Method for preparing aluminum molybdate with cationic membrane electrolysis method

A cationic membrane, aluminum molybdate technology, applied in the electrolysis process, electrolysis components and other directions, can solve the problems of long (up to several hours or even days, the reaction time of additives, etc., to achieve short reaction time, reduced preparation cost, easy effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

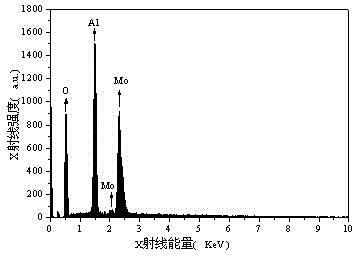

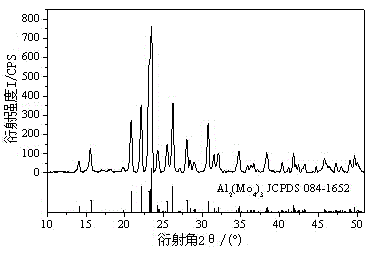

Examples

Embodiment 1

[0036] A method for preparing aluminum molybdate by cationic membrane electrolysis, specifically comprising the steps of:

[0037] (1) Use aluminum sheet as anode, inert electrode as cathode, 95ml aqueous solution containing depolarizer and sodium molybdate as anolyte, 90ml acid solution as catholyte, double-chamber electrolysis with cationic membrane as diaphragm In the tank, adopt the method of constant voltage electrolysis, control the temperature range from room temperature to 50°C, and constant voltage electrolyze the aqueous solution containing depolarizer and sodium molybdate for 10 minutes;

[0038] The inert electrode is a titanium mesh;

[0039] In the aqueous solution containing depolarizer and sodium molybdate, the concentration of sodium molybdate is 0.1mol / L, the concentration of depolarizer is 0.01mol / L, and the depolarizer is nitric acid;

[0040] Described acid solution is the aqueous hydrochloric acid solution that concentration is 0.1mol / L;

[0041] The ca...

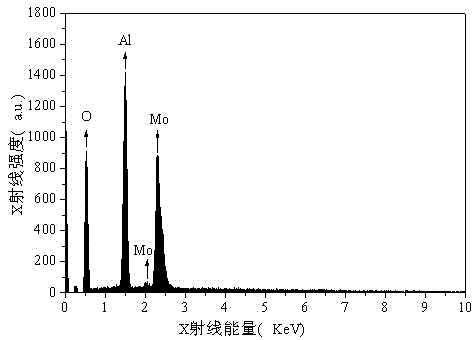

Embodiment 2

[0047] A kind of method utilizing cationic membrane electrolysis to prepare aluminum molybdate, concrete steps are as follows:

[0048](1) Use aluminum sheet as anode, inert electrode as cathode, 95ml aqueous solution containing depolarizer and sodium molybdate as anolyte, 90ml acid solution as catholyte, double-chamber electrolysis with cationic membrane as diaphragm In the tank, adopt the method of constant current electrolysis, and control the temperature range from room temperature to 50°C to electrolyze the aqueous solution containing depolarizer and sodium molybdate for 10 minutes;

[0049] The inert electrode is a titanium mesh;

[0050] In the aqueous solution containing depolarizer and sodium molybdate, the concentration of sodium molybdate is 0.1mol / L, the concentration of depolarizer is 0.01mol / L, and the depolarizer is nitric acid;

[0051] Described acid solution is the aqueous hydrochloric acid solution that concentration is 0.1mol / L;

[0052] The cationic memb...

Embodiment 3

[0058] A method for preparing aluminum molybdate by cationic membrane electrolysis, specifically comprising the steps of:

[0059] (1) Use aluminum sheet as anode, inert electrode as cathode, 95ml aqueous solution containing depolarizer and sodium molybdate as anolyte, 90ml alkali solution as catholyte, double-chamber electrolysis with cationic membrane as diaphragm In the tank, adopt the method of constant current electrolysis, and control the temperature range from room temperature to 50°C to electrolyze the aqueous solution containing depolarizer and sodium molybdate for 10 minutes;

[0060] The inert electrode is a titanium mesh;

[0061] In the aqueous solution containing depolarizing agent and sodium molybdate, the concentration range of sodium molybdate is 0.1mol / L, and the concentration of depolarizing agent is 0.01mol / L, and described depolarizing agent is sodium nitrate;

[0062] Described alkali solution is the sodium hydroxide aqueous solution that concentration i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com