Hygroscopic spandex lint with color tencel strips

A color stripe and spandex technology, applied in the field of woven fabrics, can solve the problems of heat retention, poor moisture drainage, low fabric wet strength, poor air permeability, etc., and achieve good recovery performance, soft fabrics, and high moisture absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Describe the present invention in detail below in conjunction with accompanying drawing:

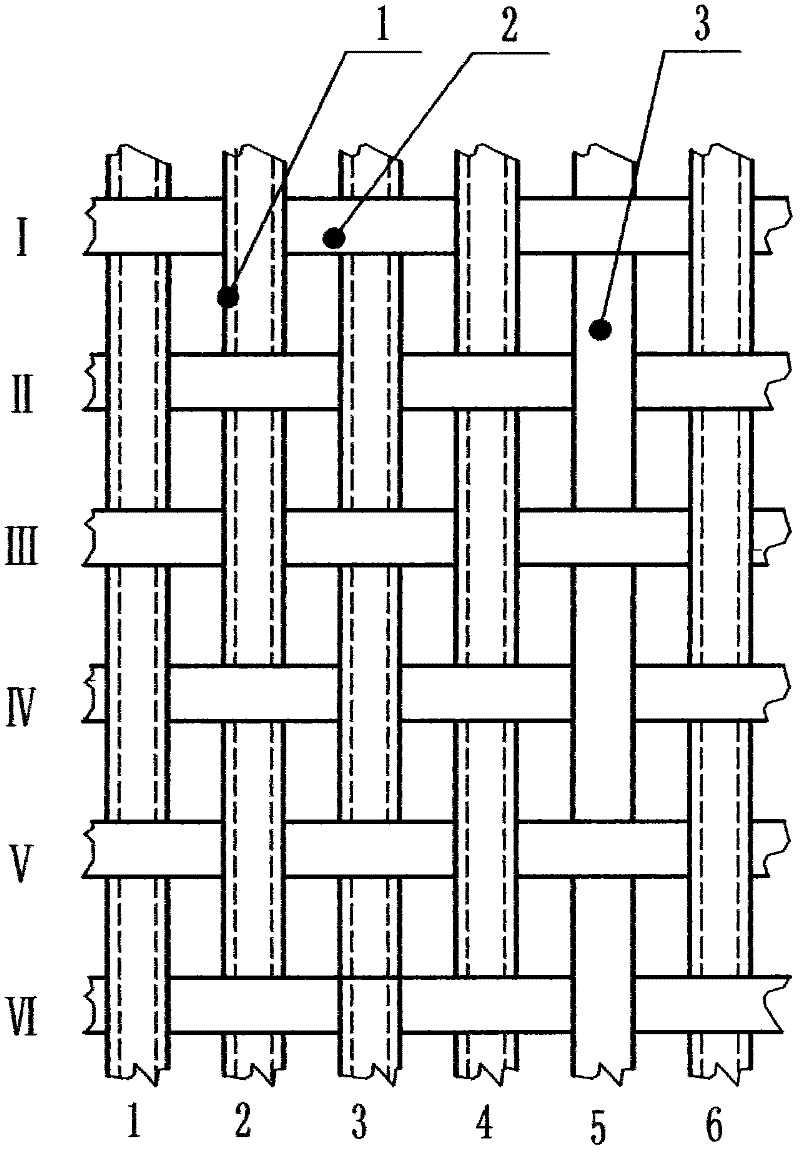

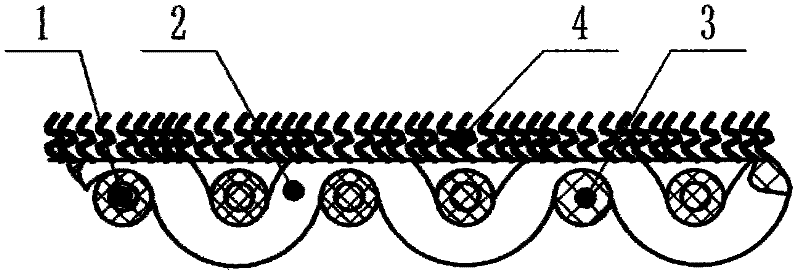

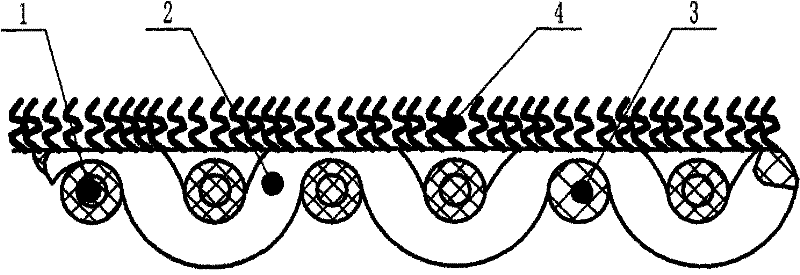

[0014] Such as figure 1 As shown, the Tencel colored striped spandex moisture-absorbing flannelette includes a set of warp threads 1 and a set of weft threads 2, and the warp threads 1 are separated by 9 cored threads covered with spandex and 1 organic conductive fiber filament 3. The specification of the organic conductive fiber filament 3 described above is 140D / 48F, which circulates in this way; the weft thread 2 is spaced apart from 15 colored tencel fiber threads plus 15 tencel fiber threads of another color, and circulates in this way; The warp 1 and the weft 2 are interwoven with each other, and the warp 1 and the weft 2 are vertically interwoven. The warp 1 and the weft 2 are contacted and connected through the intersection of the warp 1 and the weft 2 to form a fabric together; after the surface of the fabric is sanded and steamed, the surface of the fabric is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com