Preparation method and application of regenerated cellulose fiber with antibacterial, anti-mite and anti-mildew functions

A technology of regenerated cellulose and denatured cellulose, applied in the direction of single-component cellulose artificial filament, spinning solution preparation, fiber chemical characteristics, etc., can solve the problem of single function of regenerated cellulose fiber, poor anti-mite and anti-mildew effect and other problems, to achieve the effect of reliable and simple production process operation, high wet modulus and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

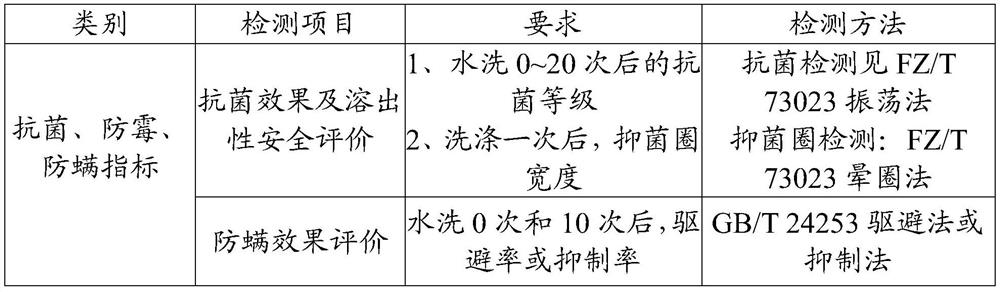

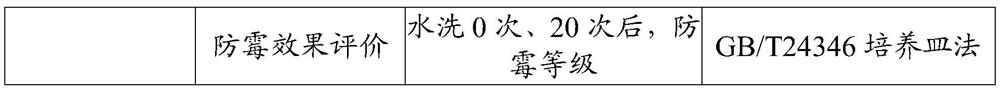

Image

Examples

Embodiment 1

[0048] A method for preparing a plant-based multifunctional regenerated cellulose fiber with antibacterial, anti-mite and anti-mildew functions with a specification of 1.11dtex×38mm, comprising the following steps:

[0049] 1. Preparation steps of composite slurry

[0050] 1) Mix, pulverize, and grind the extracts of Rhizoma Coptidis and Rhizoma Coptidis to obtain a mixed powder of the two. In the mixed powder, the mass ratio of Radix Rhizoma Rhizoma and Rhizoma Coptidis is 1:0.5, and the particle size of the powder is D90=1.279 μm ,spare.

[0051] 2) Blend the mixed powder prepared above with Litsea cubeba essential oil evenly, coat the surface of the powder with a layer of Litsea cubeba essential oil, and prepare an oily mixed powder slurry, wherein the quality of the mixed powder and Litsea cubeba essential oil The ratio is 5:1.

[0052] 3) Add methyl methacrylate to the above oily powder slurry and stir evenly, then add benzoyl peroxide and stir evenly to obtain a compos...

Embodiment 2

[0065] A method for preparing a multifunctional regenerated cellulose fiber with plant-based antibacterial, anti-mite and anti-mildew functions with a specification of 1.33dtex×38mm, comprising the following steps:

[0066] 1. Preparation steps of composite slurry

[0067] 1) Mix, pulverize, and grind the extracts of Radix radiata and Rhizoma Coptidis to obtain a mixed powder of the two. In the mixed powder, the mass ratio of Radix Rhizoma Rhizoma and Rhizoma Coptidis is 1:0.75, and the particle size of the powder is D90=1.347 μm ,spare.

[0068] 2) Blend the mixed powder prepared above with Litsea cubeba essential oil evenly, coat the surface of the powder with a layer of Litsea cubeba essential oil, and prepare an oily mixed powder slurry, wherein the quality of the mixed powder and Litsea cubeba essential oil The ratio is 6:1.

[0069] 3) Add methyl methacrylate to the oily powder slurry and stir evenly, then add benzoyl peroxide and stir evenly to obtain a composite oil ...

Embodiment 3

[0082] A method for preparing a multifunctional regenerated cellulose fiber with plant-based antibacterial, anti-mite, and anti-mildew functions with a specification of 1.56dtex×38mm, comprising the following steps:

[0083] 1. Preparation steps of composite slurry

[0084]1) Mix, pulverize, and grind the extracts of Rhizoma Coptidis and Rhizoma Coptidis to obtain a mixed powder of the two. In the mixed powder, the mass ratio of Radix Rhizoma Rhizoma and Rhizoma Coptidis is 1:1, and the particle size of the powder is D90=1.431 μm ,spare.

[0085] 2) Blend the mixed powder prepared above with Litsea cubeba essential oil evenly, coat the surface of the powder with a layer of Litsea cubeba essential oil, and prepare an oily mixed powder slurry, wherein the quality of the mixed powder and Litsea cubeba essential oil The ratio is 7:1.

[0086] 3) Add methyl methacrylate to the oily powder slurry and stir evenly, then add benzoyl peroxide and stir evenly to obtain a composite oil ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com