Copper ammonia silk-like elastic knitted fabric as well as preparation method and application thereof

A knitted fabric and artificial silk technology, applied in the field of textile and clothing, can solve the problems of poor bursting strength and insufficient elasticity, and achieve the effects of good contact coolness, good comfort and smooth hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

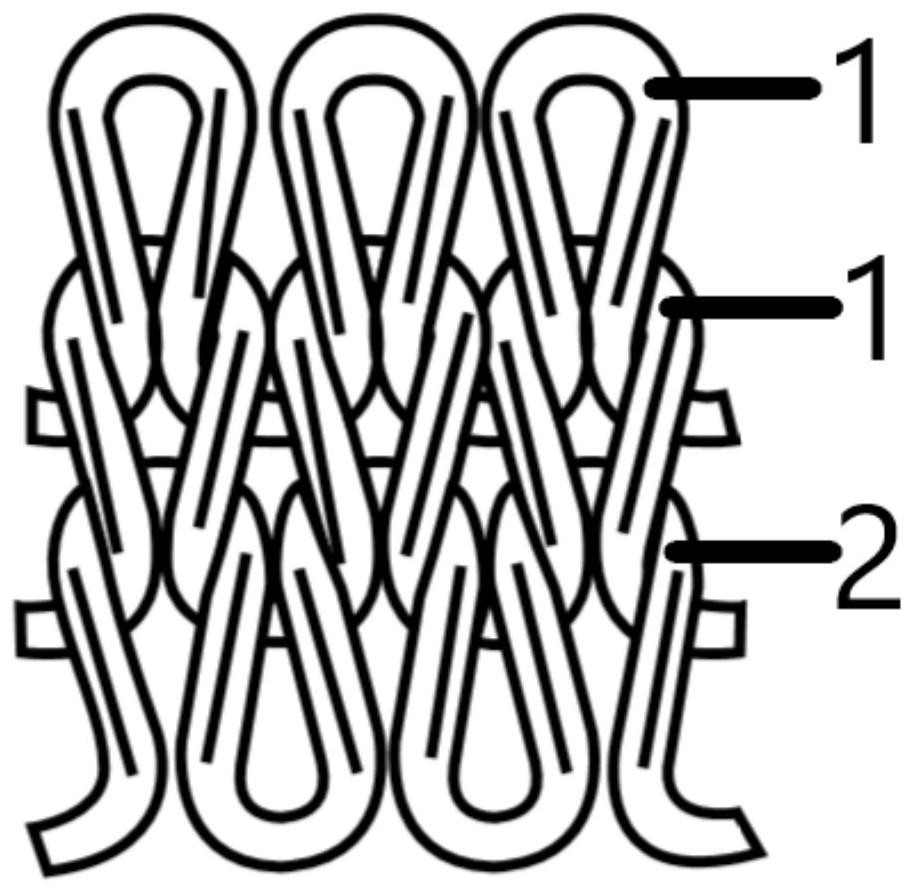

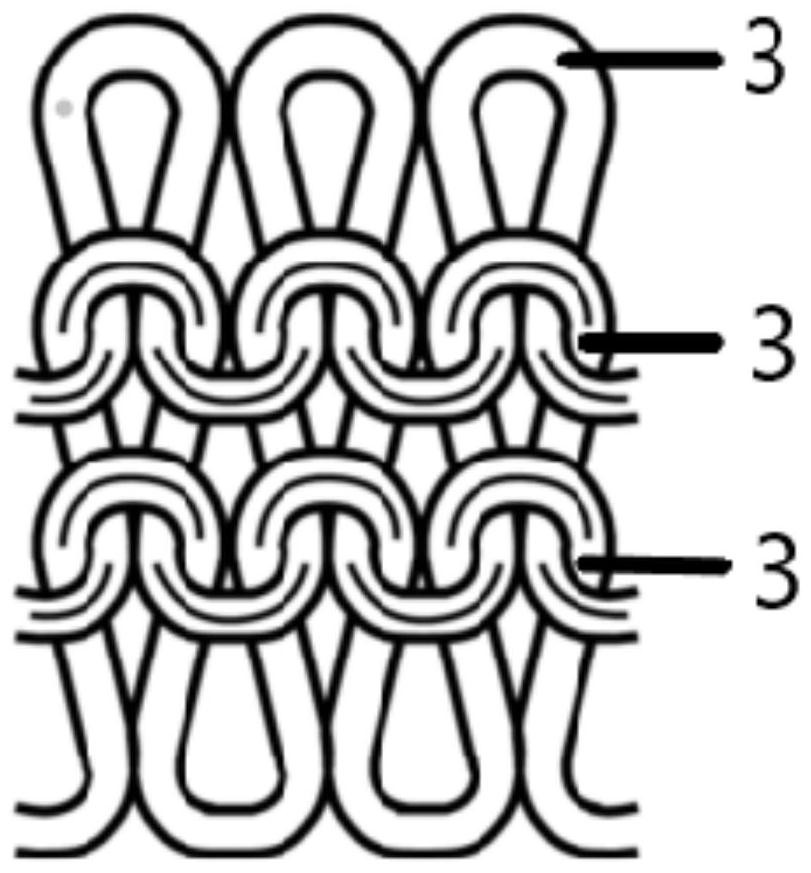

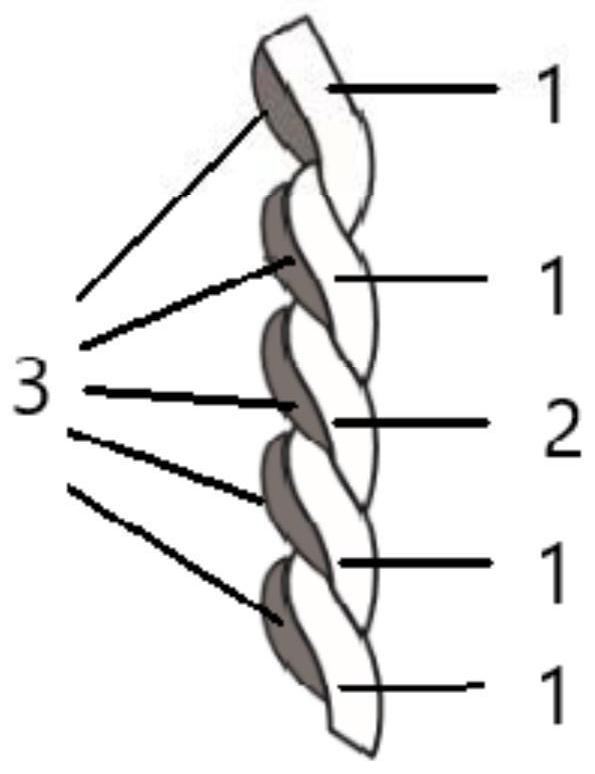

[0102] This embodiment provides a silk-like elastic knitted fabric, the fabric is alternately woven by 2 paths of cool nylon filaments and 1 path of nylon copper-ammonia composite threads, and each path of cool nylon filaments and each path of nylon copper Ammonia composite filaments are respectively covered on 1 road of spandex filaments, the coil lengths of the cool nylon filaments and nylon cupro-ammonia composite filaments are both 29cm / 100 needles, the fineness of the cool nylon filaments is 40D, The fineness of the nylon-cupro-ammonia composite filament is 68T; the fineness of the spandex filament is 20D, and the coil length of the spandex filament is 8.8cm / 100 needles, and the non-elastic yarn and elastic yarn The mass ratio is 8:2.

[0103] The preparation method of the imitation silk elastic knitted fabric comprises the following steps:

[0104] (1) Weaving: 2 channels of cool nylon filament, 1 channel of nylon copper ammonia composite yarn and spandex filament are w...

Embodiment 2

[0114] This embodiment provides a silk-like elastic knitted fabric, the fabric is alternately woven by 2 paths of cool nylon filaments and 1 path of nylon copper-ammonia composite threads, and each path of cool nylon filaments and each path of nylon copper Ammonia composite filaments are respectively covered on 1 road of spandex filaments, the coil lengths of the cool nylon filaments and nylon cupro-ammonia composite filaments are both 29cm / 100 needles, the fineness of the cool nylon filaments is 40D, The fineness of the nylon-cupro-ammonia composite filament is 68T; the fineness of the spandex filament is 20D, the coil length of the spandex filament is 10cm / 100 needles, and the quality of the non-elastic yarn and the elastic yarn is The ratio is 8:2.

[0115] The preparation method of the imitation silk elastic knitted fabric comprises the following steps:

[0116] (1) Weaving: 2 channels of cool nylon filament, 1 channel of nylon copper ammonia composite yarn and spandex fi...

Embodiment 3

[0126] This embodiment provides a silk-like elastic knitted fabric, the fabric is alternately woven by 2 paths of cool polyester filaments and 1 path of polyester copper-ammonia composite filaments, and each path of cool polyester filaments and each path of polyester copper Ammonia composite yarns are respectively covered on 1 road of spandex filaments. The coil lengths of the cool polyester filaments and polyester cupro ammonia composite yarns are both 30cm / 100 needles, and the fineness of the cool polyester filaments is 40D. The fineness of the polyester cupro-ammonia composite yarn is 86T; the fineness of the spandex filament is 20D, and the coil length of the spandex filament is 8.5cm / 100 needles, and the non-elastic yarn and elastic yarn The mass ratio is 8:2.

[0127] The preparation method of the imitation silk elastic knitted fabric comprises the following steps:

[0128] (1) Weaving: 2 channels of cold polyester filament, 1 channel of polyester copper ammonia composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com