Solvent method high-wet-modulus protein fiber and preparation method thereof

A high wet modulus, protein fiber technology, applied in the textile field, can solve the problems of high pollution, complex process, low wet modulus of viscose fiber, low dry strength and wet strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

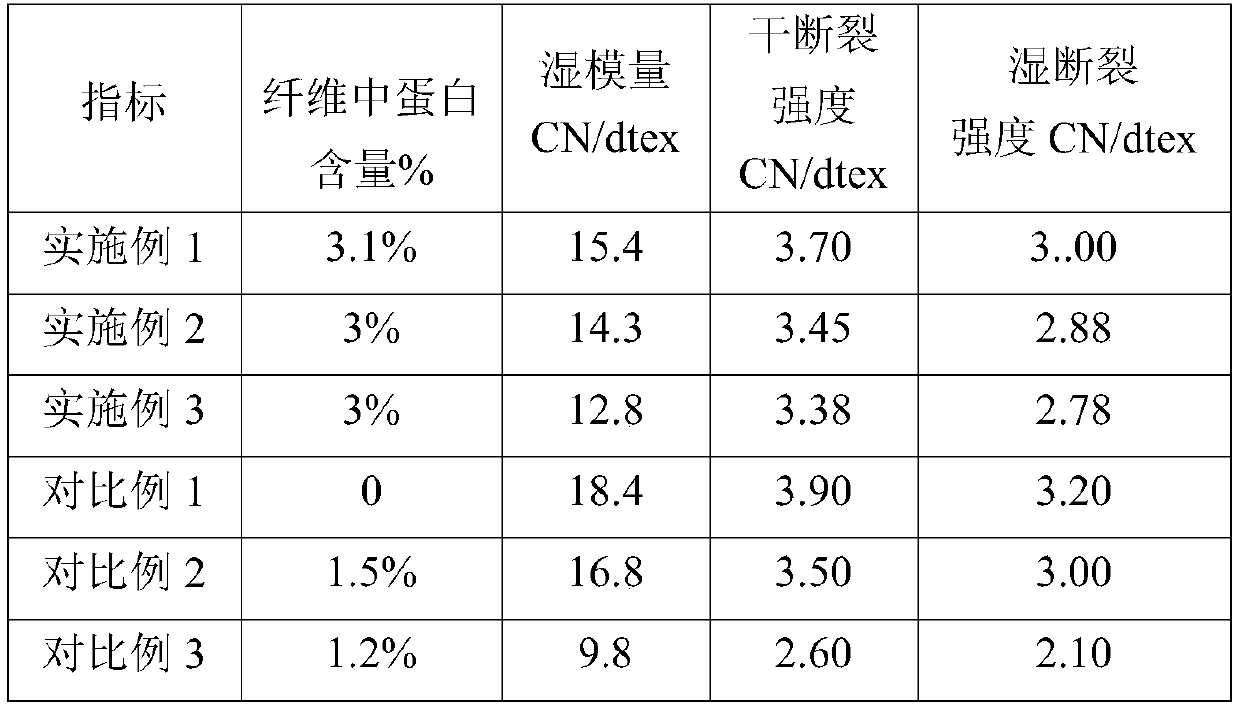

Examples

preparation example Construction

[0062] A preparation method of a solvent method high wet modulus protein fiber, comprising the following steps:

[0063] (A) activation

[0064] The activation process is simple, less chemical reagents are added, and the whole process takes about 1 hour, which is short in time and easy to operate. The process is as follows:

[0065] Prepare process water → add pulp → adjust pH value → add cellulase → terminate activation.

[0066] Among them, the deployment of process water: process water using deionized water; parameter requirements: conductivity 2 , pH 6-8, temperature 20-80°C.

[0067] Adding pulp: wood pulp or bamboo pulp is used, and the degree of polymerization is 300-1500.

[0068] Adjust the pH value: adjust the pH to 4-6 with acid and alkali.

[0069] Adding cellulase: use liquid cellulase, optional commercially available trade name AL70, product number IPL 5B06610, supplier BIOPRACT.

[0070] Termination of activation: Add alkali to adjust the pH to 9-13.

...

Embodiment 1

[0088] Add the pulp with a degree of polymerization of 500 until the conductivity is less than 5μs / cm 2 , pH value: 6.8, temperature: 50 ℃ process water, adjust the pH value at 5, add cellulase to activate for one hour, add sodium hydroxide to terminate the activation, adjust the pH value at 10.5; after the activation is terminated, the porridge is vacuum dehydrated After pressing, control the water content of the hydrous cellulose to 48wt%, and pulverize it into 3cm*3cm particles; then add protein mixed solution and 81wt% N-methylmorpholine-N-oxide aqueous solution, the protein mixed solution is An aqueous solution containing 5-10wt% protein and 5-10wt% montmorillonite; wherein the mass ratio of aqueous cellulose to protein mixed solution is 1:0.22, and the mass ratio of aqueous cellulose to N-methylmorpholine-N-oxide aqueous solution The ratio is 1:3.8, the pulp is swollen to obtain pre-dissolved pulp; the outlet temperature of the pre-dissolved pulp is 70°C, the composition...

Embodiment 2

[0093] Add the pulp with a degree of polymerization of 550 until the conductivity is less than 5μs / cm 2 , pH value: 6.0, temperature: 50 ℃ process water, adjust the pH value at 4.5, add cellulase to activate for one hour, add sodium hydroxide to terminate the activation, adjust the pH value at 11; after the activation is terminated, the porridge is vacuum dehydrated After pressing, control the water content of the hydrous cellulose to 53wt%, and pulverize it into 3cm*3cm granules; then add protein mixed solution and 85wt% N-methylmorpholine-N-oxide aqueous solution, said protein mixed solution is An aqueous solution containing 5-10 wt% protein and 5-10 wt% montmorillonite; wherein the mass ratio of aqueous cellulose to protein mixed solution is 1:0.2, and the mass ratio of aqueous cellulose to N-methylmorpholine-N-oxide aqueous solution The ratio is 1:3.3, the pulp is swollen to obtain pre-dissolved pulp; the outlet temperature of the pre-dissolved pulp is 68°C, the compositio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com