Method for in-situ synthesis of carbon coated-hydrated V3O7 nanobelt and lithium ion battery

A technology for hydrating vanadium heptaoxide nanometers and lithium ion batteries, which is applied in the direction of batteries, battery electrodes, secondary batteries, etc., can solve the problems of metastable phase structure damage, time-consuming, and complexity, and achieve high repeatability and low energy. The effect of consumption and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment is a high-temperature mixed hydrothermal method for in-situ synthesis of V 3 o 7 ·H 2 OC nanoribbon method. Specific steps are as follows:

[0031] Step 1: Add 0.182g of V 2 o 5 Add it to a cavity lined in the high-temperature mixed hydrothermal reactor, and then add 5ml of deionized water;

[0032] Step 2: Add 5ml of 0.02M glucose solution into another chamber of the lining;

[0033] Step 3: After sealing the reactor, put it into an oven to heat up;

[0034] Step 4: When the temperature rises to 200-260°C, rotate the reactor to mix the reactants in the two inner cavities of the reactor, and keep the temperature for 1 hour;

[0035] Step 4: Cool to room temperature after the reaction to obtain a precipitate;

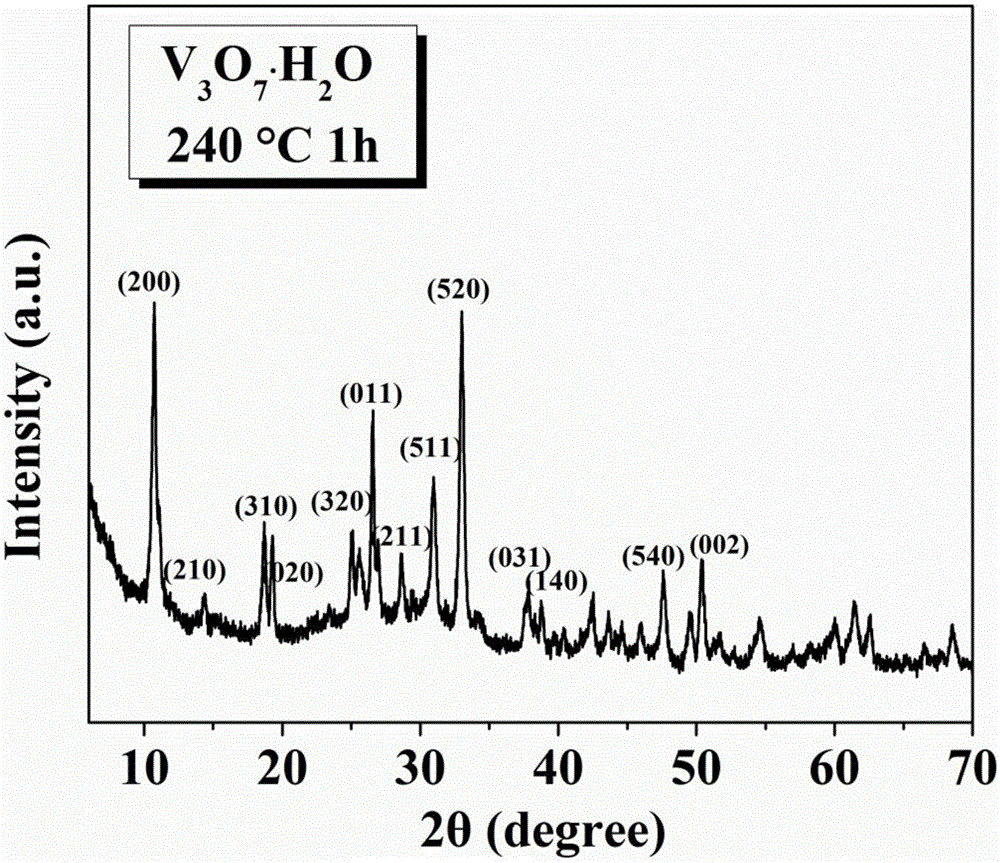

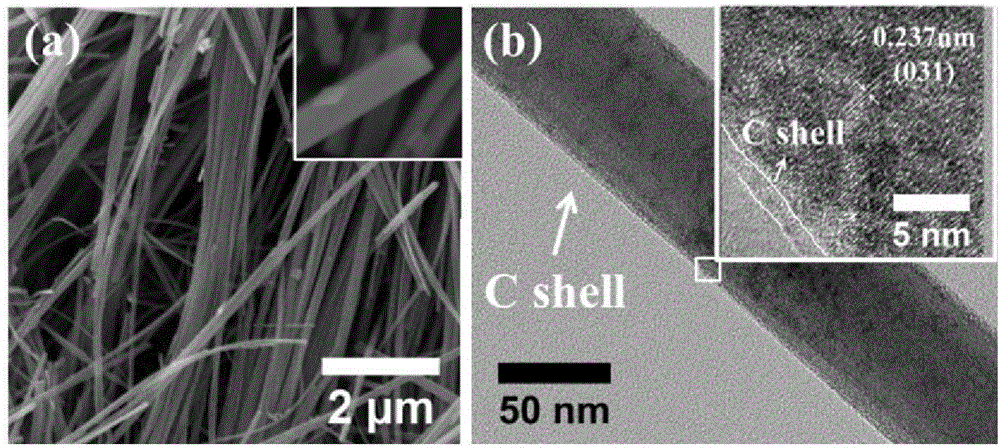

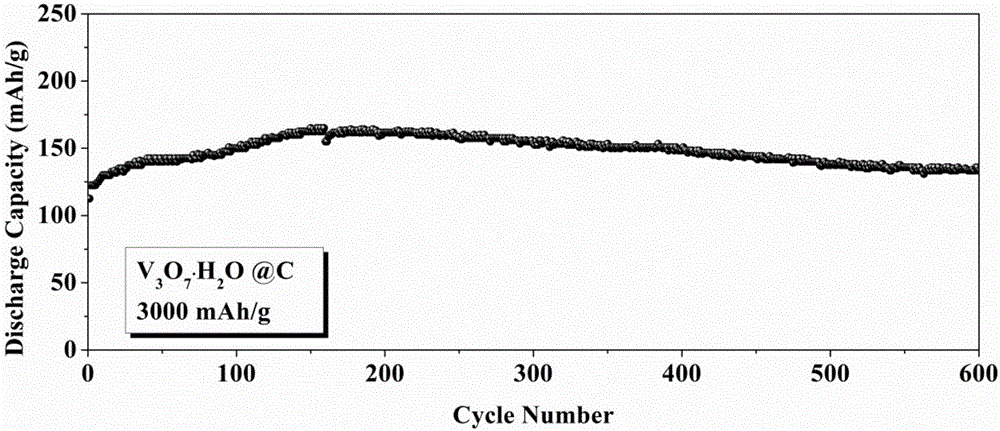

[0036] Step 5: Finally, after washing the obtained precipitate several times with deionized water and absolute ethanol, dry it at 80°C for 10 hours to obtain V with good dispersibility. 3 o 7 ·H 2 OC nanoribbon, its X-ray diffraction pat...

Embodiment 2

[0040] This embodiment is a high-temperature mixed hydrothermal method for in-situ synthesis of V 3 o 7 ·H 2 OC nanoribbon method. Specific steps are as follows:

[0041] Step 1: Add 0.182g of V 2 o 5 Add it to a cavity lined in the high-temperature mixed hydrothermal reactor, and then add 5ml of deionized water;

[0042] Step 2: Add 5ml of 0.02M sucrose solution into another chamber of the lining;

[0043] Step 3: After sealing the reactor, put it into an oven to heat up;

[0044] Step 4: When the temperature rises to 200-260°C, rotate the reactor to mix the reactants in the two inner cavities of the reactor, and keep the temperature for 1 hour;

[0045] Step 4: Cool to room temperature after the reaction to obtain a precipitate;

[0046] Step 5: Finally, after washing the obtained precipitate several times with deionized water and absolute ethanol, dry it at 80°C for 10 hours to obtain V with good dispersibility. 3 o 7 ·H 2 OC nanoribbons. Its X-ray diffraction p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com