A method for treat Ni-Co-Mn ternary waste lithium battery

A technology for waste lithium batteries and treatment methods, which is applied in the field of treatment of nickel-cobalt-manganese ternary waste lithium batteries, can solve the problems of large capital and technical investment, and achieve the effect of improving economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

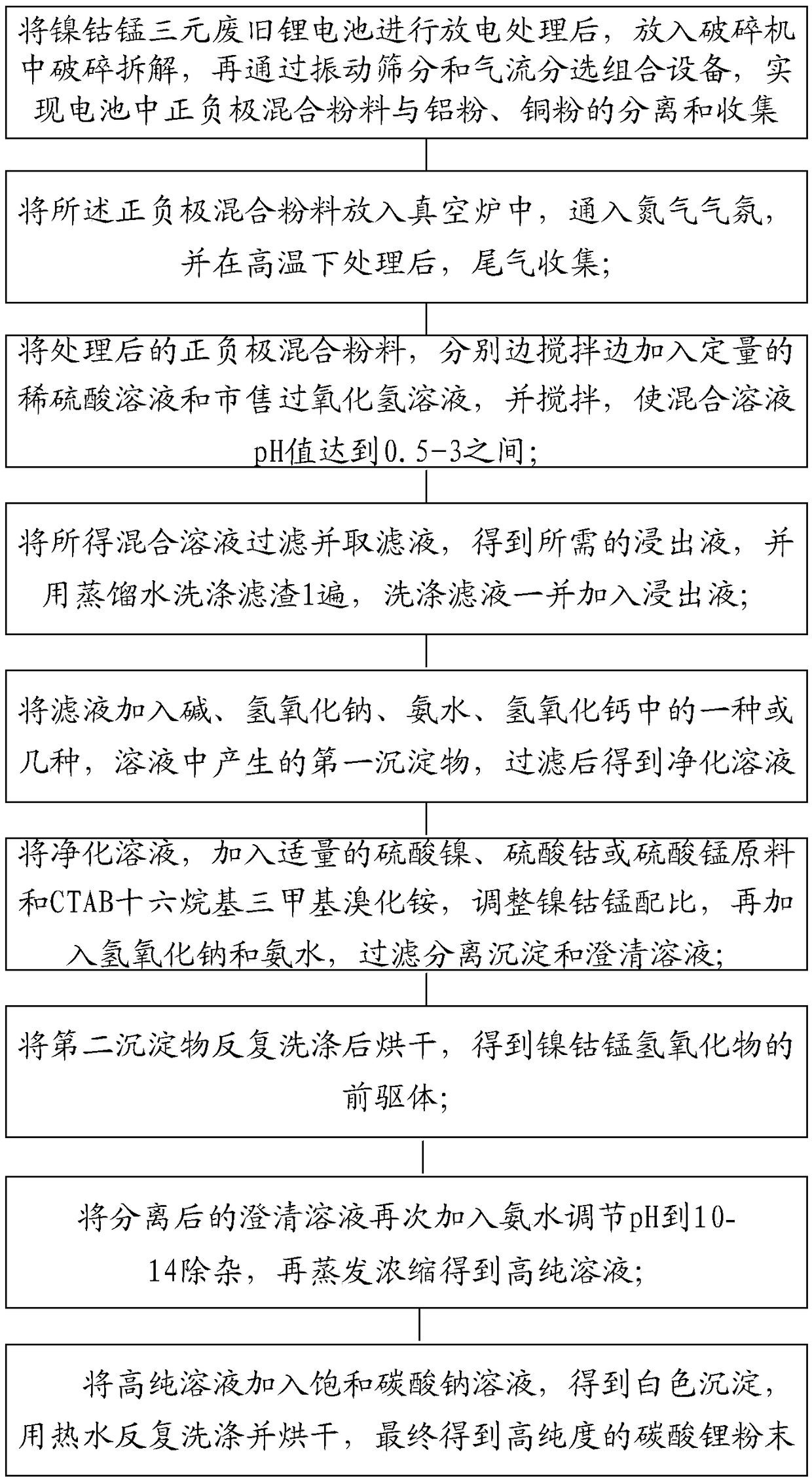

[0033] figure 1 It is a schematic flowchart of a treatment method for nickel-cobalt-manganese ternary waste lithium batteries provided by the embodiment of the present invention. Such as figure 1 As shown, the method includes the following steps:

[0034] Discharge the nickel-cobalt-manganese ternary waste lithium battery to below 2.0V, put it into the crusher for crushing and dismantling, and then use the combination equipment of vibration screening and airflow separation to realize the separation of positive and negative electrode mixed powder, aluminum powder and copper powder in the battery Separate and collect.

[0035] Put the positive and negative electrode mixed powder into a vacuum furnace, pass through a nitrogen atmosphere, and treat it at a high temperature of 400°C-600°C for 5-10 hours, and collect the tail gas.

[0036] Add a quantitative concentration of 4-10mol / L dilute sulfuric acid solution and a commercially available hydrogen peroxide solution with a mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com