Patents

Literature

30results about How to "Improve wet modulus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solvent method high-wet-modulus bamboo fiber and preparation method thereof

ActiveCN101694019AEasy to operateReduce energy consumptionMonocomponent cellulose artificial filamentVegetable materialFiberCellulose

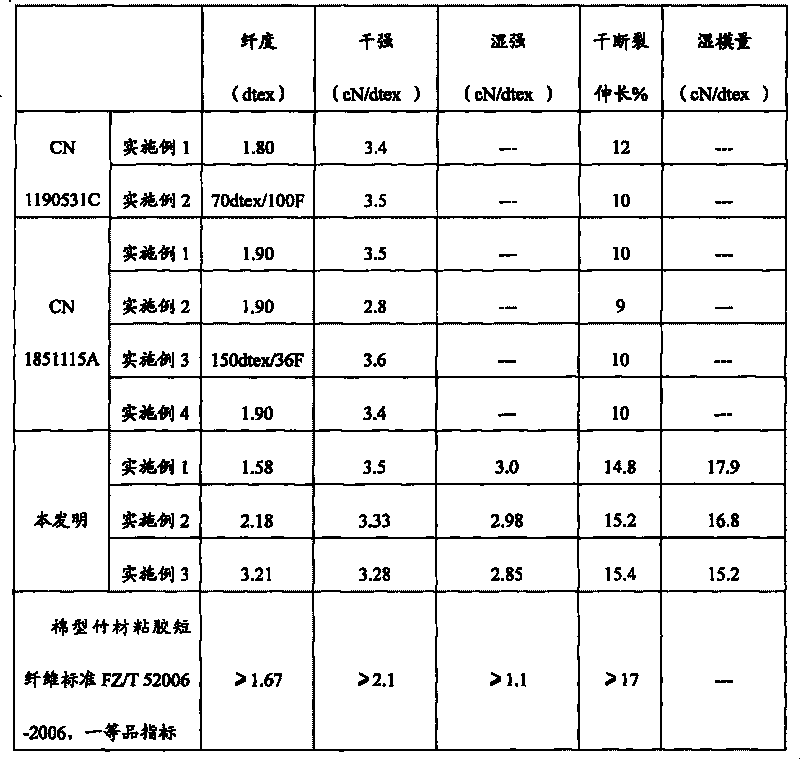

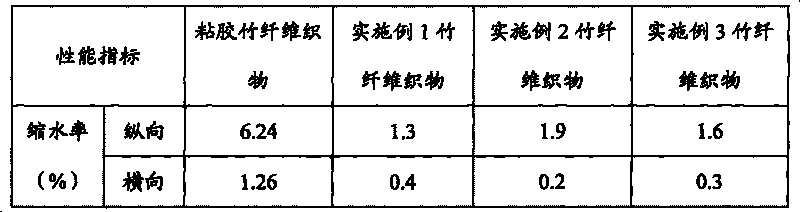

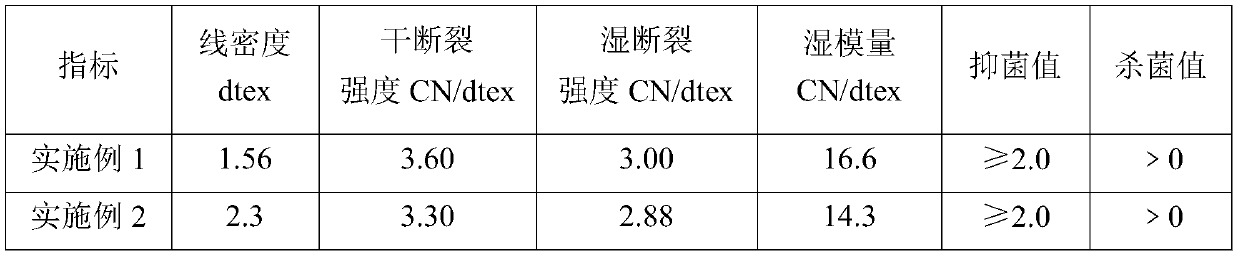

The invention discloses a solvent method high-wet-modulus bamboo fiber and a preparation method thereof. The preparation method of the bamboo fiber comprises the following steps: activation, adding bamboo pulp into deionized water, adjusting the pH value, adding cellulase for activation, and then adding alkali to adjust the pH value; squeezing, vacuum dewatering and squeezing; pre-dissolving, adding water solution containing 50-88% of N-methyl morpholine-N-oxide; dissolving, entering a dissolving machine, heating, vacuumizing, dehydrating, dissolving, homogenizing and defoaming; spinning, spraying through a spinneret plate, and molding by adopting a dry wet spinning; washing; whitening; oiling; and drying. The preparation method has simple operation, no industrial pollution, low energy consumption and high safety performance, and is applicable to manufacturing the solvent method bamboo fiber by large-scale industrialized continuous production; furthermore, the bamboo fiber prepared by the method not only maintains the natural physical and chemical properties of the bamboo fiber, but also generates no harmful chemical residue and has higher wet modulus.

Owner:SHANGHAI LYOCELL FIBER DEV

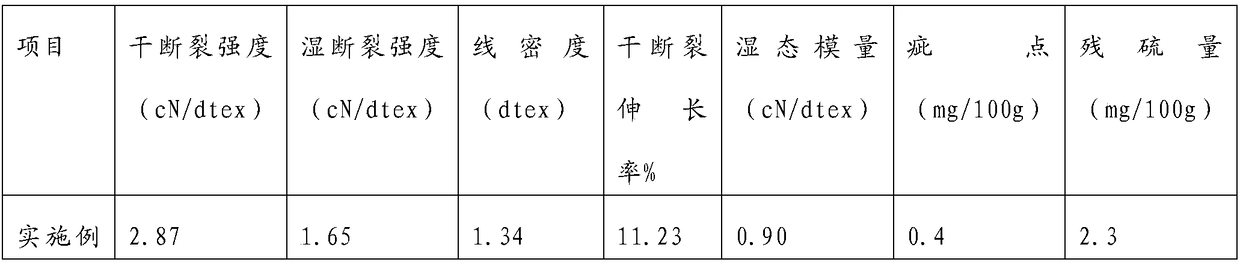

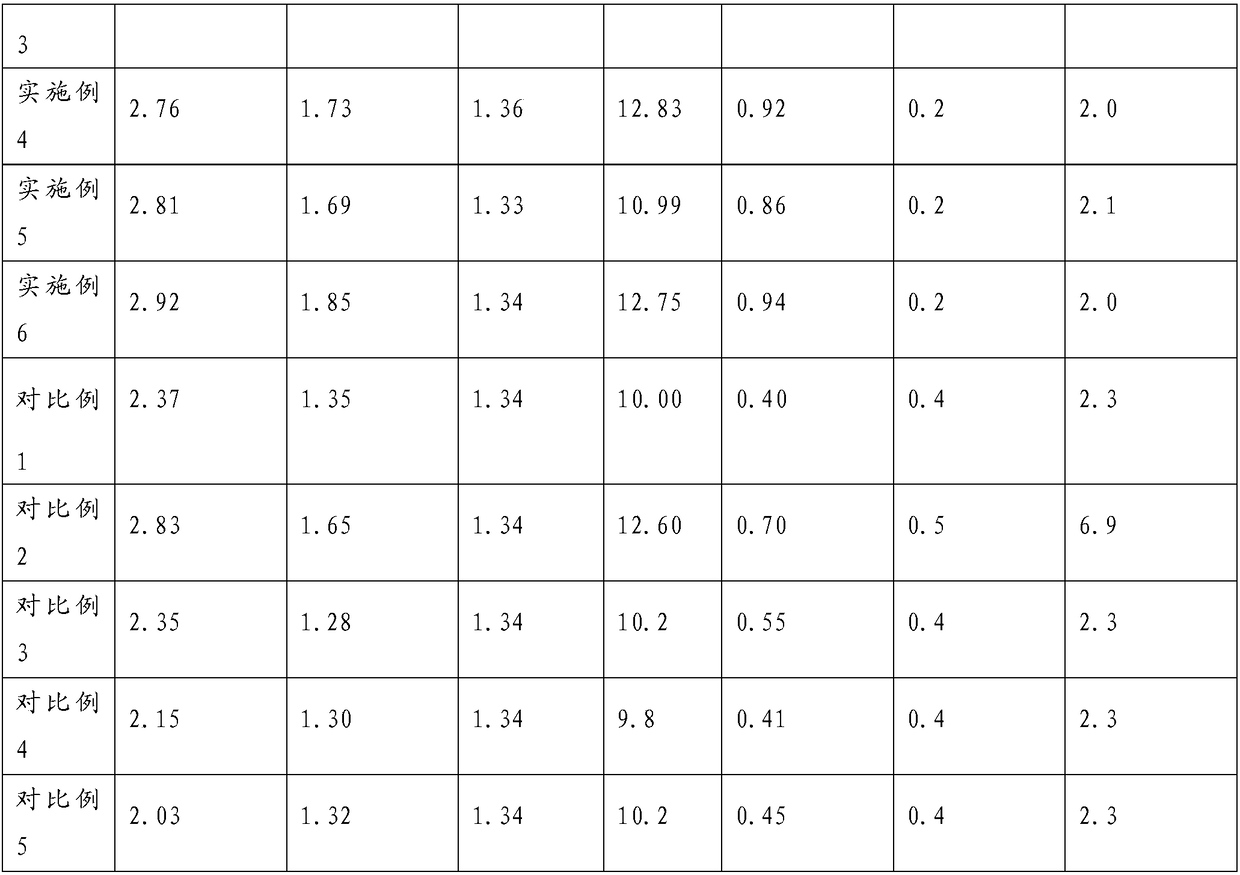

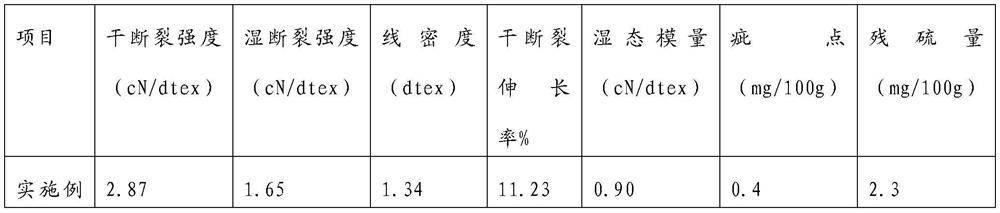

Dimensionality-stable regenerated cellulose fiber and preparation method thereof

ActiveCN102586919AImprove filtering effectImprove wet modulusArtificial filaments from viscoseViscoseWet strength

The invention relates to a preparation method of a dimensionality-stable regenerated cellulose fiber. The preparation method comprises the following steps: carrying out dipping, squeezing, crushing, ageing, yellowing, continuous dissolving, filtering, and deaeration operations on a cellulose raw material to prepare a spinning viscose glue; and spinning to prepare the dimensionality-stable regenerated cellulose fiber, wherein a mixture comprising one or more of a denaturant and a crosslinking agent is added in the continuous dissolving step of the spinning viscose glue operation or before the spinning step. The dimensionality, the dry strength, the wet strength and the dry extension of the dimensionality-stable regenerated cellulose fiber are 1.4-1.72dtex, 1.6-3.0CN / dtex, 1.2-2.8CN / dtex and 10-20% respectively. The dimensionality-stable regenerated cellulose fiber prepared by adopting the method of the invention overcomes disadvantages of low fabric preparation rate and bad dimensional stability caused by the overhigh hygroscopic expansion rate and large wet tensile elongation of common viscose fibers, and has the advantages of stable transverse section and vertical dimensionality, and strong weaving strength.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

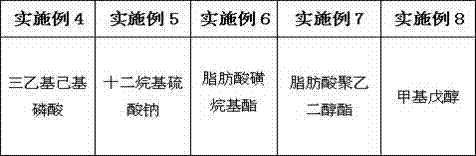

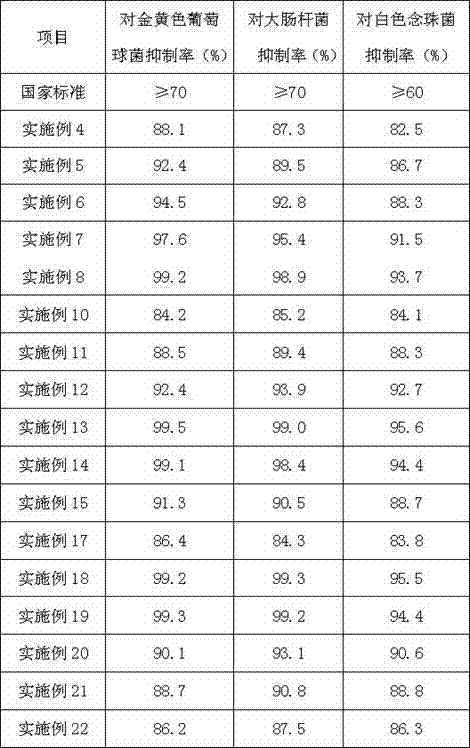

Preparation method for viscose containing wormwood extract

ActiveCN104775173AStrong antibacterial abilityHigh strengthArtificial filaments from viscoseWormwood extractComposite material

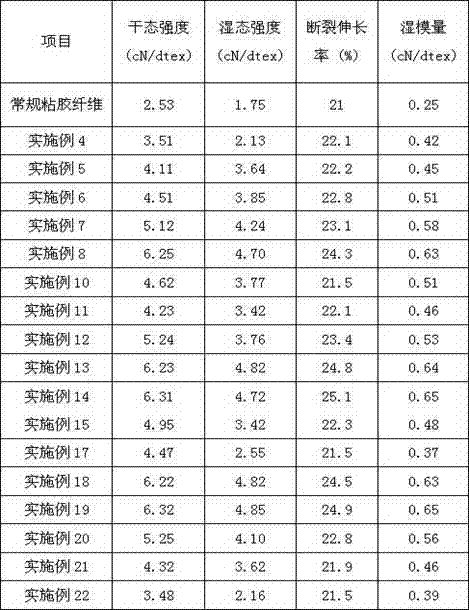

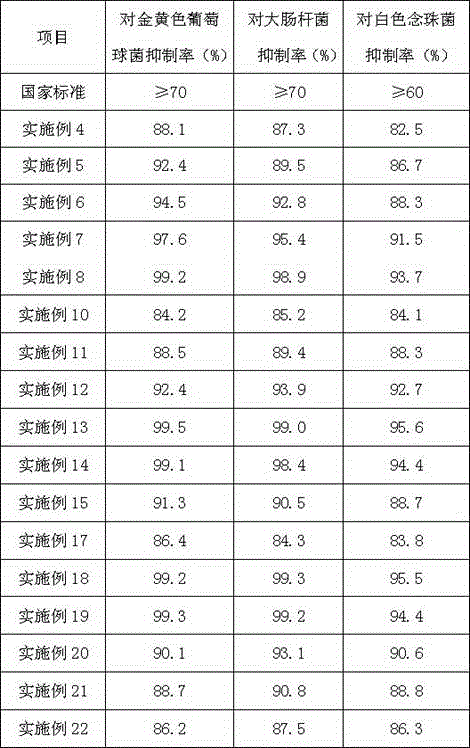

The invention provides a preparation method for a viscose containing wormwood extract. The preparation method comprises the following steps: preparing an antibacterial agent solution, adding a dispersing agent, adding sodium carboxymethylcellulose, blending with a spinning solution, spinning, and post-treating. The prepared viscose has the advantages that the dyeing effect is good, the antibacterial ability is high, the inhibition ratio to staphylococcus aureus is 99.1-99.3%, the inhibition ratio to escherichia coli is 98.9-99.3%, and the inhibition ratio to candida albicans is 93.6-95.7%. The prepared viscose has high strength and wet modulus; the dry strength is 6.21-6.34cN / dtex, the wet strength is 4.71-4.94cN / dtex, the elongation at break is 23.4-25.5%, and the wet modulus is 0.63-0.65cN / dtex.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

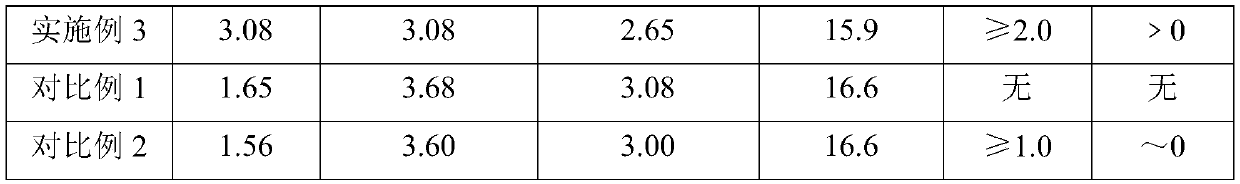

Production method of high wet modulus bamboo pulp viscose glue fiber

ActiveCN101736408AImprove wet modulusImprove stabilityArtificial filaments from viscoseWet spinning methodsBreaking strengthHigh humidity

The invention discloses a production method of high wet modulus bamboo pulp viscose glue fiber, which adopts the steps of dipping, squeezing, smashing, maturing, yellowing, spinning, drawing, refining, drying and the like to prepare high wet modulus bamboo pulp viscose glue fiber. The high wet modulus bamboo pulp viscose glue fiber prepared with the method of the invention has dry breaking strength of 3.2-3.8 CN / dtex, wet breaking strength of 2.0-2.4 CN / dtex and wet modulus of 0.60-0.65 CN / dtex, has the characteristics of high humidity modulus, better purity, favourable affinity for dyestuff, non-fibrillation, non-fibrillar structure and the like, reduces expansion, reduces water retention capacity and improves alkali stability. Prepared fabric has silky luster and draping property, is extremely soft, has excellent dyeability and vivid luster and can keep bright and colorful after being cleaned several times.

Owner:刘泳

Multifunctional compound cellulose fiber and preparation method thereof

ActiveCN107502966AStable functionImprove solubilityArtificial filaments from cellulose derivativesArtifical filament manufacturePolymer scienceCellulose fiber

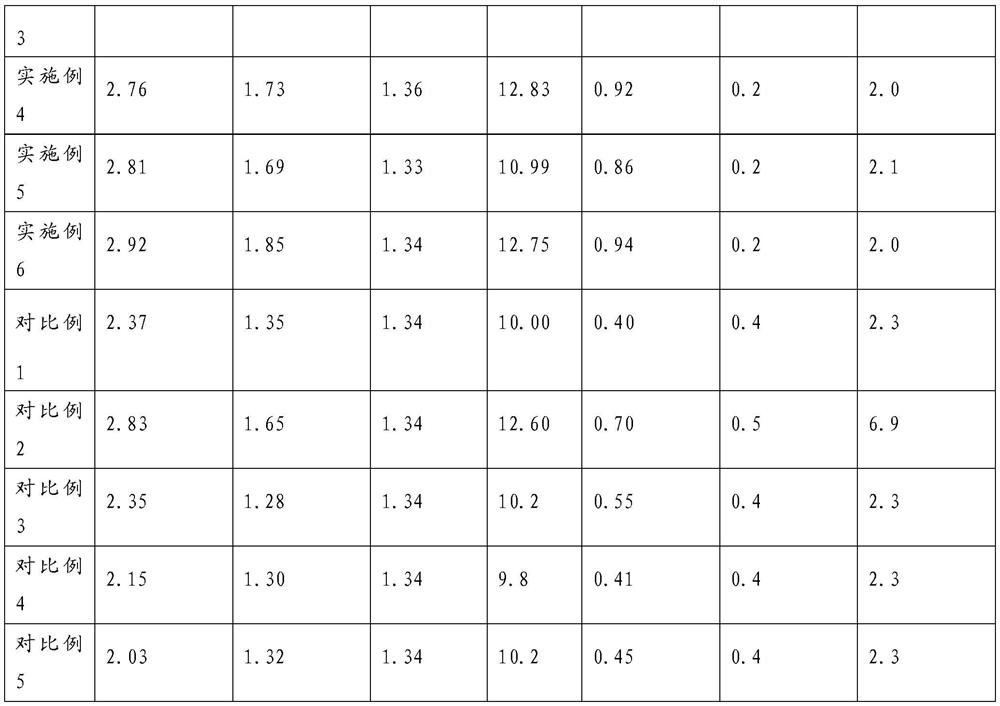

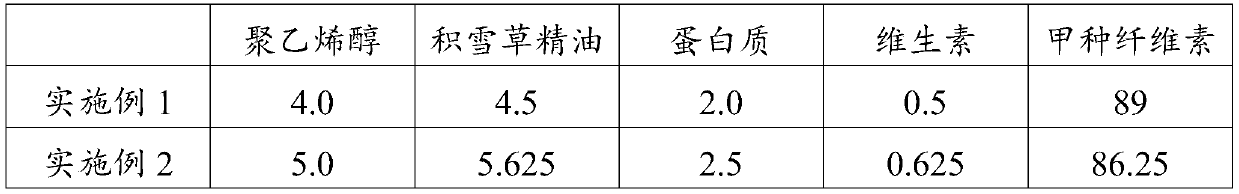

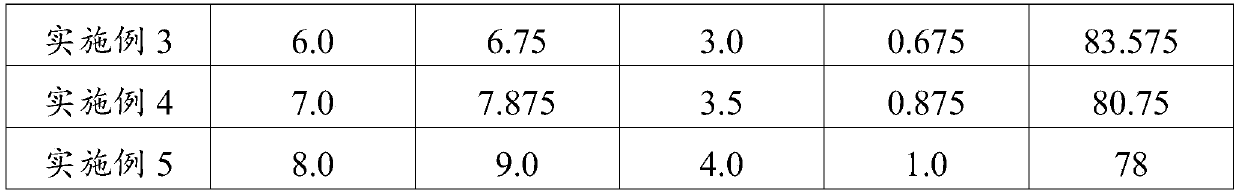

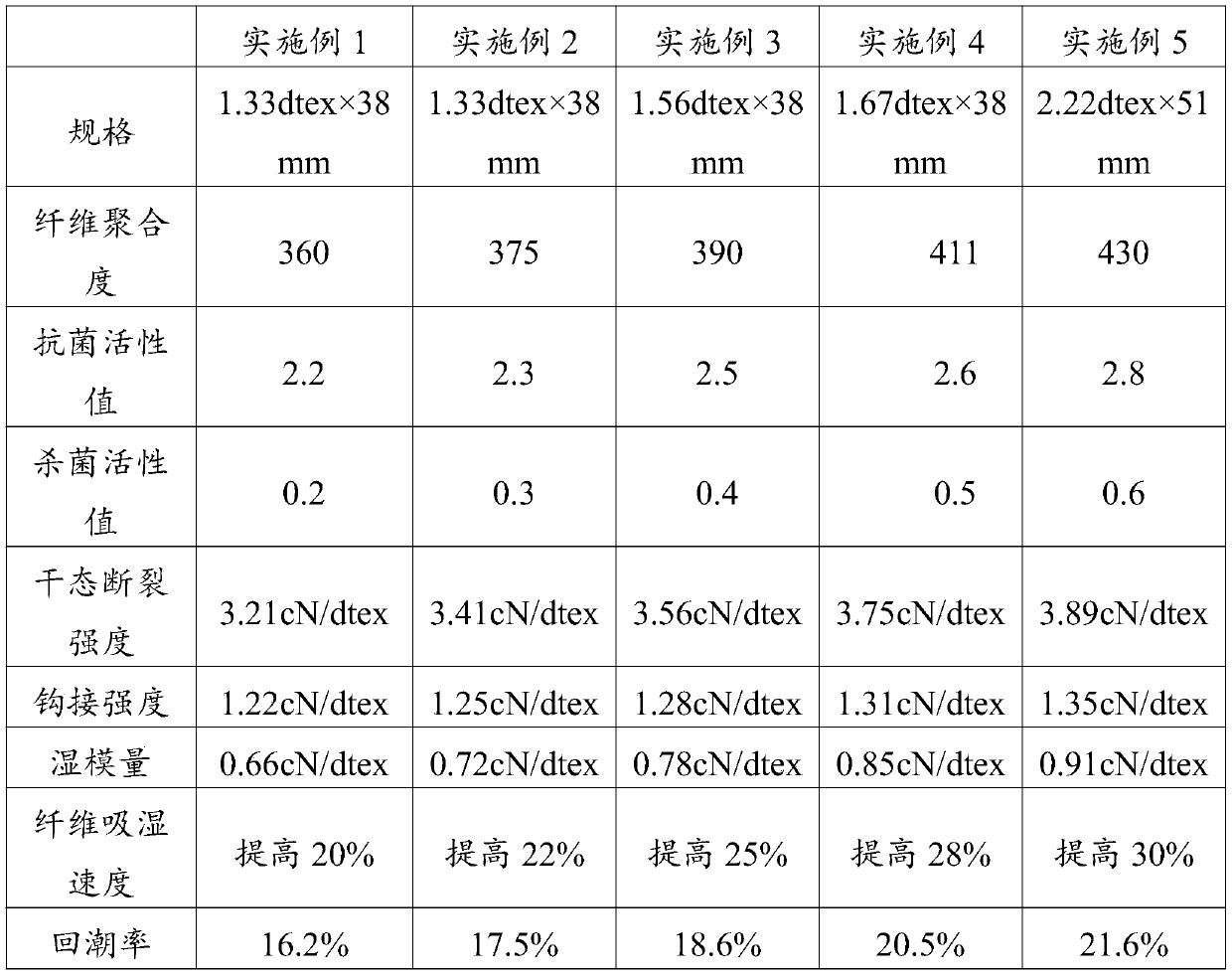

The invention discloses a multifunctional compound cellulose fiber and a preparation method thereof. By adoption of an advanced microcapsule preparation technique and modification of a cellulose fiber solution preparation process, a cellulose fiber is modified through polyvinyl alcohol, herba centellae, proteins and vitamins to obtain the multifunctional compound cellulose fiber by means of a cellulose fiber wet spinning process. The multifunctional compound cellulose fiber prepared according to the method is capable of meeting people's demands on moisture absorption, bacteria resistance, skin caring and the like of fibers, and a product is excellent in physical and mechanical performance and stable functionally and has a promising development prospect.

Owner:山东欣悦健康科技有限公司 +1

Method for spinning blended yarns with outlast air-conditioning fibers/Newdal fibers

InactiveCN101982583AGuaranteed smooth productionRetains temperature regulating propertiesYarnFiberYarn

A method for spinning blended yarns with Outlast air-conditioning fibers / Newdal fibers is characterized by configuring the ingredients Outlast air-conditioning fibers / Newdal fibers according to the weight ratio of 95-85:5-15; opening the Outlast air-conditioning fibers and the Newdal fibers respectively and spraying antistatic agents; processing the Outlast air-conditioning fibers in a plucker, a blender, a card wire opener, a double-hopper feeder, a lap machine, a carding machine and a pre-drawing machine, and processing the Newdal fibers in the plucker, the blender and opener, a multi-bin blender, a sawblade beater type opener, the double-hopper feeder, the lap machine, the carding machine, the pre-drawing machine, a silver lap machine and a comber; and finally feeding the processed Outlast air-conditioning fibers and Newdal fibers into a drawing machine, a roving frame, a spinning frame and a bobbin winder. The method retains the temperature regulation characteristic of the Outlast air-conditioning fibers and higher strength and wet modulus, excellent breaking elongation and unique high crimp property of the Newdal fibers and ensures the products to have better spinning processibility.

Owner:山东昊龙集团有限公司

Solvent Spun Bamboo Fiber with High Wet Modulus and Producing Method Thereof

ActiveUS20120241669A1Easy to operateFree of industrial pollutionOther chemical processesMonocomponent cellulose artificial filamentFiberPresent method

A solvent spun bamboo fiber with a high wet modulus and a producing method thereof are disclosed. The producing method includes: activating by adding a bamboo pulp into de-ionized water, adjusting the pH value, adding cellulase and adjusting the pH value by adding alkali; squeezing by vacuum dehydration; pre-dissolving by adding an aqueous solution containing 50-88% by mass of N-methylmorpholine-N-oxide; then dissolving by putting the above pre-dissolved mixture into a dissolver, heating, vacuumizing, dehydrating, dissolving, homogenizing and defoaming; spinning by spraying through a spinneret and forming a bamboo fiber by dry-wet spinning; water washing; bleaching; oiling; and drying. The present method is simple to operate, free of industrial pollution, low energy consuming, and highly safe. The bamboo fiber produced by the present method not only keeps the natural physical and chemical properties of bamboo fiber, but also has a high wet modulus without harmful chemical residues.

Owner:SHANGHAI LYOCELL FIBER DEV

Solvent method based high-wet-modulus bamboo, wood and cotton mixed fiber and preparation method thereof

InactiveCN109355731AEasy to operateProduction without industrial pollutionConjugated cellulose/protein artificial filamentsFiberChemical residue

Owner:SHANGHAI DEFULUN CHEM FIBER +1

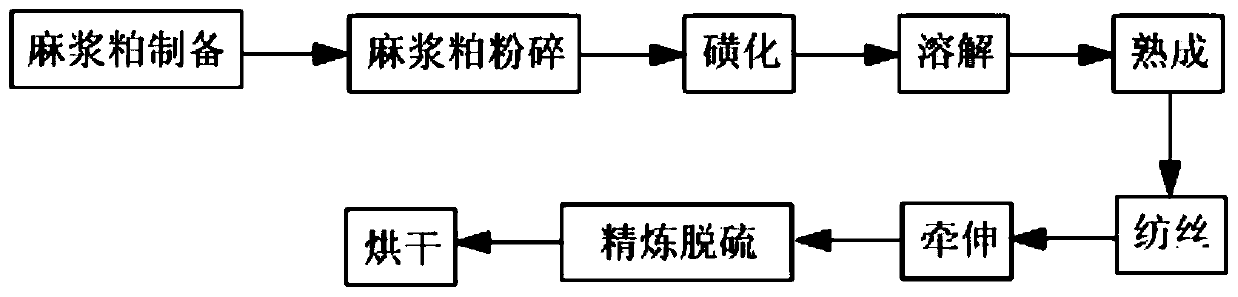

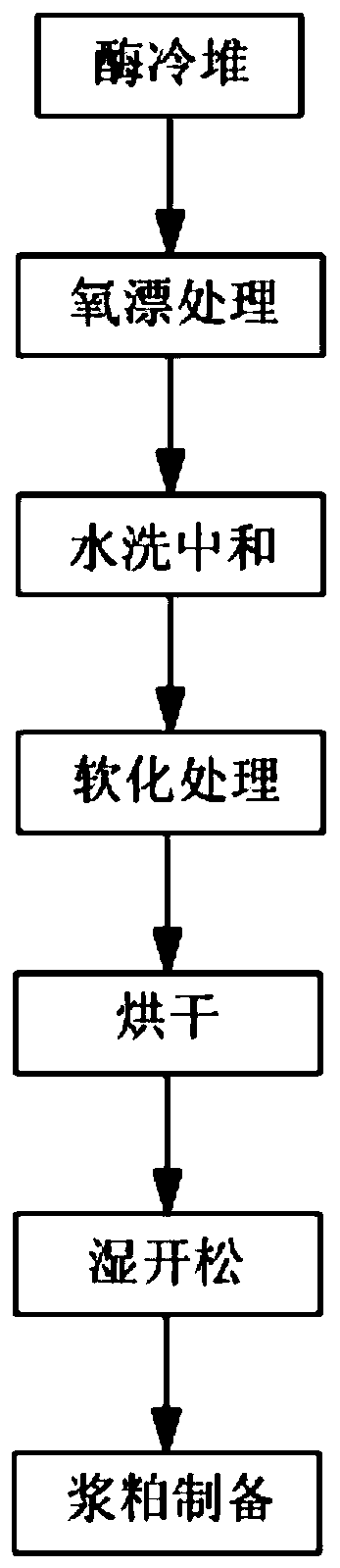

Viscose producing process based on hemp pulp

InactiveCN110528102AAvoid damageImprove solubilityPulp bleachingArtificial filaments from viscoseRipeningTextile production

The invention relates to the technical field of textile production processes, in particular to a viscose producing process based on hemp pulp. The viscose producing process includes the following steps of firstly, preparing raw materials, wherein the hemp type raw materials are collected for use; secondly, preparing the hemp pulp, wherein the hemp type raw materials prepared in the first step aresubjected to enzyme cold piling, oxygen rinsing, washing and drying treatment to prepare the hemp pulp; thirdly, preparing viscose, wherein the hemp pulp prepared in the second step is subjected to pulverizing, sulfonating, dissolving, ripening, spinning, drafting, refining desulphurization and drying treatment to obtain the viscose. The production process is simple, mild in condition, environmentally friendly and capable of saving energy; the produced viscose is large in specific surface area, the dye-uptake and elongation at break of the fiber can be increased, the viscose is good in antibacterial property, the antibacterial property of the viscose can be kept to be 70-80% of that of original hemp, and the textile fabric is higher in drape factor and softer and more smooth in handfeel.

Owner:青岛诺麻织造有限公司

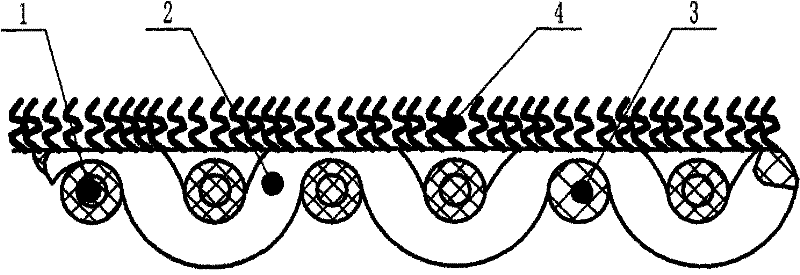

Hygroscopic spandex lint with color tencel strips

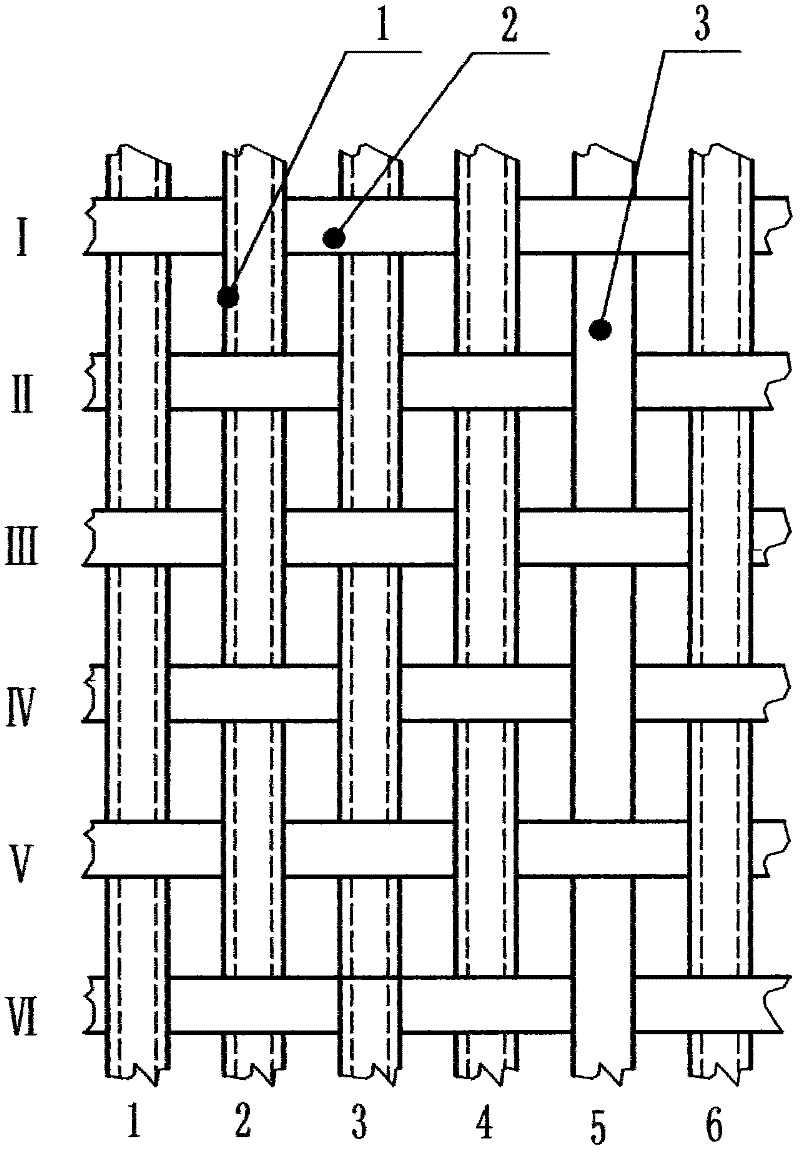

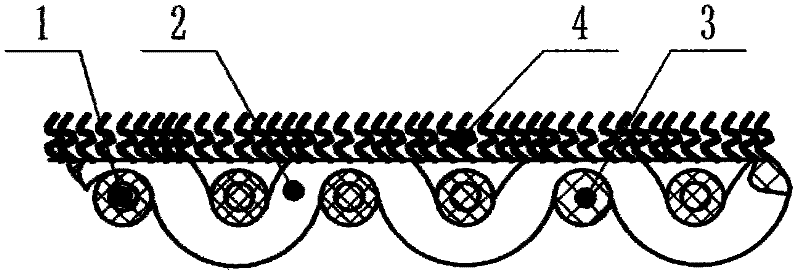

InactiveCN102454001ADimensional stabilityGood dimensional stabilityWoven fabricsTextile treatment by spraying/projectingYarnFiber

The invention relates to hygroscopic spandex lint with color tencel strips. The lint is characterized in that warps are formed by adding one organic conductive filament yarn at an interval of 5-10 core-spun yarns made of tencel coated with spandex and repeating the step again and again; wefts are formed by adding 10-20 tencel fiber yarns of one color at an interval of 10-20 tencel fiber yarns of another color and repeating the step again and again; the group of warps and wefts are interwoven, the warps and the wefts are in contact connection through the intersections of the warps and the wefts to jointly form fabric, and the surface of the fabric is provided with fluffs in a zigzag form. The fabric has the characteristics of high wet strength, wet modulus, high strength, good size stability and the like; moreover, the fabric has high-elasticity and anti-static functions of spandex fabric; due to a zigzag shape formed through finishing after sanding, micro spaces are formed among the fluffs and have superhigh hygroscopicity and air permeability; furthermore, the zigzag-shaped fluffs have excellent rebound resilience and do not fall down with good recovery performance after being pressed.

Owner:盐城明轩针织有限公司

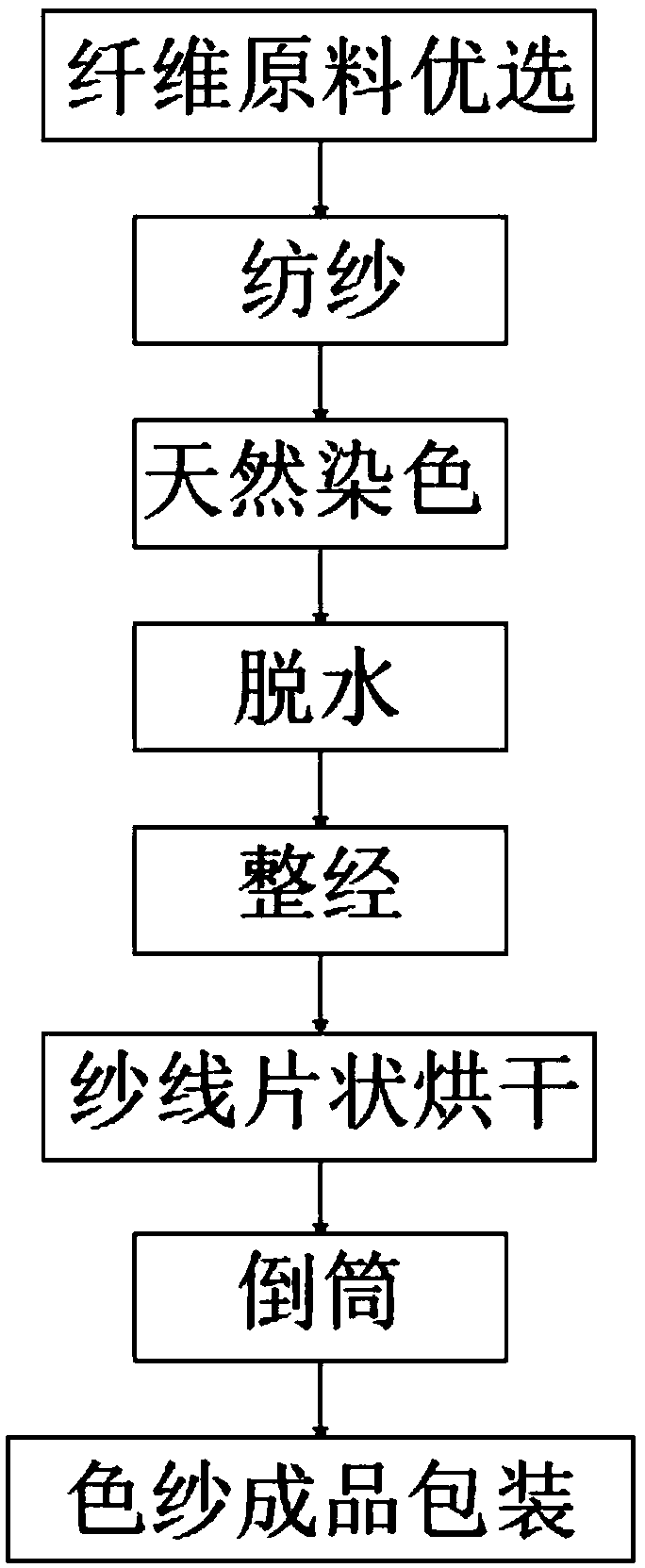

Production method of enVironment-friendly hydroscopic and fast dry natural dyeing yarn

InactiveCN108677300AGood moisture absorption and quick dryingNovel methodWarping machinesWrinkle resistant fibresYarnBobbin

The inVention discloses a production method of an enVironment-friendly hydroscopic and fast dry natural dyeing yarn, and belongs to the field of spinning. The production method of the enVironment-friendly hydroscopic and fast dry natural dyeing yarn has the adVantages that the yarn is blended with a certain proportion of cross section Viscose, the content of an enVironment-friendly polylactic acidfiber in the fiber whole content of the yarn is controlled at 60% or aboVe, the content of the cross section Viscose is controlled at 40% or below, a yarn dyeing method comprises the steps that a natural dyestuff is adopted to dye and dehydrate the blended yarn, then dyed wet-state bobbin color yarns pass through a warping machine, a certain number of strips of bobbin color yarns are warped intoflaky warp beams, then a drying deVice on a slasher is utilized to dry the wet-state bobbin color yarns in a flaky mode, then a rewinding machine producing knitted jean yarns is utilized to rewind strips of color yarns on a flaky color yarn axis into the bobbin color yarns, and it can be achieVed that the produced colored yarn has the adVantages of dyeing naturally, being enVironmentally friendly,absorbing moisture and drying quickly.

Owner:北京宇宙沙盘太空科技有限公司

Solvent-process high wet modulus chitin fibers and preparation method thereof

InactiveCN110804766AEasy to operateProduction without industrial pollutionArtificial filament washing/dryingMonocomponent cellulose artificial filamentFiberPolymer science

The invention discloses solvent-process high wet modulus chitin fibers and a preparation method thereof, and belongs to the field of textiles. The preparation method comprises the steps: (A) activating, to be specific, activating pulp dregs by cellulase to obtain paste; (B) squeezing, to be specific, squeezing and dehydrating the paste to obtain water-containing cellulose; (C) pre-dissolving, to be specific, mixing aqueous cellulose, N-methylmorpholine-N-oxide solution and a chitin solution to obtain a pre-dissolved pulp; (D) dissolving, to be specific, dissolving the pre-dissolved pulp in a dissolving machine to obtain a pulp; and (E) spinning, to be specific, performing spinning on the pulp to obtain the solvent-process high wet modulus chitin fibers. The preparation method has the advantages of good operation simplicity, zero industrial pollution to production, low energy consumption, high safety and suitability for large-scale industrial continuous production. The prepared solvent-process high wet modulus chitin fibers have high wet modulus, contain protein components, and are good in breathability and air permeability, comfortable to wear, soft to touch and favorable for continuous dyeing, are convenient to print and dye and are good for producing high-end fabrics.

Owner:SHANGHAI LYOCELL FIBER DEV

Dimensionality-stable regenerated cellulose fiber and preparation method thereof

ActiveCN102586919BImprove filtering effectImprove wet modulusArtificial filaments from viscoseViscoseWet strength

The invention relates to a preparation method of a dimensionality-stable regenerated cellulose fiber. The preparation method comprises the following steps: carrying out dipping, squeezing, crushing, ageing, yellowing, continuous dissolving, filtering, and deaeration operations on a cellulose raw material to prepare a spinning viscose glue; and spinning to prepare the dimensionality-stable regenerated cellulose fiber, wherein a mixture comprising one or more of a denaturant and a crosslinking agent is added in the continuous dissolving step of the spinning viscose glue operation or before the spinning step. The dimensionality, the dry strength, the wet strength and the dry extension of the dimensionality-stable regenerated cellulose fiber are 1.4-1.72dtex, 1.6-3.0CN / dtex, 1.2-2.8CN / dtex and 10-20% respectively. The dimensionality-stable regenerated cellulose fiber prepared by adopting the method of the invention overcomes disadvantages of low fabric preparation rate and bad dimensional stability caused by the overhigh hygroscopic expansion rate and large wet tensile elongation of common viscose fibers, and has the advantages of stable transverse section and vertical dimensionality, and strong weaving strength.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Method for producing regenerated cellulose fiber with high wet modulus from bamboo pulp

ActiveCN103556281BMeet needsReduce the degree of polymerizationArtificial filaments from viscoseAfter treatmentCellulose fiber

Owner:唐山三友集团兴达化纤有限公司

A kind of preparation method of cellulose viscose and its application in cellulose casing

ActiveCN114517338BImprove toughnessHigh strengthArtificial filaments from viscoseTextile/flexible product manufactureCellulosePolymer science

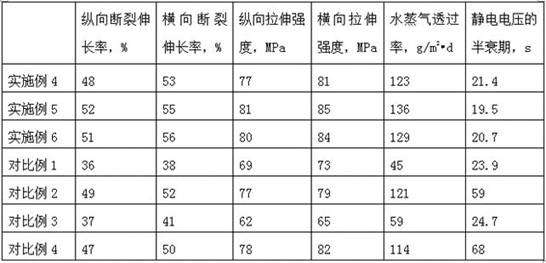

The invention discloses a preparation method of cellulose viscose and its application in cellulose casing, belonging to the technical field of viscose fibers. The preparation method of cellulose viscose includes preparing a viscose solution, modifying the viscose solution , spinning and post-processing; the application of the cellulose viscose in the cellulose casing includes weaving, shaping, primary drying, washing and setting, and secondary drying; the present invention can improve the toughness and antistatic properties of the cellulose casing. While improving the spinnability, the water vapor transmission rate, wet modulus, dimensional stability, elasticity, abrasion resistance and acid and alkali resistance of cellulose casing are improved.

Owner:WEIFANG WEISEN FIBER NEW MATERIAL CO LTD

Production method of high wet modulus bamboo pulp viscose glue fiber

ActiveCN101736408BImprove wet modulusImprove stabilityArtificial filaments from viscoseWet spinning methodsBreaking strengthHigh humidity

The invention discloses a production method of high wet modulus bamboo pulp viscose glue fiber, which adopts the steps of dipping, squeezing, smashing, maturing, sulfonating, spinning, drawing, refining, drying and the like to prepare high wet modulus bamboo pulp viscose glue fiber. The high wet modulus bamboo pulp viscose glue fiber prepared with the method of the invention has dry breaking strength of 3.2-3.8 CN / dtex, wet breaking strength of 2.0-2.4 CN / dtex and wet modulus of 0.60-0.65 CN / dtex, has the characteristics of high humidity modulus, better purity, favourable affinity for dyestuff, non-fibrillation, non-fibrillar structure and the like, reduces expansion, reduces water retention capacity and improves alkali stability. Prepared fabric has silky luster and draping property, is extremely soft, has excellent dyeability and vivid luster and can keep bright and colorful after being cleaned several times.

Owner:刘泳

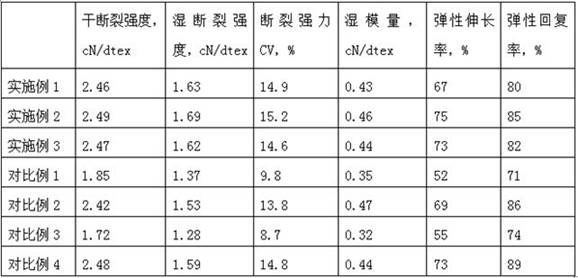

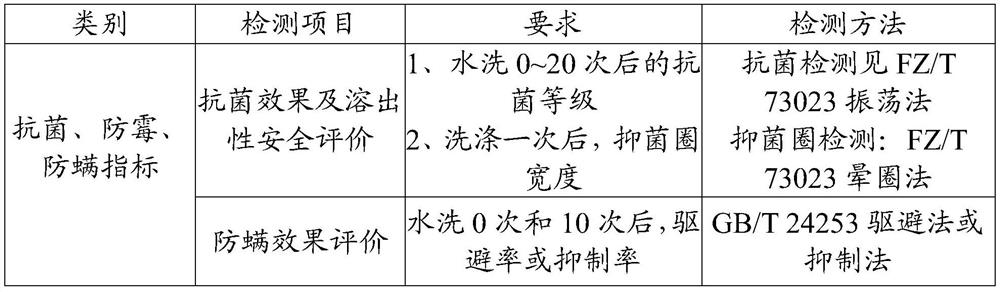

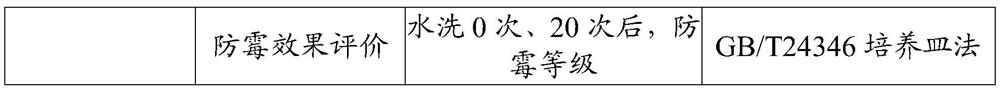

Preparation method and application of regenerated cellulose fiber with antibacterial, anti-mite and anti-mildew functions

ActiveCN108103607BAntibacterialMildew proofMonocomponent cellulose artificial filamentWet spinning methodsBiotechnologyAnti bacterial

The invention relates to the technical field of regenerated cellulose fibers, in particular to a composition and application thereof to preparation of regenerated cellulose fibers with an antibacterial anti-acarien and moldproof function. The composition provided by the invention consists of radix stemonae extract, rhizoma coptidis extract and essential oil of fruit of cubeb litsea tree. The regenerated cellulose fibers comprising the composition can resist bacteria, mites and mold, and also have good mechanical performance, and a textile prepared by using the fibers has good quality.

Owner:INFINITUS (CHINA) CO LTD

Solvent spun bamboo fiber with high wet modulus and producing method thereof

ActiveUS8926712B2Improve wet modulusEasy to operateMonocomponent protein artificial filamentArtificial filaments from cellulose solutionsFiberPresent method

A solvent spun bamboo fiber with a high wet modulus and a producing method thereof are disclosed. The producing method includes: activating by adding a bamboo pulp into de-ionized water, adjusting the pH value, adding cellulase and adjusting the pH value by adding alkali; squeezing by vacuum dehydration; pre-dissolving by adding an aqueous solution containing 50-88% by mass of N-methylmorpholine-N-oxide; then dissolving by putting the above pre-dissolved mixture into a dissolver, heating, vacuumizing, dehydrating, dissolving, homogenizing and defoaming; spinning by spraying through a spinneret and forming a bamboo fiber by dry-wet spinning; water washing; bleaching; oiling; and drying. The present method is simple to operate, free of industrial pollution, low energy consuming, and highly safe. The bamboo fiber produced by the present method not only keeps the natural physical and chemical properties of bamboo fiber, but also has a high wet modulus without harmful chemical residues.

Owner:SHANGHAI LYOCELL FIBER DEV

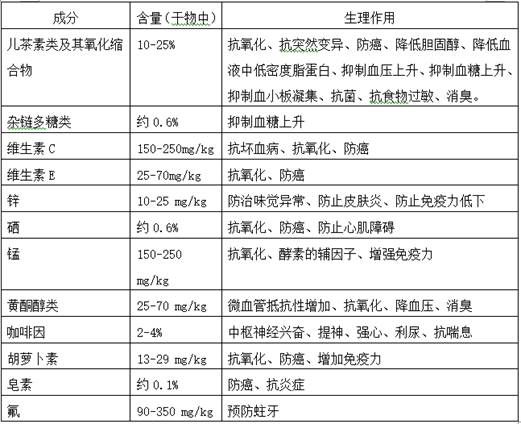

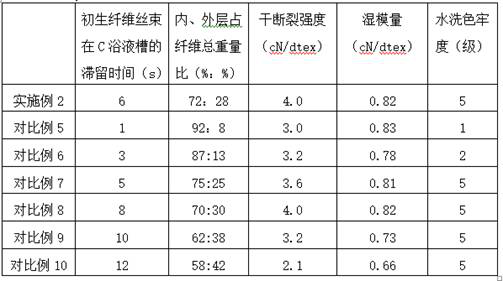

A long-acting broad-spectrum antibacterial Tiancha fiber and its preparation method

ActiveCN109505028BImprove antibacterial propertiesIncrease health functionConjugated cellulose/protein artificial filamentsWet spinning methodsPolymer scienceSpinning

The invention provides a long-acting broad-spectrum antibacterial sky tea fiber, which belongs to the field of cellulose fibers. The fiber is composed of an inner layer and an outer layer; the inner layer is distributed with micro-cavities and carbon nanotubes; the inner layer accounts for 65-75% of the total dry weight of the fiber; the outer layer accounts for the total fiber weight. 25‑35% of weight. The present invention also provides a preparation method of long-acting broad-spectrum antibacterial tiancha fiber. The method includes the preparation step of viscose spinning solution; the preparation step of the viscose spinning solution includes adding a modification aid in the dissolving process. A kind of long-acting broad-spectrum antibacterial sky tea fiber prepared by the present invention, the inner layer adopts the traditional sulfonate method glue making process, adopts the coagulation bath process formed by the skinless core layer, and the outer layer adopts the creative solvent method to homogenize the fiber. After coating and coagulation regeneration, the prepared fibers have high strength, good antibacterial durability, high wet modulus, and especially the dry breaking strength exceeds that of ordinary viscose fibers.

Owner:青岛邦特生态纺织科技有限公司

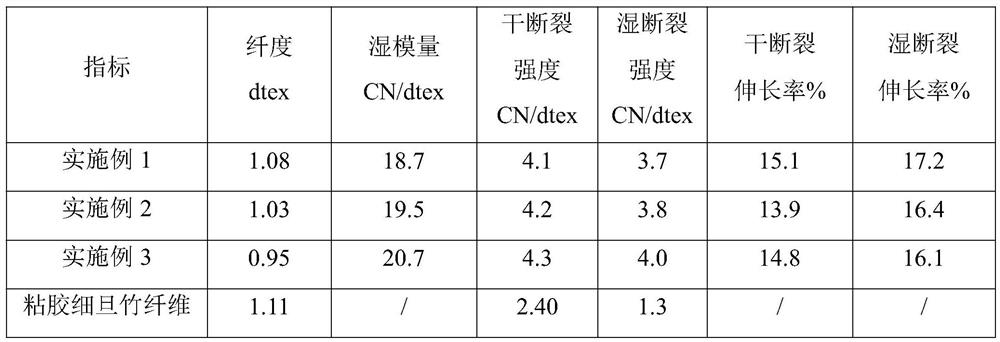

Solvent-process high-wet-modulus fine-denier bamboo fibers and preparation method thereof

PendingCN112481723AEasy to operateProduction without industrial pollutionArtificial filaments from cellulose solutionsFilament/thread formingFiberTextile technology

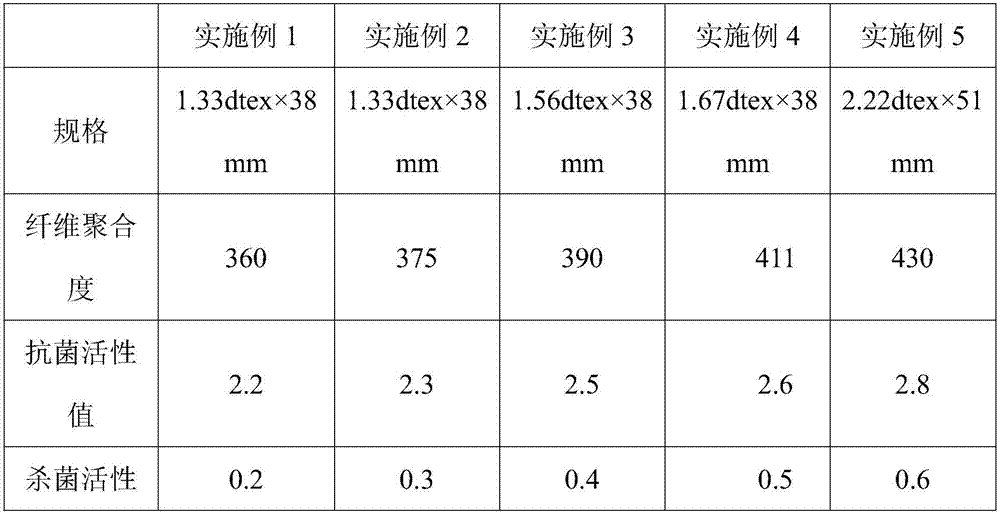

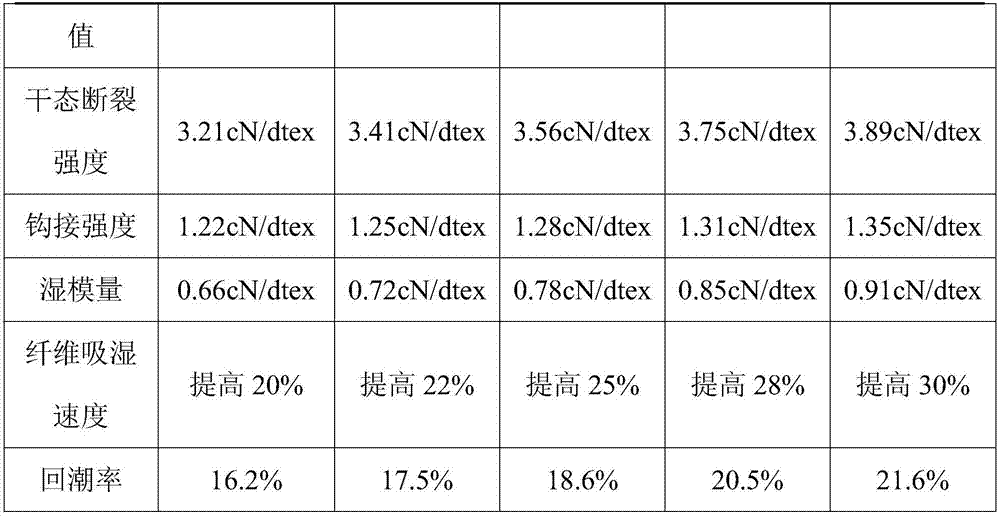

The invention relates to the technical field of textiles, in particular to solvent-process high-wet-modulus fine-denier bamboo fibers and a preparation method thereof. The preparation method comprisesthe following steps of performing activation: adding bamboo pulp with the polymerization degree of 600-1200 into deionized water, adjusting the pH value, adding cellulase for activation, and adding alkali for adjusting the pH value; performing squeezing: performing vacuum dehydration squeezing; performing pre-dissolving: adding an aqueous solution containing 65-86% by mass of N-methylmorpholine-N-oxide; performing dissolving: entering dissolving equipment, performing heating, vacuumizing, dewatering, dissolving, homogenizing and defoaming; performing filtration; performing spinning: performing spinning and forming by adopting a dry-wet process; performing washing with water; performing bleaching; performing oiling; and performing drying. The preparation method is easy to operate, free ofindustrial pollution, low in energy consumption, high in safety performance and suitable for large-scale industrial continuous production of the solvent-process fine-denier bamboo fibers; and the fineness of the prepared fine-denier bamboo fibers is 0.95-1.08 dtex, the wet modulus is larger than 18.0 CN / dtex, the natural physical and chemical properties of the fine-denier bamboo fibers are reserved, no harmful chemical residues exist, and the wet modulus is relatively high.

Owner:SHANGHAI LYOCELL FIBER DEV

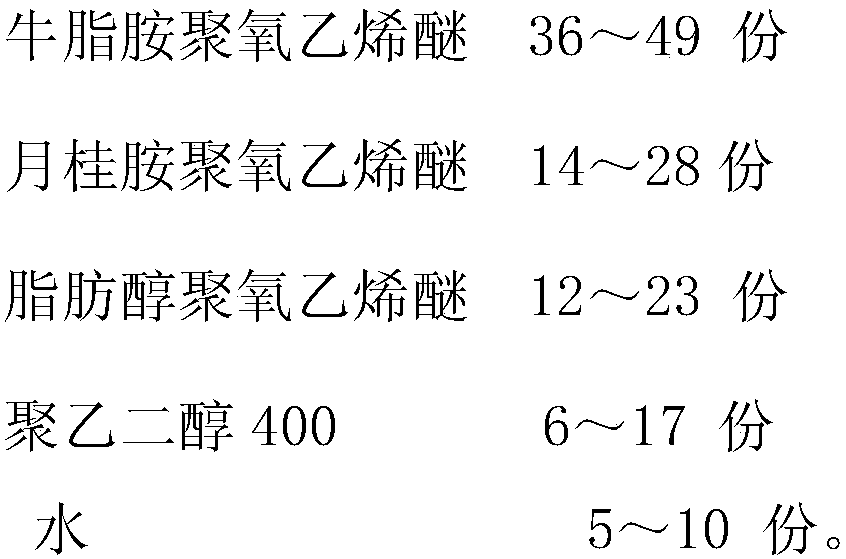

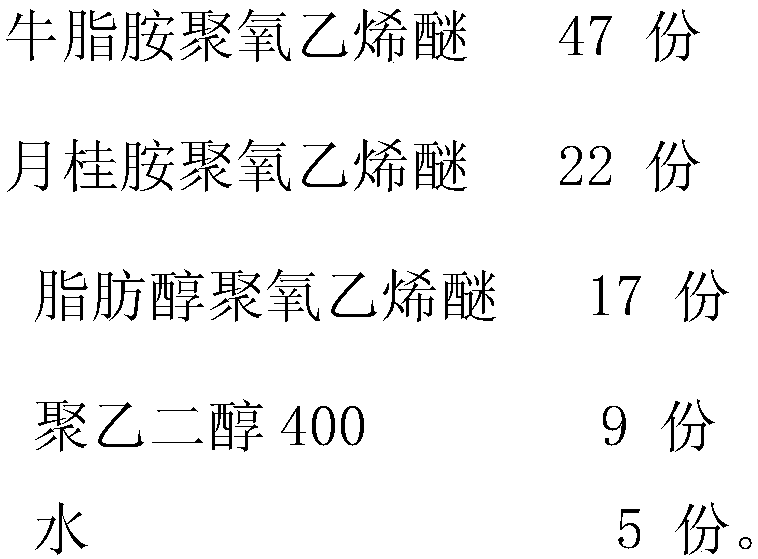

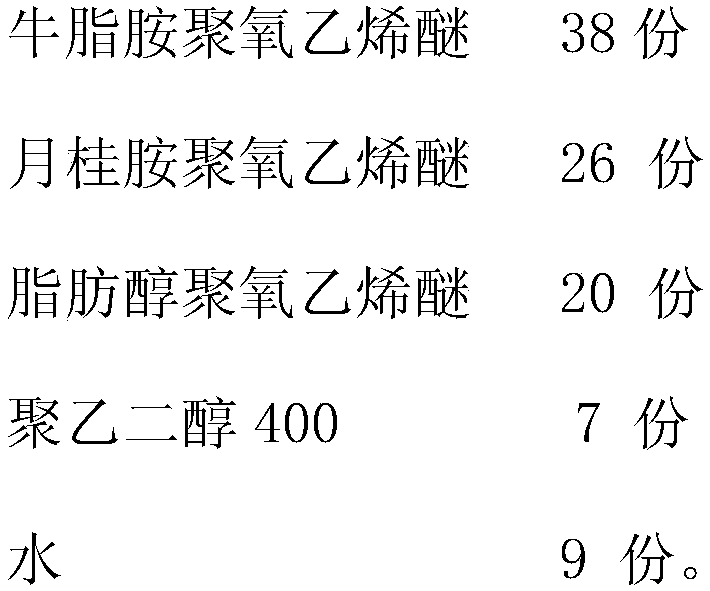

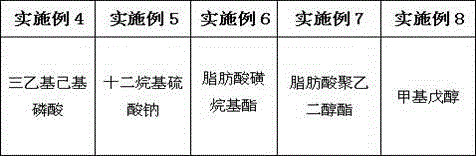

A viscose fiber denaturing agent

InactiveCN105543994BReduce manufacturing costEasy to prepareMonocomponent cellulose artificial filamentCellulosePEG 400

The invention relates to a denaturing agent for viscose. The denaturing agent comprises components in parts by weight as follows: 36-49 parts of N-Polyoxyethylated-N-tallow-alkylamine, 14-28 parts of polyethylene glycol lauramine, 12-23 parts of fatty alcohol-polyoxyethylene ether, 6-17 parts of polyethylene glycol and 5-10 parts of water. With the adoption of the denaturing agent for the viscose, the forming state during viscose spinning can be effectively changed, regeneration of cellulose is delayed, thickening of a fiber skin layer is promoted, a viscose stock solution can have a higher tensile property, and the dry-wet strength and wet modulus of fibers are increased.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

A kind of preparation method of viscose fiber containing wormwood extract

ActiveCN104775173BImprove antibacterial propertiesHigh strengthArtificial filaments from viscoseEscherichia coliCandida albicans

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

High wet modulus viscose fiber and preparation method thereof

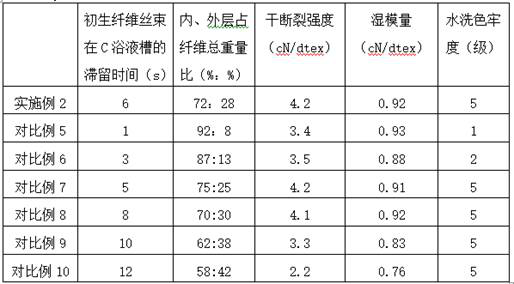

ActiveCN109267165AImprove wet modulusDimensional stability in wet stateArtificial filament washing/dryingArtificial filaments from viscoseBreaking strengthPolymer science

The invention discloses a high wet modulus viscose fiber and a preparation method thereof, wherein the high wet modulus viscose fiber has dry breaking strength of 2.4-3.5 cN / dtex, wet breaking strength of 1.3-2.1cN / dtex, dry elongation at break of 9-15%, and wet modulus of 0.7-1.0 cN / dtex. The nascent fiber tow is sequentially subjected to the following treatment steps: (1) entering a plasticizingbath, and carrying out wet heat drafting; (2) dehydrating, entering a desulfurization bath, and carrying out desulfurization; (3) dehydrating, entering a bleaching bath, and bleaching; (4) dehydrating, and carrying out multiple water washing steps while carrying out wet drafting; (5) dehydrating, entering an oil bath, and oiling; and (6) dehydrating, and carrying out hot roll drying while carrying out dry drafting to obtain the high wet modulus viscose fiber. According to the present invention, the viscose fiber with high wet modulus and stable wet size can be obtained only by adjusting the post-treatment process, such that the process has strong controllability.

Owner:赛得利(盐城)纤维有限公司

A kind of high wet modulus viscose fiber and preparation method thereof

ActiveCN109267165BImprove wet modulusDimensional stability in wet stateArtificial filament washing/dryingArtificial filaments from viscosePolymer sciencePlasticulture

Owner:赛得利(盐城)纤维有限公司

A kind of multifunctional composite cellulose fiber and its preparation method

ActiveCN107502966BAvoid drug resistanceDefense against invasionArtificial filaments from cellulose derivativesArtifical filament manufacturePolymer scienceSpinning

The invention discloses a multifunctional compound cellulose fiber and a preparation method thereof. By adoption of an advanced microcapsule preparation technique and modification of a cellulose fiber solution preparation process, a cellulose fiber is modified through polyvinyl alcohol, herba centellae, proteins and vitamins to obtain the multifunctional compound cellulose fiber by means of a cellulose fiber wet spinning process. The multifunctional compound cellulose fiber prepared according to the method is capable of meeting people's demands on moisture absorption, bacteria resistance, skin caring and the like of fibers, and a product is excellent in physical and mechanical performance and stable functionally and has a promising development prospect.

Owner:山东欣悦健康科技有限公司 +1

Method for spinning blended yarns with outlast air-conditioning fibers/Newdal fibers

InactiveCN101982583BGuaranteed smooth productionRetains temperature regulating propertiesYarnFiberYarn

A method for spinning blended yarns with Outlast air-conditioning fibers / Newdal fibers is characterized by configuring the ingredients Outlast air-conditioning fibers / Newdal fibers according to the weight ratio of 95-85:5-15; opening the Outlast air-conditioning fibers and the Newdal fibers respectively and spraying antistatic agents; processing the Outlast air-conditioning fibers in a plucker, ablender, a card wire opener, a double-hopper feeder, a lap machine, a carding machine and a pre-drawing machine, and processing the Newdal fibers in the plucker, the blender and opener, a multi-bin blender, a sawblade beater type opener, the double-hopper feeder, the lap machine, the carding machine, the pre-drawing machine, a silver lap machine and a comber; and finally feeding the processed Outlast air-conditioning fibers and Newdal fibers into a drawing machine, a roving frame, a spinning frame and a bobbin winder. The method retains the temperature regulation characteristic of the Outlast air-conditioning fibers and higher strength and wet modulus, excellent breaking elongation and unique high crimp property of the Newdal fibers and ensures the products to have better spinning processibility.

Owner:山东昊龙集团有限公司

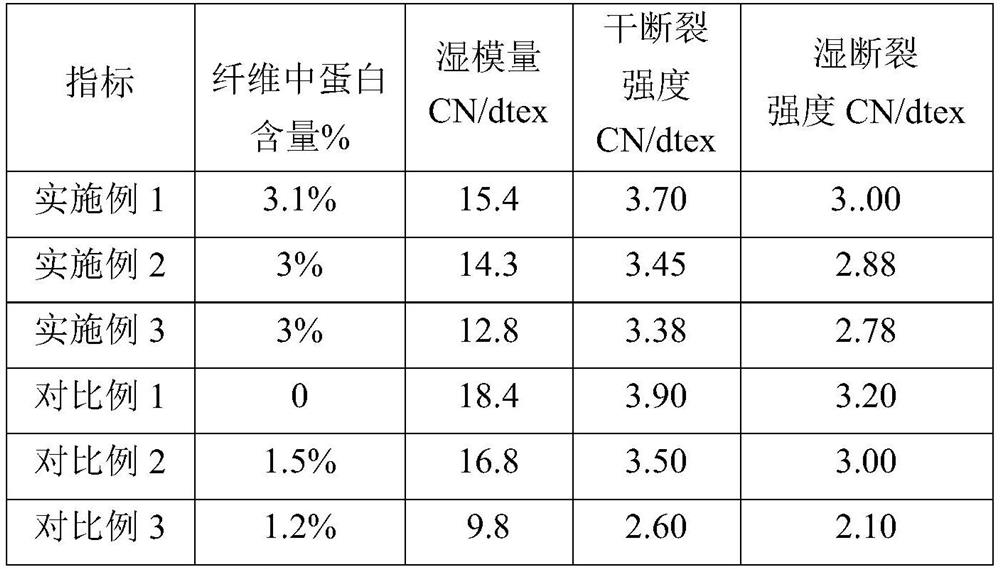

A kind of solvent method high wet modulus protein fiber and preparation method thereof

ActiveCN110886025BEasy to operateProduction without industrial pollutionMonocomponent cellulose artificial filamentCellulose/protein filament chemical after-treatmentSpinningMorpholine

The invention discloses a solvent method high wet modulus protein fiber and a preparation method thereof, belonging to the field of textiles. The method comprises the steps of: (A) activation, the pulp is activated by cellulase to obtain pulp; (B) pressing, the pulp is pressed and dehydrated to obtain water-containing cellulose; (C) predissolving, water-containing cellulose and N-methyl cellulose are obtained The morpholine-N-oxide aqueous solution and the protein mixed solution are mixed to obtain a pre-dissolved pulp; (D) dissolving, and the pre-dissolved pulp is dissolved in a dissolving machine to obtain a slurry; (E) spinning, the slurry is used for spinning to obtain a solvent-based high Wet modulus protein fibers. The method has simple operation, no industrial pollution production, low energy consumption and high safety performance, and is suitable for large-scale industrialized continuous production. The obtained solvent-method high wet modulus protein fiber has a high wet modulus, contains protein components, and has good moisture absorption and perspiration, good air permeability, comfortable wearing, soft hand feeling, is conducive to continuous dyeing, easy printing and dyeing, and is conducive to the production of high-end fabrics .

Owner:SHANGHAI LYOCELL FIBER DEV

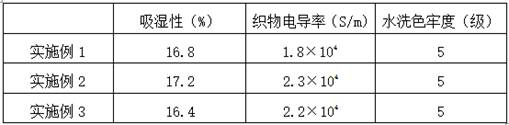

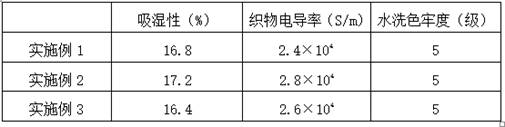

A kind of multifunctional carbon nanotube plant-derived fiber and preparation method thereof

ActiveCN109487363BImprove wrinkle resistanceImprove antibacterial propertiesElectroconductive/antistatic filament manufactureConjugated cellulose/protein artificial filamentsPolymer scienceSpinning

The invention provides a multifunctional carbon nanotube plant source fiber, which belongs to the field of cellulose fiber. The fiber is composed of two parts, an inner layer and an outer layer; the inner layer is distributed with microcavities and carbon nanotubes; the inner layer accounts for 65-75% of the total dry weight of the fiber; the outer layer accounts for the total weight of the fiber 25-35% of the weight, the electrical conductivity of the multifunctional carbon nanotube plant source fiber is ≥2.4×10 4 S / m. The present invention also provides a method for preparing multifunctional carbon nanotube plant-derived fibers. The method includes the preparation step of viscose spinning liquid; the preparation step of viscose spinning liquid includes adding modification auxiliary agent slurry; a kind of multifunctional carbon nanotube plant source fiber prepared by the present invention, the inner layer adopts the traditional sulfonate method glue making process, adopts the coagulation bath process formed by the skinless core layer, and the outer layer adopts the creative solvent method. Coating and solidification regeneration, the prepared fiber has higher strength, better conductivity, better antibacterial persistence, higher wet modulus, especially dry breaking strength than ordinary viscose fiber.

Owner:青岛邦特生态纺织科技有限公司

Rio bamboo hollow yarn

The invention discloses a Rio bamboo hollow yarn. The Rio bamboo hollow yarn is composed of a roving piled yarn and a spinning piled yarn, wherein the roving piled yarn is formed by blending Rio bamboo fibers, wools and rabbit hairs; the spinning piled yarn is formed by spinning the wools; and the spinning piled yarn surrounds the surface of the roving piled yarn and is twisted together according to a Z-direction spiral shape. The Rio bamboo hollow yarn provided by the invention has the advantages of environmental protection, antibacterial, fluffy hand feeling and strong stereoscopic impression.

Owner:JIANGSU LIANHONG TEXTILE

Solvent method high-wet-modulus protein fiber and preparation method thereof

ActiveCN110886025AEasy to operateProduction without industrial pollutionMonocomponent cellulose artificial filamentCellulose/protein filament chemical after-treatmentSpinningMoisture absorption

The invention discloses a solvent method high-wet-modulus protein fiber and a preparation method thereof, and belongs to the field of textile. The method includes the steps: (A) activation, to be specific, performing cellulase activation on pulp to obtain slush pulp; (B) squeezing, to be specific, squeezing and dewatering the slush pulp to obtain aqueous cellulose; (C) pre-dissolving, to be specific, mixing the aqueous cellulose, N-methylmorpholine-N-oxide water solution and protein mixed solution to obtain pre-dissolving slurry; (D) dissolving, to be specific, dissolving the pre-dissolving slurry in a dissolving machine to obtain slurry; (E) spinning, to be specific, spinning the slurry to obtain the solvent method high-wet-modulus protein fiber. The method is simple in operation, free from industrial pollution in production, low in energy consumption, high in safety performance and applicable to large-scale industrial continuous production. The prepared solvent method high-wet-modulus protein fiber has high wet modulus, contains protein components and is good in moisture absorption and sweat releasing properties, comfortable to wear, soft in hand feeling, beneficial to continuousdyeing, convenient to print and dye and beneficial to production of high-end fabrics.

Owner:SHANGHAI LYOCELL FIBER DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com