Production method of enVironment-friendly hydroscopic and fast dry natural dyeing yarn

An environmentally friendly and production method technology, applied in the textile field, can solve the problems of polylactic acid fiber hardening, low melting point, hardening, etc., and achieve the effect of novel and ingenious methods, low-carbon and environmental protection in the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

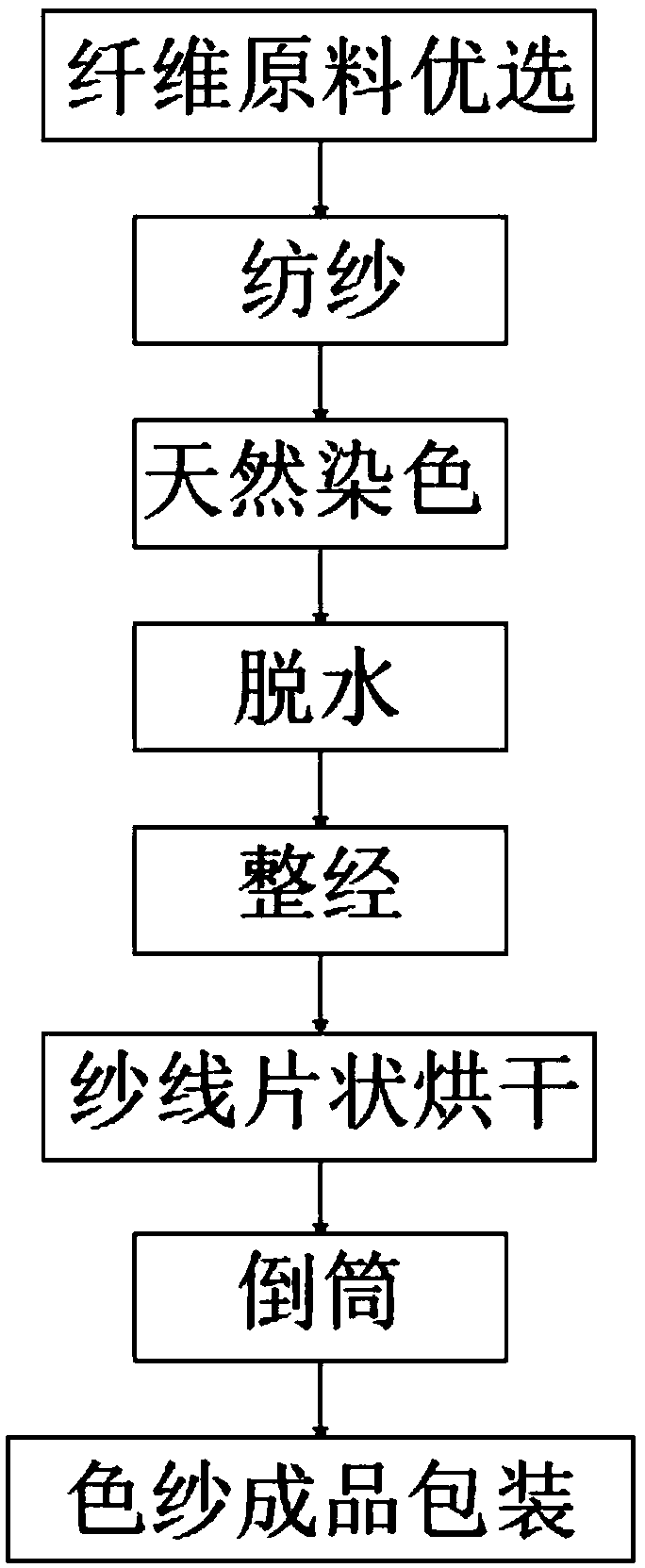

Image

Examples

Embodiment 1

[0031] This example implements an environmentally friendly production method for moisture-absorbing and quick-drying natural dyed yarn. Taking a kind of knitting yarn as an example, it illustrates the production and environmental friendliness of using optimal fiber materials, dye types and using new package dyeing and finishing methods. Methods of Moisture Absorbing and Quick Drying Naturally Dyed Yarns:

[0032] 60% environmentally friendly polylactic acid fiber and 40% cross-section viscose fiber are selected for blending, the yarn count: 40s / 1 siro spinning, and the twist of the yarn is according to the twist of the knitting yarn to obtain a white bobbin Yarn, yarn does not need pre-treatment such as alkali boiling or caustic soda mercerizing before dyeing, avoiding damage to polylactic acid fibers; viscose fiber, like other natural fibers or cellulose fibers, can be dyed with natural dyes that are very friendly to the environment , The polylactic acid fiber used in S1 is 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com