Red phosphor suitable for ultraviolet light excitation, and preparation method thereof

A technology of red phosphor powder and ultraviolet light, applied in the field of red phosphor powder and its preparation, can solve the problems of lack of red phosphor powder and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention also provides a preparation method for the above-mentioned red fluorescent powder suitable for ultraviolet light excitation, comprising the following steps:

[0026] a. Using oxides, fluorides, carbonates, and nitrates containing Ba, Mn, R, Ce, and Si respectively as raw materials, according to the chemical formula (Ba 9-y mn y )(R 2-x Ce x ) (SiO 4 ) 6 Calculation of the stoichiometric ratio of each substance in (0.005≤x≤0.25, 0.01≤y≤0.6) Weigh the above-mentioned raw materials, fully grind and mix them in an agate mortar;

[0027] b. Put the above mixture into a corundum crucible, under CO or H 2 Calcination under reducing atmosphere, calcination temperature is 1100-1350 ℃, calcination time is 2-5 hours, after natural cooling, grind to obtain the above-mentioned red fluorescent powder based on ultraviolet (UV) light excitation.

[0028] Preferably, the Ba is selected from BaO, BaCO 3 , Ba(NO3) 2 One of or BaO, BaF 2 、BaCO 3 , Ba(NO3) 2...

Embodiment 1

[0034] Preparation of Ba 9 sc 2 (SiO 4 ) 6 Phosphor.

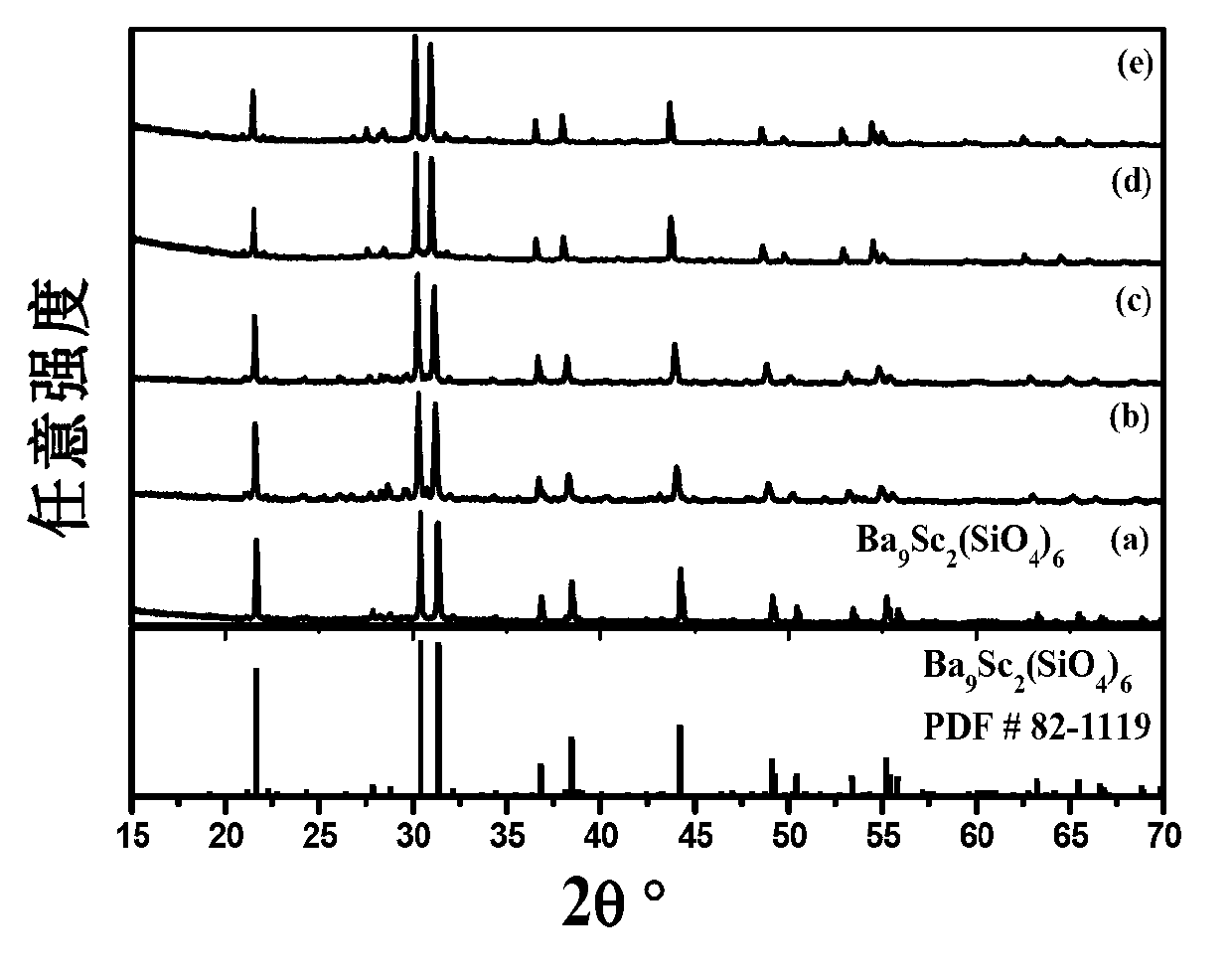

[0035] Weigh BaCO according to stoichiometric ratio 3 1.7761 g, Sc 2 o 3 0.1379 g, SiO 2 0.3605 g, mixed and ground evenly in an agate mortar, put into a corundum crucible, covered, placed in a high-temperature furnace, and roasted at 1220°C for 3 hours under the condition of carbon monoxide or hydrogen reducing atmosphere; after natural cooling, grind, i.e. get Ba 9 sc 2 (SiO 4 ) 6 Phosphor. figure 1 The a curve in the diamond structure Ba 9 sc 2 (SiO 4 ) 6 XRD diffraction pattern of crystals (PDF # 82-1119).

Embodiment 2

[0037] Preparation (Ba 8.90 mn 0.10 )(Sc 1.70 Y 0.295 Ce 0.005 ) (SiO 4 ) 6 Phosphor.

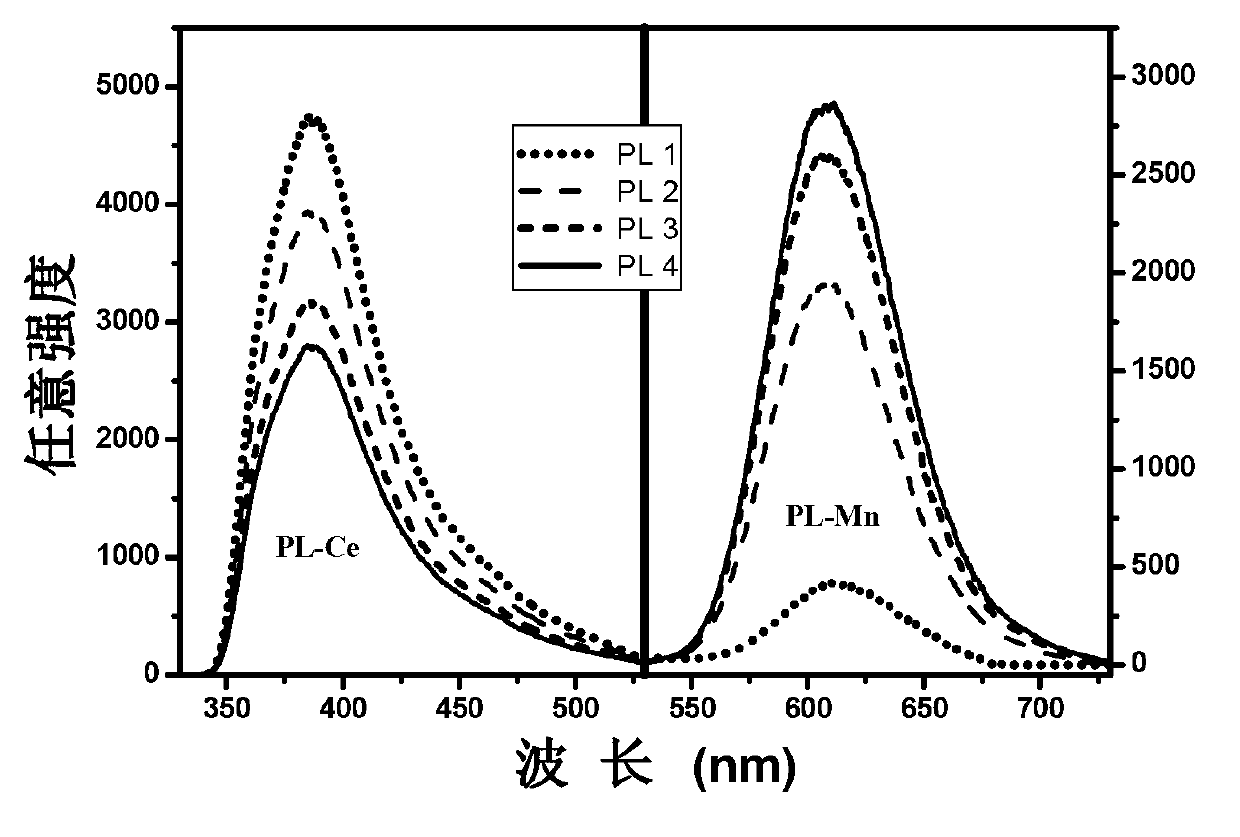

[0038] Weigh BaCO according to stoichiometric ratio 3 1.7563 g, MnCO 3 0.0115 g, Sc 2 o 3 0.1172 g, Y 2 o 3 0.0333 g, CeO 2 0.0009 g, SiO 2 0.3605 g, mixed and ground evenly in an agate mortar, put into a corundum crucible, covered, placed in a high-temperature furnace, and roasted at 1180°C for 4 hours under a carbon monoxide or hydrogen reducing atmosphere; after natural cooling, grind, That is to say (Ba 8.90 mn 0.10 )(Sc 1.70 Y 0.295 Ce 0.005 ) (SiO 4 ) 6 Phosphor. Under the excitation of 327nm, the red phosphor powder prepared in this embodiment, Mn 2+ The emission wavelength is 612nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com