Lithium ferrous silicate anode material coated with crystalline carbon and preparation method thereof

A technology of lithium ferrous silicate and positive electrode materials, which is applied in the direction of battery electrodes, structural parts, electrical components, etc., can solve the problems of reducing the volumetric energy density of positive electrode materials, low tap density of products, and poor particle contact performance. Improved electrochemical performance, fine grain size, and high powder purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

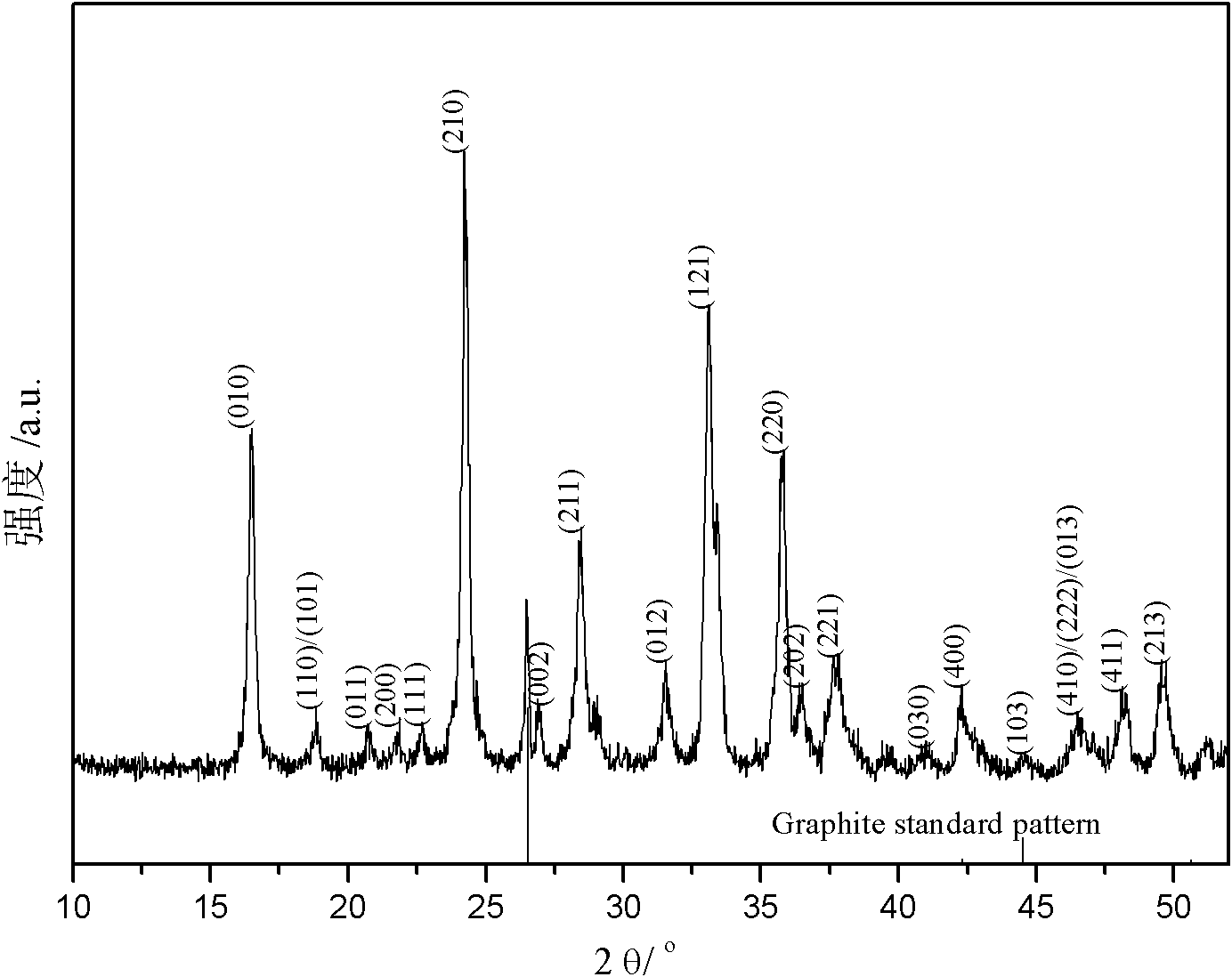

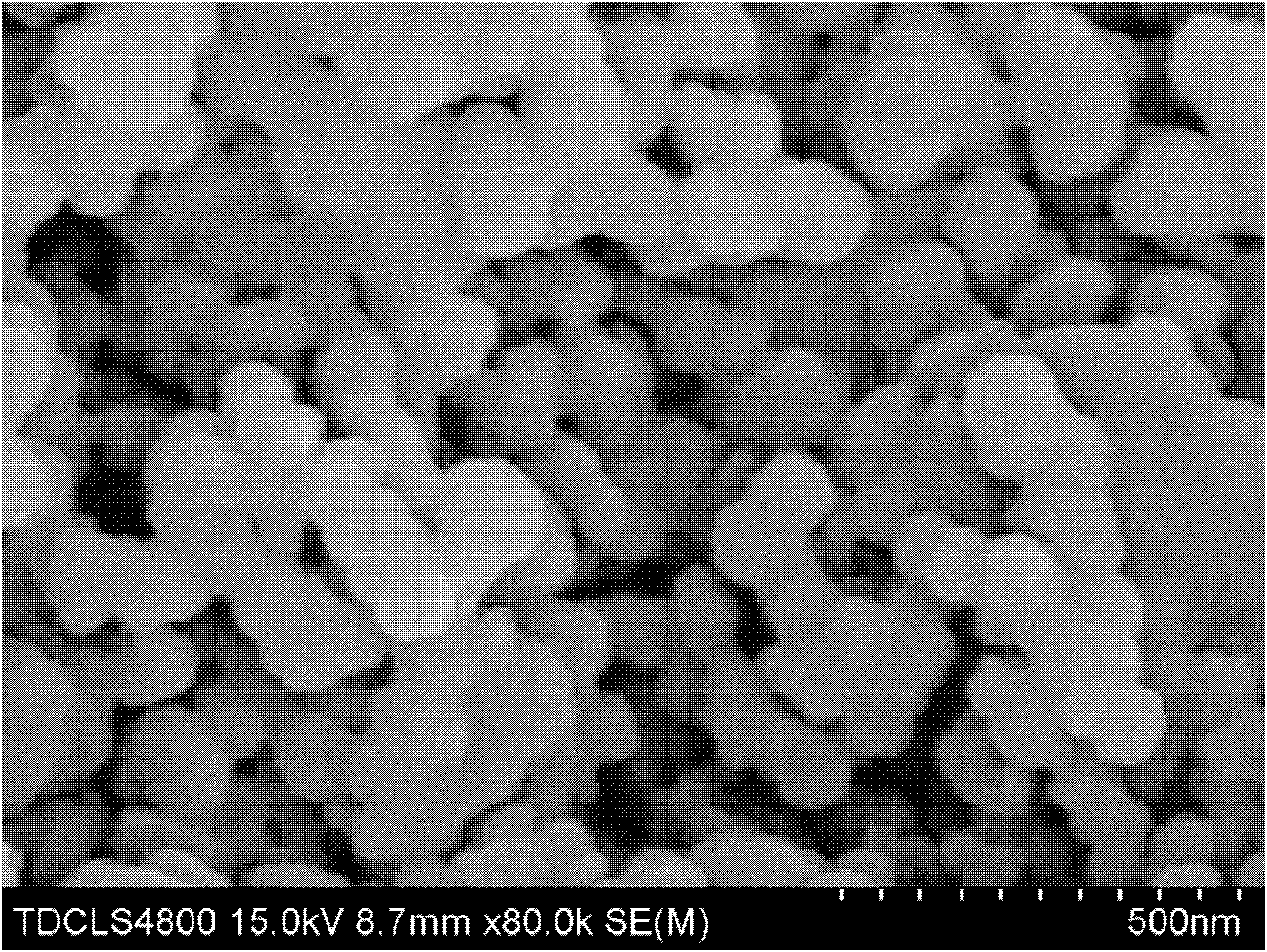

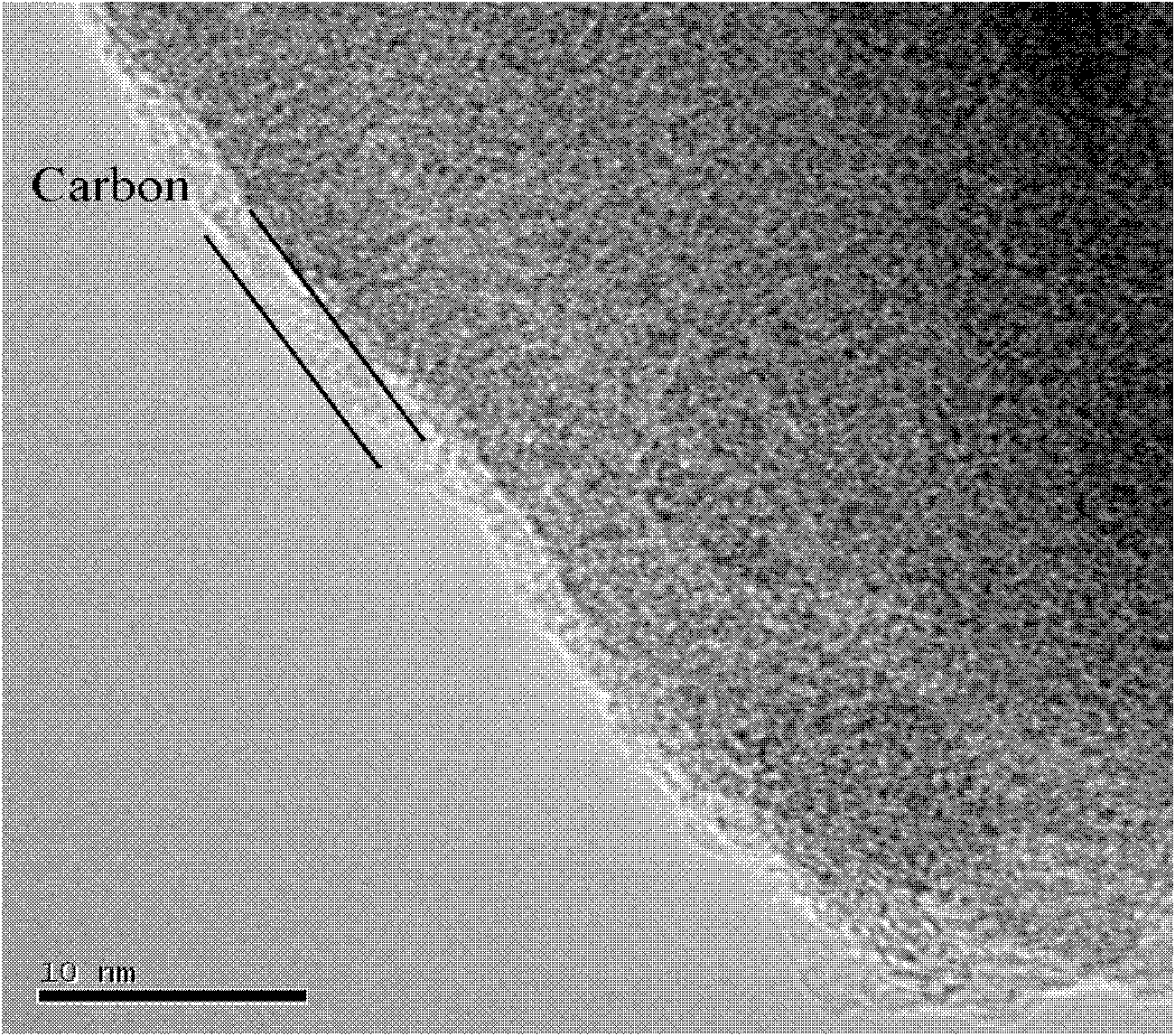

[0023] Using lithium acetate dihydrate, ferric nitrate, and ethyl orthosilicate as raw materials, weigh the corresponding substances according to the molar ratio of the substances, so that the molar ratio of Li:Fe:Si is 2:1:1, and measure 1.8ml of ethyl orthosilicate Add the ester to 15ml of ethanol and keep stirring, add 0.32ml of acetic acid dropwise, accurately weigh 1.640g of lithium acetate and add it to the above mixed solution, add 3.256g of ferric nitrate after dissolving, make 1.057g of ascorbic acid into a saturated aqueous solution, and add it dropwise to Among the above mixed solutions, the mixed solution was transferred to a reaction kettle and reacted at 120° C. for 20 hours to obtain a gel mixture, which was then dried in a drying oven at 60° C. to obtain a xerogel. Grind the xerogel, press into tablets, in N 2 Under the protection of the atmosphere, it was calcined at 650° C. for 10 h to obtain carbon-coated lithium ferrous silicate powder. Li 2 FeSiO 4 The ...

Embodiment 2

[0025] Using lithium acetate, ferric nitrate, and ethyl orthosilicate as raw materials, weigh the corresponding substances according to the molar ratio of the substances, so that the molar ratio of Li:Fe:Si is 2:1:1, measure 1.8ml of ethyl orthosilicate and add Add 0.32ml of acetic acid dropwise to 10ml of ethanol with constant stirring, accurately weigh 1.640g of lithium acetate and add it to the above mixture, add 3.256g of ferric nitrate after dissolving, make 0.700g of ascorbic acid into a saturated aqueous solution, and add dropwise to the above mixture In the solution, the mixed solution was transferred to a reaction kettle, and reacted at 120° C. for 5 hours to obtain a gel mixture, which was then dried in a drying oven at 60° C. to obtain a xerogel. Grind the xerogel, press into tablets, in N 2 Under the protection of the atmosphere, it was calcined at 650° C. for 7 hours to obtain carbon-coated lithium ferrous silicate powder. Synthetic powder Li 2 FeSiO 4 / C micro...

Embodiment 3

[0027] Using lithium acetate dihydrate, ferric nitrate, and ethyl orthosilicate as raw materials, weigh the corresponding substances according to the molar ratio of the substances, so that the molar ratio of Li:Fe:Si is 2:1:1, and measure 1.8ml of ethyl orthosilicate Add the ester to 18ml of ethanol and keep stirring, add 0.32ml of acetic acid dropwise, accurately weigh 1.640g of lithium acetate and add it to the above mixed solution, add 3.256g of ferric nitrate after dissolving, make 1.929g of ascorbic acid into a saturated aqueous solution, and add it dropwise to In the above mixed solution, the mixed solution was transferred to a reaction kettle and reacted at 180° C. for 5 hours to obtain a gel mixture, which was then dried in a drying oven at 60° C. to obtain a xerogel. Grind the xerogel, press into tablets, in N 2 Under the protection of the atmosphere, it was calcined at 750° C. for 10 h to obtain carbon-coated lithium ferrous silicate powder. Synthetic Li 2 FeSiO 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com