Preparation method for carbon-nitrogen co-doped tricobalt tetroxide

A technology of cobalt tetroxide and co-doping, which is applied in chemical instruments and methods, cobalt oxide/cobalt hydroxide, and other chemical processes, etc., can solve the problems of uncontrollable doping amount, unachievable effect, and uneven appearance of products. , to achieve fast and efficient adsorption effect, improve adsorption capacity, and the effect of product without impurity phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

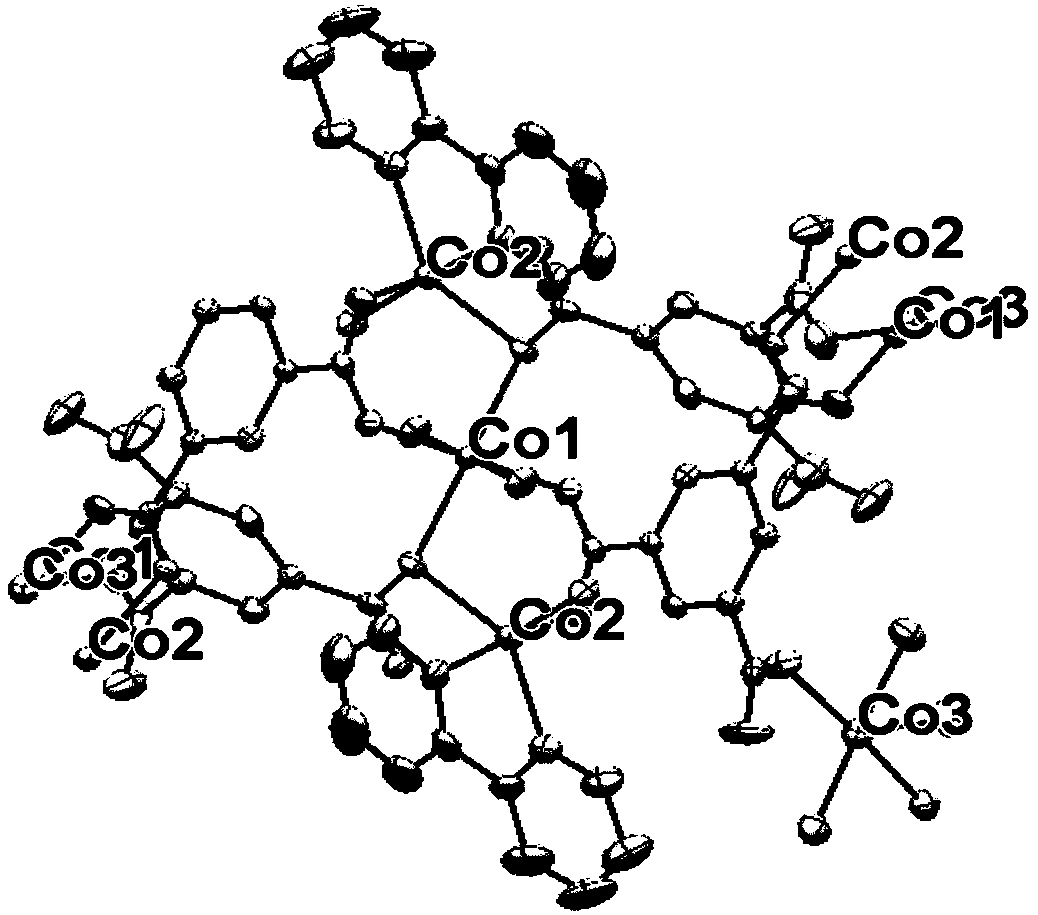

[0032] 1. Weigh raw material samples, specifically 2 parts of organic ligand trimesic acid, 1 part of cobalt acetate, and 0.5 part of alkaline regulator sodium hydroxide, and dissolve them in 25 mL of water.

[0033] 2. After magnetic stirring, place in a 50 mL stainless steel reaction kettle lined with polytetrafluoroethylene, seal the reaction kettle, and carry out a 72-hour heat preservation process at a temperature of 180 ° C, then cool naturally, and the precursor Filtered out, washed several times with ethanol and distilled water, and dried to obtain the metal organic complex precursor.

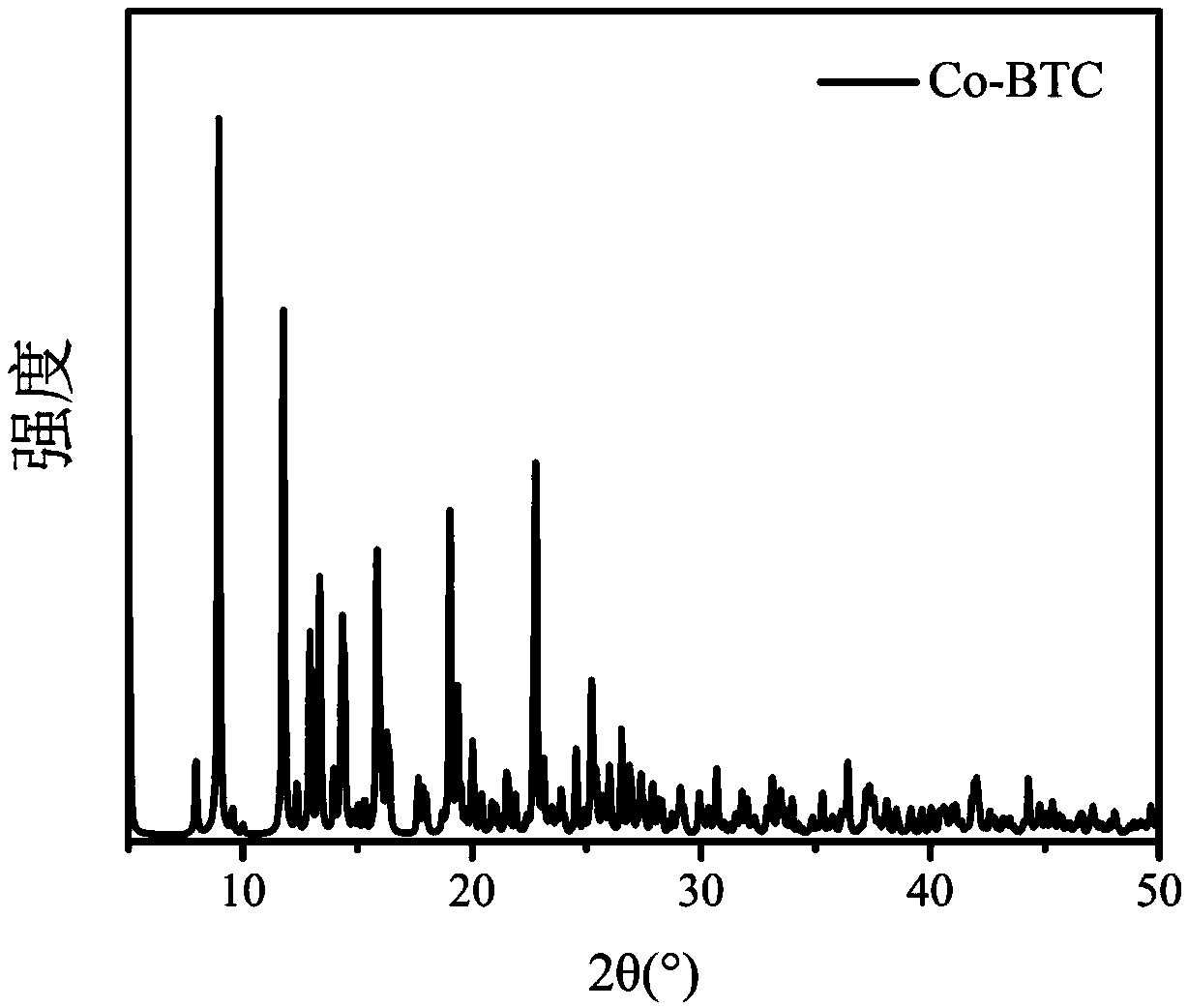

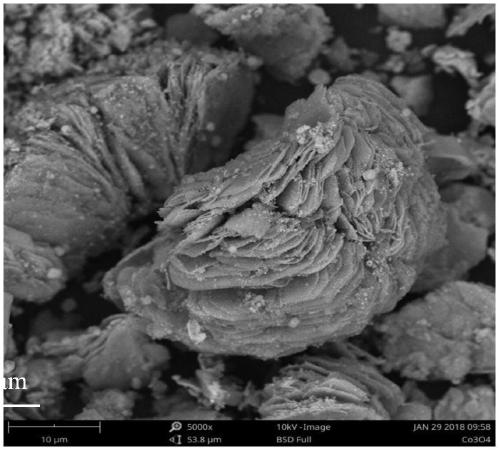

[0034] 3. The metal organic complex precursor is calcined under vacuum conditions to obtain the target product. The vacuum degree of the vacuum quartz tube is 3 hPa, at 5°C min -1 The heating rate starts from room temperature and heats at a constant temperature for one hour after reaching the target temperature of 700°C. The product is cooled with the furnace to obtain carbon-nitrogen...

Embodiment 2

[0038] 1. Weigh raw material samples, specifically 1.5 parts of trimesic acid, 0.5 parts of 2,2'-bipyridine organic ligand, 1 part of cobalt acetate, and 0.5 parts of alkaline regulator sodium hydroxide, dissolved in 25 mL of water .

[0039] 2. After magnetic stirring, place it in a 50 mL stainless steel reaction kettle lined with polytetrafluoroethylene, seal the reaction kettle, and carry out a 48-hour heat preservation process at a temperature of 150 ° C, then cool naturally, and the precursor Filtered out, washed several times with ethanol and distilled water, and dried to obtain the metal organic complex precursor.

[0040] 3. The metal organic complex precursor is calcined under vacuum conditions to obtain the target product. First vacuumize the vacuum quartz tube to a degree of 3 hPa, at 5°C min -1 The heating rate starts from room temperature and heats at a constant temperature for one hour after reaching the target temperature of 700°C. The product is cooled with ...

Embodiment 3

[0044] 1. Weigh raw material samples, specifically 1.7 parts of trimesic acid, 0.3 parts of 2,2'-bipyridine organic ligand, 1 part of cobalt acetate, 0.5 parts of alkaline regulator sodium hydroxide, dissolved in 25 mL of in the water.

[0045] 2. After magnetic stirring, place in a 50 mL stainless steel reaction kettle lined with polytetrafluoroethylene, seal the reaction kettle, and carry out a 72-hour heat preservation process at a temperature of 180 ° C, then cool naturally, and the precursor Filtered out, washed several times with ethanol and distilled water, and dried to obtain the metal organic complex precursor.

[0046] 3. The metal organic complex precursor is calcined under vacuum conditions to obtain the target product. First vacuumize the vacuum quartz tube at a degree of 5 hPa, at 5°C min -1 The heating rate starts from room temperature and heats at a constant temperature for one hour after reaching the target temperature of 700°C. The product is cooled with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com