Moisture-absorbing and sweat-releasing yarn and fabric and garment thereof

A moisture-absorbing and sweat-wicking yarn technology, which is applied in the field of textile fabrics, can solve problems such as increased clothing weight, and achieve a good one-way moisture transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Fabric name: polyester jersey;

[0036] Fabric structure: single-sided plain weave;

[0037] Weaving equipment: single-sided large circular knitting machine;

[0038] Yarn: The inner fiber is a cross-section, the monofilament fineness is 1.7dtex, the official moisture regain is 0.3%, the middle layer is round fiber, the monofilament fineness is 1.1dtex, the official moisture regain is 1.3%, and the outer fiber is round Cross-section, monofilament fineness 0.7dtex, public moisture regain 2.0%;

[0039] Yarn: 50s;

[0040] Spinning method: Saijin spinning;

[0041] Yarn strength: 3.1cN / dtex;

[0042] Finishing process: conventional softening treatment;

[0043] Fabric weight: 120g / m 2 ;

[0044] Gained fabric is carried out performance test, the result is as follows:

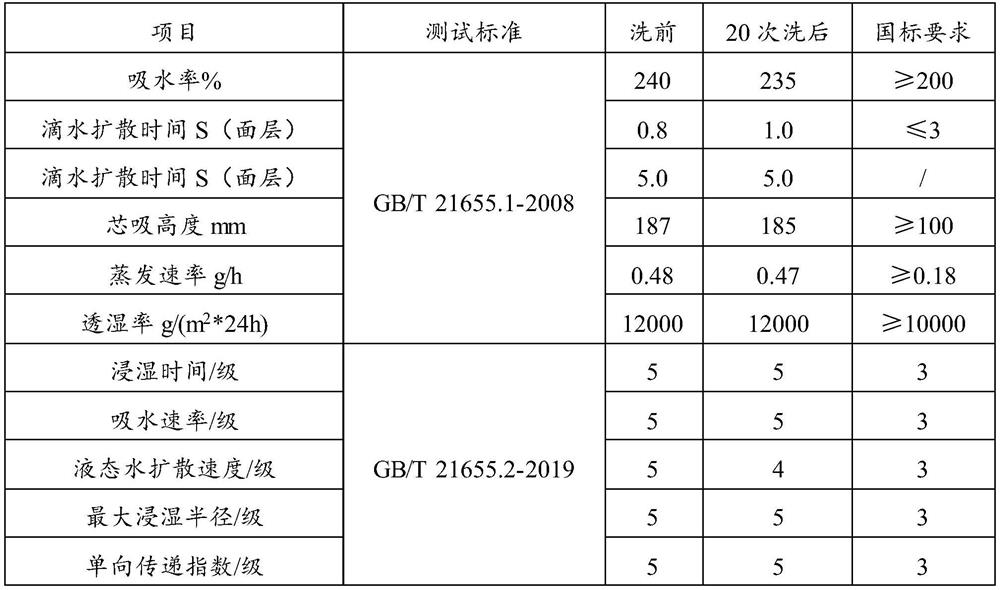

[0045] Table 1 Moisture absorption quick-drying and one-way moisture transfer test results

[0046]

Embodiment 2

[0048] Fabric name: Polyester small pinhole cloth;

[0049] Fabric structure: double-sided jacquard;

[0050] Weaving equipment: double-sided dobby circular machine;

[0051] Yarn: The inner fiber has a Y-shaped cross-section, the monofilament fineness is 1.8dtex, the official moisture regain is 0.3%, the middle layer is round fiber, the monofilament fineness is 1.2dtex, the official moisture regain is 1.2%, and the outer fiber is round Cross section, monofilament fineness 0.5dtex, public moisture regain 2.3%;

[0052] Yarn: 100D / 144F;

[0053] Spinning and spinning: composite melt spinning;

[0054] Yarn strength: 3.5cN / dtex;

[0055] Finishing process: conventional softening treatment;

[0056] Fabric weight: 135g / m 2 ;

[0057] Gained fabric is carried out performance test, the result is as follows:

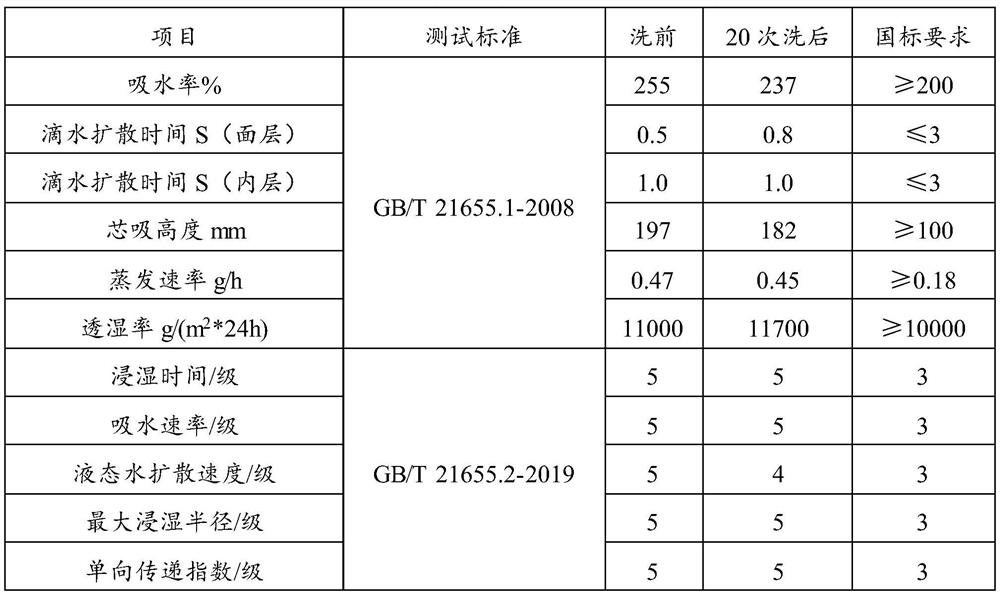

[0058] Table 2 Moisture absorption quick-drying and one-way moisture transfer test results

[0059]

Embodiment 3

[0061] Fabric name: full polyester vertical striped cloth;

[0062] Fabric structure: single jacquard;

[0063] Weaving equipment: double-sided dobby circular machine;

[0064] Yarn: The inner fiber is a maple leaf-shaped cross-section, the monofilament fineness is 2.0dtex, the official moisture regain is 0.2%, the middle layer is round fiber, the monofilament fineness is 1.3dtex, the official moisture regain is 1.5%, and the outer fiber is round Cross-section, monofilament fineness 0.3dtex, public moisture regain 4.0%;

[0065] Yarn: 50s;

[0066] Spinning method: composite core spinning;

[0067] Yarn strength: 2.8cN / dtex;

[0068] Finishing process: conventional softening treatment;

[0069] Fabric weight: 140g / m 2 ;

[0070] Gained fabric is carried out performance test, the result is as follows:

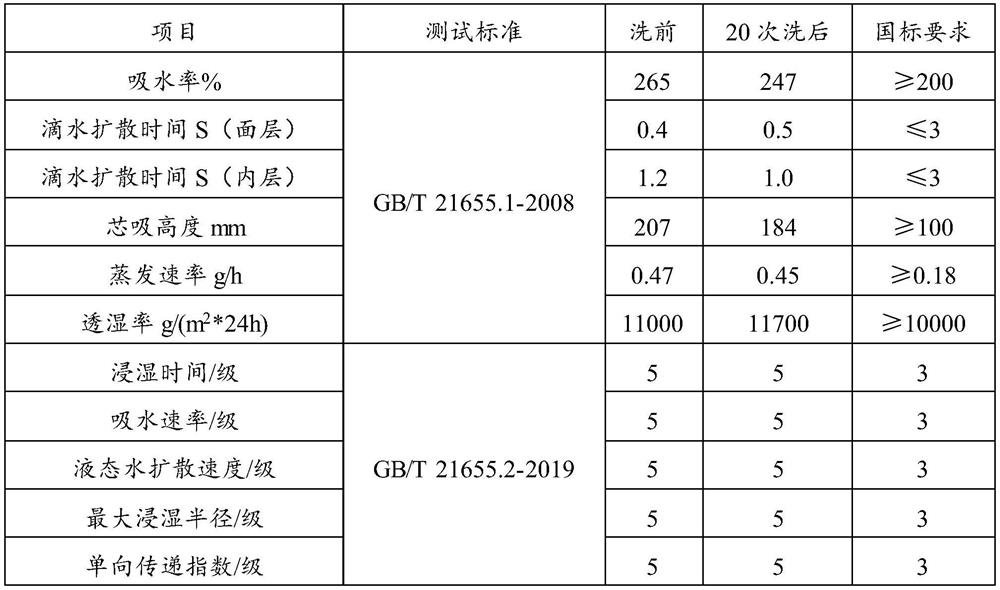

[0071] Table 3 Moisture absorption quick-drying and one-way moisture transfer test results

[0072]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com