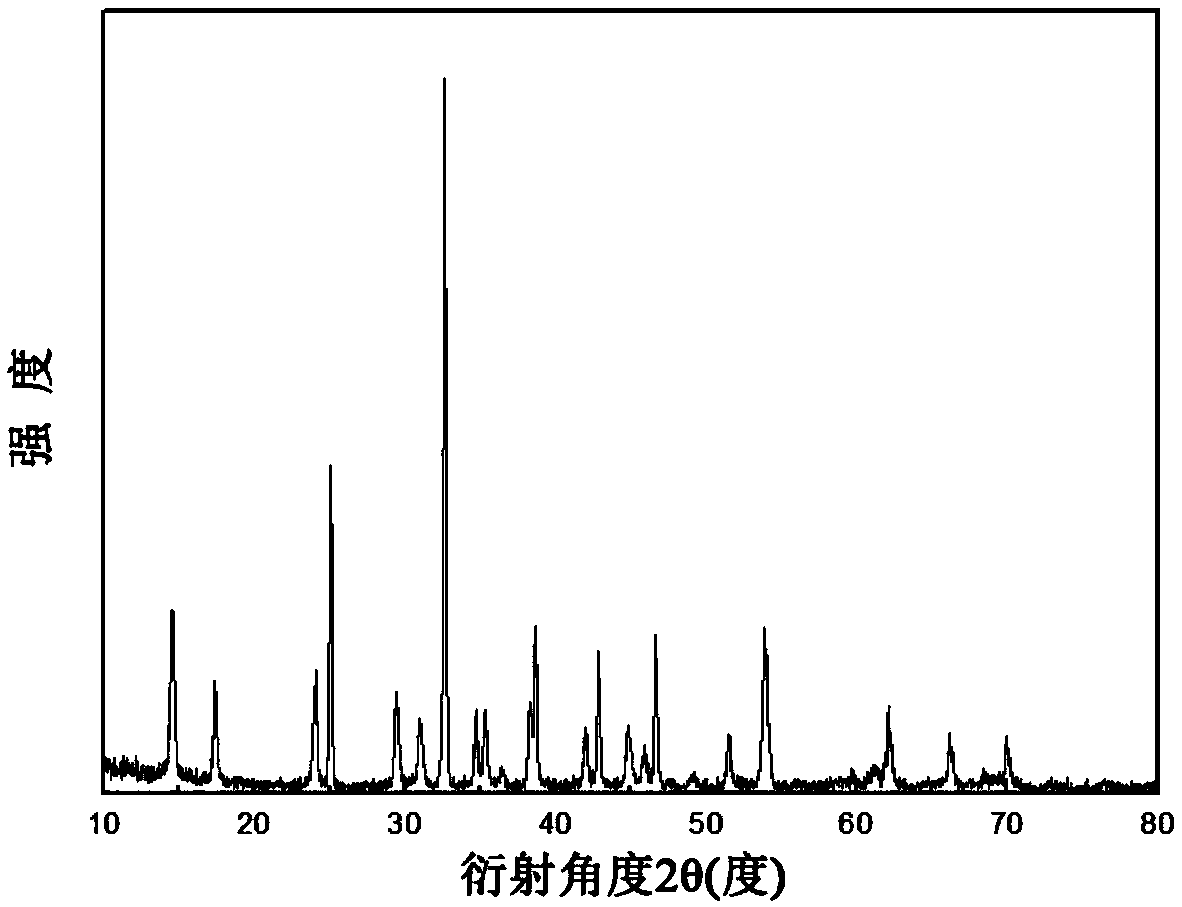

NiCo2O4, preparation method and application thereof

A technology of reaction and reaction process, applied in the field of preparation of nickel-cobalt composite oxides, can solve the problems of inability to fully explore electrochemical properties, easy agglomeration and easy agglomeration of nanomaterials, and achieve easy industrialization, simple synthesis methods, and conditions mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of NiCo of the present invention 2 o 4 The synthetic method comprises the following steps:

[0035] (1) 0.5g ammonia water (mass fraction is 30%) is made into 50mL dilute ammonia solution;

[0036] Dissolve 4.38g nickel sulfate hexahydrate, 9.37g cobalt sulfate heptahydrate, 1.0mg polyvinylpyrrolidone and 1.0mg triethanolamine in deionized water to prepare 200mL metal source solution;

[0037] Dissolve 2.0g sodium hydroxide and 2.65g sodium carbonate in deionized water to make 200mL precipitant solution;

[0038] (2) Pour the dilute ammonia water obtained in step (1) into a 1L three-neck flask as the mother liquor. After heating to 70°C in a water bath, use two peristaltic pumps to slowly add the metal source solution and the precipitant solution at the same speed at a flow rate of 2mL / min, keep system temperature constant in the process, mechanical stirring, rotating speed is 60r / min, and monitor the pH value of system with pH meter, adjust the pH value of s...

Embodiment 2

[0046] A kind of NiCo of the present invention 2 o 4 The synthetic method comprises the following steps:

[0047] (1) 0.5g ammonia water (mass fraction is 30%) is made into 50mL dilute ammonia solution;

[0048] Dissolve 8.29g nickel acetate tetrahydrate, 16.60g cobalt acetate tetrahydrate, 2.0mg polyvinylpyrrolidone and 2.0mg triethanolamine in deionized water to prepare 200mL metal source solution;

[0049] Dissolve 4.0g sodium hydroxide and 5.3g sodium carbonate in deionized water to make 200mL precipitant solution;

[0050] (2) Pour the dilute ammonia solution obtained in step (1) into a 1L three-necked flask as the mother liquor. After the water bath is heated to 80°C, two peristaltic pumps are used to slowly add the metal source solution and the precipitant solution at the same speed at the same speed. 2mL / min, keep the temperature of the system constant during the process, mechanically stir, the rotating speed is 60r / min, and monitor the pH value of the system with a...

Embodiment 3

[0056] A kind of nickel-cobalt composite oxide NiCo of the present invention 2 o 4 The synthetic method comprises the following steps:

[0057] (1) 0.5g ammonia water (mass fraction is 30%) is made into 50mL dilute ammonia solution;

[0058] Dissolve 11.88g nickel chloride hexahydrate, 23.79g cobalt chloride hexahydrate, 3.0mg polyvinylpyrrolidone and 3.0mg triethanolamine in deionized water to prepare 200mL metal source solution;

[0059] Dissolve 12.0g sodium hydroxide and 15.9g sodium carbonate in deionized water to prepare 200mL precipitant solution;

[0060] (2) Pour the dilute ammonia solution obtained in step (1) into a 1L three-necked flask, and after heating it to 90°C in a water bath, use two peristaltic pumps to slowly add the metal source solution and the precipitant solution at the same speed at a flow rate of 2mL / min, keep the temperature of the system constant during the process, mechanically stir, the rotating speed is 60r / min, and monitor the pH value of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com