Viscose producing process based on hemp pulp

A technology of viscose fiber and production process, which is applied in fiber raw material treatment, cellulose treatment with microorganism/enzyme, pulp bleaching, etc. Chain damage and other problems, to achieve the effect of improving solubility and stability, good degumming effect, and less fiber damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

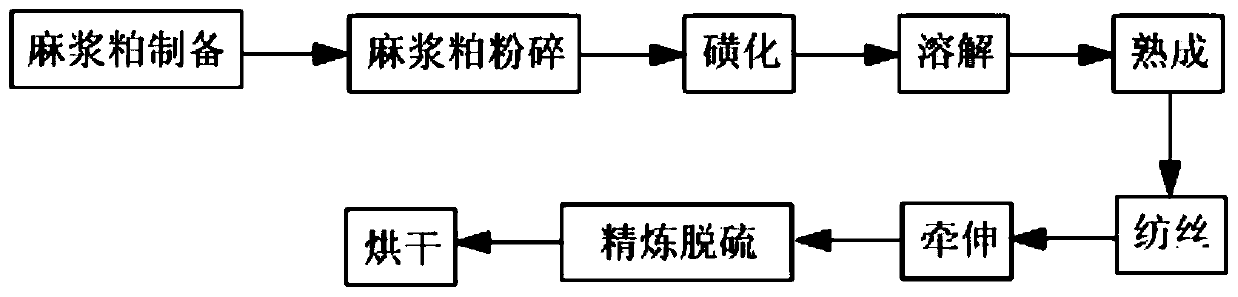

[0056] like figure 1 , 2 Shown, a kind of viscose fiber production process based on hemp pulp comprises the steps:

[0057] (1) Prepare raw materials: collect hemp raw materials and reserve them;

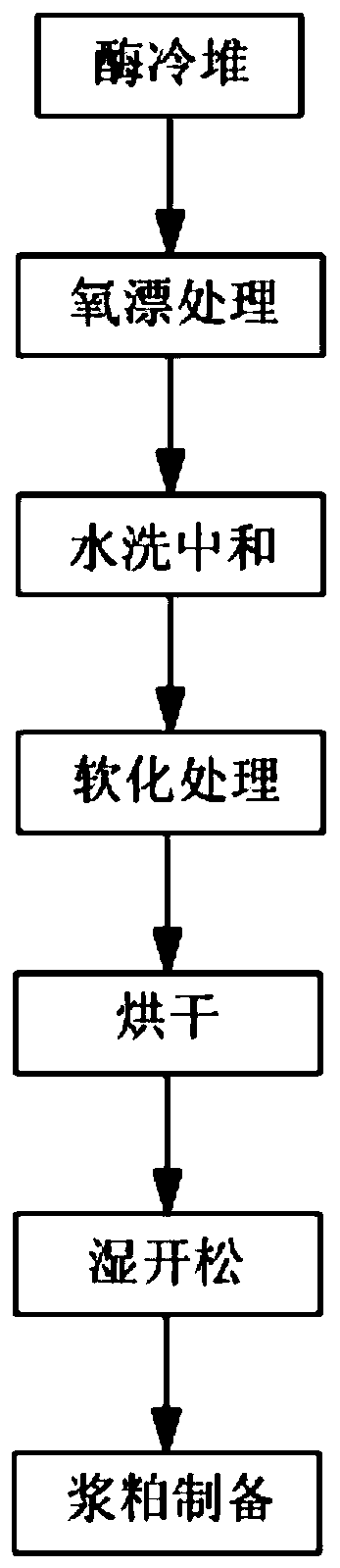

[0058] (2) Preparation of hemp pulp: the hemp raw material described in step (1) is subjected to enzyme cold stacking, oxygen bleaching, water washing, and drying to prepare hemp pulp;

[0059] (3) Preparation of viscose fiber: After the hemp pulp prepared in step (2) is pulverized, sulfonated, dissolved, matured, spun, drawn, refined and desulfurized, and dried, viscose fiber is obtained. The cross-section of viscose fiber is a circular porous structure, and its antibacterial properties can retain 70-80% of the original hemp.

[0060] Wherein, in step (3), sulfonation adopts wet sulfonation treatment, and during wet sulfonation treatment, adding CS 2 , CS 2 The addition amount of the hemp pulp is 36% of the mass fraction of the hemp pulp, the control temperature is 18° C., and...

Embodiment 2

[0083] like figure 1 , 2 Shown, a kind of viscose fiber production process based on hemp pulp comprises the steps:

[0084] (1) Prepare raw materials: collect hemp raw materials and reserve them;

[0085] (2) Preparation of hemp pulp: the hemp raw material described in step (1) is subjected to enzyme cold stacking, oxygen bleaching, water washing, and drying to prepare hemp pulp;

[0086] (3) Preparation of viscose fiber: After the hemp pulp prepared in step (2) is pulverized, sulfonated, dissolved, matured, spun, drawn, refined and desulfurized, and dried, viscose fiber is obtained. The cross-section of viscose fiber is a circular porous structure, and its antibacterial properties can retain 70-80% of the original hemp.

[0087] Wherein, in step (3), sulfonation adopts wet sulfonation treatment, and during wet sulfonation treatment, adding CS 2 , CS 2 The addition amount of the hemp pulp is 38% of the mass fraction of the hemp pulp, the control temperature is 20° C., and...

Embodiment 3

[0110] like figure 1 , 2 Shown, a kind of viscose fiber production process based on hemp pulp comprises the steps:

[0111] (1) Prepare raw materials: collect hemp raw materials and reserve them;

[0112] (2) Preparation of hemp pulp: the hemp raw material described in step (1) is subjected to enzyme cold stacking, oxygen bleaching, water washing, and drying to prepare hemp pulp;

[0113] (3) Preparation of viscose fiber: After the hemp pulp prepared in step (2) is pulverized, sulfonated, dissolved, matured, spun, drawn, refined and desulfurized, and dried, viscose fiber is obtained. The cross-section of viscose fiber is a circular porous structure, and its antibacterial properties can retain 70-80% of the original hemp.

[0114] Wherein, in step (3), sulfonation adopts wet sulfonation treatment, and during wet sulfonation treatment, adding CS 2 , CS 2 The addition amount of the hemp pulp is 40% of the mass fraction of the hemp pulp, the control temperature is 22° C., and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com