A kind of colored catalytic composite antibacterial fiber and its preparation method and application

A compound antibacterial and colored technology, applied in the field of fiber materials, can solve the problems of poor antibacterial function, achieve good moisture absorption and quick drying, uniform distribution, and prevent agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] In the present invention, the preparation method of the titanium dioxide-graphite-like carbon nitride-metal phthalocyanine composite preferably comprises the following steps:

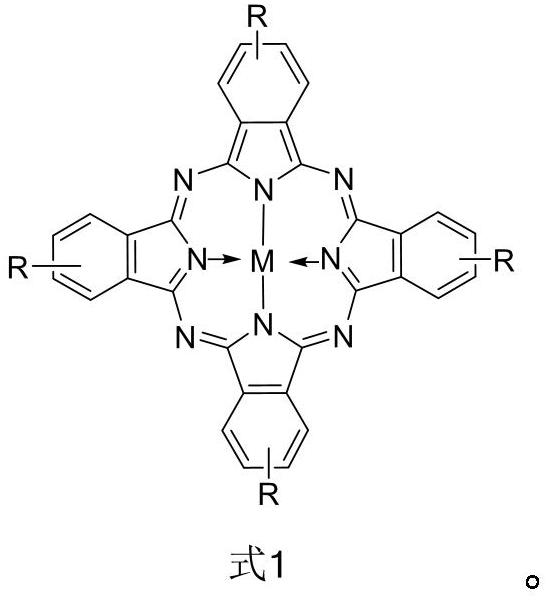

[0041] (1) mixing graphite-like carbon nitride, titanium dioxide and an aprotic organic solvent to obtain a mixed dispersion; mixing a metal phthalocyanine having a structure described in formula 1 with an aprotic organic solvent to obtain a metal phthalocyanine solution;

[0042] (2) Adding the mixed dispersion liquid in the step (1) dropwise into the metal phthalocyanine solution, heating the obtained reaction liquid to react, and obtaining a titanium dioxide-graphite-like carbon nitride-metal phthalocyanine composite.

[0043] In the present invention, the aprotic organic solvent is preferably mixed with graphite-like carbon nitride and titanium dioxide respectively, and ultrasonicated to obtain a graphite-like carbon nitride dispersion and a titanium dioxide dispersion. In the present inventi...

Embodiment 1

[0083]Get 85 parts of conventional polyethylene terephthalate, 5 parts of cadmium red, 5 parts of additives (sodium dodecylsulfonate and methyl triethoxysilane), 5 parts of composite antibacterial catalyst and melt at 260 ° C Mixing, stirring at a speed of 120r / min for 2min, then extruding through a screw extruder, cooling, drawing, pelletizing and drying to obtain colored functional masterbatches, 20 parts of colored functional masterbatches and polyethylene terephthalate 80 parts of ethylene glycol formate are melted and mixed at 220°C, stirred at a speed of 120r / min for 2min, and transported to the spinning box through the screw extruder for spinning; the temperature inside the heating box assembly of the screw extruder is 260 ℃, heat the mixed raw materials slowly, the barrel temperature of the screw extruder is 270 ℃, and spin through the special-shaped spinneret at a spinning speed of 1200m / min, that is, the colored photocatalytic antibacterial fiber is obtained. The nan...

Embodiment 2

[0086] The preparation method is the same as in Example 1, the only difference is that 85 parts of conventional polyethylene terephthalate, 5 parts of cadmium yellow, 5 parts of additives, and 5 parts of composite antibacterial catalyst are used for composite spinning to obtain colored photocatalytic antibacterial fibers . The nanometer metal particles account for 22% of the mass ratio of the composite antibacterial catalyst, and the photocatalyst (83% TiO 2 , 15% g-C 3 N 4 , 2% WO 3 ) accounts for 78% of the mass ratio of the composite antibacterial catalyst, and the colored photocatalytic antibacterial fiber protofilament is filamentous and has a diameter of 24 μm.

[0087] The colored photocatalytic antibacterial fiber obtained in this example was tested according to the method of Example 1, and the test results showed that the colored photocatalytic antibacterial fiber provided in this example had a bacteriostatic rate ≥ 95% to Staphylococcus aureus, and a bacteriostati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com