A kind of high wet modulus viscose fiber and preparation method thereof

A high wet modulus viscose and fiber technology, which is applied in the field of viscose fiber, can solve the problems of increased production and research and development costs, difficulties in adjusting production processes, and long production cycles, and achieves improved wet modulus, easy industrialization, and wet molding high volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

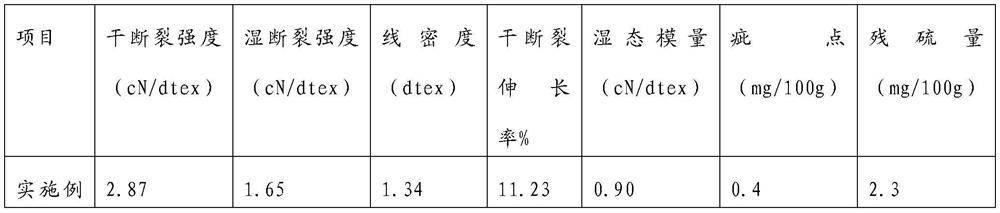

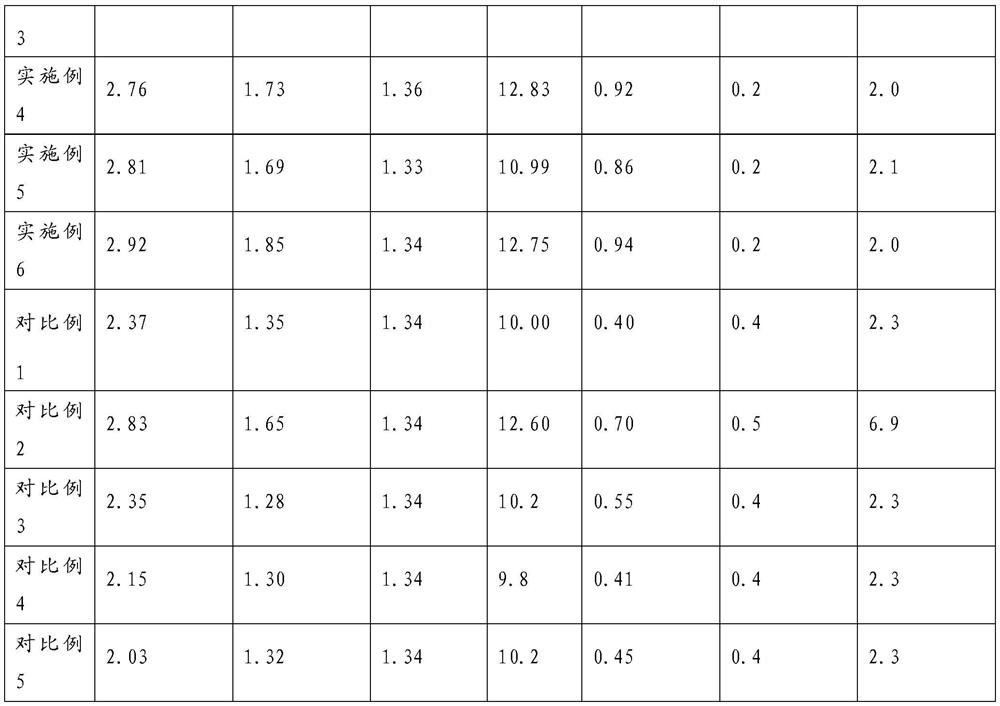

Embodiment 1

[0031] A high wet modulus viscose fiber, the dry breaking strength of the high wet modulus viscose fiber is 2.9cN / dtex, the wet breaking strength is 1.8cN / dtex, the dry elongation at break is 12.5%, and the wet modulus is 0.8cN / dtex dtex.

Embodiment 2

[0033] A kind of viscose fiber with high wet modulus, the dry breaking strength of described high wet modulus viscose fiber is 3.3cN / dtex, the wet breaking strength is 2.1cN / dtex, the dry elongation at break is 14%, and the wet modulus is 0.9cN / dtex dtex.

Embodiment 3

[0035] (1) Entering the as-spun fiber tow into a plasticizing bath for wet-heat drawing, the draw ratio of the wet-heat drawing is 10%; after passing through the plasticizing bath, sheet-like viscose tow is obtained.

[0036] (2) Dehydrating the sheet-like viscose tow into a desulfurization bath for desulfurization.

[0037] (3) Dehydrating the desulfurized sheet-like tow into a bleaching bath for bleaching.

[0038] (4) After the bleached sheet-like tow is dehydrated, go through 6 washing processes, each washing length is 1.5 meters, and the wet end is drawn while washing, and the draft ratio of the wet end drawing is 15%. ; The washing temperature is 80°C.

[0039] (5) Dehydrating the washed flake tow into an oiling bath for oiling.

[0040] (6) After dehydration, the sheet-like tow after oiling is passed through 36 drying hot rollers for cadre drafting, and the speed ratio is gradually increased by increasing the speed of the drying hot rollers step by step to control the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| draft ratio | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com